When purchasing a gas boiler for your own home, we pay attention to two main indicators: the price of the equipment and its power. For some reason, many of us do not look at a very important point - efficiency. But it is precisely this coefficient that indicates how economically the boiler you purchased will operate. The manufacturer sets a maximum value in the passport, which is determined by the correct and competent operation of the device. But in life this rarely happens, hence not only heat loss, but also loss of money from your wallet. Therefore, the question of how to increase the efficiency of a gas boiler is currently of concern to many consumers.

Let's begin to answer the question posed by noting that the efficiency of a gas boiler depends on many indicators.

- The amount of thermal energy that is transferred from the burned fuel to the coolant. This is the basis of efficiency.

- Next comes heat loss. The fewer there are, the better. The bulk of heat loss occurs due to improper combustion of fuel, in this case natural gas. There are two types of underburning: chemical and mechanical.

- And the last type of heat loss, which depends on the uneven distribution of the released thermal energy.

It turns out that by reducing heat loss, you can increase the efficiency to that declared by the manufacturer. In the case of gas heating equipment, we will be interested in only two types of heat losses - chemical and mechanical.

Competent equipment maintenance

How to increase the efficiency (efficiency) of a solid fuel boiler

Solid fuel boilers (hereinafter referred to as STN) have a sufficient percentage of efficiency compared to other heating units (gas boilers, for example) to be competitive and lead the market.

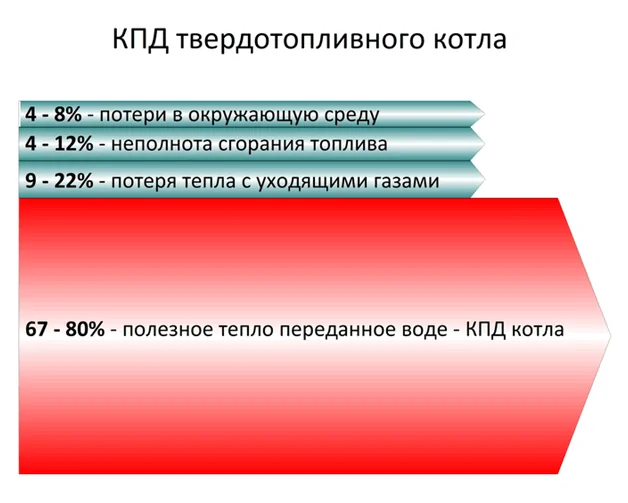

The latest THP models are equipped with the latest automation systems to optimize operation. Solid fuel boilers operate on the principle of stove heating: heat is transferred to the coolant (water) by generating energy during the combustion of coal, wood, pellets in the firebox. Each boiler has its own coefficient of performance or efficiency and depends on many conditions: choice of fuel, operating rules, quality of installation, etc. Let's take a closer look at what the efficiency of heating devices is, and how to increase this coefficient for solid fuel boilers.

What is efficiency - coefficient of performance

To correctly select the boiler power relative to the square footage of the room to be heated, we recommend paying attention to the efficiency of the unit, its efficiency, especially when it comes to solid fuel boiler houses. The coefficient of performance or efficiency is an indicator that is calculated based on the ratio between the energy expended (thermal - when burning products in the firebox) and useful heat - which enters the heating system for transfer to the room

After calculating a simple formula, we get the efficiency percentage

The coefficient of performance or efficiency is an indicator that is calculated based on the ratio between the energy expended (thermal - when burning products in the firebox) and the useful heat - which enters the heating system for transfer to the room. After calculating a simple formula, we get the efficiency percentage.

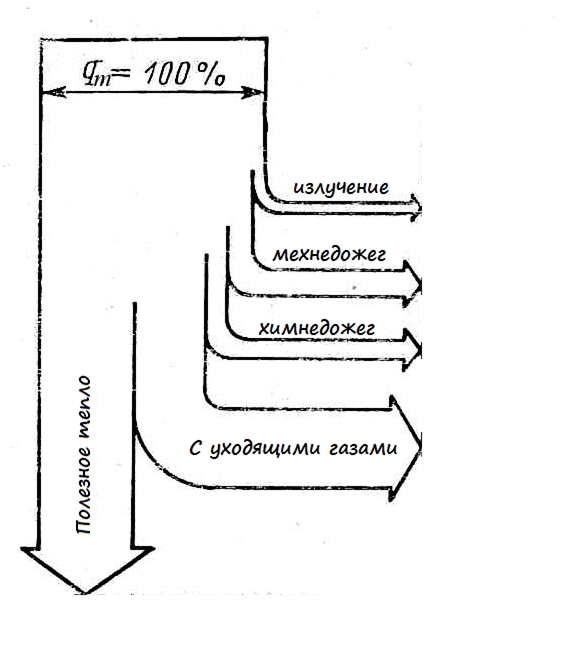

q1 + q2 + q3 + q4 + q5 = 100%

Let's decipher:

q1 is an indicator of the heat that was transferred to the coolant - water.

q2 – physical underburning – heat loss with exhaust gases.

q3 – chemical undercombustion – heat loss due to incomplete combustion of fuel.

q4 – heat loss during heat dissipation.

The efficiency percentage increases when the boiler operates optimized.

The key point that affects the efficiency indicator is how well the solid fuel boiler is installed. In addition, the choice of fuel (coal, firewood, pellets), the presence of ventilation, and operating conditions are taken into account.

Let's look at it with an example.

If the passport of the purchased boiler indicates an efficiency of 90%, it should be taken into account that this is an indicator that can be achieved if the unit operates in nominal mode and burns high-quality fuel with a low ash content. Under other factors during operation, the efficiency of a solid fuel boiler may decrease to 60% or 70%.

How can we get closer to the ideal and extract maximum heat when operating a heat pump?

How to increase the efficiency of a solid fuel boiler

Let's look at some recommendations on how to make a solid fuel boiler work at its maximum, work economically, consuming a minimum of firewood, coal or pellets.

- Load only dried fuel into the fuel pump. If you burn wet wood or coal, some of the energy will be spent drying it.

- Do not use fuel with large amounts of debris, impurities, or dust, because these inclusions will quickly clog both the heat exchange channels of the boiler, as well as the grate and chimney.

- Solid fuel boilers require mandatory periodic cleaning of the chimney and internal surfaces of the boiler, because any fuel pump becomes clogged much more than another gas boiler.

- Ensure proper draft in the chimney channel: it should not be too strong, but not too weak. If we exclude the moment of correct design of the chimney, then for this there is a throttle valve on the chimney or on the heat pump, which regulates the air draft in the chimney - it should be set to the correct value. In order to load a solid fuel boiler once or twice a day and ensure efficient heating operation in general, it is imperative to design a buffer tank (heat accumulator).

- Buy a solid fuel boiler only with a blower fan, which can accurately regulate the combustion process in the boiler and control the temperature of the flue gases.

We will select equipment, design and install a solid fuel boiler room for your premises in order to save heat and money as much as possible. To consult about the installation of a solid fuel boiler and the cost of heating installation, call tel. or or Book a consultation! We are always in touch!

Which tanks should you prefer?

Many are sure that it is better to use imbricated tanks, which have excellent characteristics. At different periods of the game, such machines were different, but soon the authors themselves nerfed them. Therefore, give preference to the tanks that you like best. Even if he doesn’t bend, you still enjoy the fight.

Every owner of a country house, garage or utility room knows what a potbelly stove is. This stove appeared a long time ago, but is still in demand to this day. Decades ago it was even used to heat food; now it is a source of heat for different rooms. You can assemble such a stove yourself using improvised materials that are not a problem to find in the garage or even on the street.

Owners of garages or small houses choose this type of heating because they have significant advantages over other types of stoves. For example, if you have a small area, it will either not be possible to install a stove, or it will simply not be rational, but you want the room to be warm all year round. Therefore, installing some kind of heating device is simply necessary.

In the case of using a potbelly stove, a problem may arise that an increase in efficiency will be required. And for this you do not need to resort to the help of specialists; such work can be done with your own hands. Let's look at what you need for this.

Each device has its pros and cons during use. In the case of a potbelly stove, we highlight the following positive aspects:

- The design of the furnace is simple and does not require large financial expenditures. Everything you need to make a stove with your own hands can be easily found in the utility room.

- If necessary, the potbelly stove can be easily transported to another house or garage. Its weight usually does not exceed 30 kilograms and its small dimensions will only be a plus.

- The stove can be quickly heated regardless of weather conditions.

- In fact, almost anyone can heat a potbelly stove. That is, it can be coals, sawdust, firewood branches, or even household garbage.

As for the negative characteristics, we highlight the main ones:

- The heated surface area is quite small, and therefore a small amount of heat enters the room.

- The room, even after using the stove for a long time, cools down quickly.

Taking into account such shortcomings, we are talking about a low efficiency, that is, the level of efficiency of the stove.

To organize heating systems for a private home, owners often use gas boilers. This is due to their good performance, a wide range of equipment, and the low cost of the fuel itself. Gas-powered devices are reliable, durable, and easy to operate.

The issue of heating is especially relevant in the winter season. Problems in the functioning of heating equipment affect not only the comfort, but also the health of the residents of the house. The design of a heating system is carried out even at the stage of construction or repair work. It is at this time that the issue of choosing a boiler is decided. The main parameter that is relied on when purchasing equipment is its power. The quality of functioning of the heating system depends on it.

Checking the efficiency of a gas boiler

Over time, gas boilers can reduce their power, which is due to wear of parts, non-compliance with operating rules, and inadequate maintenance. If you do not plan to purchase new heating equipment in the near future, you should look for ways to improve the operation of your gas boiler.

We increase the efficiency of a gas boiler

When purchasing a gas boiler for your own home, we pay attention to two main indicators: the price of the equipment and its power. For some reason, many of us do not look at a very important point - coefficient of performance (efficiency)

But it is precisely this coefficient that indicates how economically the boiler you purchased will operate. The manufacturer sets a maximum value in the passport, which is determined by the correct and competent operation of the device. But in life this rarely happens, hence not only heat loss, but also loss of money from your wallet. Therefore, the question of how to increase the efficiency of a gas boiler is currently of concern to many consumers.

By reducing heat loss, you can increase the efficiency to that stated by the manufacturer. In the case of gas heating equipment, we will be interested in only two types of heat losses - chemical and mechanical.

Below we will consider the types of heat loss, as well as ways to increase the efficiency of a gas boiler.

Main types of heat loss

Let's start with the mechanical one. In essence, this is the scheme. During gas combustion, oxygen must be supplied to the furnace. For this purpose, a small chamber with a door is installed in the design of the gas boiler itself. They call it a blower. By slightly opening or closing the damper door, we let fresh air enriched with oxygen into the combustion chamber.

If you open the damper more than the required setting, the gas will not burn completely. A draft forms inside the firebox, drawing out some of the unburnt gas along with the combustion products. Accordingly, less thermal energy will be released. This is a minus, it is a drop in the efficiency of the gas boiler.

Chemical heat loss, on the contrary, is a large lack of oxygen in the combustion chamber. That is, the damper is closed too much. Without oxygen, the gas will not burn completely and again, along with combustion products, will fly out into the chimney. In this case, the drop in efficiency will be the largest, up to 7%.

Ways to increase the efficiency of a gas boiler

You can actually create the correct operating conditions for a gas boiler and thereby increase the efficiency without calling a specialist, that is, with your own hands. What do I need to do?

- Adjust the blower damper. This can be done experimentally by finding at what position the coolant temperature will be highest. Carry out control using a thermometer installed in the boiler body.

- Be sure to ensure that the heating system pipes do not become overgrown from the inside, so that scale and dirt deposits do not form on them. Today it has become easier with plastic pipes, their quality is known. Still, experts recommend periodically purging the heating system.

- Monitor the quality of the chimney. Do not allow it to become clogged or soot to stick to the walls. All this leads to a narrowing of the cross-section of the outlet pipe and a decrease in the boiler draft.

- A prerequisite is cleaning the combustion chamber. Of course, gas does not smoke much like wood or coal, but it is worth washing the firebox at least once every three years to clear it of soot.

- Experts recommend reducing chimney draft during the coldest time of the year. To do this, you can use a special device - a draft limiter. It is installed at the very top edge of the chimney and regulates the cross-section of the pipe itself.

- Reduce chemical heat losses. There are two options here to achieve the optimal value: install a draft limiter (this has already been mentioned above) and immediately after installing the gas boiler, carry out proper adjustment of the equipment. We recommend entrusting this to a specialist.

- You can install a turbulator. These are special plates that are installed between the firebox and the heat exchanger. They increase the area where thermal energy is collected.

These are the reasons, by eliminating which you can count on increasing the efficiency of boiler equipment. Of course, there are many such reasons, but these are considered the main ones that answer the question: how to increase the efficiency of a gas boiler.

Ways to increase efficiency

In order for the heating system to operate with minimal heat loss, you should familiarize yourself with effective ways to improve the efficiency of a gas boiler

. To do this, it is necessary to eliminate as much as possible all types of heat loss.

- To reduce the percentage of physical underburning, you should monitor the condition and cleanliness of the flame tubes and water circuit. Soot forms on the pipeline, and scale forms on the circuit, so these elements of the heating system require regular cleaning.

- There should be no excess air in a gas boiler, since heat that could be used to heat the coolant also goes into the chimney with it. This problem can be solved by installing a draft limiter on the chimney pipe.

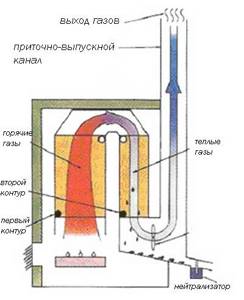

How gases circulate in the boiler

Adjusting the blower damper. This can be done using a thermometer installed in the boiler. You just need to put the damper in such a position that the maximum coolant temperature is achieved. Make sure that normal traction is maintained. It decreases as a result of the narrowing of the chimney cross-section. This can be avoided if you regularly clean the outlet pipe, because soot sticks to its walls. It is necessary to regularly clean the combustion chamber, as soot forms on the surface of its walls, which increases fuel consumption.

Installation of a coaxial chimney

If you are looking for options on how to increase the efficiency of a gas boiler, pay attention to what kind of chimney is installed. Traditional outlet pipes have a number of disadvantages, the main one of which is dependence on weather conditions

An alternative to a conventional chimney can be a coaxial chimney, which has the following advantages:

- significantly increases the efficiency of a gas boiler;

- resistant to high temperatures;

- can be made in different versions;

- allows you to save fuel;

- ensures long-term maintenance of room temperature.

The installation of a coaxial chimney does not require much effort. The design consists of two exhaust pipes of different diameters, one transports exhaust gases, and the other carries oxygen-saturated air.

If you have no experience working with heating equipment, but there is a need to resolve the issue of how to improve the efficiency of a gas boiler, contact a specialist. They will perform the work at the highest level, ensuring the most efficient functioning of your home's heating system.

The efficiency coefficient indicates the thermal efficiency of the heating boiler. This is one of the most important indicators of equipment, allowing you to predict how much fuel will be required to heat the room. The efficiency of a gas heating boiler is necessarily indicated by the manufacturer in the technical data sheet, so the buyer has the opportunity to choose the optimal model. Let's consider methods for calculating efficiency, features of choosing equipment based on the efficiency indicator.

What does boiler efficiency depend on?

To find a solution to how to increase the efficiency of a gas boiler, you should first become familiar with what parameters this coefficient depends on. Technical documents indicate a fairly high efficiency index, but the real percentage is almost always far from enough. The main parameters that affect the efficiency of a gas boiler:

- whether the type of fuel burned corresponds to the furnace where it is burned;

- what is the technical condition of the heating equipment;

- load on the heating system;

- how well the heating system in a private house is organized;

- quality of gas used for heating the house.

There are other parameters that affect the efficiency of a gas boiler. In order for the heating system to function most efficiently, all criteria on which the boiler efficiency depends should be taken into account.

How to calculate power

Before purchasing heating equipment for servicing a private home, it is necessary to calculate the power that would be enough to maintain high-quality operation of the boiler. If you do not have sufficient experience and knowledge, seek help from professionals, as mistakes at this stage will certainly affect the performance and durability of the equipment.

When calculating the power of a gas boiler, the following parameters should be taken into account:

- average temperature in the winter months in a given area;

- what materials the house is built from;

- what materials were used to insulate the house, and whether they were used at all;

- living area of the house.

You can use special formulas to calculate the power of heating equipment for a private home.

Safety measures for increasing efficiency

Just 20-30 years ago, the price of energy resources in the post-Soviet space was low, so no one paid attention to such a parameter as efficiency. After all, performance could decide everything

But when gas began to rise in price, and modern technologies were still unavailable, craftsmen began to modernize gas boilers in order to increase efficiency, using accessible methods.

When performing any work with gas equipment, it is necessary to observe safety measures and possess special skills and tools. And also you should not use methods prohibited by law to increase efficiency.

For example, attaching copper and aluminum plates to heat exchangers to improve heat transfer. Heat loss from structural elements of heating devices was reduced by welding third-party elements. The automation and heat exchangers were changed. Other similar methods were also used. Efficiency increased, but the state and the gas service did not react to the “creativity” of the craftsmen.

Now everything is different and relevant laws prohibit changing the design of gas boilers, which must be certified, like all their individual elements. As a result, it is impossible to increase efficiency by replacing mechanical, electrical and other components of heating devices with third-party ones.

Violation of these requirements may result in:

- Administrative responsibility. If Gorgaz employees detect tampering with the boiler design, but there were no incidents, they will have to pay a fine of 10-15 thousand rubles. This is indicated by Article 7.19 of the Administrative Code. In severe cases, the gas service has the right to even terminate the service contract and stop supplying fuel.

- Criminal liability. As evidenced by Federal Law No. 229-FZ of July 29, 2018 “On amendments to Article 215.3 of the Criminal Code of the Russian Federation and Articles 150 and 151 of the Code of Criminal Procedure of the Russian Federation.” These standards will come into force if design changes lead to serious consequences.

That is, it’s not worth risking people’s lives to increase the efficiency of the boiler by a few percent.

Conclusions and useful video on the topic

The first video will help you understand how to clean the boiler heat exchanger, which will help to significantly increase its efficiency.

The following video will give you an opportunity to understand how to clean a gas burner in order to increase the efficiency of the boiler.

Experience shows that maximum efficiency from a boiler can be achieved with its systematic maintenance with timely cleaning of burners and heat exchanger from combustion products and dirt. And also with proper placement and use of radiators. In addition, only modern high-tech equipment can be highly efficient.

Have you noticed a discrepancy or want to supplement our material with useful recommendations for increasing the efficiency of the boiler? Leave your comments, participate in the discussion and ask your questions to our experts - the feedback form is located below.

Step-by-step instructions for building a solid fuel boiler

So, the whole process of how to make a boiler with your own hands according to the drawings can be divided into several successive stages:

- Using a grinder, you need to cut blanks from pipes and profiles. The profiles will be racks; you need to cut round holes in them with a gas cutter for joining with the pipes. You will need to make 4 holes along the Ø50 mm pipe in the front pillars and the same number in the rear ones. In addition, we also need holes for inserting into the heating system. Sagging and deposits as a result of cutting or welding must be cleaned with a grinder so that they do not interfere with the movement of water through the pipes.

- Next, the blanks are assembled into a single structure. Two people will have to work - the welder will need an assistant to hold the tubes in a stationary position. To make it more convenient, you can place the racks with pipes on a flat surface and weld the front and back parts of the boiler.

- Now you need to ensure the supply and drainage of water from the boiler. The incoming and return pipes are welded to the finished frame, and the ends of the rectangular profiles are welded with pieces of metal 60x40 mm.

- Before installing the heat exchanger, it is checked for leaks. To do this, install it vertically, close the bottom hole and fill it with water. If there are no leaks at the seams, then you can continue working.

- The boiler body is built from brick and a heat exchanger is built into it, leaving a gap of at least 1 cm between them. The register must be installed in such a way as to create a rise towards the exiting hot water. The level difference between the outlet and the front right upper corner of the heat exchanger must be at least 1 cm. This will improve coolant circulation and eliminate air pockets.

- The brickwork should overlap the heat exchanger from above by 3-4 cm. A cast-iron slab is laid on top of the masonry. The chimney is installed at the discretion of the owners - brick, metal, or led into a ready-made pipe.

Manufacturing features and choice of materials

In addition to knowledge, skills, drawings and diagrams, for the manufacture of heating equipment you need to stock up on materials and tools. What is needed to make equipment?

Materials and tools for making equipment

Materials:

- Heat-resistant steel plates 4-5 mm thick to create a firebox.

- Steel sheets 2-3 mm thick for making the body.

- Steel pipes for the heat exchanger, the length and diameter of which are calculated individually.

- Metal pipes for the chimney.

- Arched slab and grate.

- Ash pan combustion chamber door.

- Heat-resistant brick.

- Cement solution.

Tools

- Welding equipment with a supply of electrodes.

- Device for gas cutting.

- Grinder with discs.

- Pipe bending machine.

- Level, tape measure, marker.

Recommendations for the manufacture of equipment

Homemade boilers for heating a private home are usually made of metal. It is almost impossible to make a cast iron firebox at home; buying a new one will be expensive. Many homeowners order them from craftsmen who specialize in the manufacture of heating equipment. In order not to encounter defects in the heating operation in the future, it is recommended to take part in the process. The purchase of materials and components, assembly of the heating boiler, installation and testing of the finished device must take place in your presence.

Since the combustion chamber of a solid fuel device has a very high temperature, it is made of expensive alloyed heat-resistant steel (stainless steel) 5 mm thick. In order to save money and simplify welding work, ordinary thick sheets of steel are often used instead of stainless steel. Such products are short-lived, and steel walls can become deformed due to temperature changes.

A reliable and efficient homemade solid fuel installation will cost less than a factory one

The water jacket is made of ordinary metal St 20 3 mm thick. This steel is used in the production of pipes for hot water and steam. Therefore, smoke pipes with a diameter of 48–76 made of the same grade of steel are suitable for the heat exchanger. The design of the shirt should be as rigid as possible. This quality is ensured by welding stiffening ribs to the outer walls of the firebox in increments of 120-150 mm. The outer walls of the tank are also welded to the ribs.

The doors of the blower and firebox must be double-layered. Between the metal layers it is necessary to insert a thermal insulation layer of asbestos, basalt fiber or a combination of both. The same materials can be used to insulate the body. The hinges on the doors are made adjustable, and the recesses are sealed with asbestos cord. To avoid burning your hands, the locking handles are equipped with ebonite or textolite nozzles.

Main stages of boiler installation

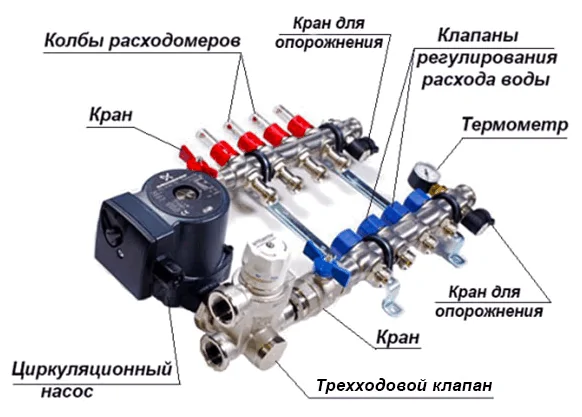

In order to install a heating system based on the use of a solid fuel boiler, you will need the heating unit itself, pipes and heating radiators, an expansion tank, a circulation pump, a heat accumulator, and components of the automatic boiler control system.

The latter include:

- safety valve;

- air valve;

- pressure gauge;

- Temperature regulator.

All manipulations associated with the installation of a solid fuel boiler and the connection of peripheral systems and devices are carried out in accordance with a strict step-by-step algorithm. So, on the eve of installing the boiler, a specialized foundation is erected at the site of its planned location.

In this case, it is imperative to maintain all the required dimensions of the indents and correctly position the body of the heating unit both vertically and horizontally.

Next, electric heating elements are installed if they are included in the boiler package. As a rule, solid fuel boilers are equipped with mounts for mounting heating elements, next to which a temperature regulator is installed.

The next stage involves installation and connection of heating system pipes

It is important to close all connections using intermediate shut-off valves, and seal the butt joints with plumbing tape or material consisting of flax fibers. This will make it easier to access for future repairs.

Installation of thermal communications is done so that during operation of the heating system it is possible to easily carry out maintenance and repair work

In the case when the heating system involves the use of connections to the home’s electrical network, at this stage it is necessary to make all the necessary wire connections, their insulation and grounding.

Next, the security group is installed. Its configuration depends on the model of the solid fuel boiler, but, as a rule, it consists of: a safety valve, an air valve, a temperature regulator, a draft sensor, a pressure gauge and other devices. All these devices are installed before all locking devices.

The next step will be the installation of the chimney pipe. At the junction points of the smoke exhaust system elements, sealing is carried out with a sealing substance that is resistant to high temperatures.

The installation method, the height of the chimney duct, as well as the cross-sectional area are calculated in such a way as to further ensure the process of natural draft at the proper level. And to do this, you must strictly follow all the instructions in the operating instructions for the boiler model being installed.

Next, the thermal circuit of the solid fuel boiler is filled with water. At first, the water pressure level should be slightly higher than the working one. This stage involves testing the system for leaks.

Then you need to check all the internal elements of the solid fuel boiler firebox: plugs for cleaning, ignition valve, fireclay stones, grate bars, etc.

And finally, you should release the pressure in the boiler to operating values, put the dampers in the firebox and in the chimney in the position prescribed in the instructions, and put solid fuel into the boiler.

Having completed all the above manipulations, you can proceed to starting the heating system based on the use of a solid fuel boiler

To start the heating process, simply load fuel into the boiler and set it on fire. Then, after 10-15 minutes, you need to tightly close the kindling damper.

After the temperature is established at 80-85 degrees, you will need to set the temperature controller to the desired heat supply mode. Subsequently, you will simply need to supply the boiler with solid fuel if necessary.

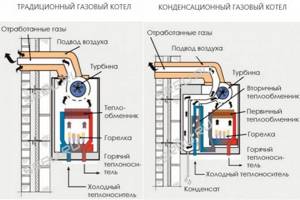

Heat loss when removing flammable gases

When natural gas burns, it releases carbon, carbon dioxide and water vapor. In boilers with a conventional heat exchanger, this entire cocktail is removed to the outside almost immediately after formation. But modern manufacturers offer condensing boilers that allow you to use the heat of combustion products to the maximum. Inside such a heat exchanger, water vapor condenses and releases energy. Cooled moisture must be periodically drained and disposed of in a special way, since it contains acid.

Typically, the declared efficiency of condensing boilers exceeds 100%, which seems incredible from a physics point of view. To understand this issue, it is necessary to distinguish between two concepts:

NUTS (lower specific heat of combustion) - energy obtained from fuel when all combustion products are released into the external environment;

VUTS (highest specific heat of combustion) is the amount of energy that takes into account the potential of water vapor.

In the regulatory documentation, all calculations are carried out using NUTS. If we take into account the energy of water vapor used, but calculate based on the lower specific heat of combustion, we get figures that exceed 100%. In general, the difference between NUTS and VUTS is approximately 11% - this is the maximum difference in the efficiency of boilers with different heat exchangers.

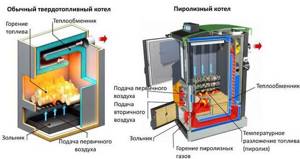

Boilers with pyrolysis combustion type

Pyrolysis boilers also use solid fuel, in particular firewood, however, the principle of their operation is fundamentally different from the installations described above. They are able to heat a house much longer and more efficiently, and use fuel more economically. In this regard, the cost of such units is approximately 1.5-2 times more than others.

The secret of gas generator (pyrolysis) boilers is that under the influence of high temperature and lack of air, wood is converted into charcoal, releasing pyrolysis gas.

This reaction requires a temperature between 200℃ and 800℃. This releases a large amount of energy, which dries the wood and heats the air. Pyrolysis gas moves through pipes into the combustion chamber, where it ignites when mixed with air - this is how most of the heat is generated.

Active carbons participate in oxidative processes during the combustion of pyrolysis gas, so the smoke coming out of the chimney consists mainly of carbon dioxide and steam - the content of harmful components is negligible. In addition, pyrolysis boilers, in principle, emit much less smoke than classic installations. Since the fuel burns with virtually no residue, gas generator boilers require cleaning quite rarely.

Thanks to automation, the combustion intensity in such a boiler can be adjusted to save fuel and create an optimal temperature in the room.

Removal of combustion products

The latest savings methods introduced relate to this point. The logic of the solution - if at the exit from the chimney the temperature of the combustion products was 200-250 ° C, then why not use them to heat the coolant? To do this, additional heat exchangers made of steel or cast iron (with high heating inertia) are installed along the path of the exhaust gases.

Additionally, work is underway to extract heat from evaporated water obtained as a result of the combustion reaction - this is done by “condensing” boilers, which set records in terms of efficiency - the temperature of the emitted gases is about 50 ° C, and the amount of heat used for its intended purpose reaches 98%.

How to increase the efficiency of heating equipment running on solid fuels

Today, many consumers, having at their disposal a solid fuel boiler, are trying to find the most convenient and practical way to increase the efficiency of heating equipment. The technological parameters of heating devices set by the manufacturer lose their nominal values over time, so various methods and means are being sought to increase the efficiency of boiler equipment.

Let's consider one of the most effective options, installing an additional heat exchanger. The task of the new equipment is to remove thermal energy from volatile combustion products.

In the video you can see how to make your own economizer (heat exchanger)

To do this, we first need to know what the temperature of the smoke at the outlet is. You can change it using a multimeter, which is placed directly in the middle of the chimney. Data on how much additional heat can be obtained from evaporating combustion products is necessary to calculate the area of the additional heat exchanger. We do the following:

- we send a certain amount of firewood into the firebox;

- We measure how long it takes for a certain amount of firewood to burn.

For example: firewood, in the amount of 14.2 kg. burn for 3.5 hours. The smoke temperature at the boiler outlet is 460 C.

In 1 hour we burned: 14.2/3.5 = 4.05 kg. firewood

To calculate the amount of smoke, we use the generally accepted value of 1 kg. firewood = 5.7 kg. flue gases. Next, we multiply the amount of wood burned in one hour by the amount of smoke produced by burning 1 kg. firewood As a result: 4.05 x 5.7 = 23.08 kg. volatile combustion products. This figure will become the starting point for subsequent calculations of the amount of thermal energy that can be additionally used to heat the second heat exchanger.

Knowing the value of the heat capacity of volatile hot gases as 1.1 kJ/kg, we make a further calculation of the heat flow power if we want to reduce the smoke temperature from 460C to 160 degrees.

Q = 23.08 x 1.1 (460-160) = 8124 kJ thermal energy.

As a result, we obtain the exact value of the additional power provided by volatile combustion products: q = 8124/3600 = 2.25 kW, a large figure that can have a significant impact on increasing the efficiency of heating equipment. Knowing how much energy is wasted, the desire to equip the boiler with an additional heat exchanger is completely justified. Due to the influx of additional thermal energy for heating the coolant, not only the efficiency of the entire heating system increases, but also the efficiency of the heating unit itself increases.

What will lead to success?

First of all, this is a skill

. Only personal experience will help you win in the future.

In second place is top-end technology. Experienced gamers do not recommend using stock vehicles, since slow tanks that do not provide effective fire support are too boring

That is why it is important to improve tanks to the top with the help of free experience

An important factor is. Training and retraining are best done using gold.

In every battle, you should have gold shells with you, which are more effective at penetrating opponents. The more often this happens, the better the team's result.

How to increase boiler performance

A self-assembled solid fuel boiler, as a rule, is characterized by significant heat losses associated with the loss of heat into the chimney. Moreover, the straighter and higher the chimney, the more heat is lost. The way out in this case would be to create a so-called heating panel, that is, a curved chimney that allows more thermal energy to be transferred to the brickwork. The brick, in turn, will give off heat to the air in the room, heating it. Often such passages are arranged in the walls between rooms. However, this approach is only feasible if the boiler is located in the basement or on the ground floor, or if a bulky multi-stage chimney is built.

Alternatively, you can increase the efficiency of the boiler by installing a water heater around the chimney. In this case, the heat of the flue gases will heat the walls of the chimney and be transferred to the water. For these purposes, the chimney can be made from a thinner pipe, which is built into a pipe of a larger cross-section.

The most effective way to increase the efficiency of a solid fuel boiler is to install a circulation pump that forcibly pumps water. This will increase the productivity of the installation by approximately 20-30%.

Of course, the boiler must be designed so that the coolant can circulate independently if the electricity in the house is turned off. And if it is available, the pump will speed up the heating of the house to comfortable temperatures.

Heat exchange within the system

The burning gas heats a container of water (coolant), which in turn heats the radiators. The latter affects the efficiency of the boiler only by how quickly and without loss the energy is transferred to the coolant. The most successful form of heat exchanger for this is a cylindrical one, inside of which the same burner is located. The coolant moves around them in a spiral, guaranteed to have time to heat up to the required temperature.

The heat exchanger material varies - from steel to cast iron and depends on the boiler model, each of which is calculated differently.

The operating principle of a condensing boiler is shown in the video below:

Answer

How to increase boiler efficiency (efficiency factor)? It doesn’t matter which one: a pellet boiler, a diesel boiler or a gas one... It’s no secret that everyone who has bought a heating boiler for their household, as a rule, firmly believes in the efficiency of the boiler, which is indicated in the instruction manual for its operation, or in the instructions for the boiler

And there, as a rule, it costs 85%, 90%, 92% and even 95%. But few people know that when the boiler is operating, it extremely rarely reaches the efficiency specified in the manufacturer’s documents. Why? Let's figure it out.

So,

Removal of combustion products

The latest savings methods introduced relate to this point. The logic of the solution - if at the exit from the chimney the temperature of the combustion products was 200-250 ° C, then why not use them to heat the coolant? To do this, additional heat exchangers made of steel or cast iron (with high heating inertia) are installed along the path of the exhaust gases.

Additionally, work is underway to extract heat from evaporated water obtained as a result of the combustion reaction - this is done by “condensing” boilers, which set records in terms of efficiency - the temperature of the emitted gases is about 50 ° C, and the amount of heat used for its intended purpose reaches 98%.

Boiler efficiency depends on many parameters:

- does the type of firebox correspond to the fuel that is burned in it,

- on the technical condition of the boiler,

- on the load at which the boiler is operated,

- from organizing the fuel combustion process in the boiler,

- on fuel quality,

- etc. and so on.

You need to know that the balance of heat generated by a heating boiler consists of the following quantities:

q1 + q2 + q3 + q4 + q5 = 100%, where

- q1 - heat transferred to the coolant (usually water),

- q2 - heat loss with exhaust gases,

- q3 - heat loss from chemical incomplete combustion of fuel (chemical underburning),

- q4 - heat loss from mechanical incomplete combustion (mechanical underburning),

- q5 - losses to the environment due to heat dissipation.

And now the most interesting part:

Heat loss with exhaust gases (q2) is greater, the more excess air passes through the boiler furnace (air that does not take part in the fuel combustion process itself), as well as the higher the temperature of the exhaust gases. Heat loss with exhaust gases can reach ... 15-25%. Such losses are typical in the winter months, when the boiler operates at maximum. How to reduce these losses - read the next article.

Heat loss from chemical underburning (q3) is greater, the more carbon monoxide (carbon monoxide), which has a high calorific value, leaves the boiler through the chimney without being burned in the boiler. The most interesting thing is that chemical underburning is a consequence of insufficient air in the combustion chamber of the boiler. When carbon is incompletely burned, part of it forms carbon monoxide: 2C + O2 = 2CO. In this case, a significant (as I already wrote) heat loss occurs. Boiler efficiency losses from chemical underburning can reach 5-7%.

Heat losses from mechanical underburning (q4) are typical mainly for solid fuel boilers. They are formed as a result of the appearance of slag in the furnace, which melts and envelops the unburned fuel. The higher the ash content of the fuel and the fewer volatile substances it contains, the greater its mechanical underburning. In general, q4 can reach 1-3%.

Heat losses to the environment due to heat dissipation (q5) are losses that occur through the walls of the boiler, through its outer lining. They can reach 1-2%.

Types of heat loss

There are nominal and real efficiency. The real one is always less than the nominal one. This is also due to the fact that there are different types of heat loss. The following types of heat loss are distinguished:

- Physical underburning. The indicator depends on how much excess air, which does not take part in the formation of thermal energy, is present in the equipment during fuel combustion. Its value is also influenced by the temperature of the exhaust gases. In winter, during severe frosts, when the boiler is operating at full capacity, physical underburning can reach 20%.

Heat loss from gas heating and low efficiency

- Chemical underburning. The value of this criterion increases depending on the amount of carbon monoxide. Carbon does not burn in heating equipment and exits through the chimney, however, it has the ability to produce large amounts of thermal energy. Carbon monoxide is formed due to the combustion of carbon. Heat loss from chemical underburning ranges from 5-7%.

- Mechanical underburning is typical for solid fuel heating boilers. This is a loss of efficiency as a result of incomplete combustion of fuel and the formation of ash. The percentage is insignificant - only 1-3.

In addition, heat loss can occur through the walls of heating devices. In this case, the heat is dissipated directly into the environment through the outer lining of the heating device.

So what is the real efficiency of the boiler?

Thus, if the passport of your boiler indicates an efficiency of 90%. You need to understand that this is the efficiency that can be achieved if the boiler operates in nominal mode and burns good fuel with low ash content. If we take into account other factors that the boiler owner encounters during its operation, then the real efficiency of the boiler can decrease to 65-70% (!!!)

How to get as close as possible to the rated efficiency?

There are small tricks that you need to know and which we will talk about in the next article, which won’t keep you waiting long.

Installing radiators for maximum efficiency

Radiators are installed in areas where heat loss in the room is most significant, for example, next to windows. To achieve maximum efficiency, the window sill should cover about 2/3 of the upper plane of the battery and be approximately 10 cm from its surface. The recommended distance between the radiator and the floor is 12 cm. The rear surface of the battery should be separated from the wall by 2 cm. This will create proper natural convection , in which a certain amount of heat is spent on heating the wall and blocking heat loss in the room, and most of the energy is directed to heating.

Rules for connecting radiators and their modernization

Other elements of greatest interest are batteries and pipes. To increase the efficiency of a heating battery, you must initially choose the right model. Ideally, it should have maximum thermal conductivity. This applies to aluminum and bimetallic batteries. If we take the efficiency of heating radiators, the table will show significant differences from cast iron ones. However, it should be borne in mind that the cooling of aluminum will take place much faster. This material does not accumulate heat. In addition, in cast iron there is an uneven distribution of the energy received.

Heat transfer characteristics of radiators depending on the degree of water heating

For comparison, you can consider the table of efficiency of steel-type heating radiators.

The larger the area of the battery, the faster the air in the room will heat up. But you need to take into account the degree of cooling of the coolant. It is desirable that the operating temperature of the radiators in the house is the same.

Radiator connection methods

Change in radiator efficiency depending on the connection method

Having decided on this parameter, you can move on to the main subtleties of increasing the efficiency of the heating battery. The main one is the method of connecting to the system. It is best to make the connection to the system on one side of the device. Then the coolant will go through a full cycle through the battery.

But in practice this is not always possible. Therefore, they prefer to choose the “golden mean” - the upper supply and the lower connection to the return pipe. This technique has the following advantages:

- You can increase the efficiency of the heating battery in other ways by compensating for 2%;

- Optimal length of the highway, which also affects the efficiency of the entire system;

- Possibility of installing a Mayevsky tap and an automatic thermostat.

Installing radiators for maximum efficiency

Coefficient value for various radiator installation options

The main rule for installing radiators of any type is optimal heating of the room. Those. they should be located in the area of the room where heat loss will be maximum. This primarily applies to window structures.

In order to make heating with high efficiency, the window sill must overlap the upper plane of the radiator by 2/3. You also need to consider the recommended distances from the structure to the walls and floor:

- From the window sill to the top of the section – 100 mm;

- From the floor surface to the battery - 120 mm;

- From the rear panel of the radiator to the wall - 20 mm.

In this way, maximum efficiency of the entire heating system can be ensured. Convection currents of warm air will be partially retained in the window sill area, heating the wall and reducing heat loss through the window.

Save with Programmable Thermostats

Many modern boilers support the ability to connect thermostats. You can place the thermostat in the room that can be used as a reference room. (Just never install thermostats in the kitchen. Due to the operation of the stove, it is always warmer there) Using the reference room, you set the temperature and the boiler already starts working from the thermostat signal. Practice shows that this method does little to make gas heating more economical.

In addition to simple thermostats, there are so-called programmable ones. They can be wired, wireless, powered or battery-powered. Options start from 2000 rubles and go on to infinity. Such thermostats allow you to set weekly operating modes.

How does this work in practice? Let's say you are a working person. And your whole family is often away from home. Study, work, etc. In fact, in your absence there is no need to heat the house to a comfortable temperature. It is enough just to maintain an adequate positive mode so that furniture, decoration and other parts of your home do not suffer. With a programmable thermostat, you can set the temperature by the hour.

Let's say you all leave for work at 9 o'clock and return home at 6 o'clock. You set the thermostat to lower the temperature from 9 am and raise it from 5 pm so that the house is already warm when you arrive.

In fact, in your absence, the heating will operate in economical mode. Savings in such scenarios can reach up to 30%.

We talked about this in more detail in the video:

There are a great variety of programmable thermostats. There are even some that can be controlled remotely from a smartphone. Here you can choose everything to your taste and color. The main thing is that they can all change their temperature depending on the time and day of the week.

The only important thing is that your boiler has the ability to connect thermostats. If you are using a simple boiler, then most likely there may not be such an opportunity.

All modern wall-mounted boilers support the connection of thermostats. This also applies to many floor-standing boilers.

Here is such a simple and uncomplicated way to make your gas heating more economical.

Ways to reduce gas consumption

To understand how to make a gas boiler more economical, you should analyze not only the characteristics and condition of the unit, but also consider the conditions of the heated area. In addition, to ensure that the gas device does not increase fuel consumption, it is necessary to timely clean its components from soot and burning, and heat exchangers from scale.

Gas boiler power

The first thing you need to pay attention to is whether the power of the installed unit matches the heated area. It’s bad if there is not enough productivity or there is a significant excess of it

If the power of the unit is not enough to heat a given room, it will constantly work at the limit of its capabilities, consuming a lot of fuel. This operating mode will shorten the service life of key boiler components. In addition, if there is insufficient power, the unit will not be able to provide high-quality heating of the home. The situation can be corrected using drastic methods - reducing the number of heated rooms or installing an additional gas appliance.

A situation where the power of the unit is more than 20% higher than optimal for a given room is also undesirable. Otherwise, the gas boiler will turn on and off too often - this is called “clocking”. It turns out that the unit heats the coolant too quickly to the set temperature, after which it immediately turns off. In this mode, some radiators will remain unheated, and equipment wear and gas consumption will be high. In this case, the unit should be switched to a lower operating mode.

Insulation of the house

The degree of insulation of a house or apartment is of significant importance in saving gas. If the building is not insulated, and the doors and windows are ventilated, a significant part of the heat will go outside. The material of the walls of the house also matters. For example, wood and block transmit heat faster than double brickwork.

Good insulation of the ceiling, floor and walls will save a lot of fuel. It is advisable to replace old frames with energy-efficient double-glazed windows, and wooden doors with a more airtight modern analogue. A well-insulated building will save up to 30% on gas.

Particular attention should be paid to insulating the attic and basement, since a lot of heat also escapes through them. Note! To increase the energy efficiency of your home, you can install reflective screens made of aluminum foil between the radiator and the wall; they will allow you to return some of the heat to the room

Note! To increase the energy efficiency of your home, you can install reflective screens made of aluminum foil between the radiator and the wall; they will allow you to return some of the heat to the room

Installation of modern automation

Thermostats that automatically maintain a given heat level help save fuel. There are a lot of different options on sale to suit every budget. These devices set the desired room temperature, and it is maintained using sensors. If the temperature in the room drops by at least a quarter of a degree, the sensor will signal the gas boiler to turn on. After reaching the desired temperature, the unit will turn off. This mode of operation will save up to 20% of fuel.

The disadvantage of a thermostat is that it allows you to maintain a given heating level in only one room. But new thermoregulation models have appeared that are equipped with outside temperature sensors. When it gets warmer outside, a signal is given to reduce the burner flame.

One of the most profitable heating options is the “warm floor” system. The coolant in it usually has a temperature of 30-45°C. To maintain coolant heating at this level, the system does not require a lot of fuel.

Reasons for decreased efficiency

Gas floor-standing boilers and wall-mounted models demonstrate the highest energy efficiency immediately after installation. Over time, this figure decreases due to two main factors:

contamination of burners - carbon deposits gradually clog thin holes, which causes poor fuel burning;

calcification of the heat exchanger - wall-mounted boilers with copper tubes of small diameter are more susceptible to this.

Also, getting the maximum return from gas equipment is hampered by the overall heat loss of the house. Dilapidated windows and doors, walls with high thermal conductivity prevent the formation of a comfortable microclimate, even if the boiler itself has high efficiency.

Radiators remain another important nuance - the efficiency of the entire system depends on them by 80%. It is important to use high-quality modern sections that will easily transfer heat to the surrounding space. Using old, clogged, painted over or corroded radiators will prevent you from enjoying the warmth in winter.

What should an energy efficient boiler be like?

The characteristics specified in the documents and rich practical experience show that imported boilers have the highest efficiency. European manufacturers pay special attention to the use of energy-saving technologies, which allows them to get the most out of their equipment. Let’s make a “portrait” of an ideal gas boiler:

modulation burner - automatically adapts to the operating mode of the system, minimizing the percentage of underburning;

heating the coolant no more than 70 degrees, exhaust gases - up to 110 degrees, which ensures an optimal balance of efficiency, it is desirable to have a condensation heat exchanger;

coaxial chimney - a closed combustion chamber requires the equipment to have a pipe-in-pipe channel for removing combustion products, which allows heating the air flow from the street;

recirculation system - allows you to use the heat of exhaust gases to heat the room.

Of course, such an ideal boiler does not exist, but a list of the best technical solutions will help you choose a worthy model.

How does a condensing heat generator work?

This type of boiler is the younger brother of a conventional gas-fuel convection boiler. Conventional gas boilers, the operating principle of which is similar, have an efficiency of approximately ~90%. Where is another 10% lost? The answer is simpler than you might imagine - they go down the drain. The products of gas combustion that leave the system through the chimney are heated to a temperature of about 150 - 250 ° C, therefore, the lost 10% heats the air outside.

The operating principle of a condensing gas boiler is somewhat different. After working out the main combustion process and having given most of the heat released during the process to the heat exchanger, the unit cools the gaseous products of the combustion results to 50-60°C, that is, until the formation of water condensate begins. This is quite enough to significantly increase the efficiency, in a particular case, the amount of heat energy that is transferred to the coolant. But that is not all.

When the dew point (temperature 56°C) is reached, steam particles begin to gather into drops, scientifically speaking, the process of condensation occurs. At this time, additional energy is released from condensed vapors, which was previously spent on water evaporation and, in standard gas boilers, goes into the pipe along with the steam-gas mixture. The condensing boiler “takes” the heat that is released when water vapor condenses and transfers it to the coolant.

Manufacturers of condensate-type boilers are sure to draw the attention of their future buyers to the fact that the efficiency of the device is much more than 100%. How does this happen? No laws of physics are violated in this case, it’s just that in this situation a different calculation system is used

When assessing the efficiency of heating boilers, the part of the generated heat that is transferred to the coolant is taken into account. If we sum up the heat that the boiler transfers to the coolant during its operation and the heat from the deep cooling of the gaseous combustion products, the result will be 100%. But if the heat that is released during steam condensation is added to these values, then the result will be about 108-110%.

If we consider the calculations from a physical point of view, we can say that they are not entirely correct. Efficiency of more than 100% is a cunning move by marketers who take advantage of the inaccuracy of outdated calculations. And yet, condensing gas heating boilers, unlike a standard convector, “squeeze” almost everything out of fuel combustion. The advantages are more than obvious - less resource consumption and higher efficiency.

Operating rules for boiler devices, compliance with which affects the efficiency value

Any type of heating unit has its own optimal load parameters, which should be as useful as possible from a technological and economic point of view. The operation process of solid fuel boilers is designed in such a way that most of the time the equipment operates in optimal mode. This operation can be ensured by following the rules of operation of heating equipment operating on solid fuel. In this case, you must adhere to and follow the following points:

- it is necessary to observe acceptable modes of blowing and exhaust operation;

- constant control over the intensity of combustion and completeness of fuel combustion;

- control the amount of entrainment and failure;

- assessment of the condition of surfaces heated during fuel combustion;

- regular boiler cleaning.

The listed points are the necessary minimum that must be adhered to during the operation of boiler equipment during the heating season. Compliance with simple and understandable rules will allow you to obtain the efficiency of an autonomous boiler stated in the characteristics.

We can say that every little thing, every element of the design of a heating device affects the value of the efficiency factor. A properly designed chimney and ventilation system ensure optimal air flow into the combustion chamber, which significantly affects the quality of combustion of the fuel product. Ventilation performance is assessed by the excess air coefficient. An excessive increase in the volume of incoming air leads to excessive fuel consumption. Heat leaves more intensely through the pipe along with combustion products. When the coefficient decreases, the operation of boilers deteriorates significantly, and there is a high probability of oxygen-limited zones appearing in the furnace. In this situation, soot begins to form and accumulate in large quantities in the firebox.

The intensity and quality of combustion in solid fuel boilers require constant monitoring. The combustion chamber must be loaded evenly, avoiding focal fires.

During combustion, it is important to prevent failure of the fuel resource, otherwise you will have to face significant mechanical losses (underburning) of fuel. If you do not control the position of the fuel in the firebox, large fragments of coal or firewood falling into the ash box can lead to unauthorized combustion of the remaining fuel mass products. Soot and resin accumulated on the surface of the heat exchanger reduce the degree of heating of the heat exchanger

As a result of all of the above violations of operating conditions, the useful volume of thermal energy required for the normal operation of the heating system decreases. As a result, we can talk about a sharp decrease in the efficiency of heating boilers

Soot and resin accumulated on the surface of the heat exchanger reduce the degree of heating of the heat exchanger. As a result of all of the above violations of operating conditions, the useful volume of thermal energy required for the normal operation of the heating system decreases. As a result, we can talk about a sharp decrease in the efficiency of heating boilers.

What's wrong with too much power?

Let's look at setting the power of a gas boiler using the example of a double-circuit device Protherm Gepard 23 MTV. This model is an analogue of the Protherm Panther unit. The same manufacturer that produces Protherm gas appliances produces Vaillant brand boilers in another production facility. Their price is much more expensive, since they use higher quality components. In design and settings, Vaillant gas devices are very similar to Protherm models.

The operating instructions say that the useful thermal power of the Protherm Gepard 23 MTV boiler is adjustable from a maximum of 23.3 kW to a minimum of 8.5 kW. In production, the units are set to a power of 15 kW.

It is good if the heating system to which the gas boiler is connected has a power within the capabilities of the burner device, in our case - from 8.5 to 23.3 kW. But what if the existing radiators require less performance?

For example, let's take an apartment with an area of 50 m². For its heating there are radiators with a thermal power of 4 kW. The installers installed a gas boiler, but did not set the appropriate power. A 4 kW heating system will not be able to accept the installed unit performance of 15 kW. The large difference between the produced and the required indicator makes it impossible to automatically adjust the boiler. Then you need to adjust the device yourself.

Note! Experts categorically do not recommend installing a gas boiler whose power significantly exceeds the required one. This leads to cyclical operation of the unit and its rapid failure.

The characteristics of the gas boiler Protherm Gepard 23 MTV indicate that the efficiency of the device when operating at full thermal power is 93.2%, and at minimum - 79.4%. If the unit operates at a capacity of 4 kW, its efficiency will decrease even more. It turns out that almost a quarter of the thermal energy will “fly down the drain.”

Cyclicity of a gas unit and its consequences

Cycling or “clocking” of a gas boiler means that the burner, after being turned on, quickly turns off when the liquid reaches a given temperature in the pipe at the outlet of the unit. But the batteries do not have time to warm up. After a short period, the circulation pump pumps cold water from the heating system into the unit circuit, and the burner turns on again.

Another difficulty lies in the fact that low-power heating pipes have a smaller diameter and higher hydraulic resistance; accordingly, the coolant flows in them more slowly. If you heat the liquid in the heat exchanger with high power, it will reach the set temperature very quickly and the burner will turn off. At the same time, the rest of the water that did not have time to reach the burner will remain cold.

Automation without human intervention will not be able to react to the situation and adjust the optimal power of the device.

Note! With the correct settings of the heating system, the temperature difference between the inlet and return should be no more than 15ºC. Cycling of a gas boiler significantly reduces the service life of the unit and increases fuel consumption

It is known that the components suffer the most wear at the moment of switching on. Also, when ignited, a maximum portion of gas is supplied to the burner, most of which evaporates into the pipe. Frequent re-ignition of the burner further increases fuel consumption and reduces efficiency. To avoid this, it is necessary to adjust the power of the unit, that is, to equalize the performance of the gas boiler and heating system

Cycling of a gas boiler significantly reduces the service life of the unit and increases fuel consumption. It is known that the components suffer the most wear at the moment of switching on. Also, when ignited, a maximum portion of gas is supplied to the burner, most of which evaporates into the pipe. Frequent re-ignition of the burner further increases fuel consumption and reduces efficiency. To avoid this, it is necessary to adjust the power of the unit, that is, to equalize the performance of the gas boiler and heating system.

What is the efficiency of heating devices

For any heating unit whose task is to heat the interior space of residential buildings and structures for various purposes, operating efficiency was, is and remains an important component. The parameter that determines the efficiency of solid fuel boilers is the efficiency factor. Efficiency shows the ratio of the expended thermal energy produced by the boiler during the combustion of solid fuel to the useful heat supplied to the entire heating system.

This ratio is expressed as a percentage. The better the boiler works, the higher the interest. Among modern solid fuel boilers there are models with high efficiency, high-tech, efficient and economical units.

The efficiency of heating equipment strongly depends on what type of fuel is used and what are the design features of the device.

For example: when burning coal, wood or pellets, different amounts of thermal energy are released. Efficiency largely depends on the technology of fuel combustion in the combustion chamber and the type of heating system. In other words, each type of heating device (traditional solid fuel boilers, long-burning units, pellet boilers and devices operating by pyrolysis) has its own technological design features that affect the efficiency parameters.

Operating conditions and quality of ventilation also affect the efficiency of boilers. Poor ventilation causes a lack of air necessary for the high intensity of the combustion process of the fuel mass. Not only the level of comfort in the interior, but also the efficiency of heating equipment and the performance of the entire heating system depend on the condition of the chimney.

The accompanying documentation for the heating boiler must contain the equipment efficiency declared by the manufacturer. Compliance of real indicators with the declared information is achieved through proper installation of the device, wiring and subsequent operation.