ERROR E25, E26 ON THE BAXI BOILER: WHAT IS THE REASON AND HOW TO ELIMINATE

The factory interpretation of error E25—reduced coolant circulation—does not provide a complete understanding of the essence of the problem. In the instructions for various models of the Baxi boiler, the emphasis is on blocking the pump. But this is not the only reason such a fault code appears on the display.

Control panel for gas boiler Baxi LUNA 3 comfort

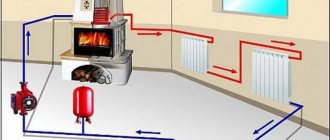

Error e25 indicates an intense increase in temperature in the heating circuit. This parameter in Baksi units is determined by the difference in readings from sensors installed at the inlet and outlet of the boiler heat exchanger. When it grows at a speed above 1 0С/sec, the operation of the unit is blocked by the protection circuit. A decrease in fluid circulation is caused by several factors, therefore there is no clear recommendation for eliminating error E25. The algorithm of actions given in the article will allow you to figure out the reason for the appearance of this fault code in a short period of time.

Characteristics of Baksi boilers

The equipment of this manufacturer can be used both in a small apartment and in a spacious country house. But the space in which the heating system will be installed must meet certain criteria:

- The size of the room should not be less than 15 m³.

- Ceiling height: minimum 2.2 m.

- Good ventilation that can withstand heavy loads is necessary.

This is important: Baxi boiler maintenance. In this video you will learn how to flush the heat exchanger:

In this video you will learn how to flush the heat exchanger:

Important nuances

In addition to grounding, other factors must be taken into account when installing equipment. The following must be taken into account:

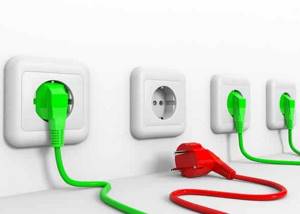

- For the boiler to function properly, 170-250 V is required. At a lower voltage, the device will turn off, and at a higher voltage, the varistor will burn out.

- The equipment is very sensitive to voltage surges. Professionals advise installing additional voltage stabilizing devices. There is no need to use a UPS when installing gas boilers.

- The connection must be made through a separate functionality.

- For phase-dependent varieties, the correspondence between phase and zero must be observed.

Advantages and disadvantages

The Baksi company occupies a leading position in the heating equipment market.

The following advantages of this manufacturer’s equipment can be highlighted:

- environmental friendliness and safety;

- ease of operation and flexible adjustable settings;

- reliable protection against freezing;

- automatic diagnostic function;

- efficiency;

- a wide range of models, the ability to select a unit to suit any requirements;

- stylish, thoughtful design.

Of course, any equipment has its drawbacks, and Baxi products are no exception. The disadvantages are:

- Sensitivity of equipment to voltage changes. For the device to work reliably, you need to connect it through a stabilizer.

- Installation is quite complicated, so it is best to entrust it to a professional.

- High price compared to models from other manufacturers.

In this video you will learn about the main malfunctions of Baksi boilers:

Types of models

The company has a large range of wall and floor heating systems. Wall-mounted boilers are ideal for private homes. They are available in three series: Luna, Prime and Eco3.

Models from the Luna line have a built-in automatic diagnostics and electronic modulation system. Such units are distinguished by the presence of two temperature regulators, which is very convenient. These are dual-circuit devices with an acceptable cost.

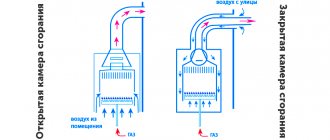

Equipment from the Prime line are high-quality and reliable economy-class boilers. They have a closed combustion chamber and are made of special composite materials. The devices operate almost silently. Models in this series are condensing and have a biothermal heat exchanger. Thanks to this they operate very economically.

The Luna-3 Comfort and Eco Four models are very popular on the Russian market. Both systems can be presented with either an open or a closed combustion chamber. Eco Four has a performance of 14-24 kilowatts. It can be connected to a thermostat or timer. This boiler is equipped with high-quality sensors and reliable protection against temperature changes. Among all Baksi devices, it has the least power.

In addition, models from the Main line are in great demand. The most famous on the Russian market was the Main Four 240, which ceased production in 2021. It was replaced by Main Five, made using new technology. This system is similar to the previous one, but it has additions, such as a draft system in the chimney.

How to repair a gas boiler control board:

Baxi gas boiler error codes

The description of most Baxi boiler errors can be found in the classifier. The most common options are described in the accompanying documentation. But, sometimes you will find that some codes may indicate several possible problems, and the status of the nodes will need to be checked. In many cases, to restore the operation of Baksi gas boilers, it is not necessary to call a specialist, and you can return the equipment to working condition on your own.

Error e00

The appearance of code E00 indicates a malfunction of the electronic board. She is responsible for managing all nodes. In this case, you will have to go to specialists to troubleshoot problems. E00 should not be confused with A00. The display of code A00 on the screen may appear if the “INFO” mode is activated and its appearance does not confirm that the equipment is technically faulty or inoperative.

Baxi gas boiler, error E01 and E04, repair methods

E01 and E04 are displayed if there is a violation in the ignition system in the baxi eco four 24 f boiler (Ecofor 24 f). If the mounted boiler is not equipped with a display, then such a problem is indicated by LED indicators.

In addition to the indicated options, error E01 in the Baksi gas boiler may be displayed in the following options:

- in the absence of gas;

- if there is no contact on the flame sensor;

- if dirt has accumulated on the flame control sensor;

- if the power wires are incorrectly positioned;

- in case of malfunctions in the operation of the gas tap, chimney or equipment electronics.

Read more: Why does a gas boiler go out? Main reasons

Error e02 thermostat

A hardware error can occur for several reasons. The following options can be distinguished:

- when the limit value of the main circuit liquid temperature is reached;

- if the sensor that monitors the temperature regime of the circuit fails;

- in case of insufficient contact on the temperature sensor;

- when there is insufficient fluid circulation in the system;

- in case of debris formation in the filter or heat exchanger, or air lock formation.

Thermostat with display A similar malfunction occurs on equipment that does not have a display installed. A sign of a problem is the glow of the indicator responsible for temperature readings.

Error e03 (draft sensor) in the Baxi gas boiler

A similar signal appears on models with a closed and open combustion chamber. The displayed code shows possible problems in the operation of the baxi gas boiler draft sensor, the operation of the thermostat or the pneumatic relay.

- large length of the chimney system;

- a foreign object has entered the chimney or the chimney channel is clogged;

- malfunctions in the Venturi injector (errors in the Baxi Luna 3 boiler);

- violation in electronics;

- the fan is not working properly or there is no contact with it;

- Incorrect connection of the pneumatic relay.

Errors e05 and e09 control of DHW and burner flame

E05 occurs when problems are detected in the heating circuit. Among the main reasons is a malfunction of the sensor itself, in some cases there may be a malfunction of the electronic board. Sometimes equipment malfunction may be due to a lack of contact between the sensor and the board.

E09 occurs when there is a problem in providing the room with hot water. But sometimes errors on a gas boiler are not related to the functioning of the hot water supply. Most problems are resolved by testing the circuits and then replacing the faulty unit, unit or part.

Error e06

If there is a problem with the DHW temperature sensor, code E06 appears. The reason is problems both in the sensor itself and in the wiring.

Error E10 minimum pressure switch for baxi gas boiler. Remedies

If the signal from the hydraulic pressure switch disappears, E10 may appear. There are several main options:

How to find and eliminate leaks in heating systems? ⇐ Read in detail!

- if there is no free space in the expansion tank or it is broken;

- when the water pressure sensor fails. Distributed on models Baxi Main four 240f, Baxi Main 24 fi;

- if the oblique filter on the return line is clogged.

Temperature errors e25, e27 and e32

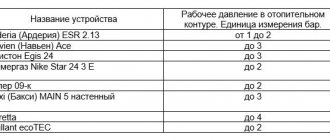

Unexpected temperature changes in the heating circuit may cause code E25, E26, E27 or E32. There are several reasons for the display: pump blockage, debris in the filter, presence of air in the system, problems in the electronic system, incorrect operation of the DHW sensor.

To eliminate it, preventive maintenance should be carried out and the nodes checked. Both electrical and mechanical testing of components may be required.

Error E35, E36 and E40, E43 flame control and gdc boiler Baxi, how to fix

The occurrence of signals is preceded by malfunctions in the gas burner flame control system and smoke removal systems. Error E35 in a Baxi gas boiler can occur when a stray flame occurs. The manufacturer explains this: a stray flame in a gas boiler is a situation when a combustion signal is received from the ionization sensor before the valve opens. E36 - a malfunction of the NTC sensor, codes E40 to E43 indicate failures during the GDC test. Some options can be fixed yourself, but in most cases you may need to call a professional.

Code E55 problems with gas supply valve

The reason is incorrect valve calibration. Accurate calibration can be difficult to do on your own. We advise you to contact the appropriate services for help.

Error E98 gas boiler Baxi

Such a manifestation indicates a malfunction in the operation of the control unit. This may be sticking of the contacts of the valve relays responsible for supplying gas to the equipment. Appears after the system performs self-diagnosis. In some cases, a malfunction may occur due to incorrect settings of the board parameters. It should be remembered that you will not be able to get rid of the problem on your own. You will need to call the technicians from the service department.

Code E99 electrical part

In most cases, error E99, E97 and E98 signals possible problems in the electronics of the Baxi Mine 24fi, Baxi Slim device. It can be very difficult to accurately determine the problem at home. There may be reasons for each option. In most cases, it lies in the electronic board itself. When calling a technician, ask him to take a working board with him. To do this, you will need to indicate the value indicated on the board or name the model of the heating device.

Automation

Automation for boiler equipment is very diverse. Some of it is preinstalled by the manufacturer. This category includes all sensors and electronic devices that ensure the safe operation of equipment.

The simplest example is a sensor that monitors the normal gas supply. When the gas is turned off, the sensor is triggered and the boiler automatically turns off. Restart will occur after the gas supply is restored.

Systems that ensure operational safety also include:

Boiler structure

- Frost protection (starts to work if the outside temperature is below 5 degrees).

- Protection against blocking of circulation pumping equipment.

- Protection against blocking of the three-way mixing valve in case of long-term equipment downtime.

- Protection against scale formation in the heat exchanger and boiler.

- Overheat protection.

- Voltage protection in the electrical network.

- Control of stray flames.

- Combustion and draft control.

- Coolant pressure control.

In addition to the pre-installed automatic systems, you can install additional electronics:

- Outdoor temperature sensor.

- Room temperature sensor.

- Thermostat.

- Electronic thermostat.

- Remote panels.

- Weather dependent sensors.

- Elements for remote control.

- Water quality sensors, etc.

Wall-mounted (mounted) double-circuit gas boiler Baxi: other faults and their elimination

When using the wall-mounted version, other problems may occur. They are not very common, but the device owner needs to know about them:

- E111 - appears if the coolant temperature reaches 95 degrees. To correct this, press the Reset button and hold it down for several seconds;

- E129 – if the fan rotation speed drops below the permissible threshold. You won’t be able to fix it yourself; we recommend calling a technician;

- E153 – when the “Reset” button is accidentally pressed. You can restore previous values by holding the button pressed;

- E154 – when liquid circulation stops. To find out, you will need to call and submit a request to the service center.

The boiler does not start

If the equipment cannot be started, it can be assumed that the reason is an incorrect electrical connection. This is possible with the Baxi Main 24 fi model. The electrical part cannot start the equipment if the phase and zero are incorrectly positioned. With this option, the display shows e01.

To resolve this you will need to take the following steps:

- check the connection and, if necessary, swap the wires;

- remove air from the system;

- if necessary, add coolant.

After completing the steps, you need to restart the equipment and make sure that the e01 code disappears and is not displayed on the display.

It is impossible to turn on the heating at full power

The main reason is incorrect setting of the pressure regulator. Another option is the occurrence of problems in the functioning of the diode bridge or valve. When such problems occur, e01 will be present on the screen. First of all, you need to check the settings and, if necessary, make the correct adjustments. If the problem is with the operation of the components, then most likely they will need to be replaced.

After starting the boiler it switches off

With such a problem, e01 will also be displayed on the display of the Baxi gas boiler. The main cause of this problem is low pressure in the gas line. If there are frequent interruptions in the main gas pipeline or the pressure is not stable, it is recommended to set the value to 5 mBar. It also happens that the heating does not turn on and the gas boiler does not give an error. In such cases, you should contact specialists.

The heating system is not at sufficient temperature

The main cause of the problem is an incorrect configuration. Typically this refers to setting the required thresholds. To eliminate the breakdown, it is necessary to adjust the parameters, adhering to the recommended values.

The equipment does not support the required parameters

Most often, the reason for this behavior is a problem with the electronic board, which is responsible for controlling the electronics.

Another option is a malfunction in the gas supply valve. It can be difficult to resolve the problem on your own. It may be necessary to test the performance of the board; if necessary, you will have to replace the non-working unit.

Sensors show incorrect value

In most cases, the cause of this behavior is the failure of one or more sensors. To return the equipment to working condition, you will need to find out which sensors have failed and replace the non-functioning components.

Popping sound when heating is turned on

If there is a pop when the equipment starts up and if Baksi does not light up immediately, then pay attention to the following possible options:

- inconsistent pressure of blue fuel in the line. Error e01 appears;

- the distance between the igniter does not correspond to the established parameters;

- check the intensity of smoke emission.

Recommended Action: Lower the minimum limit to 5 mbar. If the recommended gap does not comply, adjust it. If there is excessive draft, adjust the intensity using the damper.

Temperature drop

The reason may lie not only in the functionality of the equipment. If such a situation arises and the gas consumption of the Baxi Main24 fi boiler is high, we advise you to check the functionality of the radiators and pipes. Pay attention to the filters; they may have accumulated rust or other impurities that interfere with the free movement of fluid in the system. From the presented material it is clear that many errors can be corrected independently. The fix does not require any experience or the use of expensive tools. But even if you can’t fix the situation yourself, using the information received, you can provide the technician with the necessary information over the phone. This will help the specialist take with him the necessary tools and spare parts.

Boiler power supply

Any gas boiler requires a constant connection to the electrical network and, in particular, to the quality of this electrical network. For normal operation of the boiler, compliance with the PUE standards (electrical installation rules) is required, because very often malfunctions in the operation of electronics arise precisely due to overvoltage and lack of proper grounding. Problems can be either harmless, which the user will not even always notice, or costly: for example, the breakdown of an expensive control board. The quality of electricity is especially important in country houses, where to connect equipment it is often impossible to do without additional protection devices and ensuring autonomy (stabilizer, galvanic isolation, uninterruptible power supplies). But this is a topic for a separate article. Some models require polarity, i.e.

for them it is important to ensure that zero and phase match.

The baxi boiler must be constantly connected to power, even if the heating and hot water modes are turned off, the boiler periodically independently turns on the actuators (pump, three-way valve) to prevent souring of the actuators. Do not forget that most boilers have frost protection: when the coolant temperature drops below 5 degrees, it will automatically start and warm up the coolant.

Advice

When installing NTC in the boiler, do not forget to change the gasket (RTI is not reused) and apply a fresh layer of thermal paste to the Baxi internal circuit tube (for the clamp-on sensor).

Electronic board

Based on the information coming from the NTC, it generates error e26: the voltage is removed from the relay, through the contacts of which power is supplied to the Baksi boiler pump. If the cause of the problem is not identified when testing the heating system and unit, it is in the control module.

Baxi boiler control board

Self-diagnosis is impractical: you need a stand, detailed diagrams, and manufacturer’s guidelines. This is the case when a service technician is called. The cost of the board, depending on the modification, reaches a third of the price of the heating installation: experimenting or buying a new unit only if you suspect it may be a waste of money.

What does low blood pressure mean and what needs to be done?

- Examine the readings of the mechanical pressure gauge. If the arrow is in the red zone, go to step 2

- We find the tap water make-up tap at the bottom of the boiler. Depending on the boiler model, it can be located in different places, but this place is definitely at the entrance to the boiler water pipe and probably next to the pressure gauge. The location of the system filling valve must be included in the instructions for the boiler! In BAXI boilers, the system filling valve can be red or black with a square cross-section (see photo BAXI EcoFour), blue or black with a round cross-section.

- Once the feed tap has been found, you need to fill the heating system to the required level. We open the tap (turn it counterclockwise), usually you will immediately hear the noise of water entering the boiler; as soon as you hear the sound of water, you don’t need to turn it further - we watch the pressure gauge needle. As soon as the pressure gauge needle has risen to the green zone - more than the 1 bar mark - close the tap by turning it clockwise (do not over-tighten it - just close it).

- As soon as the pressure in the boiler is raised to a normal level, error e10 should disappear and the boiler will automatically start working.

How to proceed

Check electrical parameters

Imported boilers are sensitive to U, f. Manufacturers do not take into account the nuances that we constantly encounter: voltage surges, increased/lowered values, phase imbalances and other “surprises”. With an autonomous power supply, error E98 of the Baksi boiler is caused by incorrect operation or failure of the source (diesel, gas generator). Check, make adjustments - for this, the owner of the object does not need the help of a service technician.

Advice . Connecting the Baksi boiler via a UPS eliminates the risk of error E98 due to instability of the network voltage.

Expert opinion

Uninterruptible power supply SKAT

Check grounding

This is the main reason for the appearance of error E98 in Baksi boilers installed in apartments. In houses built according to old designs, grounding is not provided. It is easy to verify by removing the cover from the socket: two wires enter the nozzle box - phase and zero.

In the private sector, circuit testing is carried out with a device - a megohmmeter. When measuring resistance, R should show no more than 4 ohms.

Grounding the baxi boiler

Check the potential on the metal part of the boiler

Error e98 may be associated with interference (stray currents). They appear for various reasons (a power line is located nearby, a powerful radiation source, the insulation of a power cable is damaged, or something else), but the result is the same: where there should not be potential, it is present.

Advice . The gas pipe is metal, laid in the ground, so the energy going into the ground is “collected” on it. To eliminate the influence of interference on the electronic board, you need to install a dielectric coupling on the main line (between the shut-off valve and the Baxi boiler). Helps get rid of error E98 and a number of others.

Connecting a dialectical coupling

one dielectric coupling

Check boiler settings

One of the reasons for error E98 after replacing the Baksi electronic board. The code appears if the parameters (F03, 12) are entered incorrectly. To correct the configuration, you do not need to call a service technician - the instructions describe in detail the setting method.

Gas prospects

The use of gas for heating houses and apartments is one of the most promising trends in the development of engineering communications today. Manufacturers of boiler equipment have offered so many options that you can choose the right unit for absolutely any room. An example is BAXI boilers.

BAXI gas boilers can be installed in any room. They are suitable for installation in apartments and for organizing heating of a large country house. Naturally, the room where the mini-boiler room is installed must meet existing requirements:

- The room must be at least 15 cubic meters in volume.

- Ceiling height is at least 2.2 meters.

- Good ventilation, capable of providing three air changes.

Existing requirements for the organization of a chimney can be ignored if you choose a BAXI boiler with a closed combustion chamber to heat your home. Such a unit is a full-fledged mini-boiler room, which has all the necessary elements and does not harm the ecology of the house. Models from this manufacturer differ in power ratings, so BAXI boiler units can be used to heat and supply hot water to a wide variety of rooms.

The most common causes of errors during operation

Errors in Baksi gas boilers are displayed on the display as coded messages. To decipher the message, you need to use the correspondence table. It is worth noting that each model has its own, so it cannot be used as a universal one. This can lead to an incorrect diagnosis and the prescription of useless actions that will not be aimed at eliminating problems.

Malfunctions of Baksi wall-mounted gas boilers with one working circuit will affect exclusively the heating system. Moreover, electronics break down more often, because mechanical parts are made of durable metal, which undergoes additional processing and hardening. As a result, it can last for many decades without even showing visible signs of wear.

When cleaning the combustion chamber, you need to remove the naga very carefully so as not to damage the protective inner layer. If this happens, the wear rate will increase many times and the boiler will not be able to work for the entire announced period of time. You should behave in the same way when cleaning the burner. The diameter of the tool should be smaller than the holes so that they do not become loose, otherwise the device will become unusable and will have to be replaced.

Malfunctions of Baksi double-circuit gas boilers will already affect both the heating and water heating systems. There are many more options for breakdowns here, since the system is more complex than a single-circuit model. Diagnostics can take more time, and repair work is much more difficult. So in this matter, it would be better to trust the professionals so that they take on all the troubles themselves.

To avoid breakdowns and extend the life of the unit, you need to correctly configure the Baxi gas heating boiler. This is quite easy to do if you use the practical recommendations from the instructions. In addition, the “smart” automatic control system itself will prompt the user with the optimal parameters that are best suited for his system. In general, you need to carefully monitor the automation readings, as they can tell you about impending problems. Timely diagnosis increases the chances of success.

Damage to the Venturi device

This malfunction most likely occurs on boilers from other manufacturers and boilers, but I think it is necessary to describe it too. Since the plastic tubes themselves are located near the gas burner, there is a possibility of exposure to high temperatures.

This mainly happens due to the presence of other malfunctions, for example, a primary heat exchanger clogged with scale or prolonged operation of the boiler at maximum power. The tubes of the device simply melt, and any, even the slightest, deformation leads to the entire system not working correctly and the unit stopping.

If the information from this article was useful and helped you, you can share it with your friends using the social buttons below.

Almost everything described above can also be viewed in the video, which describes error e 03 in detail:

If you are interested, we have posted an article on our website with a complete list of error codes for Baxi boilers.

Decoding

The factory interpretation of error E25—reduced coolant circulation—does not provide a complete understanding of the essence of the problem. In the instructions for various models of the Baxi boiler, the emphasis is on blocking the pump. But this is not the only reason such a fault code appears on the display.

p, blockquote 2,0,0,0,0 —>

Control panel for gas boiler Baxi LUNA 3 comfort

Error e25 indicates an intense increase in temperature in the heating circuit. This parameter in Baksi units is determined by the difference in readings from sensors installed at the inlet and outlet of the boiler heat exchanger. When it grows at a speed above 1 0 C/sec, the operation of the unit is blocked by the protection circuit. A decrease in fluid circulation is caused by several factors, therefore there is no clear recommendation for eliminating error E25. The algorithm of actions given in the article will allow you to figure out the reason for the appearance of this fault code in a short period of time.

p, blockquote 3,0,0,0,0 —>

BAXI MainFour 24

Baxi Main For is probably the simplest and most affordable model of the entire line of BAXI boilers. Boilers of this series are available with open and closed combustion chambers. The difference between BAXI MainFour 24 F and BAXI Main Four 24 is only in the presence of a fan for forced removal of combustion products and a sensor for monitoring fan operation. The fourth generation of boilers has proven itself well among users due to its ease of operation and reliability. That is why, despite the release of new fifth-generation boilers, Mainfor continues to be produced and is popular.

The boiler is controlled using an electronic panel. It is possible to quickly adjust the heating temperature, hot water and switch the boiler operating modes (summer, winter, combined). The boiler configuration and parameter values are described in detail in the operating instructions.

BAXI (Baksi) - Error E25: maximum boiler temperature exceeded / no water circulation.

- Problems in the boiler electrical network : reboot the boiler - press and hold the Reset – R button for 2 seconds.

It is strictly recommended to connect heating boilers through a stabilizer (for the boiler) or a UPS; this will save you from unnecessary costs for replacing the control board.

- Checking the polarity in a plug-socket connection : turn the plug 90 degrees and insert it back into the socket or stabilizer.

Check the grounding: the main reason for the appearance of error E98 in Baksi boilers installed in apartments.

In the private sector, circuit testing is carried out with a device - a megger; when measuring resistance, R should show no more than 4 ohms.

Check the potential on the metal part of the boiler

: The error may be due to interference (stray currents). They appear for various reasons (a power line is located nearby, a powerful source of radiation, the insulation of a power cable is damaged, or something else), but the result is the same: where there should not be potential, it is present. We also do not forget about installing a dielectric coupling on the gas pipe.

Main characteristics

Manufacturers of heating systems can offer a huge selection of different models for home and industrial premises. One of the best options is Baksi gas boilers. This equipment can be used both in country houses and in city apartments.

However, before installation, you need to make sure that the room meets the following criteria:

- The size of the heated room must be at least 15 m³.

- The ceiling height is at least 2.2 meters.

- Good ventilation is a must.

In this video you will learn the reasons for errors in the Baksi boiler:

When operating Baxi equipment with a closed combustion chamber, these rules can be ignored. Such a system includes all the necessary elements and does not pose any harm to the environment. The model range of this manufacturer differs in terms of power, thanks to which the devices can be used for heating and supplying hot water in various types of premises.

The following Baxi boiler models are very popular: Main 5, Main Four 24 F, Luna 3. These units have many positive reviews and have a good price-quality ratio compared to systems from other manufacturers (for example, Alpha Color).

Installation Features

Baksi equipment uses gas as fuel, which, despite all its advantages, is dangerous. Installing such a heating system requires a professional approach. Even the slightest mistake can lead to very unpleasant consequences, so installation of equipment should only be carried out by qualified specialists.

Such boilers should be repaired by professionals, as serious problems may arise.

Here is just a small list of problems that may arise with the intervention of a non-professional:

- Carbon monoxide entering the airspace of the home.

- The occurrence of an explosion.

- Fire.

- Freezing of the system in winter.

If we consider less serious consequences, independent installation of the boiler can lead to improper functioning of the equipment. The device may not start and display an error.

The units of this manufacturer are volatile. They are unable to function without a source of electricity. The connection rules are quite simple. The device is connected to a 220 V network; grounding is required. For this procedure, it is best to also turn to professionals.

https://youtube.com/watch?v=nM50Ttfn-BU

Important nuances

In addition to grounding, other factors must be taken into account when installing equipment. The following must be taken into account:

- For the boiler to function properly, 170-250 V is required. At a lower voltage, the device will turn off, and at a higher voltage, the varistor will burn out.

- The equipment is very sensitive to voltage surges. Professionals advise installing additional voltage stabilizing devices. There is no need to use a UPS when installing gas boilers.

- The connection must be made through a separate functionality.

- For phase-dependent varieties, the correspondence between phase and zero must be observed.

Sufficient power must be supplied for the boiler to function properly