Application of new developments

Competition in the construction market forces manufacturers to look for ways to improve product quality. To achieve this, work is being done in the following directions:

- creation of acoustic drywall;

- use of special filler with noise-absorbing properties for partitions;

- elastic pads under the frame, reducing the sound of impacts;

- filling partitions and creating false walls;

- spraying cellulose fibers inside partitions.

Acoustic drywall

and Aku-Line have mastered the production of acoustic plasterboard, which reduces the noise level when finishing interior partitions and when covering walls. Increased sound insulation of the partition is achieved due to a large number of holes, creating a reflection of a passing sound wave directed at the wall surface. In addition, a non-woven fabric is glued to the cardboard on the reverse side, which absorbs sound.

Acoustic plasterboard "Knauf"

Sound-absorbing filler inside partitions

Sound insulation of plasterboard partitions also requires the presence of a sound-absorbing filler between them. The same companies are developing it. Expanded polystyrene is widely used - a foamed thermoplastic made from fused granules with air cavities. The material also successfully copes with the function of thermal insulation. The addition of a fire retardant can increase the fire resistance of polystyrene foam. Judging by customer reviews, domestic polystyrene foam is a very poor thermal insulator.

Mineral wool slabs have high protective properties against sound propagation. produces a wide range of acoustic stone wool slabs, among which 4 cm thick products are often used for soundproofing walls. For effective dispersion of sound waves, the homogeneity of the slabs, which acoustic mats have, is of great importance.

Acoustic mats "Rockwool"

Partition materials with improved soundproofing properties are more expensive than usual, but with their help they achieve complete sound insulation. In addition, you can use filler of a smaller thickness, which will reduce costs and loss of room volume.

Membranes made of thin fabric with a fleecy coating are a high-quality sound absorber. The layer can be from 2.5 to 12 mm thick.

Polyester or polyurethane foam panels are used for internal filling and to create false walls. Some of them may be a fire hazard due to the content of flammable substances.

The cheapest filler for plasterboard walls is polystyrene foam. It reduces noise to some extent, but its efficiency is low.

Spraying sound-absorbing coatings

Spraying cellulose fibers with an adhesive composition is often used due to its low cost and the possibility of mechanizing the process. The method is used to correct acoustics indoors for entertainment and public purposes.

How does cellulose spraying occur?

Ready-made Sonaspray coatings have a texture like fur coat plaster. It can be coarse or uniform, depending on the size of the cellulose flakes. Since the coatings look impressive, dyes of a wide variety of shades are added to the solution. The coating can be painted after it has been applied.

The ability to spray a foamed cellulose solution on the surface of walls and ceilings made of building materials eliminates the need to create a frame that is used to hold gypsum board cladding. The manufacturability and cost-effectiveness of the process allows the team of specialists to ensure a productivity of 300 m² per day.

If you have the necessary equipment, the sound insulation of a plasterboard interior partition can be improved by applying cellulose from the inside.

Advantages and disadvantages

The main advantage of thermal insulation of the walls of a house using plasterboard is

- ease of installation;

- high efficiency of insulation;

- ideal surface for walls and ceilings for finishing.

The disadvantages include:

- the system of frame guides takes up space and volume, this is especially noticeable in compact rooms;

- low mechanical strength of the coating, does not withstand impacts;

- You cannot hang heavy objects without installing additional guides.

Insulating walls with plasterboard has a number of advantages and disadvantages.

Nevertheless, more and more rooms are being finished with gypsum board. Working with it does not require high qualifications or expensive specialized equipment.

How to choose materials

Previously, before the invention of drywall, sound insulation was achieved by building a heavy brick or concrete wall. But it is obvious that this increases the load on the floor. Even earlier, partitions were made from so-called shingles. This is an interlacing of wooden slats, smeared with clay. This material is fragile and flammable, and the durability of the wall leaves much to be desired, fire safety even more so.

Fortunately, drywall is free from the following disadvantages:

- The material is non-flammable. If you choose a metal frame and mineral wool insulation, then you don’t have to worry about a fire in such a room. Plaster does not burn.

- The weight of one meter of brickwork is almost one and a half tons. A square meter of a single-layer gypsum partition weighs only 50 kg.

- A plasterboard partition is easy and quick to install. You just need to carefully mark everything and follow the instructions.

- The excellent sound insulation of the plasterboard surface in combination with other qualities makes the material the best option for building an interior wall.

The ceiling is both beautiful and protects from noise

Materials used for internal insulation

Materials used in the internal insulation of a house must meet certain requirements:

- Firstly, they must have low thermal conductivity in order to fulfill their main function - insulation.

- Secondly, these materials must meet fire safety requirements for premises.

- Thirdly, the material, alone or in combination with the mounting structure, must provide the required mechanical strength.

- And finally, all materials used indoors must be environmentally friendly and not release any chemicals into the surrounding air that adversely affect the health of living beings.

Penoplex insulation under drywall without frame

Step-by-step instructions will be like this:

- At the first stage, the base surface is prepared: the old coating is removed, cracks and potholes are sealed, and protrusions are knocked down. The wall should be as flat as possible.

- The surface is treated with a deep penetration primer.

- According to the manufacturer's recommendations, a special composition is prepared. If you don't have it, you can use tile adhesive.

- The inside of the insulation board is rolled with a needle roller. Another option is to brush it with a metal brush. This will ensure good adhesion to the adhesive solution.

- A fragment of insulation is applied to the wall and held for a minute. Be sure to check the correct installation at the building level.

- Begin gluing the penoplex from the bottom. It is recommended to move the rows relative to each other so that the slabs are staggered.

- The seams between the plates are filled with silicone sealant; wide cracks can be sealed with polyurethane foam.

- Drywall is attached to the insulation using glue. The scheme for applying the composition is the same as for penoplex slabs. It is recommended to place a layer of vapor barrier between them.

- After the glue has dried, which will take 24 hours, the drywall is finished. The seams are sealed using putty and serpyanka mesh, rubbed down, after which the entire surface is covered with a double layer of primer.

Insulation of balconies and loggias

Insulation with plasterboard from the inside can also be used to improve thermal insulation in rooms such as a balcony or loggia.

The technology is the same as for other rooms. First, the frame is assembled, into which sheets of heat insulation are then placed. Sheathing completes the process.

Balcony insulation

But, the specifics of such premises require compliance with certain features:

- It is important to have good waterproofing of surfaces due to the possible ingress of water;

- Sheathing walls with plasterboard should be moisture-resistant, and not the cheaper standard sheet;

- Pre-treatment of insulated surfaces with antiseptic agents will also be important.

Insulating walls from the inside with plasterboard is a simple process, however, if possible, it is best to insulate the room from the outside. But under difficult conditions, this is the only way to improve energy saving performance.

Installation of sound-absorbing panels

To assemble and cover the frame you will need the following tools:

- laser level;

- drill;

- screwdriver;

- construction stapler.

- metal profile;

- elastic polymer tape;

- plasterboard (from 12 mm);

- mineral wool slabs (thickness from 100 mm);

- polyethylene film;

- self-tapping screws;

- sealant.

The work is carried out in the following order:

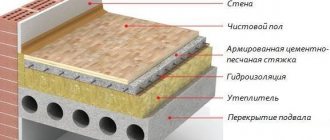

The working principle of sound insulation.

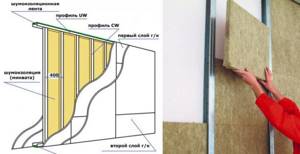

- The walls are marked under a plasterboard frame using a level.

- The profile is placed along the perimeter of the wall surface (or between the walls if a false wall is being built), then guide profiles are attached to it in increments of 40-60 cm, fixing them with self-tapping screws every 60 cm.

- To increase the sound insulation of the walls, an elastic insulating tape is laid along the edges of the frame, which should fit tightly to the profile and base.

- If a new wall is built, the frame is covered with gypsum board on one side using special self-tapping screws.

- Mineral wool slabs intended for sound insulation are placed in the cells between the sheathing elements.

- The top of the mineral wool is overlapped with waterproofing, attaching the film with a stapler.

- The frame, filled with insulating material, is covered with plasterboard sheathing.

- The seams between the sheathing and the floor are filled with sealant.

Now you can fill the seams and finish the plasterboard walls.

The technology used makes it possible to reduce the noise level to small values, since the combination of the air gap (in front of the sheathing) and the loose structure of the mineral wool dampens sounds well.

Soundproofing the walls simultaneously serves as their insulation, which is especially in demand in corner apartments.

If a room requires enhanced sound insulation, it can be obtained by combining rigid and elastic materials. Such combined sound insulation can be created, for example, by combining cork and fiberglass materials.

How to install mineral wool correctly

Before laying mineral wool, you need to have a respirator, construction gloves, and a hat.

When the frame is completely assembled, the mineral wool is cut into strips of certain sizes using a drywall knife. The cut strips are laid tightly along the frame posts. If the ends are joined, it is better to overlap from 10 to 15 cm.

Coconut cork and combination board

If it is important to achieve maximum sound insulation of a plasterboard partition, you can use balsa wood and coconut fiber boards. You can combine these soundproofing materials

Then you can achieve the maximum permissible sound insulation effect.

Expanded polystyrene boards are perhaps one of the best thermal insulation materials used in insulating plasterboard partitions. Expanded polystyrene boards come in different sizes and densities. Usually these are 120x60 and 100x50 cm with a thickness of 2 to 5 cm. They differ in density into soft, semi-rigid and hard. They are connected using grooves.

They also speak well of polystyrene foam as an insulating material. High heat transfer, a wide range of sizes and shapes, allows you to insulate any wall made of plasterboard construction.

If a decision is made to carry out insulation exclusively with the help of mineral wool, then Rockwool will be an indispensable insulation. After all, it is no worse than the same polystyrene foam. As an advantage, it is worth emphasizing the fact that Rockwool can have a heat reflector. It should be remembered that ROCKWOOL mineral wool comes in both slabs and rolls. If it is a roll, then it can have a thickness of 30,40, 50 cm; length 5, 8, 10 m, standard width 1 m. If it is a slab, then dimensions: 100x60 cm with a thickness from 5 to 20 cm. This insulation is able to withstand large temperature differences and has good water-repellent and fire-resistant characteristics.

Polymer heat reflectors are used to maintain temperature in a particular room. They are usually sold in rolls with dimensions: 2-5 mm thick. width - 1 m. length - 30 m. The thickness of the heat reflector foil itself can also be different.

Technology of thermal insulation of walls with plasterboard from the inside

The technology of insulating the walls of a room with plasterboard from the inside does not require special training of workers or expensive equipment. General construction skills and a universal tool are enough.

Tools and materials

During the work you will need:

- guides (metal profiles or wooden bars);

- gypsum boards;

- insulation in slabs or rolls;

- double sided tape;

- vapor barrier membrane;

- screws, dowels and other fasteners;

- anti-mold agents;

- putty;

- drill;

- screwdriver;

- hand tool.

The floor in the room must be cleared of debris and foreign objects.

Design

At this stage, the type of insulation, gypsum board and guides is selected.

If you are insulating a kitchen or bathroom, you should choose moisture-resistant plasterboard. For the boiler room, it is recommended to use fire-resistant.

Wooden guides are cheaper, but they are at risk of drying out and deforming in the event of temperature changes. The metal profile does not have such disadvantages. The number of guides is calculated based on a standard step of 60 cm.

When calculating the volume of materials purchased, a 5% reserve should be made in case of damage to gypsum boards and for cutting complex elements of walls and ceilings.

Stages of work execution

At the first stage, it is necessary to perform a number of preparatory work:

- clean the walls from dirt and mortar drips;

- dismantle all protruding objects: fasteners, remnants of fittings, sockets, lamps, etc.;

- fill all cracks and irregularities;

- treat with a composition against fungus and mold;

- dry the surface.

Next, marking work begins. Use a plumb line or a laser rangefinder and a chop cord

special attention should be paid to:

- parallelism of the marking of the mounting points of the guides;

- marking in corners and junctions of building structures: arches, window and door openings, columns, bay windows, ceiling beams.

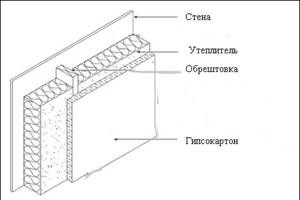

After marking, they proceed to the installation of frame guides.

- The starting profile is glued to the floor using double-sided tape; the adhesive tape will improve sound insulation and protect against drafts;

- vertical profiles are attached to the starting strip with metal screws, and to the wall with screws on dowels.

The process of insulating walls with plasterboard

A very important stage is laying insulation into the guides. The quality of insulation will directly depend on the accuracy of the work:

- insulation sheets are placed in the guides from bottom to top;

- they should fit between the profiles without gaps, with some effort;

- the sheets are additionally attached to the wall with adhesive or disc-shaped dowels;

- All cracks and gaps must be tightly filled with scraps of material or sealed with foam.

Now it's time to install a vapor barrier:

- penofol is mounted with foil inside the room;

- The vapor barrier membrane is attached with the rough side inward; double-sided tape is used for installation.

And the final stage is the installation of drywall sheets. They are mounted horizontally, from bottom to top. Before screwing the sheet to the guides, you need to use markings and a level to make sure that it is positioned strictly horizontally. After the first layer is secured along all the guides, the next one is installed on top of it. Here you also need to ensure that the position is horizontal and that the gaps between the sheets are minimal.

As a rule, the size of the room does not allow installing only whole sheets of drywall. Pieces have to be mounted in corners and under the ceiling. Drywall should be cut on the floor, in a horizontal position, on a flat surface. It is enough to cut through the top layer of paper with a mounting knife. Now the cut piece can be broken off along the cut line.

Upon completion of installation, all joints between the sheets should be thoroughly puttied. After the composition has dried, it is leveled with fine sandpaper, achieving a completely flat surface of the wall or ceiling.

Now the surface of the insulated wall is ready for final finishing. Two main types are used:

- wallpaper;

- water-based paint.

When insulating rooms with high humidity with plasterboard, moisture-resistant types of plasterboard with special hydrophobic and antifungal impregnations are used. These panels are easy to distinguish: they are painted green. In wet rooms it is also necessary to arrange supply and exhaust ventilation to prevent air stagnation and mold formation.

Types of drywall and its use

Articles on the topic - how to cut mineral wool correctly.

Drywall can be used to insulate walls inside a building. Use either moisture resistant or wall.

Moisture-resistant can be used in dachas or for rooms with a high degree of humidity: bathrooms and kitchens.

Important! Moisture-resistant plasterboard, the best solution for rooms where heating is not provided.

This material is not at risk of cyclical temperature fluctuations. After installing the sheets, you only need to apply a waterproof primer or protective paint to the front part. You should also treat drywall with an antiseptic to kill harmful germs and bacteria.

Wall types are suitable for living rooms where the humidity is no more than 70%. Sheets are marked in blue on a gray surface.

As for the sizes of sheets, it is best to purchase products 2.5-3 meters long and 1.2 meters wide. In terms of thickness, canvases of 12.5 mm are perfect (9.5 mm is the ceiling type).

Drywall is:

- ordinary;

- moisture resistant;

- moisture and windproof;

- enhanced strength;

- fire resistant.

Related article: Independent insulation of balcony walls from the inside.

There are 3 methods of insulation:

- Glue method. The sheets are attached directly to the wall using gypsum or polymer-cement glue. With this finishing, the area of the room does not become smaller. The only disadvantage of this method is that it is impossible to lay thermal insulation, and the walls must be strong.

- Frame method with thermal insulator.

- Frame method without insulation.

The last two methods of installing drywall are used most often. In order not only to insulate the room, but also to achieve good sound insulation performance, you will need to use profiles. The only drawback is that the room is significantly reduced in size.

What not to do

Often, when trying to limit themselves from noise, many people use materials that are not the most suitable for this. First of all, this applies to polyurethane foam.

Not only does it provide poor protection from noise, but it is also not fire safe. The foam melts perfectly and releases a suffocating gas. The same can be said about polystyrene foam.

By creating a simple partition made of gypsum sheets to protect against noise, and not filling it with a noise absorber, they thereby turn it into a large resonator, which only worsens the situation.

Insulation from sound penetrating through technological openings - sockets, air ducts and the like - is required. If nothing special is done with the air ducts and ventilation ducts, then the outlet can be treated from the inside even with a simple sealant, which, although slightly, will reduce the amount of incoming noise.

When using roll sound insulators and membranes, you must not leave joints or gaps between the parts of the coating. It is necessary to glue them overlapping.

Installation of gypsum board sheets

If working with drywall is new to you, you need to first familiarize yourself with some of its features. Before installing the guide profiles, a special tape is laid along the intended installation lines. It will serve as protection against contact with plaster. In this case, the drywall will be protected from the cold that comes from the metal profile.

Metal profiles are usually installed at a distance of 2 cm from the wall. It is recommended to install a frame made of galvanized profile. After installing the frame, insulation boards are placed behind it. The material must be inserted vertically. In no case should the edges of the insulation protrude beyond the front side of the profile.

When is it necessary to insulate indoor walls?

The most effective option for wall insulation is installing thermal insulation on the outside of the façade. But only owners of private houses can afford this. This method is also expensive. In apartment buildings, if they are not insulated from the outside with thermal insulation materials, residents have only one choice for insulating the walls themselves - internal thermal insulation. Private homeowners also often choose this option as an economical one.

They prefer to use plasterboard for wall cladding because it has a number of advantages over other finishing materials:

- lightweight and easy to handle;

- has thermal insulation properties;

- allows you to quickly create perfectly smooth surfaces;

- under such a coating you can place any type of insulation, even soft ones;

- its cost is not high.

Which way to choose - from the inside or the outside?

If the thermal insulation material is placed outside, that is, the facade of the house is directly insulated, the dew point (condensation forms along this boundary during temperature changes) falls precisely on the additional layer. In this way, the impact of temperature changes and changes in air humidity on the load-bearing wall is neutralized, resulting in an extended service life of the building.

If insulation is carried out from the inside using mineral wool covered with gypsum board or similar cladding, the dew point moves. Usually this boundary is between the wall and the insulation, in such conditions there is a high risk of fungi and mold growing. If internal thermal insulation of partitions and walls in an apartment is carried out, two conditions must be taken into account - the presence of a protective layer on the side of the facade and the total thickness of the wall. The best option is to strengthen the load-bearing structures on both sides.

Features of thermal insulation with plasterboard

Advantages of gypsum board cladding in terms of wall insulation in an apartment:

- low conductivity of panels;

- installation is carried out only on flat surfaces, most often the sheets are installed on the sheathing - such a frame forms an air gap between the wall and the sheathing, which has a positive effect on retaining heat in the room;

- free space (cells in the sheathing) can be filled with materials with a high ability to retain thermal energy;

- In summer, such rooms will be cooler due to the fact that additional layers will not allow heat from outside.

In apartment buildings, internal insulation is more accessible than external insulation; plasterboard is one of its most economical options. The panels are easy to process and undemanding in maintenance, they can be applied with any type of finishing, they form a perfectly flat surface without weighing down the load-bearing structures

GCRs are combined with most types of insulating (hard, soft) and finishing materials, which is important when creating interior design

Types of suitable insulation materials, their properties

The insulating structure is selected in accordance with the brand of plasterboard panels, they can be:

- wall,

- fire resistant

- gypsum fiber reinforced,

- ceiling,

- moisture resistant,

- gypsum fiber moisture resistant.

To insulate partitions and load-bearing structures, moisture-resistant wall variations that are fire-resistant and have increased strength are used. Additional insulators vary in density, consistency, thermal conductivity, and thickness.

Slab materials are optimal for walls; compared to roll insulation, they are much easier to install. The parameters of the products are suitable for placement in the grooves of the sheathing; you don’t have to waste time on adjustment. It is only important that the slabs are positioned closely, without gaps. Glass wool, basalt wool, polystyrene foam, and isolon can be mounted on walls under drywall.

Styrofoam

The granular substance is based on polystyrene, is characterized by low weight and low density, and is molded into slabs of varying thickness. The popularity of the solution is due to ease of installation and low cost; the disadvantages are fragility and insufficient sound insulation, and the need for additional ventilation. Rodents are interested in the material; additional protective measures will be needed.

Foam plastic - insulation for drywall

Minvata

Basalt wool is more expensive than glass wool and polystyrene foam, but it is in great demand due to its optimal performance properties. The natural insulating resource is made from molten rocks and is characterized by being hypoallergenic, fire-resistant, environmentally friendly and durable. The texture is formed from thin stone fibers alternating with layers of air, which ensures thermal insulation.

Unlike other categories of mineral wool, basalt does not absorb water, so it can be used in rooms with high humidity. In addition to the price, the disadvantage is the large thickness of the slabs, which “eats up” useful space.

Glass wool

A flexible, soft solution with a small thickness, kept in the budget segment, and has low thermal conductivity. This option is dangerous for use in everyday life, since glass fibers upon contact with mucous membranes and skin provoke severe burning and itching. During installation, you need to use a respirator, special clothing, safety glasses, and gloves.

Glass wool - insulation for drywall

Izolon

One of the new insulation options, formed as a result of polyethylene foaming under the influence of propane. It is characterized by low density and weight, as it is saturated with air bubbles. Izolon perfectly protects against heat leaks, exhibits high sound insulation with an acceptable thickness, and with its help you can save the usable area of the apartment. Some brands have foil vapor protection.

Stages of thermal insulation of a wall

In order for the work process to proceed quickly and properly, you should prepare the necessary tools. This will significantly speed up the work on protecting the walls with insulation.

The following materials will be required:

- plasterboard sheets;

- self-adhesive tape;

- insulation;

- membrane to ensure maximum vapor barrier;

- screws, nails;

- hammer, screwdriver, hacksaw;

- yardstick;

- metal profiles or wooden slats for constructing the frame;

- fastening materials.

For 1 sheet you need approximately 30 pieces of self-tapping screws. It is best to buy screws 20 mm long.

As for the manufacture of the frame, the profile must be taken of 2 types: marked CD and UD. The length is selected based on the size of the room.

Frame design

It consists of drawing the perimeter and thinking through how the frame will be positioned on the wall. A simple pencil and a building level are enough.

Preparation:

- surface cleaning;

- smooth out all the unevenness and fill up the cracks and depressions;

- drying with a heater or blow dryer;

- getting rid of mold and mildew.

Sometimes it is necessary to treat the walls with a special waterproofing putty to prevent the occurrence of dampness. First, the layer is applied vertically, then horizontally.

Frame construction

Installation of a frame from profiles for plasterboard You need to mount the frame according to pre-made marks. To avoid contact of the metal structure with the wall, a tape prepared in advance is glued to the base of the profile. The frame parts are fastened to the wall using self-tapping screws and dowels.

Before laying the insulator, the surface is prepared in advance. Weak areas of plaster are removed or restored. To eliminate the possibility of the formation of fungus and mold, it is necessary to treat with a primer and an antiseptic.

Sheets of plasterboard are installed on a frame made of metal or wood. A metal frame will last significantly longer than one made of timber.

In the area where batteries are located, where installing thermal insulation is difficult, penofol can be used.

You can make a frame from bars under drywall

Assembling the frame begins with the installation of guides created from the UD profile. The slats are mounted on the ceiling and floor with a distance of 50-60 mm from the walls. A section of the rack profile is inserted into the guides. The ends are fixed using small self-tapping screws (“fleas”). The edges of the hangers are folded from the sides and connected to the slats. The pitch between the profiles must be observed so that there are 3-4 slats per sheet.

To improve the rigidity of the structure, it is necessary to make transverse bridges from the CD profile. The profile is cut so that its length overlaps the adjacent slats by half. Use metal scissors to cut off the shelves. Then the blanks are fixed with fleas onto the frame.

Vapor barrier device

Penofol is often used as a vapor barrier. Before attaching it, you need to make sure that the side of the material with foil is facing inside the room.

As for the vapor barrier material, which has a rough surface, its uneven side should also be directed into the room.

Insulation

The insulation should be cut using a special knife. The insulation should be cut into pieces, the size of which should match the parameters of the frame cells.

If you use foam plastic as a thermal insulation material, then it should be attached with special glue prepared with the addition of water. Each piece should fit tightly to the surface. If gaps appear between the parts, they are filled with polyurethane foam. After the glue has dried, the foam is fixed with dowel umbrellas. Dowels should be placed in the corners of the sheet and one in the center.

After laying the internal thermal insulation, they begin to sheathe the frame with sheets of plasterboard.

When the screw is screwed in, its head should sink slightly, by 1-1.5 mm, but without tearing the cardboard. To make fixing easier, it is better to buy bits with a limiter.

After the walls are completely covered with plasterboard sheets, the surface is finished in any usual way. Insulated walls can also be covered with wallpaper or painted.

How to sheathe insulation under gypsum boards inside a house with your own hands

Internal insulation of walls under drywall can be done independently. It is only important to carry out all stages of work correctly, follow technologies and recommendations.

- Preparing the walls. To avoid having to quickly dismantle the drywall and re-do the repairs, you need to take care in advance that the walls are dry, clean, free of fungal areas, cracks and holes. If there are even small spots of mold, they must be completely removed, and then the walls must be treated with a special antiseptic, antifungal composition. All cracks and crevices must be filled with putty to avoid heat leakage and moisture penetration from the outside. The applied layer of plaster will be an additional protection against dampness, but an antiseptic must also be used. Because in the future, insufficient ventilation under the insulation layer, in the absence of a protective coating, can cause the formation of mold.

- Fastening the sheathing. To create fastenings for drywall, a sheathing is made of metal profiles or wooden slats. The advantages of a metal profile are that it does not deform over time. Wooden slats have good thermal insulation properties, but are susceptible to drying out, which can affect the quality of the cladding. To create the sheathing, metal or wooden slats are fastened with flat cutters along the perimeter of the wall, and then vertical slats are installed at a distance of about 60 cm (you need to take into account the width of the insulation boards so that it fits tightly into the space between the slats).

- Installation of insulation. Methods of attaching insulation depend on the type of material. Foam boards are attached to the wall with glue and special dowels. All joints between them are additionally sealed with construction tape, and the gaps between the slabs and the ceiling (floor) are sealed with silicone sealant. Mineral wool is attached with a special foam adhesive, which is applied around the perimeter of the slab and a couple of strips in the middle.

- Finishing the insulation surface. To ensure good vapor barrier, it is necessary to apply a protective layer of construction foil or plastic film on top of the insulation. Only after this can finishing be done with plasterboard.

- Installation of drywall. Drywall sheets are attached to the sheathing with self-tapping screws. Then all the cracks are puttied, cleaned with emery cloth, and covered with a special tape or paint compound to prevent cracking at the seams.

If a metal profile is used as a sheathing, then the cavities inside it must also be filled with insulation tapes to avoid the formation of “cold bridges”.

Advantages and disadvantages of plasterboard wall structures

To begin with, it probably makes sense to briefly highlight the positive and negative aspects of a wall frame structure made of plasterboard. Having understood them, it will be possible to competently decide whether such a partition is suitable for a particular case or not.

After finishing work, the plasterboard structure will look like a full wall.

So, the advantages of plasterboard partition structures include the following points:

The materials used for the construction of such walls are quite light, so they will not weigh down the interfloor floors. Consequently, the mounted structure will be absolutely safe for the building. Walls and partitions made of plasterboard are not permanent, so their construction does not require obtaining a permit, the obtaining of which involves the loss of a considerable amount of time, money, effort and nerves. Drywall is produced in several versions - these are simple sheets (GKL), moisture-resistant (GKLV), fire-resistant (GKLO). Lightweight sheets are produced for ceiling structures

Therefore, walls and partitions can be erected from this material in any of the rooms, including in the bathroom or near the stove or fireplace. The affordable cost of both the drywall itself and the components for building the frame allows a family to purchase them for repairs, even with a modest budget. It is quite possible to design and install plasterboard walls that have complex decorative and useful shapes, such as arched doorways or functional niches and cabinets, allowing you to avoid purchasing furniture accessories. When leveling walls with this material, you will not need to remove the old plaster. The construction of walls made of plasterboard (or when leveling walls with plasterboard using a frame method) allows for immediate insulation and sound insulation work. You can hide electrical wiring in the frame of the wall being built. There is a complete opportunity to do without the involvement of a team of builders, since all the work can be done independently or with one assistant. The material is “breathable” and environmentally friendly, which is important for furnishing residential premises. A wall or partition erected using this method turns out perfectly smooth, suitable for any facing material, be it wallpaper, paint or ceramic tiles.

Moisture-resistant plasterboard sheets are used to level or line the walls in the bathroom.

Drywall prices

drywall

Now, for the objectivity of the picture, it is necessary to consider the negative aspects of the plasterboard structure. It is advisable to know about them in advance, so that later, when using the rooms, you do not encounter some unexpected inconveniences. :

Wooden bookmarks in a metal frame of a plasterboard structure

- A wall made of this material will not be able to withstand hanging any heavy objects directly onto the plasterboard, since the sheets are quite thin (12.5 mm), fragile, and the gypsum itself is not particularly strong. Therefore, if in the future there is a plan to hang, for example, a TV or sconce on the wall, then their location must be determined at the design planning stage, and additional jumpers made of a metal profile with wooden bookmarks must be provided for fastening.

- The wall structure will have a minimum thickness of about 80 mm, and often much more. This reduces the area of the room somewhat. But think about it, what if you use other materials for the partition? Almost any other will give even greater thickness. Therefore, this drawback can be called very doubtful.

How long will the insulation last?

The service life of insulation depends on its type. Cheap materials are on average suitable for use for 20-30 years. Some expensive brands have a service life of up to 50 years in their technical specifications (but this is not always tested in practice).

Over time, the substance ages, the structure of the material is destroyed, it dries out or cakes, and loses more than 1/3 of its thermal insulation properties. Most types of insulation are recommended to be replaced at least every 35 years.

To create a healthy, favorable microclimate in the house, you can independently carry out the work of insulating the internal walls. For this purpose, lightweight, easy-to-install materials are used. With their help, you can make high-quality wall repairs with your own hands, even without professional training, using tools available in everyday life.

Soundproofing of plasterboard partitions

Properly selected material for soundproofing plasterboard partitions is the key to peace and quiet. By protecting against intrusive conversations, music or TV in the next room, it helps maintain nerves and healthy relationships.

A typical modern interior partition is made of a wooden or metal frame covered with plasterboard on both sides. Such a wall does not resist the passage of sound well. If a similar redevelopment has been made in the apartment, then only soundproofing of plasterboard partitions will save you from noise.

Best materials

The most effective material that completely guarantees results does not yet exist and is unlikely to ever be made. There is also no universal, one-size-fits-all guide to follow when making a room barrier.

The effectiveness of activities depends on each stage. The very first is the installation of the frame. Its design will simply ring if you do not take protective measures - insulate the floor and ceiling from it. Without using a damper tape, it is impossible to achieve any significant results. An excellent damper is the proven Vibrostek-M tape.

As for the frame, there is not much to think about what to choose from - either wood or a metal profile. Their indicators are approximately the same, and little depends on the choice in favor of one or the other.

The panels covering the frame play a significant role. Acoustic plasterboard produced by Knauf or similar products from the Aku-Line line manufactured by Giprok can significantly reduce penetrating noise.

A responsible approach to the task requires that the sheets be laid in 2 layers. Just one layer does not give a quality result. Acoustic triplex, a specialized three-layer material for sound insulation, can also be used as sound insulation under drywall.

A good triplex is produced under the SOUNDLINE-dB brand.

The main role is played by the layer of aggregate laid between the panels. Sound-absorbing boards SCHUMANET-ECO have good performance and suitability for domestic use in apartments.

If the partition has already been built, there is not much to choose from. But it is not necessary to disassemble it and rebuild it. Sound absorption can be significantly improved by using wall membranes. Thanks to them, the volume of reflected sounds directed at the surface of the walls is reduced.

The process of installing sound insulation in a plasterboard partition

A good result depends not only on the materials, but also on how correctly and responsibly the sound insulation is done. Here we can highlight the following, most significant stages:

- Soundproofing a plasterboard wall in an apartment begins with mounting its frame on vibrating tape. It is laid in two layers, attached to the walls, floor and to each other with vibration sealant;

- Frame installation. It is advisable not to place sockets and switches on the future wall - sounds are transmitted very well through them. A rational solution would be to make the distances between the profiles correspond to the size of the soundproofing slab;

- Installation of plasterboard sheets of partitions on one side. Acoustic plasterboard is installed with perforations facing outwards;

- Laying sound-absorbing slabs in the interior partition. Their thickness determines what the thickness of the interior partitions will be;

- The final stage is when the slabs are covered with gypsum boards. To do everything correctly here, the joints need to be sealed with vibration sealant.

Selection of internal insulation

Let's talk about insulation under plasterboard sheets. There are mainly three types of insulating materials that are well suited for this purpose. This includes:

- basalt wool;

- glass wool;

- Styrofoam.

Related article: Fringe for curtains: how to sew beautifully and correctly?

Due to constant debate among experts about the health hazards of polystyrene foam and expanded polystyrene, their use is now not as widespread as it once was.

The external similarity between basalt and glass wool is undeniable, but at the same time they have many differences that need to be paid attention to. The first is, of course, the composition. The basis of glass wool is glass fibers, the basis of basalt wool is rock of igneous origin. Second: thermal conductivity coefficient. For basalt wool, this indicator is lower than that of the “opponent”, so it manages to retain heat much better.

A significant difference between these two materials is also visible in the fire resistance indicator. When exposed to fire and high temperature, glass wool simply sinteres into a single mass, while basalt wool remains virtually unchanged.

In work, again, basalt wool is more convenient than glass wool. Very fine fibers of glass wool can cause unpleasant itching, so good care should be taken with protective clothing, goggles, gloves and a respirator. When working with basalt wool, it is enough to wear only gloves.

Important! If glass wool fibers get on your skin, be sure to wash them off with water. You cannot use a washcloth!

If we talk about savings, then the balance certainly tips in favor of glass wool, which is on average three times cheaper than basalt. But don’t forget that glass wool needs to be laid in two or even three layers.

Manufacturers offer to buy insulation both in slabs and in rolls. Plates are much more convenient because they do not need to be cut during the insulation process. Usually their width does not exceed 60 cm, which makes it possible to attach them between the posts of the so-called skeleton without any problems.

If you still have doubts, it would be a good idea to watch a couple of videos that will help you imagine what and how.

Conclusion

Insulating the walls of an apartment from the inside with plasterboard can easily be called a process that will help maintain heat in the apartment and eliminate all kinds of drafts and other troubles.

Also, if the insulation process is carried out competently and taking into account all the requirements, you can eliminate unnecessary financial costs for the purchase of additional heaters and other equipment. In the video presented in this article you will find additional information on this topic.

Of course, it should be noted that in order to achieve a high level of thermal insulation of an apartment, along with plasterboard insulation, it is also necessary to insulate plastic windows and insulate the loggia (see more in the article How to insulate a loggia and what is required for this). Such an integrated approach to the process will help create the most comfortable living conditions in the house, a real “homely” atmosphere of comfort.

Insulation of the outside of the building

Insulation of walls outside

The technology for insulating walls on the outside remains essentially the same as on the inside (see video). True, it is not as diverse as in an apartment.

Apply universal tile adhesive to the insulation at five points (along the edges and in the center) and apply it to the primed wall. Then we additionally fix it with fastening mushrooms at the same five points. We try to maintain the plane as much as possible. Carefully seal the joints with the same glue and apply a layer of it to the foam-covered wall.

After the glue has dried, we can give free rein to our imagination. There are several options for exterior finishing of walls insulated with foam plastic. This includes external putty followed by painting work, bark beetle, and cladding with brick or clinker, siding or the same plasterboard. And these two options have several more sub-items.

Attention! Do not try to insulate an apartment or house above the first floor yourself. This is LIFE DANGEROUS! Such work is carried out by professionals who have a license and permission to work at heights.