The problem of insulating communications in the basement, as a rule, is not familiar to ordinary city residents. But it is very often encountered by all those who live outside the city or have a dacha (or private house) for seasonal residence. Insulation of pipelines is not only useful, but also often a necessary measure, protecting the entire building from many potential problems.

What to consider when performing thermal insulation

Before you begin insulating a structure located in the basement of an apartment building, you should understand the basic requirements in order to get the expected result and avoid numerous problems.

- Maximum service life.

- Self-extinguishing ability.

- Availability of water-repellent properties.

- Easy to install.

- Low cost.

- Environmentally friendly.

- Low thermal conductivity.

Thermal insulation in an apartment building

Which materials are preferable?

Today, the variety of materials with which you can easily and quickly insulate the water supply in the basement is impressive.

Among the effective and most popular are the following:

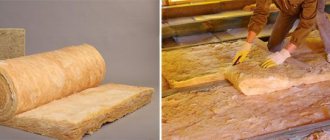

Mineral wool

Elements made on the basis of mineral wool will cope with temperature changes. With its help, you can insulate not only pipes in the basement of an apartment building, but also those located outside or in the ground. You can see what mineral wool looks like in the photo below.

Polyurethane foam

Ideal for insulating basement water pipes and attics. In essence, it is the outer shell of the water supply system. This design minimizes heat loss and adds strength. This heat insulator is not afraid of chemical influences and does not rot. But it has one drawback - high cost.

Expanded polystyrene

This material is characterized by a high level of rigidity. Expanded polystyrene insulation is sold in the form of a part of a pipe that has protrusions for fastening.

Foamed polyethylene

This heat insulator is best suited for internal insulation of a heating system.

Styrofoam

Polystyrene foam is good for insulating heating and water supply systems on ground and basement floors. Has a low level of moisture absorption. Foam plastic is also very durable and can be used for more than two decades.

Foam rubber

The heat insulator has a number of advantages. It is elastic, temperature resistant and not afraid of fire. Due to the fact that it is fire resistant, it is suitable for insulating external pipelines.

Liquid heat insulator

High-quality material that can compete with others on equal terms. For example, one layer of paint can replace a 5-centimeter layer of polyurethane. In addition to its insulating properties, liquid thermal insulation can protect metal from corrosion and give pipes a good appearance. But it is not used for thermal insulation of plastic pipes.

Regardless of the material you choose, the main thing is that the insulation is effective and there are no problems with tearing or other damage on cold days. More detailed instructions for installing a particular heat insulator can be viewed in the video on the Internet. It is worth noting that working with insulation is not difficult; you can easily do it yourself.

The problem of insulating communications in the basement, as a rule, is not familiar to ordinary city residents. But it is very often encountered by all those who live outside the city or have a dacha (or private house) for seasonal residence. Insulation of pipelines is not only useful, but also often a necessary measure, protecting the entire building from many potential problems.

Recommendations from experts

When choosing a suitable material for thermal insulation of a ventilation system, consider:

- The thermal conductivity coefficient should be as low as possible.

- Moisture resistance. The loss of insulating properties due to moisture absorption can nullify all the advantages of the material, including the low price.

- Difficult to install. The cost of specialist services depends on the danger of the material and the characteristics of its fastening. Insulating with cheap insulation can end up costing more than the highest quality insulation. If the work is supposed to be done independently, then the investment of time and effort is important.

- Fire safety class. This indicator can be decisive when choosing between two insulation materials with similar characteristics, if we are talking about a room with a high risk of fire.

According to experts, the best option for insulating vent pipes is foamed polyethylene. Foam rubber surpasses it in all characteristics and has no disadvantages.

Insulation of ventilation ducts.

The need to insulate communications

People who are not familiar with the specific features of thermal insulation and waterproofing simply do not understand why it is necessary to insulate pipes through which hot water flows. After all, a pipe with hot water will not freeze even in very cold weather.

Thermal insulation in the basement of an apartment building.

But the point is that you need to insulate the pipes in the basement not at all in order to avoid the risk of them freezing during frost. Insulation of communications is necessary, first of all, to reduce heat loss.

Materials for thermal insulation

Today, a variety of materials can be used to reduce heat loss and insulate heating pipes. The choice of one or another heat insulator for basement pipes will depend, first of all, on the specific requirements of the owner of the house, operating conditions and pipe sizes.

There are a huge number of thermal insulation materials on the modern market, but not all of them are suitable for heating pipes.

This point must be taken into account before purchasing this or that thermal insulation material.

Of course, the most common and traditional thermal insulators, which are used everywhere, include fibrous insulation, including mineral wool. It can be used in a variety of conditions, and almost always the thermal insulation will be quite effective. Materials based on mineral wool can potentially withstand extremely high temperatures, so they can be used in basements and boiler rooms.

What can be identified from the main advantages of this heat insulator?

Mineral wool, according to experts, is excellent for thermal insulation of external pipelines, as well as heating systems in the basement of a private house.

In recent years, derivative materials have been increasingly used: basalt wool and glass wool, which also have good performance and performance characteristics. Materials of this type are suitable for most country homeowners.

Ventilation aerators

Installation of roof aerators

A roof aerator is a modern and convenient type of ventilation. It is a pipe covered with a cap on top. Aerators remove steam, moisture and stagnant air, providing ventilation for a cold attic in a private home. Aerators are installed on roof slopes, where air movement is ensured by differences in temperature and pressure, replacing ridge vents. Aerators can be continuous or point. Point aerators are equipped with fans and guarantee good air movement. Outwardly, they resemble fungi.

Continuous aerators are a plate along the ridge with holes. Being covered with a roof on top, they are practically invisible and provide intense air movement due to the large area of the holes.

Various types of aerators are created specifically for roofing from:

- bitumen shingles;

- flat roof;

- metal ceramics;

- ceramics.

Aerators are installed only where eaves vents are provided. There are other conditions for their installation:

- Only roofs with a slope of 15 - 45 degrees are suitable;

- a distance of at least 30 cm is maintained from the chimney or wall;

- aerators look 25 cm above the slot at both ends of the ridge;

- point models are mounted no further than 50 cm from the ridge.

Insulation with polyurethane foam

Recently, more and more people have begun to pay attention to modern heat insulators. And one of the most popular and effective is polyurethane foam (PPU). This type of material is excellent for pipes and is, in fact, the outer shell for a water pipe (“pipe within a pipe”).

Polyurethane foam significantly reduces heat loss.

This type of design not only minimizes thermal energy loss, but also gives the pipes a high level of strength.

Positive characteristics of polyurethane foam:

- the material does not contain any compounds hazardous to humans;

- high level of resistance to climate impacts;

- increased mechanical strength;

- neutral to electricity and biological influences.

Polyurethane foam insulation materials will not rot or be destroyed by chemical exposure. The only obvious drawback of the material is its high cost. In fact, only this can be considered a reason to refuse thermal insulation from polyurethane foam in the basement of a private house.

Ready-made polyurethane foam shells.

It should be noted that insulating pipes with polyurethane foam is not so easy to do with your own hands, so it is better to hire specialists for this work. In the basement of a private house, the use of polyurethane foam often does not look like a very profitable option: the cost of a single installation (for example, for one or two pipes) will be quite high, so there is no urgent need for it.

Heating

When planning the installation of winter water supply, you need to keep in mind that insulation only helps reduce heat loss, but cannot provide heat. And if at some point the frost turns out to be stronger, the pipe will freeze. Particularly problematic in this sense is the area where the pipe leads from the underground sewer into the house, even a heated one. Still, the soil near the foundation is often cold, and it is in this area that problems most often arise.

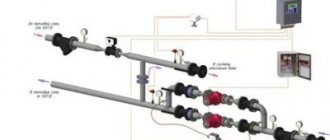

If you don't want to freeze your water supply, heat the pipe. For this, a heating cable or heating plates are used, depending on the diameter of the pipes and the required heating power. Cables can be laid lengthwise or wound in a spiral.

Method of attaching the heating cable to the water pipe (the cable should not lie on the ground)

A heating cable is good for everyone, but it’s not so rare that our electricity goes out for several days. What will happen to the pipeline then? The water will freeze and may burst the pipes. And repair work in the middle of winter is not the most pleasant experience. That’s why they combine several methods - they lay a heating cable and insulation on it. This method is also optimal from the point of view of minimizing costs: under thermal insulation, the heating cable will consume a minimum of electricity.

Another way to attach a heating cable. To reduce your electricity bills, you also need to install a heat-insulating shell on top or secure roll insulation

Laying a winter water supply system in a dacha can be done using the type of thermal insulation shown in the video (or you can take the idea and do something similar with your own hands).

Polymer foam materials

In addition to polyurethane foam, other synthetic heat insulators are often used, which are designed to insulate heating pipes in the basement in the best possible way. Among the most common are:

- Foamed rubber. High level of elasticity and increased resistance to temperature changes. The rubber will not burn, but will begin to fade when exposed to direct fire. That is why the material is actively used in those rooms where there is a possibility of exposure to direct flames or sparks.

- Foamed polyethylene. It is best suited for internal insulation of heating pipes in the basement of a private house. Sold in the form of tubes with special cuts of various diameters.

- Expanded polystyrene. Its characteristics are largely similar to polyethylene foam, but has a higher level of rigidity. The heat insulator is sold in the form of pipe parts that have special protrusions for fastening. When using the material, no cold bridges are formed. Long-lasting operation.

- Foam glass. Today it is used very rarely, but at the same time it has excellent performance properties. The minimum thermal conductivity coefficient allows you to protect the heating pipes of the basement of a private house from heat loss. The high density of the material does not allow it to deform even under severe mechanical loads.

Expanded polystyrene

This insulation is made in the form of two shells of different sizes; they are fastened together using special grooves, but for a reliable connection they must be additionally secured with special glue or tape.

When connecting on pipes, the halves of the insulation are connected to each other and the two parts are shifted in different directions by several centimeters. The next link is also connected, and the remaining ends are joined together, resulting in a kind of “overlap” of one connection onto another, which provides a better bond.

To insulate awkward areas and corners, shaped shells that have unequal dimensions are used.

In order to carry out high-quality insulation with this material, you need to calculate in advance the length of the pipeline, the number of joints and bends. This is necessary to purchase the required number of connecting parts.

Liquid thermal insulation

Liquid thermal insulation is a special composition that has increased heat transfer resistance. The composition must be applied to the pipes in a thin layer. The manufacturer notes that one layer of liquid thermal insulation can replace a layer of polyethylene or polyurethane foam thermal insulation up to 50 mm thick.

Liquid thermal insulation in the basement.

In addition, one cannot fail to note other advantages of using this heat-insulating material: ease of installation, aesthetic appearance, protection of metal parts from corrosion. In addition, the layer of liquid thermal insulation is not exposed to temperature, so the applied composition will not lose its integrity even after 10-15 years of active use.

You can insulate heating pipes in the basement of a private house using liquid thermal insulation with your own hands. The composition is applied with a regular brush or roller, after which you need to wait some time for the insulation to harden, and you can start moving water through the pipes.

Website editor-in-chief, civil engineer. He graduated from SibSTRIN in 1994, since then he worked for more than 14 years in construction companies, after which he started his own business. Owner of a company engaged in suburban construction.

An event such as thermal insulation of pipes in the entrance is necessary not only to protect them from frost in cold weather, but also to avoid heat loss

Basement heating pipes in apartment buildings need to be insulated so that heat is not lost on the way to the consumer and the temperature of the radiators in the rooms remains high. For this purpose, the lines are covered with thermal insulation elements

Why are pipes insulated?

The operating principle of the heating system is that the air in the room is heated with the help of a coolant (water circulating through pipes and radiators). The water gives off heat and returns to the boiler to be heated.

If the heating system inside the apartment does not need additional insulation, then outside it it is simply necessary. The pipe through which hot water flows cannot freeze even in extreme cold, some are sure. However, the pipe is not insulated for this reason, but in order to minimize heat loss.

Often the boiler room, which heats a building (or several buildings), is located separately from it - at a distance of tens or even hundreds of meters. Heat is supplied to houses through separate mains, sometimes of considerable length. While it reaches the consumer, the water temperature decreases. In addition, the walls in houses are often cold, and the glass in the windows is cracked, as a result of which the temperature in the entrances is low. To avoid heat loss, the pipeline is “wrapped” in the basements of apartment buildings (apartment buildings), in attics and stairwells - so that heat is not lost and the radiators remain hot.

Sometimes you have to deal with the fact that the pipes in the entrance were not initially insulated or the coating is outdated. Due to old mistakes that were made during the installation of heating networks, heat losses can reach 50 percent! This increases consumer costs and shortens the service life of the pipeline, turning thermal insulation of heating networks into a current solution.

| Heat loss can reach 50%!, due to installation errors |

How to insulate heating pipes with your own hands - selection and installation of pipe insulation

Heat loss in the pipeline is the main problem of both autonomous and central heating system lines. And if the reduction of heat loss within the region is entrusted to public utilities, then the owner of a private house needs to take care of the insulation of heating pipes himself, and due to the insignificant amount of work, do it himself.

Is it necessary to insulate heating pipes and what benefits does it give?

Thermal insulation for heating pipes allows:

- reduce heat loss in places where pipes pass along the ground, are mounted by air (ground) or are located in an unheated room;

- prevent freezing of the liquid, which is the coolant (freezing is fraught with a pipe break);

- reducing the likelihood of corrosion on the surface of the pipe (for metal pipelines);

- saving money on heating your home.

Thus, the more reliably the heating system is insulated, the more heat the user will receive (the higher the efficiency), and the less he will have to pay for gas for heating (or for electricity, if an electric boiler).

Read more: How to refuse a salary card at an enterprise

Due to the fact that the coolant moves through the heating system, the task of pipe insulation is reduced to minimizing heat loss and preventing rupture of the system due to freezing.

A popular solution in this case is the use of thermal insulation materials. This is the most cost-effective and easiest insulation method from the point of view of independent implementation.

Thermal insulation for outdoor heating pipes

A variety of insulation materials makes it possible to choose exactly the one that is best suited for a specific location of application (outdoors, in the ground, in the basement, in the attic) and budget.

The selection of a heat insulator is carried out taking into account the following factors:

- heating system pipe diameter;

- operating conditions (location of the heating system);

- average heating temperature of the coolant;

- thermal conductivity indicator of insulation (the lower, the better);

- water absorption rate. Shows the ability of the insulating material to perform its functions in a humid environment;

- resistance to combustion, biological and chemical activity, ultraviolet radiation and other environmental factors;

- life time;

- ease of installation (provided that sufficient tightness is ensured);

- price.

How to insulate outdoor heating pipes with your own hands

To choose the right pipe insulation, you need to know what types of thermal insulation for heating pipes exist, and what are the features of each of them.

Classification of thermal insulation materials for heating pipes

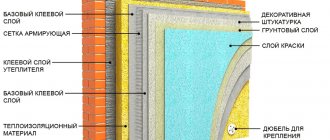

1. According to installation method:

- rigid sheet insulation

. These include: polystyrene foam and polystyrene foam. Despite the high thermal insulation properties, the installation of such insulation is quite complicated from the point of view of ensuring the tightness of the insulation;

- roll insulation

. These include: polyethylene (used as an additional component of insulation), foil penofol, wool (mineral and glass wool). The use of rolled materials requires the arrangement of their reliable fastening to the pipe;

- segmental (shell) insulation

. There are two types of such insulation: hard - shells made of polystyrene foam, polyurethane foam (PPU) or polystyrene foam, and soft - polymer pipes. The advantage of segment materials is that they hold their shape well, are easy to install and provide the required level of tightness between the heat-insulating material and the heating pipe;

- sprayed insulation, incl.

thermal paint . Penoizol has proven itself to be an excellent sprayer, as it allows you to insulate even small cracks. Thermal paint has the same property. The only disadvantage of these materials is that they are quite expensive and applying them yourself is problematic.

Thermal insulation of heating pipes with hard, soft and sprayed insulation

2. By type of insulation:

- polystyrene foam and polystyrene foam

. They have the best characteristics in terms of maintaining the original temperature of the coolant. Their use in the form of a shell simplifies installation and provides reliable protection of the system;

Thermal insulation for heating pipes - polystyrene foam shell Thermal insulation material for heating pipes - polystyrene foam and polystyrene foam

- wool (mineral, glass wool)

. Can be used as a roll or sectional material. Regardless of the type and configuration, cotton wool insulation for heating pipes has a significant drawback, which is that cotton wool is hygroscopic. Those. it needs additional protection from moisture. When wet, cotton wool loses its properties. Therefore, sections often have additional protection in the form of a foil layer. But cotton wool is great for insulating pipes in the basement or attic.

Thermal insulation for heating pipes – casing made of mineral wool Thermal insulation for heating pipes – casing made of foil-clad basalt wool

- foil penofol

. Due to its small thickness, it is used primarily for insulating pipes indoors.

Thermal insulation for heating pipes - foil penofol Insulation of heating pipes with penofol

- foamed polyethylene

– (EPE, PPE) polyethylene foam for pipes.

Thermal insulation for heating pipes - polyethylene foam (PPE) Insulation for heating pipes - polyethylene foam pipe

Comparison of thermal insulation materials for pipes - video

Heating pipe insulation technology

The choice of pipe thermal insulation and the method of its installation are influenced by the location of the pipeline.

Insulation of heating pipes on the street

External thermal insulation of pipes is the most difficult method of insulation, since in the open air it is not only the pipes that need protection, but also the insulation itself. For outdoor installation, non-hygroscopic materials or other materials are used, but reliably protected from moisture by a film or casing.

In addition, it is advisable to use the densest and thickest insulation outdoors. Another requirement is the use of a material that is resistant to ultraviolet radiation, bad weather and mechanical damage.

Insulation of heating pipes in an unheated room

Basement, cold attic, boiler room - a feature of such rooms is the absence of heating radiators. But since the pipes are filled with coolant and are located in an environment with minimal humidity, there are no special requirements for either the thermal insulation material or its thickness.

Thermal insulation of heating pipes in an unheated (cold) room

Insulation of heating pipes underground

The specificity of installing heating pipes underground is that they must be laid below the freezing level of the soil, which is a depth of one and a half to two meters. If you do not adhere to this requirement, the coolant will cool greatly while it passes through the heating main located in the ground. In order to reduce heat loss, you need to take care of high-quality insulation of the underground pipeline.

Experts say that the optimal solution in this case would be to use a cable pipe heating system. But due to the high cost, users prefer enhanced thermal insulation of heating pipes.

Good insulation of underground heating pipes requires the following requirements:

- insulation of insulation from moisture in the soil;

- eliminating the possibility of deformation of the insulation, because in this case, its properties are reduced. This is especially true for soft thermal insulation materials;

According to reviews, the optimal solution is thermal insulation of heating pipes using polyurethane foam shells.

Note. Users recommend using a combined insulation system for pipes that are laid above the ground freezing level, namely: a combination of cotton wool and a hard polyurethane foam shell with a protective fiberglass coating. Ideally, even at the installation stage, use factory-made multilayer pipes in polyurethane foam insulation.

What is insulation like?

There are several effective ways to insulate pipes.

Types of insulation by application method:

- painting;

- roll;

- "shell";

- liquid.

However, the most convenient are pre-insulated (insulated) pipes. The advantage of such a system is that it is pre-insulated, but the disadvantages are that installation is not very convenient, especially when it comes to laying the main line in hard-to-reach places and connecting parts (the joining points will have to be additionally insulated). Also, pre-insulated pipes are more expensive than conventional materials without insulation.

Thermal insulation paint

It is used when pipes do not require special insulation. One layer of paint is equivalent to a layer of synthetic insulation. It is environmentally friendly, resistant to temperature fluctuations and dampness. The paint is simply applied to the surface of the pipe and left to dry. A dense layer remains at the application site, protecting the pipe from heat loss.

Roll

Previously, the pipe was wrapped in mineral wool, tied with wire and a galvanized casing was put on top. This design is not afraid of cold and damage. But the material is not suitable for thin pipes, and mineral wool does not tolerate air humidity well.

Therefore, the insulation can additionally be enclosed in a fiberglass or zinc flask.

Other rolled materials include polyethylene and foil penofol.

Shell

It is a cylinder, whole or consisting of two parts. If heating is being installed, it is stretched onto a pipe, and if an existing structure is being insulated, it is cut into two parts. Shell materials:

For thermal insulation of pipes in the entrance, experts recommend choosing a material taking into account the level of humidity in the room. On the ground and basement floors, preference is given to foam glass or foam insulation - these insulation materials are characterized by low moisture absorption coefficients.

Liquid insulation

Thermal paint works on the principle of a thermos and comes in two varieties:

This material is applied by spraying. By covering the pipe with a thin (half a centimeter) layer of ceramics, you can be sure that heat loss will be reduced by half, and, in addition, the surface is well protected from corrosion. Foam thermal paint is applied to large diameter pipes. It is environmentally friendly, resistant to fire, corrosion, and condensation.

Technological process

When thermally insulating pipes in an apartment building, first of all, make the necessary calculations and purchase the required amount of materials. As a starting step, wrap the pipe with foil tape, which acts as a heat reflector. Then insulation is installed around the pipe. A casing or soft material is put on the heating element or blanks are cut and wrapped around it. The fasteners are tape, wire or plastic clamps.

To install rigid insulation, they take shells or create a kind of “box” around the pipe. The material must adhere tightly to the surface, for which it is secured with plumbing tape and, if necessary, protected with film. The joints are sealed with metallized tape.

Liquid coatings are applied to the pipe at an air temperature of at least 7 degrees Celsius. Prepare the surface - remove the layer of dirt, degrease, and wipe with a rag.

After mixing the contents of the container with liquid insulation, apply it in a thin layer with a brush. After letting it dry, cover it with 2 more layers. Movable areas of shut-off valves must not be painted so that they do not end up under the insulation crust.

When spraying foam thermal paint, use a special device with a hose.

Since the attic usually does not have high humidity, it is ventilated; mineral wool is used as insulation, which is cut into sheets and overlapped twice around the device, putting clamps on the joints.