When renovating or building, many people think about proper insulation of the room - this is a priority for any owner of the room. Thermal insulation can be achieved by using building insulation materials for walls.

How to choose the right material to ensure high-quality, durable insulation? We will try to consider the main types of heat insulators, their characteristics and properties.

Common types of insulation

Before you go shopping for the best thermal insulator, you should decide what type of insulation you want to use: internal or external.

If we are talking about insulating a private building, then any specialist will advise you to use external thermal insulation. This is due to the fact that this method does not reduce the usable area of the room, there are no cold bridges, and the walls are protected from environmental influences.

If you need to insulate an apartment, then only the internal option is suitable, using thin insulation for the walls, since in an apartment, every centimeter of usable space counts.

Thermal insulators that the modern market offers are suitable for any type of insulation, so it is selected based on needs and necessity.

If the thermal insulation for the walls is chosen correctly, then in winter the house will not be cold, drafts and coolant losses will be eliminated.

What is important to observe when insulating

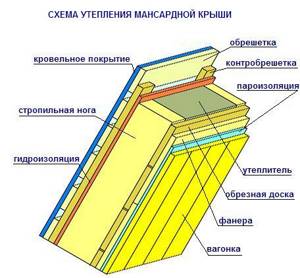

Important for the roof:

do not overload the rafter system - in any case, the use of a thermal insulation layer must be agreed upon with the designer; ensure ventilation of the insulating layer - all the steam from the house rushes upward, even waterproof insulation on the roof is moistened; ensure sound insulation in the structure - there can be no such thing as a residential attic and speech if the wind and rain create a cacophony in the house. prevent the nesting and breeding of rodents, birds and insects in the layer of structures, as well as bacteria and fungi (moistening, decomposition...), i.e.

e. ensure biostability; the heat transfer resistance of the entire roof must be no lower than standard values, or according to economically sound design decisions. This value is mainly determined by the thickness of the effective insulation layer.

Modern insulation - main characteristics

High-quality materials for wall insulation must have the following characteristics:

- waterproof;

- sound insulation;

- natural security;

- breathability;

- environmental friendliness;

- biostability;

- strength;

- fire resistance.

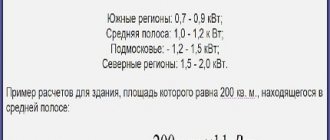

When choosing the best insulation for the walls of a building, you should take into account what building material the building is made of, the number of floors and the climate zone in which the house is located. For example, thermal insulation material for a frame building - polystyrene foam, mineral wool, glass wool - is not suitable for inter-crown insulation.

Thermal insulators are divided into: organic and synthetic.

The first option of insulation:

These thermal insulation materials are considered the most preferable from an environmental point of view, but they are expensive.

There are a lot of insulation materials for walls of synthetic origin:

Organic insulation materials are considered the most environmentally friendly, but they are subject to rotting and attack by insects and rodents, so the service life of these insulators is much shorter than that of inorganic insulation materials. Let's look at the rating of the most popular insulators to understand how to choose insulation for walls.

Styrofoam

It has a cheap price, and therefore is perceived by many as the best solution. But at the same time, everyone points to the shortest service life - the material decomposes, breaks.... Based on this factor alone, it already inspires serious concern in structures behind the skin, where it is difficult to check its condition.

There is also some difficulty in placing between the rafters, since the foam sheets are not as elastic as mineral wool. Precise adjustment with a float is required, leaving gaps that need to be foamed...

There has been some progress in sound insulation compared to polyurethane foam, since it is possible to cover the rafters with a layer in the counter-lattice.

But the downside is fire safety - it requires a continuous fireproof fence from the living space. Mice and birds love this material and love to breed in it. They destroy it with pleasure. Therefore, the structure must be securely closed, which is difficult to do...

Types of heat insulators

Inorganic insulation materials have become very popular recently - they are durable and inexpensive, but which insulation to choose is up to you.

Styrofoam

This is a foamed mass, the slabs of which have a low specific gravity. The use of this material for thermal insulation of walls has many advantages:

- environmental friendliness - the insulation is produced from raw materials that do not emit toxins;

- durability - as such, the foam itself does not have a shelf life, it does not decompose, microorganisms do not live in it;

- vapor barrier properties, low thermal conductivity;

- fire resistance - thanks to the fire retardant introduced into its composition, the material is capable of self-extinguishing;

- light weight - does not place additional load on the base;

- easy to install, not expensive.

There are many advantages, but there are disadvantages:

- low mechanical strength, when installing the material it needs additional protection;

- afraid of chemical influences;

- the material does not breathe.

Despite this, many developers choose this thermal insulator due to its inexpensive cost.

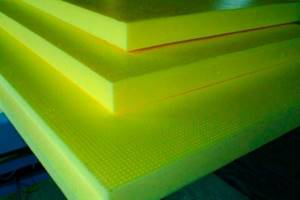

Extruded polystyrene foam is a type of foam that undergoes foaming when melted using high temperatures. This material is much more durable than conventional polystyrene foam and at the same time its technological characteristics are much higher.

Expanded polystyrene sheets are a type of polystyrene foam, only of a small fraction. It is produced in yellow layers, as the insulator contains a dye. The slabs are laid without seams, thanks to a special phase formed on the sides.

To insulate a house, you need to choose yellowish-colored slabs, and you need to remember that the thinner the sheets, the less heat they retain.

Mineral wool

Many builders consider this material the best insulation, which is classified as fiber insulators. Mineral wool for partitions and insulation, produced in rolls and sheets, and can be used for interior decoration of rooms with insulation and facade insulation.

Advantages:

- breathability;

- low cost;

- service life 50 years;

- environmental friendliness;

- non-flammable;

- resistance to deformation;

- good sound insulation characteristics;

- low thermal conductivity.

Negative characteristics:

- water permeability;

- To install thermal insulation with mineral wool, you will have to build a frame, which, with internal insulation, will reduce the usable area of the room.

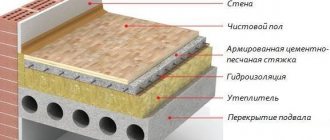

When installing this heat insulator, it is necessary to carry out waterproofing work, otherwise the mineral wool will absorb moisture and its insulating properties will decrease, in addition, mold may appear in the material.

Glass wool

Don’t know which insulation is best for a building? Note the fiberglass. This material has been used as an insulator for a very long time. The material is produced from natural components, in sheets or rolls.

Glass wool has positive characteristics:

- ease of arrangement:

- does not burn;

- excellent thermal insulation qualities;

- can be installed as a sound insulator;

- inexpensive cost;

- the material is universal and can be used for any type of insulation work - it is an effective insulation material.

Flaws:

- during installation you need to use protective equipment - gloves, a respirator, the fibers of the material are sharp and can be dangerous, especially if inhaled;

- severe shrinkage;

- the material is very fragile.

When working with a heat insulator, you need to wear protective clothing, which is disposed of after installation.

Ecowool

The material is applied by spraying and mostly consists of wood, which is its advantage. Ecowool is not subject to combustion, as special additives are introduced into its composition. The heat insulator is environmentally friendly and does not emit toxins. In other words, this material is called cellulose fiber.

There are other positive aspects:

- good sound insulator;

- moisture resistant;

- breathable, when sprayed, the walls continue to “breathe”;

- has a small specific gravity;

- small price.

Any material has disadvantages, and ecowool is no exception:

- Over time, the material shrinks and its quality decreases;

- the complexity of application, since it is impossible to install the material without the use of special equipment;

- the application process is very labor-intensive;

- the material can be used on limited surfaces;

- on vertical walls the material shrinks.

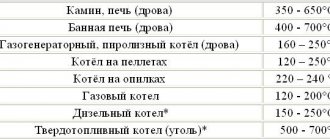

Advice! Do not use ecowool on fireplace chimneys, as it may begin to drain due to constant exposure to high temperatures.

Penoizol

This is a material that looks similar to foam plastic, only with a semi-liquid consistency. The composition is supplied by a special device and fills all the cracks and gaps, forming a completely sealed insulation structure. The cost of penoizol in comparison with other heat insulators is slightly higher, but the characteristics are better.

Penoizol has many positive qualities:

- low thermal conductivity, allows you to insulate not only residential premises, but also industrial buildings - penoizol 10 cm thick, the thermal insulation properties are equal to brickwork;

- fireproof - this material does not burn and does not even melt when the building burns;

- not exposed to chemical influences, rodents and microorganisms do not grow in it;

- penoizol absorbs water, but unlike mineral wool, after drying its properties continue to meet the highest requirements for thermal insulation;

- the material is hygroscopic, therefore it allows the walls of the house to “breathe”;

- due to the method of application and consistency, penoizol adheres to the walls of the building very firmly, while the thermal insulation is high-quality and durable;

- experts have determined that the service life of the material is 50 years;

- environmentally friendly for humans. Harmful substances evaporated into the air are within normal limits.

Mineral wool

Materials created from thin interwoven mineral fibers have the qualities necessary for roofing insulation.

First of all, which is very important, mineral wools are good sound absorbers. In its design, this insulation forms a serious soundproofing layer, at least an order of magnitude better than other effective insulation materials.

It is only important that the rafters are covered with such a layer, which are bridges of cold and sound. The material is completely biostable, does not decompose, and living creatures do not live in it. It is fireproof. The thermal conductivity coefficient, under operating conditions, is close to 0.05 W/m? ° C; Samples of increased density, from 80 kg/m3, or layered, with a top layer of such density, are not blown through by a ventilation stream. They also do not cake and are durable. But their cost is increased.

Criteria for choosing insulation for walls

How to choose building insulation for walls based on its purpose and thermal insulation characteristics? Before you go to a hardware store to make a purchase, evaluate the surface that is to be insulated. It is important to take into account the material from which the structure is made, the humidity of the insulated surface, and the method of installation of the insulating material.

You should not settle for the cheapest materials, as the result of thermal insulation work may turn out to be unsatisfactory, and after a few years you will feel that your house has become cool in the winter. And these are extra heating costs. What determines the choice of insulation?

Depending on the type of thermal insulation work, materials for wall insulation are selected, slab or sprayed, in order to achieve maximum thermal insulation effect.

Cheap insulation: types and methods of insulation. Thermal insulation of loggias and plastic windows

Fluffy soft snow, a cold windy wind and frost that leaves a blush on the cheeks are not all the surprises presented by the Russian winter. The rise in prices for heat and energy resources traditionally occurs during the harsh winter months.

Therefore, thrifty owners should take care of insulating their own home in advance and thereby save a significant amount of money. This article will discuss which insulation is the cheapest and most environmentally friendly.

Properties of insulation that you should pay attention to when choosing

All insulation materials used to protect against cold differ in the following characteristics:

- Non-flammability : insulation must comply with fire safety standards, not heat up and prevent the spread of fire;

- Vapor permeability and water resistance : thermal insulation must effectively remove vapors from the premises, but not absorb moisture;

- Low thermal conductivity : a comfortable temperature must be maintained in a house or apartment both in winter and summer;

- No shrinkage : only such material will retain its original thickness for a long time, providing excellent insulation over time;

- Durability : ideally, the service life of the insulation should be no less than the service life of the building;

- Environmental friendliness.

When choosing insulation for interior decoration, it is important to choose environmentally friendly materials, because they will remain in the room for a long time without emitting substances that are harmful or hazardous to health.

Types of cheap insulation

When choosing insulation materials, price is often the deciding factor.

The cheapest types of thermal insulation materials today are:

- Glass wool . Since Soviet times, fiberglass has been used to insulate roof floors, pipelines and walls, both external and internal.

Thanks to the molten glass fibers that make up glass wool, this material meets all safety requirements and provides good heat and sound insulation.

The main disadvantage of glass wool is moisture permeability, which leads to its shrinkage and inevitable deformation;

Fibrous structure of glass wool

- Basalt (stone) wool . Made from fibers of various lengths that do not contain metal oxides, basalt wool fully complies with the concepts of environmental friendliness and safety of insulation.

Used to insulate any, even very large, surfaces inside and outside buildings and structures;

Basalt wool is produced in the form of slabs and rolls

- Expanded polystyrene (foam plastic) . For decades, biologically neutral and non-toxic polystyrene foam has remained the most convenient and economical, and therefore in demand, thermal insulation material.

Polystyrene foam used in apartment conditions is guaranteed to last you from 50 to 80 years.

When thinking about the cheaper way to insulate a house outside and inside, you need to know the features of the most popular insulation materials listed above, their disadvantages and advantages relative to each other.

Insulation methods

What is the best way to insulate a house with your own hands?

Traditional cold bridges are sections of walls at the joints of slabs, doors and windows. Therefore, you need to approach the thermal insulation of your home comprehensively.

Undoubtedly, specialists should be involved in insulating the facades of apartment buildings. Even non-professionals can provide warmth and comfort in a single apartment or private house - just strictly follow the instructions set out in this article.

Stages of work on insulating a loggia

The loggia, especially if after redevelopment it has become part of the room, must be insulated, otherwise you risk freezing and also suffering from loud sounds outside the windows.

Work on insulating the loggia is carried out in several stages:

- The process begins with clearing the area of unnecessary things and old glazing, if any;

- Next, a new window structure is installed. At this stage, installers will work for you;

- Waterproofing. The most popular and cheapest waterproofing material is roofing felt. Its pieces are overlapped and laid on the walls and parapet and glued. The joints are glued together using a gas torch;

- Then comes the turn of the insulation. It is attached in two ways. Foam plastic for insulating a loggia is screwed to the walls with dowels or glued, and for glass wool or basalt wool you will have to build a frame from wood or metal slats;

- A layer of penofol or polyethylene foam will perfectly protect the insulation from steam escaping from the room.

The final layer of penofol

The insulation of the loggia is completed.

Often, lining is used for loggia walls as insulation and for decorative purposes. This finishing material, so popular in Soviet times, still has its loyal fans. Lining should be used in combination with other materials, since wood conducts heat well, and its structure has many cracks and gaps.

If you have insulated all surfaces of the walls, loggia and doors, and drafts continue to flow through the apartment, take a closer look at the windows - perhaps it’s all about them.

Do-it-yourself insulation of plastic windows will likely require the involvement of specialists to replace the sealing rubber on the windows.

However, if you are “friendly” with tools and want to save on calling a specialist, step-by-step instructions will help you:

- Carefully remove the worn seal from the open window frame by prying it with a sharp object, such as a screwdriver;

- Checking the length of the removed seal, measure a new one and cut it off, adding 3-4 cm for adjustment;

- Carefully place the new seal in the groove, cut off the remaining excess length and tuck the tip inward;

The new seal will carefully retain heat and protect from cold

- Adjust locking mechanisms.

The polyurethane foam on which the window is installed must be protected with layers of plaster from the inside and concrete mortar from the outside, because when it is destroyed, not only cold, but also moisture will enter the room.

Thanks to affordable, environmentally friendly and safe insulation, your home has become truly warm and comfortable. We hope that our advice helped you choose the most optimal type of thermal insulation

Why is it preferable to insulate a house from the outside?

If you insulate the house from the inside, it will become warmer, but then the walls will begin to collapse. This will happen due to the appearance of condensation formed at the dew point. The consequence of this is mold and mildew.

Destroys building envelopes and freezes if they are not insulated.

Concrete and brick walls accumulate temperature, then gradually return it. If you insulate the walls from the outside, the flow of cold air to them will be blocked, and they will warm up from the inside. As a result, ventilation through the window does not cool the house down, but only lowers the internal temperature by a few degrees.

Having decided to inexpensively insulate the inside of the house, you need to know that when the walls freeze, the room will quickly cool down even with short ventilation.

Cold bridges created by floor slabs are also a big problem. Most of the heat escapes through them. Insulating a house from the outside means neutralizing the influence of external influences, thereby extending its service life.

Before you decide to insulate the outside of your home inexpensively, you should know that such insulation does not always work. This happens when there is an air gap in the walls, i.e. the wall consists of two parts - internal and external facing.

Most often, this situation arises when a ready-made house is inexpensively insulated from the outside by using cladding. The gap remaining between the main wall and the cladding must be closed. When this is done, the main and decorative wall on the outside with a void between them works like a thermos.

If this was not done or the blockage became unusable over time, cold air will begin to penetrate into the gap. In this case, it will not be possible to insulate the structure inexpensively from the outside. The facing wall will not work as thermal insulation.

Popular inexpensive insulation materials

What kind of thermal insulation can protect and insulate a house inexpensively.

Glass wool

Glass wool is one of the cheapest time-tested insulation materials. To a large extent, the price depends on the characteristics. When choosing glass wool, pay attention to the thermal conductivity coefficient, it should be 0.041-0.043 W/m•K. This parameter is indicated on the packaging. The main manufacturers produce glass wool with a density from 8 kg/m³ to 130 kg/m³ in slabs and rolls.

Glass wool is used to insulate roofs, attics and walls. The structure of this material retains still air, so heat does not escape from the house in cold weather, and on hot sunny days it is not stuffy.

Glass wool in rolls is the cheapest roof insulation; it is convenient to work with on large vertical surfaces.

Glass wool insulation is a very budget solution.

Advantages of glass wool:

- perfectly protects the room from excess noise;

- when packed, it takes up very little space;

- the flexibility and elasticity of the material allows it to be combined with complex structures;

- fiberglass does not burn or ignite;

- not susceptible to rot, mold or other fungi. Rodents and various bugs do not eat it.

Disadvantages of glass wool

- waterproof, which can lead to deformation when wet;

- Glass wool fibers are thorny; when working with it, they can get into the lungs when you breathe.

The use of rolled glass wool is only suitable for horizontal floors.

Foam plastic (expanded polystyrene)

This is the cheapest wall insulation. It is made from gas-filled pellets. The density of the foam varies from 100 to 150 kg/mK. Polystyrene foam, which has a high density, is stronger and more moisture resistant, but its price will be significantly higher.

With proper insulation, this material will last at least 30 years. Polystyrene foam is produced in the form of compressed slabs.

Important! When insulating with foam plastic, it is necessary to avoid contact with paints and other liquids that contain benzene and acetone, as they dissolve the foam.

To insulate the facade, it is better to buy polystyrene foam PSB-S-40. Polystyrene foam is the cheapest insulation for the ceiling in a concrete house. The sheets are simply glued to the ceiling. In this case, no additional finishing is required.

After insulation with foam plastic, it must be plastered

Pros of polystyrene foam

- keeps the house warm;

- It is lightweight, so it does not load the foundation.

- the cellular structure of the material dampens sound waves;

- resists dampness, mildew and mold;

- flexible-elastic structure

Flaws

- easy to paint when cut and pressed;

- destroyed by ultraviolet radiation.

Although polystyrene foam is cheaper than other insulation materials, when installing it you need to know many nuances, and you will also need additional materials. To attach polystyrene foam to the wall, use special glue and plastic dowels with wide caps. After the work, the insulated surface is reinforced with foam plastic, plastered and painted to prevent rapid destruction.

Note! Polystyrene foam is not suitable for insulating wooden walls, since the vapor-proof layer is obtained from the outside. Therefore, the wood under such insulation begins to get wet and rot.

Extruded polystyrene foam

For basements, loggias, basements, external walls and floors, it is better to buy extruded polystyrene foam. Material density 35 kg/cub.m. This type of polystyrene foam is not one of the cheapest insulation materials, but it will be the most cost-effective solution when insulating the basement of a house.

Pay attention to the cell size when choosing extruded polystyrene foam.

Advantages:

- does not absorb moisture unlike conventional foam;

- has a high level of thermal conductivity;

- not afraid of freezing and thawing;

The smaller the cell size, the better the insulation. Large cells increase the water absorption coefficient.

The density of extruded polystyrene foam can be from 28 to 35 kg/m³.

Foam insulation

When using the specified material for thermal insulation of the external walls of a building, the thickness should be observed, since failure to comply with this rule is fraught with freezing of the walls and blowing out. And for really high-quality insulation, foam plastic with a thickness of 50 mm, or even 100 mm, is suitable.

As practice shows, foam plastic 50 mm thick is most often used for insulation; this is quite enough in our climate zone, provided that the walls of the building do not face the north side.

In the second case, in order to insulate the walls of the house you will have to resort to foam plastic 100 mm thick.

Polystyrene foam also has negative qualities:

- Weak strength of the material. No plaster will give the material strong strength, so it can be easily damaged by mechanical stress;

- Despite its simplicity, the technology of insulating a house using polystyrene foam has many nuances. For example, failure to properly mark the seams can result in numerous cracks appearing on the walls within a week. A similar situation can arise at the corners of a building.

In addition to this, there are other disadvantages to this material, but it still has many more advantages and this makes it very popular.

An article on liquid foam insulation can be found here:

Calculation of insulation thickness

Before starting insulation work, the first thing you should do is familiarize yourself with the technology of using polystyrene foam. And, first of all, it is necessary to make calculations on the thickness and specific gravity of the material. This will help you choose the warmest option.

In terms of thickness, it must correspond to the design dew point; in practice, this figure is at least 70 mm; this is necessary so that even in the most severe frosts, the adhesive for the foam plastic to which it is glued does not thaw and the foam does not fall off the wall.

True, insulation is carried out with 4 and 5 cm sheets, which is acceptable in our latitudes.

Preparatory stage

First of all, remove from the walls all materials that may interfere: crumbling plaster, peeling paint, etc.

Optimally, if the house is old, before cleaning the walls in parts, it is better to strip them to the ground. After this, we clean the walls of small crumbling particles. Or wash the outside walls with plain water using a mini-wash, but if you don’t have one, you can use a regular hose.

After drying, the walls must be thoroughly coated with a regular primer.

Beginning of the insulation process

The density of the materials used must be at least 25 according to GOST, which means that 1 m2 of material will weigh 15 -25 kg. To securely attach the material to the wall, you should use special glue and special “umbrellas” - plastic dowels with wide heads.

This work is very similar to laying tiles, since glue is also prepared here, the adhesive composition is applied in the same way and also levels itself. The differences here are only in dimensions and technology for maintaining seams.

However, foam insulation is inexpensive, and tile installation can have varying prices.

Separating the seams when gluing foam plastic must be carried out, since otherwise the plaster on top of the foam may simply crack. When gluing slabs, regardless of the insulation of the floor or wall, close attention is paid to both external and internal corners.

To prevent vertical cracks from appearing at the corners, individual slabs of material are bandaged according to the principle of laying bricks. The main task here is to maintain a level plane.

Subtleties of insulation

Although thermal insulation with foam plastic is inexpensive and costs much less than insulation using other materials, it requires compliance with many small details, the failure of which can lead to dire consequences.

It is necessary to focus on the insulation of slopes, since cracking most often occurs here.

So, on the side of the window, under the foam plastic, a reinforcing mesh should be laid, which should look out from under it by 20 cm. Next, it is bent over the slope and used as reinforcement. After the foam has been glued, it should dry for at least a day.

After it dries, the “umbrellas” are installed, holes are drilled and “umbrellas” are inserted, and plastic nails are hammered into their middle. The procedure is carried out at the rate of five nails for one sheet of foam plastic, one in each corner and one in the middle of the sheet.

Foam reinforcement

After hammering the nails, a cheap method of thermal insulation, which you can do yourself, involves reinforcement.

Excess glue is removed using a wide spatula. Gluing the mesh is done only with special reinforcement glue. Also, insulation using polystyrene foam means that it is necessary to glue the reinforcing mesh overlapping, since if it is glued end-to-end, cracks will appear after the glue dries.

Insulation of slopes

It should be noted that polystyrene foam is used both for walls and for insulating slopes. The fact is that window openings are characterized by certain not good specifics.

Even if the reinforcement was done correctly, after some time cracks appear in the upper and lower corners of the opening. Only double reinforcement will quickly fix this; of course, the price will be slightly higher, but the thermal insulation of the walls will be better and the slopes will be stronger. To do this, strips of reinforcing mesh are glued diagonally at all corners of the window opening.

Mineral insulation

Stone wool is produced in rolls; in slabs or lamellas. One of the main advantages of this insulation is safety. Mineral insulation is one of the most environmentally friendly materials. The average density of basalt wool ranges from 50 to 200 kg/mK.

Rolled mineral insulation allows you to inexpensively insulate roofs, floors and basements. This elastic material adheres well to surfaces of any curvature and shape, so it can be used to insulate a roof of complex configuration.

Supplied in packages, after opening they restore their shape and size.

This is an ideal insulation for any walls and floors, roofing pie, attic floors and floors, the main thing is to purchase the right brand. When purchasing this insulation, you need to take into account that you will additionally need to buy materials for vapor barrier and a diffusion membrane to protect the roof space from moisture. Therefore, when calculating how much it costs to insulate a floor or roof, you also need to take these factors into account.

Basalt insulation is an inexpensive thermal insulation material

Pros:

- not flammable,

- has a high density;

- environmentally friendly,

The main disadvantage is the same as that of glass wool - loss of quality when exposed to moisture. Therefore, it is better not to use mineral wool for thermal insulation of surfaces with high humidity.

We save with benefit: the cheapest insulation for walls

Mineral wool is suitable for insulating all vertical surfaces of walls and roofs of frame houses. There are several types of wool, but only two are used for insulation: glass wool and stone wool.

And besides wool, there are also cheap options for insulating frame houses. Straw is such insulation. Houses insulated with straw came to us from America, in principle, like many other things.

Installation of mineral wool can be organized in several ways; the final price of thermal insulation of a house depends on these methods.

There are the following insulation methods: ventilated and wet facade.

Mineral wool for insulation comes in two types

According to all construction rules, insulation of a house inside cannot be carried out under any circumstances. To calculate the cost of inexpensive insulation, you need to consider the methods separately.

To perform insulation using the wet facade method, you need basalt wool with a density of at least 45 kg per cubic meter, plaster, mesh, fungi, universal construction adhesive, paint and primer. To create a ventilated facade, you need: lathing, insulation, wind protection and finishing material.

Insulation such as mineral wool is considered to be one of the cheapest options for roof insulation. In addition to wool, the price should also include a vapor barrier and a diffusion membrane.

Ecowool

Inexpensive, environmentally friendly material made from recycled materials. Ecowool has proven itself best as an internal insulating layer.

Positive properties:

- sound absorption is very high,

- biostability;

- breathability;

- environmental friendliness

Flaws:

- flammability;

- significant shrinkage over time.

Many builders believe that ecowool is the best insulation for the walls of a frame house.

Liquid penoizol

This is the cheapest insulation. But it is suitable for insulating cracks and gaps. Penoizol has a low density and is not destroyed by microorganisms. The foam adheres well to almost any material.

Liquid foam insulation is used to seal cracks

Table. Review of prices of inexpensive thermal insulation materials: recommended manufacturers and where they are used

| Name of insulation | Manufacturers | Scope of application | Approximate price (rub) per 1 cubic meter |

| Stone wool | TechnoNIKOL, ROCKWOOL, Paroc, Termolife. | Suitable for indoor and outdoor insulation, including roofs. | from 1500 to 3500 rubles - depending on quality. |

| Styrofoam | KNAUF, "Stroykomplekt" | For walls and ceilings. | From 1200 to 3000 rub. |

| Extruded polystyrene foam | "Penoplex", "TEPLEX", "TechnoNIKOL" | They insulate the walls of facades, basements, loggias, and basement structures. | From 2500 to 4500 per 1 cubic meter |

| Glass wool | URSA, KNAUF, ISOVER | For interior and exterior work when insulating horizontal surfaces | From 1200 to 3300 |

| Ecowool | Ekovilla, Termex | Partitions, frames, inner layer. | From 1200 to 2600 |

| Liquid penoizol | Facades, roofs, frame walls, floors. | From 1100 rubles |

Experts recommend using a mixed type of thermal insulation, using some materials for floor insulation, others for walls, and others for the roof.

“>

Extruded polystyrene foam

Based on the same polystyrene, but much denser and stronger.

Experts estimate its service life as longer. It has the best heat-insulating qualities and acts as a complete vapor barrier. But the main thing for the consumer is that this material is expensive, almost like sprayed polyurethane foam.

Therefore, it is simply not recommended in projects due to economic feasibility or fire hazard outside the conditions of its normal use, where there is nothing to replace it with (humidity, compression, soil).