The cost of energy resources in our country is constantly growing, as a result of which we have to pay more and more for heating and hot water. To reduce costs, it is necessary to take care of high-quality thermal insulation of the building envelope. However, its effectiveness directly depends on the correct choice of insulation, and the most popular types in this group of materials are mineral wool and polystyrene foam.

The concept of mineral wool covers three types of insulation - slabs or mats made from:

- fluffed basalt fibers;

- glass;

- slag waste.

In order for the comparison of cotton wool with polystyrene foam to be correct, only basalt slabs can be considered. The fact is that the other two insulation materials are hygroscopic and actively absorb moisture, while slag wool also releases toxins when wet.

With polystyrene foams it’s not so simple either. Plain white foam is flammable and cannot be used for thermal insulation of buildings. Conventional molded polystyrene foam has a porous surface and partially absorbs moisture. Therefore, to insulate the external walls of residential buildings, only extruded polystyrene foam boards with a waterproof smooth surface can be used.

Foam plastic: features, characteristics, advantages and disadvantages

Polystyrene foam is considered a popular material, due to its porous structure, it is an effective heat insulator.

Foam is considered a popular material, thanks to its porous structure, it is an effective heat insulator. The foam production technology includes the addition of polystyrene, which is obtained through the polymerization of styrene, as well as the process of gas filling of styrene granules. The substance lends itself perfectly to molding, painting, machining and even gluing. It is produced in the form of white slabs (see example in the photo).

Advantages of polystyrene foam:

- environmentally friendly material;

- low level of thermal conductivity, the product perfectly allows air to pass through and at the same time retains heat, this is due to the fact that the foam contains 97% air, which creates ideal thermal insulation;

- does not require waterproofing work;

- saves usable space;

- compatible with cement, lime, gypsum;

- the product is a fire-resistant material, during combustion the foam releases air and water, if the product is made taking into account the entire process and using high-quality raw materials, it will not burn;

- resistant to the environment and temperature changes;

- due to its low rigidity, polystyrene foam is a good sound insulator;

- the material does not emit harmful substances.

Foam plastic is distinguished:

- polyurethane - made of polymers, widely used in industry;

- polyvinyl chloride - made from a polyvinyl chloride composition and used as insulation;

- polyethylene - made of polyethylene, it is a thin transparent sheet, used for packaging household appliances and glass.

The cost of polystyrene foam varies from 17 to 53 dollars per square meter. The scope of application of the product is varied:

- Polystyrene foam gets along well with soil and moisture, so it is better for them to insulate the façade part of the structure.

- When building houses and pouring a monolithic foundation, the subfloor is insulated with it, then the entire area is filled with mortar and the walls begin to be built.

- When constructing a foundation, foam plastic slabs are placed in a structural element, covered with bulk material and waterproofing is laid; this method ideally protects the foundation from severe frosts;

- Plates can also be used to insulate non-ventilated roofs. For this type of work, PSBS type slabs with mandatory waterproofing are used. For cold roof types, thermal insulation is performed using a different method. Insulate the inside of the roof with foam plastic, while always leaving a small gap for ventilation.

- The floor and interfloor ceilings are also insulated with this product, a layer of waterproofing is laid down, and everything is filled with concrete mortar on top.

- Widely used for thermal insulation of freezers and isothermal vans.

Which is better: polystyrene foam or mineral wool? Which is warmer and cheaper?

Polystyrene foam is an insulator consisting of 98% air. It is made from polystyrene by foaming with hot water steam. Polystyrene foam comes in different densities, thicknesses and sizes.

Foam plastic as an insulating material can be characterized as follows:

- Minimal hygroscopicity and ability to transmit steam.

- Highly flammable and combustible.

- Convenient to work with, easy to cut to desired size.

- High level of thermal insulation, retains heat well.

- Average degree of sound insulation.

- Inexpensive.

When comparing polystyrene foam with mineral wool, it is impossible to say clearly which one is better. In terms of thermal properties they are approximately equal. The difference is that mineral wool is very hygroscopic, and when wet it practically loses all its thermal insulation properties. Therefore, when laying it, a special hydrobarrier is used to protect the material from moisture and prolong its service.

Polystyrene foam, on the contrary, is not afraid of water and is not affected by moisture, so it is not afraid of fungi and mold. However, polystyrene foam has another significant disadvantage - it burns very easily. Therefore, it should not be used in places with a high fire hazard. In such places it is better to use mineral wool; it is practically not afraid of fire. Both, if used correctly, retain heat well inside the room and easily cope with noise insulation.

Another disadvantage of polystyrene foam is that over time it is damaged and destroyed; its warranty period is much shorter than that of mineral wool. As for prices, polystyrene foam is slightly cheaper than mineral wool, but the difference is not significant.

Which insulation is best in different situations?

Penoplex is usually used to insulate the roof, foundation, and walls, both inside and outside. However, it is not recommended for use in thermal insulation of bathhouses, swimming pools and other structures with high humidity levels. In addition, it lacks noise insulation properties.

Mineral wool is perfect for insulating buildings made of wood, brick and other breathable materials. It is also better to use it in those buildings that require increased fire safety measures. It is fair to say that both building materials have almost the same number of disadvantages and advantages, and by and large, the choice of the most suitable insulation depends on the conditions in which it will be used.

Repair and constructionComment

Mineral wool: features, characteristics, advantages and disadvantages

Mineral wool is a fairly good material for home insulation, available in roll or sheet form in the form of a slab

Mineral wool is a fairly good material for insulating a house. The release form is roll or sheet in the form of a plate (see example in the photo).

All products are distinguished by high thermal insulation and acoustic properties, as well as high fire resistance. The following raw materials are used:

- Glass or glass wool, which is formed in the process of melting quartz sand, broken glass and blown into thin fibers. Glass wool has a uniform structure and light yellow color.

- Stone - the product is called stone (basalt) wool, the production technology is similar to fiberglass, only the main substance in its production is rock. This insulation also has a uniform and dense structure; the color palette is presented in light yellow and dark brown tones.

Mineral wool has the following advantages:

- excellent thermal insulation properties;

- fire resistance, in case of fire the material does not ignite, and accordingly does not emit harmful toxins, its melting point is above 1000 degrees;

- the material is vapor permeable; when steam gets under the plaster and insulation, moisture and condensation immediately disappear;

- It insulates noise due to its porous structure; mineral wool has excellent acoustic properties and high sound insulation;

- resistant to deformation and mechanical damage, due to which its service life is longer than that of foam plastic;

- not susceptible to attack by rodents and insects;

- no shrinkage due to thermal or natural influence;

- easy to install, the work will not take much time, and you can even cut a sheet of cotton wool using a stationery knife;

- The product can hold its shape on any surface.

Mineral wool for insulating the facade in the photo

The cost of the product varies from 25 to 150 dollars per 1 square meter

The cost of the product varies from 25 to 150 dollars per 1 square meter; due to its availability, it is very popular in finishing work.

Experts conducted research and found that cotton wool contains dangerous carcinogens that negatively affect human health. However, manufacturers assure that the number of carcinogens in the fiber is acceptable and it is not capable of harming the life and health of others. Another disadvantage of cotton wool is its possible wetting; when wet, it loses its thermal insulation qualities. This is perhaps all the shortcomings of this material. Before buying insulation, take an interest in the manufacturer’s reputation and read product reviews. As a rule, the product is used for insulating floors, walls, roofs, attic floors, and soundproofing interior partitions. Experts recommend using mineral wool for cladding the following structural elements:

- insulation and insulation of the roof, including pitched roofs, and attic rooms, with a small gap for ventilation;

- cladding of brick structures, where the middle thermal insulation layer is mineral wool;

- the use of fiber as protection against very hot objects (basalt wool can withstand temperatures of 1000 degrees);

- use for sound insulation of frame buildings of any type, insulation of the house is possible with horizontal, vertical and even curved surfaces;

- in wooden houses, cotton wool is used to insulate the facade of the building; in structures built from other materials, cotton wool is used for cladding floors, partitions, and ceilings.

Biostability

The less the material is exposed to insects and rodents, the longer it can last.

Quartz-based thermal insulation and basalt insulation do not require additional treatment with insecticidal compounds. As a rule, they do not attract rodents and insects and do not grow mold.

Insects or fungi usually do not grow in polystyrene foam, since it is a synthetic material. But mice can gnaw on it - they sometimes sharpen their teeth on the insulation and make nests in it. If the foam is damaged by rodents, it can quickly deteriorate, become unusable and require replacement.

Conclusion: both materials are bioresistant, but mineral wool is considered less attractive to rodents.

Comparison of characteristics

When comparing which insulation is better, polystyrene foam or mineral wool, let’s consider several basic technical and operational characteristics:

- environmental cleanliness;

- thermal conductivity;

- lifetime;

- ease of installation;

- resistance to biological effects;

- price;

- insulation density;

- water absorption;

- strength;

- Fire safety;

- soundproofing properties.

Which is more environmentally friendly?

Under normal operating conditions, both insulation materials are absolutely harmless to human health. But with increasing temperature, and even more so when exposed to an open flame, polystyrene foam can become dangerous.

When polystyrene melts, the active release of toxic and poisonous gases begins. And therefore, in most European countries, the use of PPS boards for insulation is prohibited by law. Although in our country it is used everywhere.

Which retains heat better?

Both insulation materials have excellent thermal insulation characteristics. But if we compare the thermal conductivity coefficients, we can say for sure that polystyrene foam is a more effective insulation material.

Which is cheaper?

The cost of basalt mats ranges from 1400 to 2300 rubles/m3. Expanded polystyrene is sold for 1900-2300 rubles/m3, i.e. the price is almost the same. But, as mentioned above, polystyrene foam is warmer and will require 40-50% less of it. It turns out that PPS slabs are cheaper than mineral wool.

Which will last longer

When considering the technical characteristics, it was already said that the service life of PPS slabs is 25, and that of basalt wool is 50 years. Here the clear leader is cotton wool. However, when choosing insulation, you should take into account the finishing method used. Thus, a facade plastered using the “wet” method will last no more than 25 years. Therefore, the use of expensive durable cotton wool simply loses its meaning.

The easier it is to insulate

The installation technology for both insulation is identical. The insulation is initially placed on glue and then additionally secured with plastic mushroom-type nails.

What is less attractive to pests

Both polystyrene and mineral wool are not susceptible to mold and mildew. But rodents very willingly make burrows in polystyrene foam, which is significantly inferior in this regard to basalt fibers.

Other criteria

When choosing insulation, it is recommended to pay attention to such comparative qualities as:

- polystyrene foam is much lighter than mineral wool;

- expanded polystyrene absorbs moisture less and does not lose its properties when wet;

- basalt mats have greater bending strength, which makes it possible to insulate surfaces with complex configurations;

- the fire protection characteristics of polystyrene foam are significantly lower than those of its competitor;

- Polystyrene has virtually no vapor permeability.

Stability of linear dimensions

The insulation should not shrink or change geometric dimensions. Otherwise, gaps may form at the joints, which will become “cold bridges.”

Mineral wool is resistant to temperature changes; it does not shrink or expand. Basalt insulation does not “shrink”. Mineral wool tolerates deformation well and quickly restores its original dimensions. When compressed, it becomes more dense, so it is used in systems that experience static loads.

Foam plastic, as a rule, does not shrink; it has virtually no thermal expansion. But it can break under mechanical stress. For this reason, it is not recommended to insulate facades that are under stress with polystyrene foam.

Conclusion: both insulation materials have stable geometric dimensions.

What's better

The insulation that you will use when building a house must meet the climate requirements of your area. The choice of a particular material is directly influenced by the quality of the surface requiring thermal insulation.

It is advisable to do the thermal insulation of a loggia or balcony using penoplex. This material is denser in structure; for installation it is not necessary to fill the lathing, which will make it possible to save space.

Thermal insulation of private houses is best done with mineral wool. Cooled air will not pass through it, it does not burn, and it is easy to lay it in the voids of the sheathing. The characteristics of all thermal insulation materials differ markedly; it is difficult to say which is warmer; the choice of a particular insulation is directly influenced by the conditions of its use.

Soundproofing

This is not the main function of the insulation, but an additional bonus. If the material absorbs outside noise, the house will be quiet and comfortable.

Mineral wool provides excellent sound insulation. This is due to the structure of the material: it consists of randomly located fibers. When a sound wave passes through the insulation, it becomes entangled between the fibers and goes out.

Foam can also protect against third-party sounds due to the cellular structure of the material. The sound wave fades as it passes through the "bubbles" of polystyrene foam.

Conclusion: both materials are effective sound insulators.

Advantages and disadvantages

So, let's compare two insulation materials and find out which is better, polystyrene or stone wool. To begin with, we will determine the quality indicators of each material, after which we will move on to a more detailed comparison of individual characteristics.

Mineral wool and expanded polystyrene are completely different in manufacturing technology and internal structure. Basalt mats are obtained by melting and fluffing natural stone, and EPS slabs are obtained as a result of a chemical reaction.

Extruded polystyrene foam

This type of foam is made by foaming styrene and forming flat rectangular slabs in an extruder. The structure of the finished products is porous and consists of 96-98% of small voids filled with carbon dioxide with a small amount of air, as a result of which expanded polystyrene becomes an effective insulation.

General characteristics:

- thermal conductivity coefficient – 0.028-0.042 (W/m*K);

- moisture absorption when immersed in water for a day – 2-4%;

- compressive strength when reaching 10% deformation – 0.05-0.2 MPa;

- mechanical bending strength – 0.07-0.35 MPa;

- density – 20.0-50.0 kg/m3.

The difference in indicators is associated with different brands of PPP produced. Higher performance refers to denser and stronger material.

Pros:

- excellent insulating qualities, increasing with increasing foam density;

- long service life reaching 50 years;

- operating temperature range from -50°C to +75°C (with a maximum permissible +160°C);

- flame retardant ability;

- low cost;

- easy installation (using glue and plastic nails);

- low density, which does not weigh down building structures;

- inertness to the effects of cement-based liquid solutions;

- good adhesion to plaster solutions and paints and varnishes;

- is not affected by mold and mildew even with constant exposure to moisture.

Minuses:

A serious disadvantage of PPS boards is the need to test the material for flammability. The fact is that some of these foam plastics are capable of fire and belong to class G3. However, the addition of fire retardants transfers polystyrene to class G1 - self-extinguishing materials.

Therefore, when purchasing, you need to take a piece of the stove and set it on fire. The combustion should stop after 4-5 seconds. If this does not happen, then such thermal insulation cannot be used to insulate the facade.

In addition, critics of PPS slabs note:

- release of styrene when heated above 30°C and the absence of a continuous surface coating;

- release of hydrocyanic acid, phosgene and other toxins when melted under the influence of an open flame;

- ability to be destroyed under the influence of certain types of paints and glue;

- ability to resonate and transmit noise and vibration vibrations;

- aging under the influence of solar ultraviolet radiation.

Polystyrene foam is one of the favorite materials for rodents. Therefore, the lower part of the thermal insulation coating must be additionally protected from their influence.

Basalt wool

To form mineral wool slabs, thin fibers obtained from molten basalt are used, which are fluffed with a strong air flow. After this, the mass of fibers is compressed by a press until the required density is obtained. The result is insulation with:

- thermal conductivity coefficient – 0.035-0.045 (W/m*K);

- moisture absorption when immersed in water for 24 hours – 1-2%;

- compressive strength when reaching 10% deformation – 8-60 kPa;

- mechanical bending strength – 0.12-0.16 MPa;

- density – 30-40.0 kg/m3.

Several brands of mats made from basalt fibers are produced, which is responsible for the variation in the given technical characteristics.

Positive traits:

Among the main advantages of mineral wool, experts note:

- durability exceeding 50 years, but this is only a statement by the manufacturers, since the production of the material lasts no more than 25 years;

- excellent thermal insulation qualities;

- non-flammability and ability to withstand heating up to 1100°C;

- lack of hygroscopicity;

- resistance to aggressive chemicals;

- high elasticity;

- environmental cleanliness and safety;

- simple installation technology;

- resistance against fungus, mold and rodents.

Flaws:

The main disadvantage of basalt mats is the high cost associated with high energy consumption during its production. In addition, it should be noted that there is a large amount of dust generated during the installation of the thermal insulation layer.

We advise you to study - Living room in Scandinavian style - practical and elegant

Hygroscopicity of mineral wool and polystyrene

This is what installation errors lead to.

The second no less significant factor that will help determine whether foam plastic or mineral wool is better for insulation is hygroscopicity (the ability of the material to absorb moisture). Moisture absorption is measured as a percentage of the weight of the material per day. That is, how much moisture, as a percentage of its own mass, is absorbed by the insulation when immersed in water for 24 hours. Stated characteristics:

- polystyrene foam no more than 1%;

- extruded polystyrene foam 0.04%;

- mineral wool 1.5%.

The degree of water absorption of the insulation determines the possible areas of its application. For example, EPS practically does not absorb moisture, which is why it is used for laying in the ground. Polystyrene foam begins to crumble from moisture, and mineral wool, once wet, does not retain heat at all, so it is not of much use either. At the same time, based only on the hygroscopicity of materials, it is impossible to determine whether it is better to insulate a house with foam plastic or mineral wool. The issue must be considered holistically and the following characteristic is important.

There are long-burning coal stoves for homes that are heated using the convection method, and there are those with a built-in heat exchanger for water heating.

You can read about how the Buleryan stove works here.

Pros and cons of foam plastic

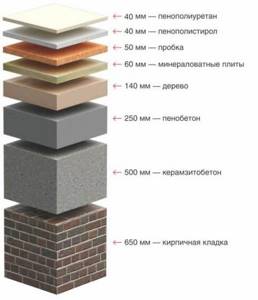

Often, when insulating balconies, owners prefer to use plastic foam material that has a low thermal conductivity coefficient. It is polystyrene foam. According to its characteristics, it is the best heat insulator on our planet. And concrete numbers can serve as proof of this. Thus, it is calculated that a polystyrene foam board with a thickness of only 10 cm is similar in its heat-shielding properties to:

- 60 cm of aerated concrete;

- 40 cm of wood;

- 150 cm of brick with voids;

- 90 cm of expanded clay concrete;

- 400 cm of reinforced concrete.

I immediately want to find out what is better - mineral wool or polystyrene foam for this characteristic? Calculations indicate the advantages of the foam material itself. Thus, a 10 cm thick foam board can retain heat in the same way as 16 cm of mineral wool. Of course, according to this characteristic, you should prefer the first material of the two considered.

When answering the question of what is better for sound insulation - polystyrene foam or mineral wool, you should pay attention to the second insulation. Foamed plastic materials are not suitable for noise reduction

The next characteristic to be considered is vapor permeability. It directly depends on density. As for polystyrene foam, its vapor permeability varies. It depends on the type of teaching staff. Thus, low-density polystyrene foam is similar to cotton wool in this indicator. It lets out steam easily. Another thing is high-density foam. Of course, it lets through steam, but with great difficulty. That is why this material is used to insulate dense walls.

Another important characteristic of polystyrene foam, on which the owner’s choice will depend in the future, is its environmental friendliness. However, there is no consensus on this issue

Thus, even Soviet scientists proved that polystyrene foam releases toxic styrene into the environment. This process only occurs under certain conditions. Other conclusions are drawn from the results of modern research on the material. They confirm the harmlessness of expanded polystyrene foam. Yes, during operation it releases a certain amount of styrene. However, it is so tiny that it does not produce any effect on the human body. Nevertheless, experts advise before purchasing to clarify the content of residual styrene in the foam. In environmentally friendly material, this indicator should be in the range from 0.01 to 0.05 percent.

Depending on the quality of the foam, its service life also varies. The most durable are non-press brands such as PSB-S and PSB. Their main characteristics do not change even with long-term use (10-40 years). Extruded foam will serve its owner even longer. It can be used without changing its characteristics for up to 80 years.

Mechanical strength

The material must withstand mechanical stress. Otherwise, it may “fail” during transportation or installation.

Mineral wool is difficult to break - this will require a lot of effort. The elastic material cannot be broken.

Polystyrene foam is considered more fragile; it can break under mechanical stress. This can make transportation and installation more difficult. You must be extremely careful, otherwise the insulation may crumble and become unusable.

Conclusion: mineral wool, as a rule, is more resistant to mechanical stress.

Scope of application of polystyrene foam and expanded polystyrene

Considering that polystyrene foam is the same polystyrene foam, but of higher density, its use in construction is mainly limited to insulating structural elements of buildings and structures. For example, non-pressed polymer material is quite often used for insulating facades, given its high thermal insulation properties and adhesion ability.

Roof insulation with polystyrene

But penoplex is good for insulating basement, foundation and basement elements of buildings, loggias and balconies. With a smaller thickness, it retains all the thermal insulation properties inherent in thicker foam.

At the same time, it is not recommended to carry out insulation with these materials indoors, especially residential ones, due to the fact that during production the insulation is treated with fire-retardant compounds, which can be released into the environment throughout its operation. In some countries in Europe and America, the use of polystyrene foam as a thermal insulation material is not permitted. The reason is the release of toxic substances during a fire.

Base insulation

Extruded polystyrene foam is used in the production of decorative interior products.

Polystyrene tiles as a finishing material in the interior of premises

In the medical industry, expanded polystyrene, just like polystyrene foam, is used as a material for making packaging.

These materials serve as insulation in household appliances, industrial refrigerators, they are used to make buoys, floats, life jackets, and they are used to fill the compartments of ships, which ensures their ability to float on the water.

In the food industry, packaging for products and fragile items is made from extruded polystyrene foam.

Foam plastic in the production of food packaging

Polymer materials obtained without pressing or by extrusion are used in various fields, and when the question arises of what to choose, you need to know what the difference is and the properties of these materials.

Analysis of material characteristics

Almost any structure can be insulated with foam plastic or mineral wool. Both types of insulation are easy to use and allow for quick installation. But what to choose? First of all, it is worth understanding the operational features of both insulation materials.

Expanded polystyrene

Expanded polystyrene is a foam plastic familiar to everyone. Today they also produce an improved modification for insulating facades - polystyrene foamed by extrusion.

Types of material

Conventional polystyrene foam consists of easily separated light grains, each of which has a porous structure. It is used for insulating facades, attics, and outbuildings.

Advantages

Does not accumulate moisture, easy to install. During the cutting process there is no dust that irritates the skin and respiratory tract.

Flaws

Able to support combustion, melts at high temperatures. Does not allow steam to pass through, so condensation may appear on the surface.

What is insulated with foam plastic

Extruded polystyrene foam is used to insulate the façade if necessary, to protect the interior or supporting frame from the influence of moisture.

Mineral wool

The best insulation is mineral thermal insulation based on fiber from volcanic rocks. It does not burn, does not react with chemical compounds, and does not attract interest from rodents and insects.

Types of mineral wool

Mineral wool insulation is distinguished by the degree of density, the origin of the fiber, and the form of delivery. Two types of thermal insulation building materials - slab and roll - are used for different areas that require insulation.

Advantages

Fire safety, environmental friendliness, long service life.

Flaws

Can absorb moisture, accumulating it between the fibers. As a result, the quality of insulation decreases; also, in the case of installing roll-type cotton wool, the material can slide and cake under the weight of the accumulated moisture.

Where is it better to use mineral wool?

Mineral wool thermal insulation materials are used on facade walls (slabs) and for insulating gables. During installation, it is worth considering the need to lay a moisture and vapor barrier membrane.

The best manufacturers on the market

When choosing insulation, you should pay attention to materials from leading brands. Among the mineral wool manufacturers, Rockwool and Knauf stand out.

The Danish brand Rockwool is the main company producing mineral wool. Buyers note the complete absence of shedding and shrinkage, the ability to choose from a large number of sizes and packaging options. Rockwool mineral wool is considered the most environmentally friendly, it absorbs noise well, has a high level of fire safety, and is able to maintain its properties at the desired level for a long time. The Knauf company produces mineral wool based on basalt fibers and distributes the products into series depending on their purpose. Available options include products for roofing, roofing, balconies and entry doors.

The best manufacturers of expanded polystyrene and polystyrene foam are considered to be the companies TechnoNikol and URSA. URSA brand products are in great demand in Europe. The manufacturer has the ability to extrude the material, which is created using innovative technology. TechnoNikol operates in Russia and produces insulation materials that can compete with European analogues. Each plant of the company has a separate scientific laboratory, where new production technologies are created and previous ones are improved.

What is better to insulate with mineral wool, and what is PPS optimal for?

Here are a few basic jobs for which different insulation materials are suitable:

- Foundation. To insulate it, you should choose polystyrene foam. It does not absorb water, so it will become an excellent layer that can be in contact with wet ground for a long time. In addition, it will be protected from sunlight, and therefore will not collapse.

- Roofs are of unventilated type. Mineral wool requires ventilation, so in this case it is better to lay polystyrene foam (the best option is PSBS). However, it is necessary to lay a layer of waterproofing on top of the foam.

- Rooms with elevated temperatures. In this case, it is better to give preference to mineral wool. It is also used to insulate chimneys and other objects exposed to extreme heat.

- House made of wood or brick. Everything is obvious here. There is no logic in making an environmentally friendly, “breathable” house and using foam plastic as insulation. If the house does not have many floors and is built of brick, then preference should also be given to mineral wool. It is also suitable for reinforced concrete, sandwich panels and other types of materials. But if the panels are in a metal casing, then you should not use slag wool. It oxidizes.

For floors and ceilings, both materials can be used. However, if you plan to fill the floors with concrete, then you can lay insulation, polystyrene foam boards and fill everything with cement. But if you need not only heat, but also good sound insulation, then it is better to use basalt wool. It has the highest noise reduction rates.

Thus, although mineral wool has a lot of significant advantages, it cannot be said that it is the only one to choose. Modern polystyrene foam is lighter; in addition, it is made using new technologies, thanks to which it lasts longer and can even withstand fire for some time.

Optimal use of each type of thermal insulation

Depending on the purpose and design features, certain thermal insulation options are appropriate. For example, in low-rise brick houses, as well as in three-layer concrete panels, it is better to use mineral stone wool as the middle thermal insulation layer

We advise you to study - Interior design in the English style - the basics and rules of design

The insulator will also be appropriate for thermal insulation in wooden houses, where it is important to use “breathable” materials. In addition, you can save heat using mineral wool:

- in attics and pitched roofs;

- in attics and ceilings;

- in rooms with very hot appliances and a risk of fire;

- in pipeline systems and heating mains;

- frame buildings of any type.

Expanded polystyrene boards are used for insulation and sound insulation:

- in brick and block structures to eliminate the risk of dew point;

- foundations and underground engineering structures in contact with wet soil;

- horizontal part of foundations with a layer of waterproofing under operating conditions at low temperatures;

- floor coverings and areas between floors with concrete screed;

- non-ventilated roofs with a layer of waterproofing;

- freezers, isothermal vans and refrigerators.

Having studied the characteristics of expanded polystyrene and mineral stone wool as insulation materials, certain conclusions can be drawn. In terms of thermal conductivity, foam plastic is definitely better in all respects, while only stone wool can compete for the title of material that removes moisture and steam. However, in a humid environment, foam plastic retains functionality better than mineral wool, although it is not able to remove moisture outside.

In terms of fire safety, both materials are dangerous, while polystyrene foam as insulation is always a risk of ignition, while mineral heat insulators burn and melt only at the highest temperatures and the inclusion of additional synthetic components. High-quality basalt wool with the most natural composition can withstand temperatures up to 1000 degrees Celsius.

Mineral wool weighs more than polystyrene foam, so it is more difficult to install. Expanded polystyrene is lighter, more convenient to cut and simply attached to the surface. The disadvantage of the latter is the joints and possible cold bridges, which are excluded when choosing mineral wool.

One way or another, you need to choose expanded polystyrene or stone mineral wool for insulation from trusted manufacturers, taking into account the purpose of the structure. High-quality foam plastic is slabs with uniform polyhedrons securely fixed to each other, while low-quality insulation is easy to distinguish by the balls interlocking with each other.

Mineral insulation materials must have relatively high densities and a special arrangement of fibers that eliminates increased looseness of the material, which indicates a low level of quality.

What is better: mineral wool or polystyrene foam - differences and best areas of application

What is desirable to insulate with foam plastic

The material is distinguished by its ability not to lose its properties in high environmental humidity.

- Polystyrene foam is very convenient for insulating retail outlets, bathhouses, gazebos and other structures that fall under the definition of “small architectural forms.”

- Expanded polystyrene boards are an ideal solution for insulating loggias and balconies.

- Insulation of utility buildings, production workshops and premises can also be done using polystyrene foam.

- Interfloor ceilings, floors, and the roof in use are insulated with high-density material. Waterproofing is placed under it and concrete is poured on top.

- The outside of the house is effectively insulated with foam plastic. It is more convenient to work with brick and block walls.

- Cold roof and forced-ventilated residential attic.

- The foundation of any house and the floor of the first level in a house without a basement.

Differences between mineral wool and polystyrene foam

Foam plastic is more often used for external work, mineral wool - for internal

It is necessary to select polystyrene foam or standard mineral wool taking into account the requirements and technological criteria of the building that needs to be insulated. Mineral wool belongs to a number of roll insulation materials; polystyrene foam is produced in the form of convenient slabs. The most important parameter is the coefficient of thermal conductivity: for mineral wool it is 0.039 W, for foam plastic it is 0.038 W. Despite the slight difference, the thermal capacity of each material differs significantly, because of this, foam is more suitable for external insulation, while mineral wool is ideal for internal installation.

The safety of the material is of great importance; this indicator can be determined by the level of vapor barrier. The foam has a dense structure and almost does not allow water to pass through; for this reason, the convection process between the surface and the insulation does not start. Condensation accumulates inside, leading to the destruction of walls if the dew point shifts. Mineral wool has a higher level of convection and allows air to pass through well, which eliminates the stagnation of moisture inside the insulated surfaces.

When installing, foam plastic has more advantages, since its plates fit very tightly to each other. If you additionally putty the seams, a layer of monolith is created that prevents the penetration of cold air. Mineral wool is capable of losing its shape, for this reason the areas in the places where the elements are connected become separated, losing heat. All mineral wool slabs are laid as closely as possible towards each other and secured well.

What is insulated with mineral wool?

Mineral wool has its own characteristics, which must be taken into account during its installation:

- This material is most often used for insulating wooden houses. This is due to the fact that wood walls need to “breathe”. Polystyrene foam is not suitable for insulation in this case. In this case, the beneficial properties of the tree will be reduced to nothing. If the façade is insulated, it must be of the hinged ventilated type. Such walls must have a vapor barrier membrane.

- Mineral wool is used to insulate attic spaces.

- Basalt wool is used in three-layer concrete panels.

- Since mineral wool can easily withstand high temperatures, it is used to protect a room from heated objects.

- It is better to insulate any frame buildings with mineral wool. In addition to thermal insulation, it well insulates rooms from external noise.

- This material is often used to wrap heat pipes.

These features of using mineral wool should be taken into account before starting insulation. Now, knowing the features of popular insulation materials, it is much easier to figure out which is better - polystyrene foam or mineral wool.

Scope of application of mineral wool

When working with mineral wool, you need to remember to leave the necessary ventilation gaps and use a vapor barrier film.

- Mineral wool is the best insulation in any frame structure. It is also used for sound insulation.

- Attic and attic spaces, pitched roofs, house floors.

- For “breathable” façade walls, you don’t have to think about what insulation to use. Insulated with mineral wool, they retain their properties.

- They insulate and soundproof partitions in rooms and offices.

- Fire protection of cable passages, air ducts, load-bearing columns.

- Floors with joists.

The answer to the question of what is better for insulation, polystyrene foam or mineral wool, depends on many factors. And for each element of the house structure it will be individual. The main thing is to weigh all the pros and cons of materials in order to make the right choice.

To summarize: so which is better to choose?

Expanded polystyrene or mineral wool, which is better? In order to make the right choice, you need to take into account the following nuances and criteria:

- financial component: remember that most subtypes of mineral wool are more expensive than expanded polystyrene (with the exception of expensive brands of extruded type of material);

- type of room and its features, such as: humidity level, wall construction material, need for sound and vapor insulation, and others;

- design characteristics (presence of irregularly shaped elements, communications that need insulation);

- purpose of the premises (residential building or, for example, outbuildings in the form of a garage, bathhouse, basement, etc.).

In other respects, both materials are equally suitable for insulation. After all, it is worth remembering that they are similar in many ways, so the choice, by and large, depends on the consumer.

Main characteristics of insulation

In its structure, mineral wool consists of small fibers, they are obtained as a result of heating rocks to a high temperature, and its characteristics are noticeably superior to the previously widespread glass wool.

Appearance of insulation

Penoplex is an improved foam plastic; it has more positive qualities, but is also more expensive. These insulation materials differ in composition and production technology.

- Thermal insulation properties. Mineral wool has a coefficient of 0.032-0.046; penoplex has a coefficient of 0.03-0.032. Heat loss is lower with a lower rate, so the heat inside the room is better retained;

- Life time. Penoplex is a material with increased strength, it crumbles poorly, practically does not dry and does not rot. The insulation does not lose its qualities when properly stored - in a cool room, protected from sunlight. Mineral wool also does not dry out, in the absence of physical activity it can be used for a long time, it is not afraid of heat and low temperatures, and is not afraid of sunlight. Bacteria and mold cannot grow in this material. But without proper fastening, mineral wool settles, crumbles and slides down the wall. Both heat insulators can last at least 50 years;

- Ecological properties. Both insulation materials are produced without using toxic materials that can harm humans. But they need to be installed, creating a barrier to prevent small particles from getting into the air;

- Ease of installation. When insulating with penoplex, it is easier to create a very flat surface. It is easy to process and sand, and the L-shaped edge eliminates cold bridges. It is not necessary to install a vapor barrier for it; if there is no tongue-and-groove edge, you will have to lay the material in 2 overlapping layers or seal the seams. Mineral wool weighs a little more, but retains heat much better, makes installation work easier, and is easier to install on disproportionate structures. But the job requires protective clothing;

- Insulation. When thermally insulating the facade of a house, you need a layer of penoplex with a thickness of at least 50 mm, while the layer of mineral wool must be at least 60 mm;

- Moisture absorption. Penoplex absorbs little moisture, and mineral wool can become completely saturated, losing some of its properties. Penoplex is much better, especially in regions where it often rains;

- Fire resistance. Mineral wool perfectly withstands high temperatures and does not burn. Can only melt at temperatures exceeding 1000 degrees. It contains a small amount of adhesive base that can catch fire, but it is very small. Penoplex melts and burns;

- Price. The costs of purchasing both insulation materials are almost the same. There is a slight difference only when choosing a manufacturer.

Easy installation

It is desirable that the installation is simple - then you can do it yourself. It will also take less time.

Mineral wool is easy to install; even a beginner can handle this task. The material lends itself well to cutting and is easy to install on the facade. The only caveat is that you must follow safety precautions. To prevent cotton wool fibers from getting on your skin, hair, or eyes, use a mask, gloves, or a protective suit. Do not inhale mineral wool dust.

From a technical point of view, no special skills are required to install polystyrene foam. But it must be carefully cut (the edges of the material may crumble) and installed. When installing foam sheets on the wall, we do not recommend pressing on them - they may break.

Conclusion: Both materials are easy to install, but foam usually requires more careful handling.