What to consider when choosing a material for a chimney?

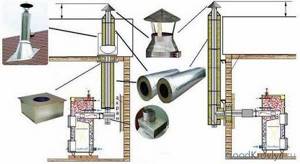

A chimney is a complex structure consisting of a vertical pipe, an umbrella for protection from precipitation, an inspection window for maintenance, a tray for collecting condensate and other elements. The vertical pipe is considered the main part of the chimney, and the safety and efficiency of the stove or boiler depends on it.

To choose the right chimney material, you need to clearly understand what fuel will be used : natural gas, diesel fuel, coal, firewood, peat or sawdust. Each of them has a different combustion temperature, temperature and composition of the exhaust gases. Therefore, when selecting material for a chimney, the following parameters are taken into account :

- flue gas temperature. Naturally, the material must withstand slightly higher temperatures than those characteristic of the exhaust gases;

Approximate flue gas temperature (*high sulfur fuel) - corrosion resistance . When some types of fuel burn, vapors of sulfuric and hydrochloric acid are formed, which not every material can withstand. The more sulfur in the fuel, the more resistant to the effects of sulfur compounds the material must be. According to this parameter, chimneys are divided into three classes : the first - for removing gas combustion products, the second - firewood and liquid fuel with a sulfur content of up to 0.2%, the third - for coal, peat, diesel fuel;

- presence of condensate in the chimney;

- gas pressure in the chimney . There are designs designed to work with natural draft, and there are those that are designed to work with pressurized boilers;

- soot fire resistance. The temperature in the chimney when soot ignites, if present, can briefly rise to 10,000C - not every material can withstand this.

From all this it follows that:

- for wood stoves, solid fuel boilers, sauna stoves and fireplaces, it is necessary to choose a material that can withstand operating temperatures of about 7000C and a short-term increase to 10000C. These are brick and less often ceramic chimneys;

- gas boilers require a chimney that can withstand temperatures of 2000C with a short-term increase to 4000C. Typically, metal pipes are used for these purposes;

- For boilers using liquid fuel and sawdust, a material for the chimney pipe is needed that can easily withstand temperatures up to 2500C with an increase to 4000C, and if we are talking about diesel fuel, then resistant to the aggressive environment of exhaust gases.

Now let's look at the properties of the most popular materials that are used to construct a chimney pipe.

Common mistakes

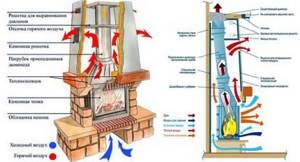

In first place among the mistakes is the incorrect height of the chimney pipe. An option that is too high creates excess draft, which increases the likelihood of tipping over and drawing smoke back into the firebox and the room with the stove. 5–6 meters are considered optimal, but much here depends on the size of the combustion chamber and the configuration of the chimney.

A constant flow of air into the firebox is a must for good draft in the chimney, which is why it is so important to equip a room with a fireplace or stove with high-quality ventilation

The chimney should not be overcooled or overheated as a result of intensive combustion of fuel in the firebox. Everything must be in moderation, otherwise the pipe may crack. To make it easier for yourself to identify these cracks, you should whitewash the section of the chimney in the attic. All soot “drips” will be visible on a white background.

Often, when installing a steel chimney, beginners forget to ensure condensate drainage. To do this, you need to make a special collection and insert inspection hatches into the pipe. Mistakes are also made in choosing the steel grade.

During normal combustion of wood, gas or coal in a fireplace or heating boiler, the chimney warms up to 500–600 °C. However, the temperature of the smoke, even for a short time, can rise to 1000 ° C. Moreover, just a few meters from the firebox they cool down to 200–300 degrees and do not pose a threat to the pipe.

But its initial meter section from the boiler manages to heat up very strongly. The steel must be heat-resistant and able to withstand these loads. And the insulation of a steel pipe should be done only a couple of meters from the firebox in order to prevent overheating of this segment of the chimney.

To increase fire safety, passages through ceilings and walls are made through special non-flammable inserts; direct contact of hot pipes and flammable building materials is unacceptable

When laying bricks by an inexperienced craftsman, vertical displacement of their rows relative to each other is often allowed. When building walls, this is allowed, but in the case of a chimney, it is absolutely unacceptable. This greatly reduces the efficiency of the chimney duct, as flow turbulence and soot deposits on the walls begin to form in it, which will require cleaning over time. You can read how to do this correctly in this material.

The foundation under a brick chimney must be extremely reliable, otherwise the pipe may be pulled to the side with subsequent partial or complete destruction. And if smoke removal is done for a gas boiler, then it is better to exclude brick. It quickly breaks down under the influence of the alkaline environment formed during the combustion of natural gas.

No. 1. Brick chimney pipe

Brick has been used for chimney construction for a long time, and it has already become a traditional material. Today it cannot be called universal, which, however, does not reduce its popularity. A brick chimney is installed inside the walls of the building; those sections of it that pass through unheated rooms or outside the building are carefully insulated so that the flue gases inside do not cool. For the construction of such a chimney, red solid brick of a grade no lower than M150 is suitable; lime or lime-cement mortar is used for its laying.

The main advantages of brick chimney pipes include their durability and excellent heat resistance (ceramic brick can withstand temperatures up to 8000C), and they look great in appearance, and in terms of fire safety they have practically no equal. A brick chimney is suitable for wood-burning stoves and fireplaces , and when working with liquid fuel, gas, pellet and solid fuel pyrolysis boilers, it is quickly destroyed. The thing is that such boilers are designed in such a way that the exhaust gases have a low temperature. They quickly condense and settle on the pipe walls, due to which the latter are constantly moistened. Considering the fact that the exhaust gases contain aggressive chemicals, including sulfuric acid, the brick quickly deteriorates. The results of such exposure appear as wet spots on the outer surface of the pipe.

True, there is always a way out of the situation. To connect a modern gas or liquid fuel boiler to a brick chimney pipe, a steel or ceramic pipe , which has slightly different performance qualities, is built into the brick channel.

Since the surface of the brick is rough, soot settles well on it, which gradually leads to a decrease in traction. Cleaning and repairing a brick chimney is not an easy task. In addition, the large weight of the structure will necessarily require a foundation. On the other hand, it is difficult to find a worthy analogue for arranging the chimney of a stove or fireplace.

Characteristics

High-quality draft can only be ensured if the diameter of the chimney pipe is selected correctly. The calculation of the diameter depends on the power of the furnace equipment. Possible diameter options:

- for stoves with power up to 3500 W - 14 by 14 cm;

- for equipment with power from 3500 to 5000 W - 14 by 20 cm;

- for stoves with a power of 5000-7000 W - 14 by 27 cm.

You also need to take into account the characteristics of the material and the type of fuel used.

Oven (Photo: Instagram / fornaks.ru)

No. 2. Chimney made of steel pipe

For gas and solid fuel boilers , steel pipes are best suited, but at the same time it must be stainless, heat-resistant and acid-resistant , since sulfur particles, which are found in almost every type of fuel in one quantity or another, when combined with moisture and coal particles form aggressive environment. Stainless steel can withstand temperatures up to 5000C ; pipes with a wall thickness of 0.6 mm are used to construct chimneys, but for solid fuel boilers it is better to use steel with a thickness of 1 mm. Steel pipes are a whole system of straight sections and various shaped elements, incl. adapters, bends, tees, etc. Such a system can be installed independently or built into an existing brick channel.

The main advantages of steel pipes:

- simplicity and high speed of installation, because the weight of the structure is small, there is no need for a foundation, and even not the greatest professional can assemble the entire system from ready-made elements without any problems;

- repair work is easy to carry out;

- soot particles do not accumulate on smooth walls, their surface is easy to clean, so we can talk about consistently high aerodynamic characteristics for the passage of exhaust gases;

- high corrosion resistance;

- the ability to create complex structures;

- high tightness, due to which you can create forced exhaust.

Among the disadvantages is the high cost, especially when compared with a brick or ceramic analogue, but if simplicity and speed of installation, light weight and resistance to aggressive environments are important, then it is better to choose a steel chimney. Disadvantages sometimes include low heat resistance, but for modern boilers with a slow combustion system, greater heat resistance is unnecessary.

Depending on the characteristics of the room, boiler and climate, one of the following types of steel chimneys is used:

- single wall steel pipe , consisting of one layer of stainless steel. This is the simplest and cheapest option; such a chimney is laid in a specially laid vertical channel. Often such chimneys are installed in a bathhouse, and the heat released from the steel pipe is used to heat water;

- single-wall steel pipes for reconstruction of a brick chimney may have an oval shape. Such a restoration process and adaptation of an existing chimney to work with a gas boiler is called “linering”;

- double wall sandwich panels, consisting of two steel pipes, in the space between which a layer of insulation (basalt wool) is placed. Using the latter allows you to prevent the formation of condensation inside the pipe, while its outer surface hardly heats up. Ease of assembly and excellent performance allow such systems to be used both indoors and outdoors on the wall;

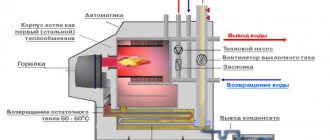

- coaxial chimneys made of steel also consist of two pipes placed one inside the other, only there is no insulation between them, and the resulting space is intended to supply air to the boiler to support combustion. Combustion products are discharged through the inner pipe. Such chimneys do not behave very well in harsh domestic winters. Cold outside air passing through the outer pipe can sometimes greatly cool the inner pipe and the gases flowing through it. This leads to a sudden drop of condensate and its freezing on the surface of the pipe. The chimney gradually becomes clogged, and the automation, reacting to this, turns off the boiler, so in this case it is better to equip chimneys with two separate pipes.

It is worth noting that sometimes thick pipes made of low-alloy steel are used to construct a chimney - this option is usually found in sauna stoves. Also, craftsmen sometimes use cast iron sewer pipes for the same purposes.

Installation features

To properly make a chimney and install it in the house, you need to follow the rules:

- The adjacent surfaces to the stove and pipeline must be covered with a layer of thermal insulation, which will prevent them from igniting.

- Technical communications should be laid away from the chimney.

- Where the chimney passes through the roof or ceiling, non-combustible plates must be secured. Additionally, you can use a special sleeve.

- The system should be designed so that there are fewer bends and turns. The length of horizontal sections should not exceed 100 mm.

- The joints of individual pipes must be covered with a layer of heat-resistant sealant to increase the tightness.

We must not forget about attaching a special head to the top of the pipeline. It will protect the chimney from leaves, dust, debris, moisture, and snow.

Chimney installation (Photo: Instagram / termostatus_official)

No. 3. Ceramic chimney pipe

Ceramic chimney pipes are considered the most versatile, and among their main advantages:

- durability;

- resistance to aggressive environments and corrosion;

- soot does not linger on the smooth inner surface, making pipe maintenance easier;

- high heat-absorbing characteristics;

- resistance to high temperatures. For solid fuel boilers, ceramic pipes are used, which can withstand up to 6500C and are resistant to a sharp increase in temperature when soot ignites. For gas boilers, you can use pipes that can withstand up to 4500C, are designed to operate in a wet state and have condensate drains.

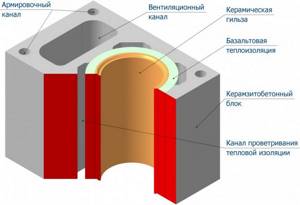

To install a ceramic chimney pipe, a separate channel is required. The shell is constructed from special concrete blocks with voids. A layer of mineral wool insulation is placed around the pipe to protect adjacent structures from excess heat and reduce the formation of condensation. Both the pipe and the insulation are capable of absorbing water, so they need to be provided with normal ventilation. It is created due to the presence of vertical air channels between the insulation and concrete blocks. By the way, concrete blocks also contain channels for placing reinforcement in them. Be sure to reinforce the part of the chimney that faces the street.

To expand the scope of use of ceramic chimneys, they are produced in a steel casing , as well as in the form of rectangular elements .

The former do not require the construction of a foundation or the creation of special channels, the latter can be used for the reconstruction of brick chimneys.

Polypropylene

Polypropylene

Polypropylene pipes are excellent for installation in heating system structures.

In addition, they have an attractive advantage - an affordable price.

However, when choosing, you should pay attention to the possibility of operating such pipelines with hot coolant, since not all types of polypropylene pipes fit this category.

Polypropylene has many advantages, in addition to the already mentioned reasonable cost.

These include:

- Lightness of the design, as a result of which after installation there will not be a significant load on the walls of your house;

- Smooth inner surface. Thus, even after many years, there will be no lime deposits or rust in them;

- Durability. The service life of polypropylene pipes is approximately 20 years, and all their qualities will remain unchanged during this period;

- Low temperature resistance. They are ideal for country houses, because the owners do not live there permanently, but come only for a short period of time, and naturally, in their absence, the heating system will be turned off;

- Comparatively better appearance. Polypropylene pipes do not need to be painted every year and do not change color.

- Possibility of installation inside walls. The closed method of pipeline installation will save you from constantly observing the pipes with the naked eye. However, it will be necessary to take into account that the linear expansion of a segment 5 m long will be about 4-5 mm. It is also advisable to install compensators to prevent damage to wallpaper or wall decoration.

However, despite a sufficient number of advantages, polypropylene also has disadvantages:

- Soldering required. However, in the case of polypropylene pipes, you do not have to hire a professional welder and pay for his services, unlike the installation of steel pipes. You can install them yourself, and for this you will need a little time to master the soldering technique itself and the soldering machine itself, which can be easily purchased or rented at any specialized store in your city.

- Not elasticity of the material. To make the necessary turns of the pipeline, it will be necessary to purchase special adapters, angles and couplings, and this can lead to various difficulties in cases where the heating system is non-standard. However, there is also a plus - the price of fittings is low and affordable for everyone. To cut pipes, you will have to purchase special scissors for plastic.

- Only in exceptional cases will you be able to repair your pipes. Most often, you will have to completely replace the faulty section of the pipeline with a completely new one.

- Reduced rigidity. This is fraught with sagging pipes as a result of prolonged exposure to high coolant temperatures. To fix this problem, you will need to purchase special clips that will be attached directly to the wall.

- Inability to work with high temperatures. The permissible coolant temperature in polypropylene pipes is 70 degrees Celsius. An indicator of 90 degrees is possible only for a short time. This is not entirely convenient, because when the temperature outside is below zero, more heat will be needed to heat residential premises, and the best solution would be to increase the temperature, which is unacceptable in this case.

No. 4. Chimney made of asbestos-cement pipe

A couple of decades ago, asbestos-cement pipes were widely used to construct chimneys. Actually, they were not originally intended for such purposes, which is easy to see by studying their performance characteristics. The only advantage of the material is its low price , but there are disadvantages :

- the material can withstand temperatures up to 3000C, and often this is not enough. Such a pipe can only be used at the maximum distance from the firebox, where the smoke passes through already cooled;

- Soot quickly accumulates on a rough surface, which tends to catch fire. But if a brick chimney can easily cope with this, then a chimney made from an asbestos-cement pipe can simply explode;

- instability to condensate, which contains aggressive chemicals. Moreover, condensate can be absorbed into the pipe, destroying it and worsening its appearance;

- heavy weight and difficult installation;

- leaking joints.

You can use an asbestos-cement pipe for a chimney only if you are sure that the installation will be done correctly, as well as if the chimney is regularly cleaned, but it is better to pay attention to other options.

Device

All sandwich pipes have different technical characteristics, but the main requirement for creating a chimney from sandwich pipes is absolute tightness. Moreover, this requirement applies both to structures installed for baths, and to those devices that are mounted directly on the roof of the building.

It is also worth noting that some versions of such chimneys may have an outlet through the wall. The only thing that should be taken into account when installing a chimney is the number of elements of the device and their type. Read the review of stainless steel chimneys.

A standard sandwich chimney will consist of many elements. You can study them in more detail using the diagram presented below.

Sandwich chimney device in the photo.

Attention! Before installing a sandwich chimney on a wooden structure, it is necessary to make a hole of the appropriate size in the wall. Then waterproof it and only then will it be possible to carry out and fasten the connecting element between the outer and inner parts.

No. 5. Vermiculite chimney pipes

Not so long ago, vermiculite chimney pipes appeared on sale. These are stainless steel pipes coated inside with a 5 cm thick layer of the mineral vermiculite. This mineral has low thermal conductivity, therefore, in fact, it is a natural heat insulator. Moreover, vermiculite is absolutely inert to aggressive combustion products.

Other advantages of vermiculite pipes include high durability, relative ease of installation, and no need for chimney insulation. The main disadvantage is the ability to accumulate soot, so you will have to clean the chimney often.

Stainless steel

It is most optimal to use “stainless steel” in conditions where there is a possibility of the system overheating, clogging and getting wet. Take into account the temperature capabilities of the pipes; they can heat up to 500 degrees without melting yet. By the way, pay special attention when purchasing, study the characteristics and type of material; it should be indicated that the material has acid-resistant protection. Keep in mind that a fairly aggressive environment always forms in the chimney, which can destroy an unsuitable alloy. What else is positive about “stainless steel”?

- Reliable.

- Small mass.

- Anti-corrosion.

- Variety of shapes.

- Gas tightness.

- Aesthetics.

- Price.

However, such a chimney pipe has a somewhat short service life, usually no more than 10 years.