What material features need to be taken into account

More than 90% of the volume in the material is air. It is enclosed in small round plastic balls glued to each other. This structure makes the foam lightweight, perfectly retains heat and insulates sounds, which are valuable properties for insulating various structures.

But at the same time, it is very unstable to mechanical loads: it breaks easily from impacts and other influences. When you try to cut or saw a slab, its surface is crushed, and the material itself crumbles badly, since the weak connection between the balls cannot withstand the pressure.

As a result, the cut line turns out to be rough, and in the process a large number of crumbled plastic particles are formed, which are highly electrified. Therefore, before cutting polystyrene foam at home, you need to think about the upcoming cleaning and move the process outside or cover the floor with unnecessary film.

Styrofoam balls stick to surfaces and are difficult to collect Source 2.bp.blogspot.com

The most accurate way to do this job is to use a thin and very sharp blade, and without using excessive force.

Another feature of the material is its fusibility. It does not burn very readily, but melts at a high temperature, which is a big drawback from the point of view of using the material, but simplifies its cutting and eliminates the formation of crumbs.

How to properly cut polystyrene foam with a knife so that it does not crumble

When slabs of polymer material are used in the process of insulating walls, ceilings, and roofs with your own hands, thermal cutters are not always justified. Structures, as a rule, have strictly geometric shapes, and it is quite possible to cut the material with a simple knife, the main thing is that the blade is thin and its length exceeds the thickness of the insulation sheet. A good tool for such work is a stationery knife if you have to cut thin polystyrene foam.

To cut foam with a knife, you need to choose a long blade

The fact is that the blade of such a tool is very thin and when cutting a sheet of great thickness, a perfectly even cut is unlikely to be achieved; wrinkles may form on the cut, which will not allow the individual parts of the insulation to fit tightly together. And this will lead to the formation of cold bridges.

In addition to the knife you will need:

- A rigid measuring ruler or a ruler of ideal shape.

- Roulette.

- Simple pencil, marker.

They cut polystyrene on a solid base so that the sheet does not “play” in your hands. Marks of the required size are made on the surface of the polystyrene plate, after which a rigid ruler or strip is laid and a cut is made with a sharp knife. If the length of the knife blade is not enough, you can make cuts on two opposite sides of the sheet, the main thing is not to lose the size. Then the sheet is simply broken along the cut. With proper skill, the work will proceed quickly, without unnecessary noise and waste of electricity. Of course, there will be debris, but not as much as from a hacksaw. The main thing is that the tool is very sharp and of the required length.

Before cutting the material, the tool must be heated and the blade must be sharpened periodically.

How to cut polystyrene foam without using heat tools

The principle of cutting sheets of foam plastic using a hacksaw, regardless of whether it is for metal or wood, is no different from cutting with a knife, the main thing is that the teeth are small and the blade is of sufficient length.

In this case, the cut will be smoother and a lot of small debris will not form. The saw movements must be made smoothly, without jerking. But even with this cutting method there will be a lot of expanded polystyrene crumbs.

You can cut foam sheets using an electric jigsaw or an angle grinder (grinder). However, with this method, a huge amount of garbage is guaranteed.

Grinder for cutting foam plastic

The high speed of rotation of the grinder disk and fairly large teeth will provoke severe destruction of the structure of the material at the cutting site. When using a jigsaw, it is also impossible to obtain a perfectly flat surface on the cut due to vibration of the file, which also leads to the formation of small polymer debris.

The least amount of foam crumbs is formed when cutting it if you use a homemade device for cutting foam. The simplest type of such a device is an ordinary thin wire (string), with handles attached to the ends for greater convenience. The wire diameter should be chosen as small as possible, no more than 0.5 mm. One person cannot cope here; an assistant will be needed. The wire is installed along the intended mark on the foam and uniform movements are made on both sides. As a result of the friction of the metal wire against the polystyrene foam, it heats up and the material begins to melt at the cut site.

Cutting foam plastic with a string is the most effective method in terms of creating a minimum amount of debris, but the time spent on such work is much longer than when cutting with other tools.

Cutting tools

When choosing the best way to cut polystyrene foam at home, you should take into account its features and requirements for the quality of the resulting ends. You can use both standard “cold” cutting tools and thermal cutters, the main working element of which is a wire heated by electric current.

Mechanical cutting tools

Standard tools are suitable for cutting products made of polystyrene foam and similar materials: a knife, a hacksaw, an electric jigsaw, a grinder, and also a well-tensioned metal string. But any of them must be applied correctly.

On a note! When using “cold” tools, even if you follow the instructions absolutely exactly, you will not be able to do without crumbs.

An ideal solution to the problem of cutting thin foam plastic would be a stationery knife with replaceable retractable blades. They are very thin and sharp, which is what is required in our case. The main thing is that the length of the blade should be greater than the thickness of the material being cut.

Therefore, it is preferable to cut thick slabs with a hacksaw with the smallest tooth - for metal.

To obtain the most even and neat edge, proceed as follows:

- lay the material on a rigid and level base;

- Use a tape measure and a marker to mark the cutting line;

- attach a ruler, rule or other straight line to it;

- With a confident movement, cut the sheet with a knife to its entire depth, leading it along the rail.

If the blade is not sharp enough, it will begin to wrinkle and tear the material, so it must be periodically sharpened (when using a regular knife) or broken off dull plates.

Marking the slab before cutting with a hacksaw Source i.ytimg.com

Tool No. 1: shoe cutting tool

Sample of a shoemaker's knife

A shoe knife is sharp enough that its blade can pass through plastic bubbles without catching them.

But there are still some notes on its operation:

- It is possible to cut only those sheets whose thickness does not exceed 40 mm ;

- The blade dulls quite quickly , which is why sharpening is required after passing approximately every 200 cm of foam. But this only matters for large volumes of work;

Always keep a sharpening stone handy when using a shoe knife.

- As the blade passes through the foam, it rubs against the plastic bubbles with a terrible sound. So be prepared.

If you have a lot of foam plastic slabs waiting for you that need to be cut with the tool described, I recommend putting on headphones right away, otherwise you will be in a very bad mood by the end of the work.

Protect your hearing and mental health

Video description

This video shows how to cut a circle out of foam plastic and finish the edges:

A grinder and a jigsaw are not the most suitable tools. Even if you choose a wheel or saw with a fine tooth, they produce jagged edges and too much chips due to the high frequency of movement of the cutting element. They can be used to speed up work and with low requirements for edge cleanliness.

If you are deciding how to cut polystyrene foam at home to prevent it from crumbling, you can use the simplest homemade tool - a strong thin string with handles attached to its ends. For cutting, you will need an assistant who will pull the second handle. The work itself resembles cutting wood with a two-handed saw, but the material is not cut, but rather ground and melted under the metal heated by friction.

Thermal cutting tools

Expanded polystyrene is not only insulation. Interior design elements are made from it: baseboards, moldings, imitation columns, etc. Decorators also appreciate this material, cutting out various figures, letters, and frames from the lightweight and plastic solid material.

New Year's decor made of polystyrene foam Source toppennewyear.ru

A little about the material itself

Before moving directly to the most important thing, I want to devote a few words to foam plastic. Essentially, this material is foamed plastic, a set of thin-walled plastic vessels filled with air. The description is very exaggerated, but it very clearly conveys its device and the presence of technical characteristics associated with it.

The cellular structure is very easy to see even with the naked eye

What is the problem with cutting?

In the photo above, the tiny fragments that make up the foam board are clearly visible, and you can even see that in some places they have already flown off. This is where the difficulties associated with even cutting of this material lie: fragility. It easily crumbles or even breaks completely when in contact with various tools or even just bare hands.

The slab can turn into crumbs very quickly

Thus, during the cutting process, it is necessary to achieve such a result that the tool passes through the foam with minimal resistance, without causing destruction of its structure.

Density is important

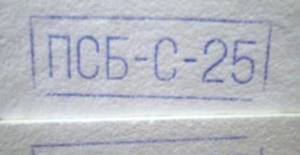

In addition to the technology that you choose to implement your plan, an important factor is also the density of the foam, which is easily determined by the markings applied to it:

- PSB-S-15. The cheapest and most fragile brand , which is used exclusively as a thermal insulation material placed behind decorative trim. Technical data:

| Characteristic | Meaning |

| Density | 10.15 kg/m3 |

| Compressive strength | 0.05 MPa |

| Flexural strength | 0.07 MPa |

| Coefficient of thermal conductivity | 0.037 W/(m×K) |

This is what the markings on purchased foam sections may look like

- PSB-S-25. The most popular option when carrying out finishing work, as it is still incredibly cheap, but at the same time has higher strength characteristics that simplify its operation. Technical data:

| Characteristic | Meaning |

| Density | 15.25 kg/m3 |

| Compressive strength | 0.1 MPa |

| Flexural strength | 0.18 MPa |

| Coefficient of thermal conductivity | 0.035 W/(m×K) |

Example of marking PSB-S-25

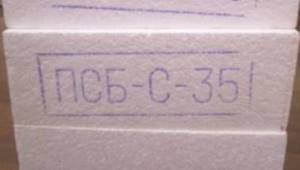

- PSB-S-35. These samples can withstand physical impacts much better, which is why they are widely used in the construction of swimming pools, sports fields, lawns and insulation of foundations. Accordingly, their cutting is easier with less waste. Technical data:

| Characteristic | Meaning |

| Density | 25.35 kg/m3 |

| Compressive strength | 0.16 MPa |

| Flexural strength | 0.25 MPa |

| Coefficient of thermal conductivity | 0.033 W/(m×K) |

Sample of applied marking PSB-S-35

- PSB-S-50. This brand has the highest density , which allows you to create the most complex artistic figures from it with your own hands, even with simple tools.

PSB-S-50 - the most durable foam boards

Thus, the first thing to do to prevent foam from crumbling is to choose a product of the appropriate brand. Although, of course, if the quality of the cut does not matter in your situation, then there is no need to overpay for strength.

Briefly about the main thing

When deciding what is better for cutting foam at home, you choose between conventional tools and devices with a “hot” blade. A sharp kitchen knife or a high-quality stationery knife can be used to cut thin slabs. For more massive products, it is better to use a hacksaw with a fine tooth or a thin, stretched string. But these tools leave behind a lot of debris and do not guarantee the quality of the edges. Much more convenient are the so-called thermal knives, which accurately and accurately melt the material along the markings without forming crumbs. They are not cheap, so home craftsmen assemble them with their own hands, which does not require a lot of time and money.

Ratings 0

What and how to cut foam plastic

In order to cut a specific shape of insulation, any device for cutting foam plastic can be used:

- knife;

- hacksaw for wood or metal;

- soldering iron;

- an angle grinder called a “grinder”;

- thin metal wire like a string;

- thermal cutter;

- foam cutting machine;

- jigsaw with heated file.

If you choose a hacksaw for wood, then its teeth should be as small as possible. All tools that are not heated to a certain temperature do not guarantee that the foam will not crumble. Such tools are used for small volumes of work, but when it is necessary to insulate all the enclosing structures of a house, it is better to use a foam cutting machine, the action of which is based on heating the cutting element.

Cutting polystyrene foam with a soldering iron

Expanded polystyrene boards lend themselves well to processing using a soldering iron. This tool makes it possible to complete work in less time. To carry out similar work with a soldering iron, its end must be flattened with a hammer. You need to put a specially prepared part on it, which was previously made from a blade, a fountain pen cap made of steel.

The blade is installed on the end of the soldering iron. After heating the purchased tool, you can cut the material.

Expanded polystyrene lends itself well to painting, so decorative elements acquired through cutting can be painted. Each option for cutting foam has its own advantages, but it is recommended to choose the one that will be least difficult for you.

In construction, work is often carried out related to the insulation of structures, where polystyrene foam is used as the cheapest material. Accordingly, the density of such a heat insulator is low, which, when cutting it, leads to the formation of a huge amount of debris, which is quite difficult to collect, because pieces of foam plastic tend to become electrified and stick to everything that comes their way. To facilitate the process of cutting insulating material, there are many methods and devices that help cut foam without crumbs.

Cut out foam parts with even cuts

Knife cutting

When insulating a floor or ceiling using foam boards, it is not at all necessary to use special equipment.

To cut polystyrene foam at home you need to have:

- Nice knife.

- A ruler more than one meter long.

- Pencil.

The procedure for cutting polystyrene foam boards in this way is quite simple:

- First, on the surface of the material, the starting and ending points of the cutting line of the cut are marked with a pencil.

- Next, a ruler is applied to these marks, clamped, and an incision is carefully made along it with a paint knife (it is not necessary to completely cut off the piece of foam plastic).

- The polystyrene foam plate is turned over to the other side, and a cut is made in the same way, parallel to the cut already made.

- After making the cuts, you just need to break the foam along the mowing line.

This method of cutting material is the cheapest, quietest and fastest, and there is practically no debris after finishing the work. Be sure to check the sharpness of the knife before cutting foam.

Sources:

https://iv-proect.ru/krysha/chem-rezat-penopolistirol-v-domashnih-usloviyah-rezchik-penoplasta.html

Features of foam

Polystyrene foam is a lightweight material in all respects. The polymer is mixed with air and foam filling components. Its structure is similar to glued balls. It is this feature that explains why we cut the foam instead of breaking it. Otherwise, the cutting will be uneven.

In some types of material, the balls of the structure are held tighter and do not crumble. But quite often the foam crumbles, sometimes very badly. Such destruction of the material is dangerous for the sheet. The fragility of foam plastic leads to a change in shape, a decrease in properties and functional qualities.

If it is necessary to adjust the dimensions of the array, this operation is carried out using a special tool. In this case, the sheet will not be destroyed.

Easy way to cut

The presented approaches make it easy to cut foam. Folk craftsmen give advice on how to cut such material. They came up with another way. It will be quite effective, especially when cutting large sheets of foam.

To do this you will need a thin and strong string. Its ends are tied to wooden handles. If the sheet is large, you need to do the work together with an assistant. In this case, there are 2 people on both sides of the array. Everyone takes a wooden handle with a string attached. Next, they move the thread along the pre-drawn markings. It heats up from friction.

The material is easily and quickly cut. If the leaf is small, you can perform this procedure yourself.

Recommendations from professionals

There are a few tips from professional installers to take into account when processing foam. It will be easy to choose what to cut it with. Experts say that each of the presented methods is suitable for cutting. It all depends on the skills of the master and the amount of work he performs.

Before cutting, the material must be marked with a simple pencil. With the mechanical and thermal method, the foam can heat up. In this case, it releases harmful substances into the environment. Therefore, the work is carried out outdoors.

In this case, special equipment is used. Otherwise, when heated, the material will stick to the blade. A grinder or jigsaw works at low speeds. This allows heat to be removed from the cutting zone.

By following these recommendations, you can quickly and efficiently cut foam for any application.

Types of foam shredders

You can choose the type of crusher for foam plastic based on the amount of material. If the main task is to obtain 1-2 small bags of crumbs, you may not need to assemble a special unit at all to complete it. It is enough to use a metal brush, which is used to rub sheets of foam insulation, or a homemade “grater” from a box with cells. This method will be ineffective, but will avoid costs.

It is better to immediately purchase high-quality material for roof vapor barrier than to redo all the work later.

The method for installing a vapor barrier on the floor is somewhat different from installing it on the roof.

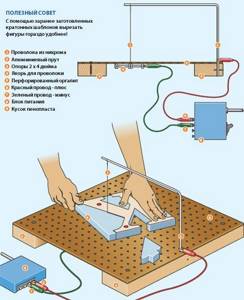

Wire cutting

You can make a special device for processing (cutting) foam plastic at home with your own hands. To do this, you need to purchase a step-down transformer, a string, springs with which the string will be tensioned, and a pipe with a thickness of 2 cm for the lining. The thickness of the polystyrene foam board itself, which will be cut, must be at least 2 cm.

To arrange a tabletop for this equipment you will need a table, a profiled sheet, a board. Making such a device for cutting polystyrene foam at home will not be difficult.

The principle of operation of a do-it-yourself foam crusher

In the production of foam chips the following is used:

- production of granules of a given size using a special technology by foaming polystyrene balls;

- waste recycling - shredding polystyrene foam residues in special structures for shredding polystyrene foam.

Crushed material is used in construction as a component of cement mortar to level the surface and form concrete floor screeds. The recycled foam product is the basis for the production of polystyrene concrete.

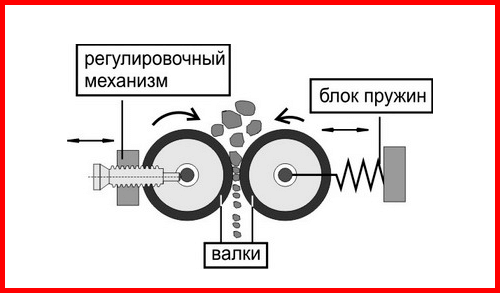

The expanded polystyrene shredder consists of the following components:

- grounds;

- motor casing;

- bunker;

- tank;

- damper handles.

The crushing chamber structure includes a body, a base, a knife plate and a mesh. Using an adjusting mechanism and a spring block, the distance between the rolls is set.

Waste foam is loaded into a tank, from where it enters the work area. During rotational movements, the shaft passes through the axes of the drum, the foam falls between the knives and is cut into fractionated parts.

The crushed material is removed from the working area for sorting onto a mesh with air. Large pieces of waste are again returned under the knife for grinding, and the crushed foam is fed into the dispensing hopper.

Types of foam shredders

There are several types of polystyrene foam granules, which are also called polystyrene foam balls, crushed foam, recycled material, and crumbs. Crushed foam is a material obtained by grinding. A shaft crusher is used for its production.

The shredder is designed as a grater that is mounted on a shaft. The movement of the drum on the shaft occurs with the help of a motor through a gearbox, which reduces the number of revolutions.

The waste pieces are fed through a guide pipe onto the grater. The adjusted gap between the cutting elements and the float holes determines the fraction of material at the outlet. If such an installation is located indoors and a dust collector is installed on the engine, then you do not need to use a protective casing around the shaft.

The hammer crusher is designed for crushing dense grades of molded foam while maintaining the throughput of the mechanism. A mesh installed at the outlet makes it possible to obtain small particles. The rotary design equipped with sieves has high productivity. The size of the output fraction is regulated by a calibrating grid.

Foam cutting machine

Expanded polystyrene is a good insulation material, an excellent raw material for various decorative elements, which you can make yourself. For decorative cutting of foam plastic, you will need a specialized machine. There are many options for such equipment, it all depends on the intended design of the product.

Cutting the material can be done using a tungsten filament. It should be noted that this thread is hot, but its temperature can be adjusted . In addition to polystyrene foam, you can cut other materials with this thread. This is especially true in the manufacture of various components intended for stucco.

The required stencil is applied to the expanded polystyrene plate, and an object is created using a tungsten filament. This procedure is not difficult and does not take much time.

You can also use a construction blade or cutter for the equipment. The design of the machines may differ, but the principle of operation remains the same - the use of a tungsten filament, which is connected to the electrical network. Using such a device, you can independently produce decorative elements from polystyrene foam of any configuration.

To perform cutting, it is recommended to purchase the following tool:

- Tungsten filament.

- String.

- Thermal cutter.

If you assemble the cutting machine correctly, there will be no difficulties during the work process. The main thing is to use a high-quality tool, show maximum diligence and care. And to perform such work, you do not need to contact experienced craftsmen.