The difference between Technoplex and Penoplex: which is better?

After the construction of a building, the owners always wonder what kind of insulation is best to use for, strictly speaking, thermal insulation of the home.

And this question is quite reasonable, since the construction market has a colossal number of different insulation materials, which, as it seems to many, only specialists can compare in terms of efficiency.

Insulation of the room with Penoplex

Fortunately, this is a misconception, and everyone can figure out which insulation is better. It is only necessary to have information and technical parameters of the analyzed thermal insulation materials.

And given the fact that Penoplex and Technoplex are now the most popular insulation materials, this article will focus on which of these insulation materials is better, and what is the difference between them.

General properties and differences

Despite the different names, both materials belong to the same type - extruded, or extruded polystyrene foam. In abbreviated form, you can also find both the Russian abbreviation - EPPS, and the international abbreviation - XPS. For insulation of enclosing structures, EPS is produced in the form of rigid slabs, for thermal insulation of communications - in the form of a rigid detachable cylindrical shell.

Apart from the slight difference in absolute values, both types have a low specific gravity, low coefficients of thermal conductivity and vapor permeability, high resistance to mechanical stress, and extremely low water absorption. The only competitor among thermal insulation materials is rigid polyurethane foam, and only those types whose structure is at least 90% closed cells.

Both EPPS still have some intraspecific differences. For example, in its “pure” form, expanded polystyrene (including extruded) has a flammability class of G4, and when added to fire retardants, it has a G3 flammability class.

The main difference between technoplex and penoplex is that it contains graphite nanoparticles. According to the manufacturer, TECHNONICOL, this additive reduces thermal conductivity and increases strength.

What is better: technoplex or penoplex?

Given the abundance of offers of various types of thermal insulation, choosing the appropriate material for insulation is quite difficult. Ravaterm, polyspen, stirex, penofol, penoplex and technoplex are just some of the foam materials used for insulation of external and internal premises. There is not much truthful information about what modern insulation based on styrene polymers is, so many experts prefer to collect practical reviews on which is better, technoplex or penoplex. This is a complex and time-consuming path, so first it is better to compare the characteristics and draw a conclusion about how penoplex and technoplex differ, and what is the difference between them.

Harmful or not

Insulation under siding

You can find a variety of reviews on this issue, but you need to understand that if the material is mounted outside, then there can be no harm from it. Inside, such materials are subject to additional insulation, so the question of their harmfulness during operation is also irrelevant.

First of all, when they talk about the dangers of a particular material, they mean fumes during its operation. If the material is protected, they will not be able to penetrate outside. Penoplex usually undergoes additional finishing. For example, to protect it from ultraviolet rays it is covered with siding, and after plastering the walls it is covered with paint.

Let's consider the question of the dangers of penoplex during a fire. It turns out that people often die not from fire, but from harmful fumes, so it is recommended to install it outside.

If you are concerned about the question of whether mice chew penoplex, then there is simply no better remedy for them than a cat. Mice chew on anything, even concrete.

Is penoplex harmful and you will learn the answers to some other controversial questions about this material from the video:

https://youtube.com/watch?v=Ea94bC7aIp0

What is foamed polystyrene

Penoplex is produced by the company of the same name using its original technology and is pressure-foamed, extruded polystyrene. Approximately the same data can be found from open sources about Technoplex insulation produced by the TechnoNIKOL company. The details of the technological process are not reported by Technonikol and Penoplex, but based on fragmentary data, the following conclusion can be drawn:

- Granular raw materials - highly purified polystyrene - are mixed with a gasifier, heated to a high temperature and pressed through calibrated micro-holes;

- When passing through a nozzle with several hundred microholes, the main stream of polystyrene is broken into microfilaments, the polymer molecules are stretched, form bonds with each other and are simultaneously strengthened by pressure;

- At the moment of exiting the dies, polypropylene foams in measured doses and turns into a porous material of millions of tiny frozen bubbles.

The general picture of the production of technoplex and penoplex is the same, but there are slight differences in the composition of the materials and strength characteristics. According to TechnoNIKOL, the technoplex contains a small amount of amorphous carbon or graphite to make it easier for rolling rolls to form a sheet of the required thickness.

Flammability

Both products belong to the fourth fire resistance group.

Many novice builders believe that materials made from polystyrene foam have properties similar to polystyrene foam, but in reality everything looks somewhat different.

High-quality material does not support combustion.

If polystyrene foam easily ignites under the influence of an open fire, then penoplex and technoplex begin to melt under the influence of high temperatures, but they do not support combustion. During this process, carbon dioxide and carbon monoxide are released.

Comparing technoplex and penoplex

In fact, the composition of technoplex and penoplex is much more complex; it includes stabilizers, fire retardants, antioxidants and substances that slow down secondary polymerization. The difference may be in temperature, pressure and the use of gas-forming agent.

What is the difference between foamed polystyrenes?

What is the difference? The powder or liquid gas-forming agent can be better mixed and distributed throughout the volume of polystyrene granules, so such insulation materials have more stable thermal insulation characteristics.

But this is not the only reason why the modern production of technoplex and penoplex refuses to use freon:

- In the sealed cells of new, unused material, freon gas remains for some time, which is formally considered safe, but in practice it is better to get rid of it, since it often leads to lung problems, especially in children;

- Over time, the gas is replaced by air and water vapor. If not the purest raw materials with styrene residues were used for the production of expanded polystyrene, then gradually part of the contents of the technoplex cells will be squeezed out into the environment.

For “technical” grades of EPS, for example, penofol, such processes are not of particular importance. According to the manufacturer, penofol is best used for insulating foundations, basement parts of buildings, and for use in the construction of highways, so a mixture of freon and carbon dioxide is used for its production. The contact compressive strength of penofol is approximately equal to the strength characteristics of technoplex.

Often, contractor companies recommend that developers use foam insulation, motivating their offer with a low price. To understand which is better, penoplex or expanded polystyrene, it is worth remembering the production technology.

The use of the extrusion process makes it possible to obtain a linearly oriented structure and very dense elongated pores. As a result, extruded polystyrene foam resists water and water vapor significantly better, and has higher bending and compressive strength. Therefore, all extruded polymer foams used for insulation - penofol, technoplex, penoplex - have the best strength characteristics, which makes them different from expanded polystyrene, or in other words - polystyrene foam.

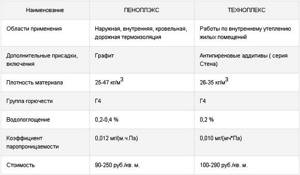

Main characteristics of technoplex and penoplex

The most reliable way to determine which insulation is better is to compare their main characteristics. The most important parameter is thermal conductivity; for penoplex the coefficient is 0.029-0.030 W/m∙K, for technoplex – 0.030 W/m∙K. The difference is negligible, so both materials retain heat equally well.

The second characteristic concerns strength. According to reviews, penoplex cuts better and is less deformed during installation. The bending strength of technoplex is almost two times lower than that of penoplex, but its manufacturer initially states that its products are better used for internal thermal insulation, and penoplex better withstands pressure from heaving of the soil and the mass of the concrete foundation.

What is better to choose

To answer this question, it is recommended to study the differences according to several important criteria:

- application area;

- advantages and disadvantages;

- strength.

Penoplex is universal because it can be used for internal and external insulation, including roofing and road insulation. As for Technoplex, it is most often used for interior decoration of residential premises. Along with this, the differences are also related to strength - as already mentioned, Penoplex is stronger. And besides, it costs less.

Technoplex is often used for internal thermal insulation

However, for a more objective picture, it is necessary to identify differences in other indicators - the pros and cons of each material. If we talk about Penoplex, its main advantages are:

- versatility;

- low price (by 5-10%);

- strength;

- ease of installation.

The disadvantages include:

- flammability;

- vulnerability to rodents;

- low vapor permeability.

Technoplex has the same disadvantages, but other disadvantages are added to them:

- less strength;

- higher cost;

- risk of deformation during installation.

Thus, Penoplex objectively outperforms its competitor. This conclusion can be reached based on a review of the differences between both types of insulation, as well as customer reviews.

What is penoplex?

Penoplex is represented by extruded polystyrene foam cells, capable of providing a high level of thermal insulation of premises when the material is used as an element of building structures.

A notable property of the material in question is its resistance to water. Penoplex almost does not absorb moisture - and its use will be effective when it comes to structures in the basements of houses that may be exposed to water resulting from melting snow or due to water supply leaks.

Penoplex is used in the construction of balcony structures, to complement the foundations of houses, and placement between ceilings and attics.

The most important advantages of penoplex:

- simplicity and efficiency of laying elements made from the appropriate material;

- ease;

- ability for effective sound absorption;

- stability and long service life.

The structure of penoplex is represented by extremely small cells - this is its difference, for example, from polystyrene foam, in which the corresponding elements are noticeably larger. The manufacturing process of penoplex involves processing polystyrene at very high temperature and pressure. A special additive is added to the heated mass of raw materials, which gives the mixture a foaming effect. After that, extrusion is carried out.

Strength indicators

If you cannot decide which is better - penoplex or technoplex, then you can pay attention to mechanical strength. The described materials have almost identical compressive strength values at a deformation of 10%, the figure is 250 kPa. If we talk about when exposed to static bending, then for penoplex this figure, depending on the type, will vary from 0.4 to 0.7 MPa. This indicator for technoplex is lower and is only 0.3. From this we can conclude that penoplex exhibits more impressive resistance to bending and is able to withstand greater loads.

What is a technoplex?

The basis for the manufacture of technoplex is the same polystyrene that has undergone extrusion processing. However, the production of the corresponding material is complemented by a remarkable production operation - the addition of tiny particles of graphite to the raw material. The result is a highly effective insulating material characterized by versatility, relatively low price and ease of installation.

Technoplex has generally the same advantages as penoplex. It is resistant to water, can effectively absorb sound, and has a long service life.

Water absorption and thermal conductivity

If you are faced with the question of what is better - penoplex or technoplex, then it is important to pay special attention to the ability of water absorption and thermal conductivity. The first material is capable of conducting heat, depending on the type and external conditions under which operation occurs. This indicator varies from 0.028 to 0.031 W/mK.

The opponent has a thermal conductivity within 0.031 W/mK. This indicates that both materials are effective insulators. The water absorption of the technoplex is also important; it does not exceed 0.2% by volume during the day. Whereas, if we consider type 35 penoplex, water absorption is 0.1%. If this material is immersed in water for 28 days, it will expand by only 0.2% of its volume. Among other things, this thermal insulator retains its original properties after an impressive number of freezing and thawing cycles. After 1000 cycles, penoplex will change the thermal resistance by only 5%.

Comparison

The main difference between technoplex and penoplex is that graphite is present in the structure of the second material. Its presence determines the lower thermal conductivity and reduced water absorption of the technoplex.

Both materials are based on polystyrene, which is subjected to an extrusion procedure. Therefore, in structure and cell size, penoplex and technoplex are very similar. Both materials have a generally common scope of application - they are mainly used to provide thermal insulation and sound insulation of rooms.

The differences between the materials under consideration can be traced in various aspects.

For example, by comparing their strength. Tests carried out by experts show that penoplex with statistical bending can withstand a load of about 0.4 MPa. In turn, for technoplex the corresponding indicator usually does not exceed 0.35 MPa. However, much depends, as experts note, on the specific building structure, the specifics of its configuration, and the location of the slabs.

Penoplex and technoplex differ in operating temperature. For the first material, the optimal conditions are from minus 50 to 75 degrees. Technoplex is able to maintain its properties at temperatures from minus 70 to 75 degrees. True, the rather rarely noted advantage of the technoplex can be observed in practice. But if the house is actually being built in the North, it is quite possible that the appropriate material will be indispensable.

Table

| Penoplex | Technoplex |

| What do they have in common? | |

| Both materials are produced from polystyrene - using the extrusion method | |

| Both materials are used in the same field: they are used to make slabs for thermal insulation, sound insulation, and sometimes water insulation. | |

| The materials are similar in structure, represented by small cells | |

| What is the difference between them? | |

| Has a slightly higher thermal conductivity - about 0.03 W/(m*K) | It has a slightly lower thermal conductivity - closer to 0.029 W/(m*K) |

| Capable of operating at temperatures from minus 50 to 75 degrees | Capable of operating at temperatures from minus 75 to 75 degrees |

| Has a degree of water absorption of about 0.4% | Has a degree of water absorption of about 0.2% |

| Can withstand 0.4 MPa static bending load | Can withstand static bending loads of about 0.35 MPa |

Technoplex or penoplex: what to choose?

The house should not only be beautiful and comfortable, but also warm.

Therefore, it is very important to choose the right insulation. There are many different insulation materials on the construction market. This article will tell you about such modern insulation materials as Technoplex and Penoplex, how they differ and which one is better to choose.

Let's start with what they consist of. Both insulation is made of extruded polystyrene foam (EPS). EPS is heated polystyrene (the familiar white foam balls) and a foaming agent.

Insulation of various structures

In principle, both insulation materials have a wide range of applications, but when insulating external walls, it is sometimes advisable to purchase inexpensive and breathable foam plastic, and when arranging a loggia, penoplex.

The latter material is durable, which allows it to be used for thermal insulation of floors, insulation of pipes (due to its good ductility), and even insulation of the base or foundation of a house. But, as mentioned above, penoplex is much more expensive

, and in some cases the additional costs are simply not worthwhile.

Exterior walls of the house

Foam, which is applied to external surfaces, must not only be protected from exposure to ultraviolet radiation, but also take into account that this material does not allow steam to pass through. Otherwise, the isolated part will become a breeding ground for various bacteria.

Therefore, wooden houses should not be treated with polystyrene foam.

It should also be taken into account that this material is highly flammable

, it can spread combustion and independently increase the fire, while releasing toxins dangerous to human health. That is, if simple polystyrene foam is used outside during the construction of a building, it must, at a minimum, be insulated with special care.

When using penoplex to insulate external walls, it can be used not only as insulation, but also as a building material for some auxiliary structural elements.

In addition, penoplex is not so afraid of moisture; it is more biologically stable than its competitor; rodents do not like to live in it. True, it also does not have high fire safety, although, unlike foam plastic, it simply burns without supporting or spreading the fire further.

In general, polystyrene is actively replacing polystyrene foam for external insulation of walls more and more often. In Europe, foam plastic is not used at all for external buildings; in other countries, including ours, it is also increasingly being replaced with polystyrene foam.

Interior walls of the house

Regarding the issues of active energy saving, experts in this field increasingly recommend thoroughly insulating walls using modern insulation materials to reduce heat loss. These are both foam plastic and penoplex, and both are equally suitable for this purpose, having excellent thermal insulation properties.

Polystyrene foam is inexpensive and very easy to install; you can carry out insulation work on your home yourself, without involving specialists. It is used for insulation of warehouses where non-combustible materials are stored, technical buildings, and other buildings.

Penoplex is more resistant to mechanical damage, its slabs do not crumble, but their insulation will cost, as already mentioned, more.

Sometimes it is necessary to create additional sound insulation in a room, for this they take three-centimeter polystyrene foam

, foam plastic will have to be used much thicker. By the way, this will reduce the total space of the room, which is important, especially in a small apartment, which is not very large anyway.

Read our article about what material to use to decorate the walls in an apartment.

To insulate a balcony, you can use any of two materials. The loggia should be insulated with a simple five-centimeter polystyrene foam; there is no need to buy expensive materials for this work.

If the winters are very cold, you can take thicker foam, up to ten centimeters. But if the balcony is small, you can purchase penoplex for this purpose.

Floor

The floor is insulated only with penoplex,

Since the foam is too fragile, it has a low density, so you cannot place a screed on it. Penoplex, on the contrary, will withstand high loads, and the floor will not only be warm, but also durable.

This material is used to create a system called “warm floor”, where thermal insulation plays a key role, as it reduces heat transfer in two directions at once (top and bottom). Floor insulation with penoplex is effective even with high humidity and constant mechanical loads.

Attics and roofs

When insulating the roof inside, both materials are suitable

, but if you need a warmer floor in the attic, you should still choose penoplex. By the way, in the attic you can not put other materials on top, you can walk directly on the foam.

To insulate the roof, foam boards are also used, which are carefully covered with a waterproofing layer

. If the roof is cold, its part is insulated with polystyrene foam, and the outer part with penoplex, while leaving sufficient space for ventilation.

Thus, for thermal insulation you can use both of the materials described above, depending on what needs to be insulated. Penoplex is suitable for exterior decoration, for floors and roofs, but it is much more expensive, and sometimes foam plastic is enough.

You can watch the process of insulating external walls in the video:

Penoplex and mineral wool are materials for external and internal decoration of buildings with similar characteristics, but each in its own way is better suited to certain conditions of use and has characteristic advantages.

Mineral wool is a material made from fibers that are formed during the melting of rocks, significantly superior in its characteristics to the well-known glass wool.

Penoplex is a more modernized foam plastic, which has significantly surpassed its predecessor in most qualities. It is significantly inferior to it only in cost.

The manufacturing technologies and composition of both insulation materials are radically different.

Eps insulation

This is a unique material that has the following properties:

- low water absorption, almost equal to zero;

- high strength;

- not subject to rotting;

- low thermal conductivity;

- high frost resistance;

- non-toxic to humans;

- easy to install;

- durability;

- light weight;

- environmental friendliness.

The disadvantages of polystyrene foam insulation include:

- strong flammability and intolerance to direct sunlight. This is important to know, because storing polystyrene foam in the sun can completely ruin the material, and this will be unpleasant ;

- Although manufacturers claim that polystyrene foam is not chewed by mice, consumer reviews show the opposite;

- And of course the price, which is quite high.

But what is the difference between Technoplex and Penoplex? What's better?

Technoplex XPS and penoplex - what is the difference and what is needed as a layer of warmth on the floor?

We have to do the floor. The apartment is on the ground floor, below is a heated basement. We think about it: sound insulation on the slab, then a thin screed. The expert recommends EPPS with a density of 45 cm and a thickness of 3-4 cm. But on the Internet I find two types of similar insulation - technical density XPS 30-38 and orange penoplex with a density of 25-30. Explain the situation and tell me what material is needed for this work? Thank you.

The floor uses Epps (extruded polystyrene foam) with a density of 45. The walls use EPPS with a lower density because it is not static load bearing.

« The specialist recommends EPPS 45 density, 3-4 cm thick.

»

Do you doubt the competence of this specialist?

No, I have no doubt. I just didn’t find this density. And I don't know what I indicated, is it extruded or not, what is needed?

It's repressed. And it's still not compressed—it's foam. White like, made of small balls. and its density is even lower. There is no need to lay it exactly on the floor.

Everything is clear, so you need to find the right density. Yes, also, and do you need to install a metal grille for rigidity?

The mesh is necessary - both in terms of rigidity and strength of the surface of the plaster layer.

No questions yet, thank you very much for your advice and patience, but all the repair work is ahead of us, so you should worry about it.

Technoplex XPS and Penoplex - what is the difference and what is needed, like a layer of heat on the floor, repair ideas

We have to do the floor. The apartment is located on the ground floor, downstairs in a heated basement. We think about it: soundproofing on the slab, then a thin spout. The expert advises EPPS with a density of 45 and a thickness of 3-4 cm. But on the Internet I find two types of similar insulation - technoplex

Extruded polystyrene foam

Technoplex is a tile insulation made of extruded polystyrene foam with graphite particles.

Thanks to graphite, the plates acquire a gray color and increased strength. 50 mm of technoplex is equivalent to a 600 mm wide foam block wall. Technoplex is recommended for use for interior work. Produced by Technoplex.

Insulation is produced in the form of slabs of various widths, lengths and thicknesses:

- Length – 1180/1200 mm.

- Width – 580/600 mm.

- Thickness – 20, 30, 40, 50, 100 mm.

Technoplex is operated at temperatures from -70 0 C to +75 0 C. Its water absorption is only 0.2% - this is a very good indicator. Thermal conductivity is 0.032 W/(m*K).

Features and Specifications

Penoplex thermal insulation is a board made of extruded polystyrene foam. A boutique materials company specializing in the production of synthetic insulation for a variety of roofing, foundation, wall and interior applications. For example, Penoplex 45 is supplied only to industrial sites and is used as thermal insulation for loaded structures, railways and roads, and airport runways.

The presented products in this series have reliable strength, resistance to biological influences, low thermal diffusivity and zero water absorption. Considering the manufacturer’s description, such insulation does not burn from environmentally friendly components without the addition of phenol-formaldehyde resins. This ensures a healthy indoor climate and a guaranteed service life of 50 years.

Radiator "Technoplex" produces a wide range of TechnoNIKOL products in the field of goods, including roofing, construction chemicals, special equipment and much more. Extruded insulation has proven itself mainly for interior work - insulation of partitions, balconies, floors. It is even used in installations of thermally insulated floor systems.

During the production of Technoplex, graphite nanoparticles are added to the same polystyrene foam, which, in turn, reduces thermal conductivity. Consequently, according to the manufacturer, the stability of Technoplex properties throughout its entire service life, reducing water absorption and vapor permeability. Neutral, biostable, practically non-shrinking polymer material takes care of gasoline solvents and bitumen adhesives. Well suited for use under plaster.

Extruded polystyrene foam

Penoplex is a tile insulation made from extruded polystyrene foam.

Unique thermal insulation characteristics are achieved thanks to the smallest cells filled with air. Penoplex has a bright and recognizable orange color. Penoplex has excellent chemical resistance, but it is important to know that it is absolutely not resistant to gasoline (just like Technoplex). Due to its good strength properties, Penoplex can be used for external insulation.

There are different types in the Penoplex line (their names speak for themselves):

- roofing (insulation of attics and roofs of various configurations);

- wall (basement, walls, partitions, facade are insulated);

- foundation (used as insulation for the basement and floor of the first floor);

- comfort (can be used for any work, but is especially well suited for insulating apartments and balconies);

- 45 (has the best characteristics of all types, used in road construction and bridge construction).

. Penoplex is available in standard width and length - 600 mm by 1200 mm, respectively. But the thickness varies - from 20 mm to 150 mm.

Penoplex is used at temperatures from -50 0 C to +75 0 C. Water absorption - 0.4% - slightly worse than Technoplex, but still a very high figure. Thermal conductivity is 0.03 W/(m*K).

House insulation with TECHNONICOL polystyrene foam

Extruded polystyrene foam boards can be used to insulate all surfaces of a private home.

Insulation of foundations

The use of XPS for façade insulation allows one to avoid cold bridges, frost heaving of soils, protect waterproofing, and ensure drainage of groundwater, while reducing their pressure on underground structures and the base.

With traditional foundation insulation, slabs without mechanical fixation are mounted using glue on a waterproofing layer and covered with coarse sand or sand-gravel mixture.

If there is a need to install a shallow foundation, then XPS slabs are laid on the prepared base before waterproofing and pouring the reinforcement frame.

When additionally insulating the basement from the inside, a layer of waterproofing is applied, if necessary, to the leveled walls, XPS boards are fixed onto it using an assembly adhesive compound, then a vapor barrier with foil is laid and secured with polyurethane glue inside the room, vertical guides and sheet trim are installed.

Wall insulation

Walls can be thermally insulated from the inside, outside or inside the building envelope:

- Internal wall insulation is carried out in constructed buildings if quick heating of the room is needed or when the façade cannot be changed. The slabs are pressed against the wall with wooden beams, between which extruded polystyrene foam is also laid, then a vapor barrier film is carefully glued.

- The middle thermal insulation layer in a three-layer masonry allows you to reduce the thickness of the walls. The material used in this layer has high requirements for durability and quality, because if something happens, the masonry will have to be dismantled for repairs. The slabs are attached to the internal load-bearing wall using an adhesive composition; the inner and outer parts are connected to each other by flexible fiberglass ties, which are installed 4-5 pieces per square meter, through thermal insulation. First, a facing layer is laid up to the level of the connections, then thermal insulation is installed with a protrusion in height. The supporting layer is erected to the next level of connections. The layers must be mounted tightly to each other, filling the gaps with dry sand.

- Plaster (“wet”) facade is external thermal insulation, when polystyrene foam slabs are attached to a prepared wall surface using glue and mechanical connectors and covered with several layers of plaster made of synthetic materials and fiberglass.

- If the wall is sheathed with decorative material, clapboard, facade panels or siding, then the thermal insulation slabs are laid out in a checkerboard pattern and fixed to the base with longitudinal slats, on which, in turn, the finishing is mounted.

Roof insulation

lay thermal insulation boards

There are options for thermal insulation of the roof, when slabs of extruded polystyrene foam are attached to the rafters from the inside, and the space between the rafters is also filled. Additional insulation is also possible. Thermal insulation of a pitched roof allows you to avoid cold bridges along rafter structures and create comfortable conditions in the house not only in winter, but also in the summer heat.

Thermal insulation of attic floors

If the attic is not planned to be used as a living space, then it is insulated, not the roof. A flooring of boards or boards is laid on top of the beams, then thermal insulation slabs are laid on it, the joints between them are taped, and a cement-sand screed is made on them and covered with gypsum fiber sheets.

TECHNONICOL extruded polystyrene foam from the company of the same name is an effective thermal insulation that allows you to save heating costs and provides reliable insulation for many years to come for almost any building structure.

Comparison

The main technical characteristics of insulation are its thermal conductivity, water absorption and operating temperature.

The flammability group for both insulation materials is G4 (highly flammable). Their prices differ by 10% (Technoplex is more expensive).

After comparing them, it is clear that there are no significant differences between these insulation materials.

Yes, Technoplex has slightly better characteristics, but the cost is also higher. Despite the fact that Penoplex is cheaper, with individual construction the savings are insignificant.

The tighter the better

Density is of no small importance for thermal insulation materials. Its resistance to mechanical loads, ability to withstand compression, and degree of heat retention depend on it. Both “candidates” are produced in slabs for various purposes with different densities. Let's consider their ranges in the brands presented for research. Penoplex sheets have densities from 28 to 47 kg/m3, while technoplex - 25 - 45. Moreover, their density range is equally good - 20 units.

What to choose

If we compare these two insulation materials, then Technoplex is more technologically advanced and has better qualities, but the difference between it and Penoplex is so insignificant that it is impossible to say for sure which one should be chosen.

By choosing polystyrene foam insulation, regardless of whether it is Technoplex or Penoplex, you can get not only thermal insulation, but also sound and vapor barrier.

However, it is worth remembering that polystyrene foam is still a chemical insulation, not a natural one. Therefore, when burned, it releases very caustic substances.

Modern technologies do not stand still, and today liquid foam has become widespread. Details here: https://teplo.guru/uteplenie/utepliteli/zhidkiy-penoplast.html

Comparing expanded polystyrene foam with other insulation materials

The main competitor for such materials are felt and fiber insulation. Some prefer to use mineral wool, others prefer Technoplex or Penoplex. Which is better, penoplex or mineral wool for insulation? Each of the materials has its own positive and negative properties. In the photo below you can see the features of expanded polystyrene foam.

Like mineral wool, they are durable, safe and environmentally friendly. True, the thermal insulation qualities and moisture absorption of mineral wool are worse.

Private one- and two-story premises are best treated with Penoplex. It is much more effective. Mineral wool is used for finishing high-rise buildings. The fact is that it does not burn at all. Fire retardant additives will not be able to protect EPPS 100%; mineral wool is better in this regard. However, it is not recommended to use it in damp and damp areas.

Another competitor for EPPS is isolon. This is insulation made from foamed and modified polyethylene. Some people ask, Izolon or Penoplex, which is better? Izolon is suitable for insulating internal walls and ceilings of a building. And the thermal conductivity coefficients of the materials are almost the same. Izolon can withstand heating up to 80 degrees Celsius throughout the day. The material has excellent sound and noise insulation. It is safe and environmentally friendly. When heated, it will not emit harmful substances. The main disadvantage is the softness and flexibility of Izolon. When laying it on the wall, it requires fixing with sheets of plasterboard or MDF boards. You cannot glue wallpaper or plaster on Izolon. This is why it is recommended to use it in conjunction with EPS insulation.

You can also find the following queries on the Internet: Ravaterm or Penoplex, which is better, Polyspen or Penoplex, which is better, or Stirex or Penoplex, which is better. It is impossible to answer the question unequivocally. All of them belong to XPS and have almost identical characteristics. The difference is the price and some additional nuances.