Reasons for clocking (pulse operation) of the boiler in heating mode

You might think that regularly shutting down a gas heat exchanger would result in significant resource savings. But the few cubes saved will not cover the wear and tear of the equipment. Starting and stopping produce an increased load, painfully affecting the technical condition of the boiler.

Conclusion: if you need to periodically turn off the boiler, then the intervals between starts should be quite large.

Another problem arises here: stopping the boiler for a long time will lead to severe cooling of the coolant. As a result, upon reheating, condensation will form on the heat exchanger, which can lead to a reduction in service life. And the burner will generally fail due to moisture.

Closed heating circuit with circulation https://i.pinimg.com

Factory settings are designed for optimal pressure and flame height. Trying to change them yourself risks being left without heating in the middle of winter.

When is maintenance and repair necessary?

In case of emergencies that threaten the normal technical condition of both auxiliary equipment and the heating system, repairs of Vailant gas boilers are carried out immediately. Efficiency of work is especially important in the frosty months of the year, when there is a risk of rupture of heating network pipes due to freezing.

For high-quality operation, gas heating boilers require regular maintenance, which is advisable to carry out in the warm season, preferably in August or September.

Adjusting the pumping station - how to properly adjust the water pressure switch

The purchase of a pumping station ensures regular water supply in the house. However, for a stable pressure of supplied water, equipment for autonomous water supply requires correct configuration and competent operation. It should be noted that not every owner of a pumping station is familiar with the settings, and incorrect actions can completely damage the equipment. To avoid such trouble, you need to know how to adjust the water pressure switch, what techniques and rules should be used to eliminate malfunctions in the operation of the equipment. It is also important to know why the pressure in the system drops and how such a problem is solved.

How to resolve error F20 (F76) of a Vaillant boiler?

This signal indicates overheating of the unit. In this case, the boiler stops working.

- The cause of the malfunction may be a failure of the temperature sensor or thermostat. The error can also be caused by malfunctions in the circulation circuit.

- If there is a problem with the temperature sensor, an incorrect signal is sent to the board, indicating a lack of contact between the temperature sensor and the board .

- Also, the reason for the boiler shutting down may be a circulation disorder in the main circuit. Cause: clogged heating circuit filter or primary heat exchanger.

What speed should I set on the heating pump at low boiler power?

Adjusting the power of the circulation pump is usually carried out in order to increase or, conversely, reduce its performance . The higher its speed, the faster the hot water passes through the pipes and the more heat it gives off. In turn, the lower it is, the slower the liquid passes through the system, the faster it cools and, accordingly, the heat transfer will be less.

The minimum power of heating equipment is set mainly in the spring . At this time, it is already quite warm outside, but the house itself does not warm up enough and there is a need for a little heating of the room.

Pump speed modes may vary depending on the model and configuration. On average, the minimum is 30-35 l/min , the maximum is 80-90 l/min .

Why do you need to check the settings?

To ensure maximum performance of the device, before using it . This is done, as a rule, according to two parameters.

Noise insulation. There are several reasons why a heater may make a lot of noise:

- incorrect installation;

- air in pipes;

- voltage fluctuations;

- device malfunction.

To avoid these problems, it is better to entrust the installation to a specialist who will carry out comprehensive diagnostics and ensure the correct installation and functionality of the device.

Uniform heating. The main reason for uneven heating of radiators is insufficient power. Low speed contributes to the rapid cooling of the water, as a result of which the heat simply does not reach the end of the system.

Airiness or an incorrectly selected thermostat mode also leads to a similar problem . May affect the performance of the device and improper installation . This is especially true for aluminum and bimetallic batteries, which must be installed as level as possible.

Types of wall-mounted boilers

Atmospheric gas boiler NAVIEN ATMO 24-AN

There are three types of wall-mounted heating devices of this class on the domestic market:

- Navien atmospheric (open) boiler;

- turbocharged wall models;

- condensing devices.

Each of these positions requires separate consideration.

Atmospheric gas boilers

Units of this type have an open combustion chamber. Represented by the Navien Atmo model. It is intended for operation in conditions of uneven gas pressure (its differences can reach 8-17 mbar) and the coolant itself - from 0.6 to 8 bar. The power of the offered units varies from 13 to 24 kW. At an operating temperature of 80°C, the coolant heats hot water to 60°C with a production volume of 10 liters per minute. To remove combustion products, they are equipped with standard chimneys.

The heating circuit in atmospheric boilers is made of copper, and the heat exchanger body is made of stainless steel.

Turbocharged units

Turbocharged boiler Navien Deluxe 10 Coaxial

The group of units of the second type (with an isolated combustion chamber) includes models of the following series:

- Prime, represented by boilers with a capacity of about 13-35 kW;

- Deluxe, whose declared power ranges from 13 to 40 kW;

- modern Smart TOK models with an indicator of 13-35 kW.

Portions of air are forced into the isolated combustion chamber - they are pumped through a special fan installed in a coaxial pipe. Thanks to this, units with a Coaxial design have a higher efficiency, sometimes reaching a record figure of 93%. Gas boilers from the Navien Deluxe series are able to withstand significant changes in supply voltage, as they are equipped with a built-in stabilizing device. In addition, they have the option of automatically maintaining the temperature of the media at a level not lower than the “cooling point” (6-9 degrees).

Condensing boilers

Condensing gas boiler Navien NCN 40KN

The third type of Navien gas boilers is represented by samples of equipment from the NCN and NCB series. Due to additional heating of the carrier with the heat of the condensate, their efficiency was increased to 99%. The functionality of these units is even higher than that of turbocharged boilers - the controller built into them allows you to set temperature parameters for a week in advance.

The Navien NCN product series includes four varieties with power from 22 to 40 kW, and NCB has the same number of products with ratings of 24-40 kW. The water in them is heated to 65°C, and the coolant circulating through the pipes is heated to 90°C. These units are able to withstand media pressure up to 10 Bar.

The air supply in equipment of this class is organized through a coaxial or conventional chimney.

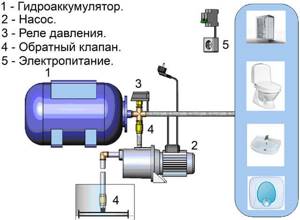

Pumping station design

Factory-made pumping stations are fully equipped by the manufacturer and ready for use. Their main purpose is forced water supply. To understand how to set up a pumping station, you need to know its structure.

Such mechanisms operate according to a fairly simple scheme. Inside the accumulator there is an elastic container into which water is supplied using a pump. Filling the tank with water puts pressure on another part of the hydraulic tank filled with air or gas. When the pressure reaches the set values, the pump turns off. Taking water from the storage tank leads to a decrease in pressure in the system and when the minimum value is reached, the pump turns on again.

To turn the pump on and off, the equipment is equipped with a special pressure regulator for the pumping station. The owner can control the pressure level according to the readings of the pressure gauge, also installed on the equipment.

Other malfunctions and solutions

If the reverse draft diode blinks, then either it is faulty, or the combustion products are not completely removed but enter the room.

The repair instructions in this case are as follows: first you should clean the chimney, then check the quality of ventilation. After this, you can replace the backdraft sensor. Initially, during installation, it is important to comply with all safety requirements. Quite often the gas burner becomes clogged and soot is deposited on it. It should be cleaned regularly to ensure full control of the flame level.

Air pressure control

At one of the stages of production of a pumping station, all its constituent elements are adjusted, including adjustment of the water pressure switch. However, after purchasing equipment in a store, it is necessary to recheck the pressure, since in most cases there is a decrease in air pressure in the interval between leaving the production line and direct sale. During operation, pressure indicators are monitored approximately twice a year. In such a situation, it is important to know how to set up automation at the pumping station.

You can measure pressure using a pressure gauge, but it is recommended to use the most accurate measuring instruments. The fact is that a deviation from the specified parameters even by 0.5 bar can negatively affect the operation of the equipment. The most reliable results can be obtained by using a car pressure gauge, which has a scale with the smallest graduation and a pressure sensor at the pumping station.

The air pressure in the membrane tank depends on the switch-on pressure values set using the relay and is 0.9 of it. In addition, in tanks with different volumes the air pressure can be 1-2 bar. The indicator is adjusted by means of a nipple through which air is pumped in or released.

A smaller amount of air in the system allows you to fill the container with water more, while the more water, the stronger the pressure. Accordingly, as water is withdrawn, the pressure will gradually decrease. If this factor is not significant for the consumer, then it is quite possible to set the lowest pressure value in the water supply station. However, the air pressure should not be less than 1 bar. Otherwise, the bulb filled with water will constantly rub against the walls of the tank, which may cause damage.

If water supply under high pressure is required, then the pressure value when adjusting the water pressure switch in the water supply system must be set within 1.5 bar. In this case, a more even and strong flow of water is ensured.

Step-by-step instructions for assembling and installing the pump

After purchasing the device and choosing the location for its installation, it is necessary to carry out assembly and installation. It is first necessary to install ball valves on both sides of the pump, and install a mud trap in front of the unit to retain scale, dirt, and abrasive particles. The upper part of the bypass must be equipped with an air valve.

Assembling and connecting the pump to the heating boiler is carried out in the following sequence:

- Before installation, drain the liquid from the system. For complete cleaning, you need to fill it with coolant and drain it, then repeat this procedure a couple more times.

- Install the pump into the system.

- After installation, all connections must be carefully sealed.

- Fill the system with liquid. Remove excess air.

- Connect the device to the electrical network.

The number of circulation devices required in the system depends on the length of the pipeline.

Relay operating principle

The main element of the pressure switch can be called a group of contacts mounted on a metal base. It is this part that turns the device on and off. A large and small spring is located next to the contacts; they regulate the pressure inside the system and help in deciding how to increase the water pressure in the pumping station. A membrane cover is attached to the lower part of the metal base; under it you can directly see the membrane and the metal piston. The entire structure is covered by a plastic cap.

To understand how to properly set up a pumping station, you need to know that the pressure switch works according to the following scheme:

- When you open the tap, water from the storage tank flows to the collection point. In the process of emptying the container, the pressure begins to gradually decrease, and accordingly, the degree of pressure of the membrane on the piston decreases. The contacts close and the pump starts working.

- While the pump is operating, the taps at the dispensing points can be open, at which time water is supplied to the consumer. When the tap is closed, the hydraulic tank begins to fill with water.

- An increase in the water level in the tank leads to increased pressure in the system, which begins to put pressure on the membrane. It begins to put pressure on the piston, which opens the contacts and stops the pump.

A properly adjusted water pump pressure regulator ensures normal frequency of switching on and off of the pumping station, normal water pressure and equipment service life. Incorrectly set parameters cause continuous operation of the pump or its complete stop.

Heating boiler Navien: the best of its kind

The Navien boiler is considered the most popular among heating and heating devices. The company presents only high-tech models for installation in all kinds of premises. On sale, everyone will be able to find a device that will serve them well for a very long time - and all this at a fairly attractive price. Wall-mounted solutions are best suited for heating apartments and small private houses.

Korean Navien gas boilers are double-circuit boilers that have an open and closed combustion chamber. They are used for heating and heating water for domestic and technical purposes. The entire automation system and documentation have been translated into Russian, thanks to which everyone can easily study the existing instructions, as well as successfully save on heating costs by continuously maintaining the desired temperature in the premises. Uninterrupted and safe operation of the boiler is possible even in conditions of frequent power outages. If the voltage in the network fluctuates, the SMPS protection system is activated, after which the boiler continues to operate properly. In particular, thanks to this function, these double-circuit boilers have a long service life without breaking down or requiring subsequent repairs.