[contents]

There are several reasons why water boils in a heating boiler. For example, boiling is often a consequence of the fact that the liquid is heated in the boiler faster than the thermal energy is transferred to the heating main. This happens due to:

- incorrect installation of the system;

- the fact that there is no circulation (or its speed is low) - usually occurs in open-type systems with an expansion tank;

- too much power of the device compared to batteries;

- low amount of water in the main.

what to do if the heating boiler boils

Boiler boiling

2. At some point, the nearby circuits stop heating, and all the batteries become cold, and the boiler begins to boil.

The heating system is boiling. Why? Conclusion

3. Then I achieve the desired result in different ways: I feverishly twist the central plug in the pump, releasing steam and coolant, turn the pump on and off, the last time this all lasted more than 2 hours, the process is completely uncontrollable. It seems that the pump works on its own and does not pump anything, I do everything at random.

4. Then at some point suddenly everything seems to break through, the batteries ALL instantly become hot, and the temperature in the boiler drops to 60 degrees. Then everything can remain like this and work well for several hours, or again after 2-3 hours the batteries can cool down and the temperature in the boiler rises.

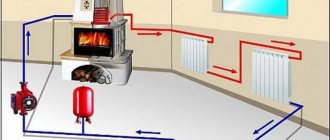

Heating scheme

Unfortunately, you did not indicate whether this is the first start after installation, or whether the heating system has worked successfully before. We will assume that the design and installation were carried out correctly, the capacity of the compensation tank and the cross-sections of the pipelines were chosen correctly. The floor wiring diagram that you sent is simple and should ensure satisfactory coolant circulation. By the way, connecting the radiator on the stairs to the vertical main is irrational; the correct solution would be to connect after the riser.

There may be several reasons why the coolant temperature periodically rises to a critical level, but the radiators remain cold:

Most often, such problems are caused by a “plug”, either air or mud. Air is released especially actively in the first month after filling the system; it is recommended to bleed it daily. An air ventilator (Maevsky tap) should be installed on each heating device. Automatic air vents are installed at the top points of heating lines, in the boiler room, on the boiler itself, on the collectors (judging by the diagram, you don’t have them). Airing of the system is the most common cause of unstable heating operation. We recommend starting the inspection by thoroughly bleeding the air, first at the top, moving down. If air has to be released frequently and the pressure in the system drops, the tightness has been broken somewhere.

The air ventilator should be installed on each heating radiator

A mud “plug” can also hinder the free flow of coolant. The first thing you should check is the filter, if there is one. Deaerators, especially needle type ones (Maevsky taps), can also clog dirt and sludge.

Such a device combines the functions of an automatic air deaerator and a dirt filter. Easy to maintain, allows you to ensure cleanliness and normal gas composition of the coolant

The reasons for unstable heating operation may also lie in your circulation pump. Although, more often it fails immediately and for good. You can check whether the pump is working by placing your hand on the body. A slight vibration should be felt. First, we recommend checking and cleaning the electrical contacts. The reason may lie in the wear of electric motor parts or in the formation of lime deposits if unprepared tap water is used as a coolant.

Circulation problem

If you have a circulation pump, but the system is unstable, then the problem may lie there. To check the functionality, place your hand on the battery - if you feel a slight vibration, it means the pump is working normally, if not, follow these steps.

- Check and clean electrical contacts.

- Check the pump parts for wear and lime deposits (if using regular tap water).

- Finally, you can turn off the pump, unscrew the plug and turn the shaft with extreme caution. This should help for a while. Citric acid can be used to remove deposits.

Why does a gas boiler boil?

During normal operation of the equipment, the coolant in the circuit warms up to the set temperature. After which it is distributed naturally or forcibly through the heating system through the pump. This is how the radiators in the room warm up. The liquid then moves along the return circuit and returns to the boiler.

In case of overheating of the coolant, thermal sensors are activated. As a result, the operation of the device is blocked. What to do if the boiler boils? To restore heating, it is necessary to find the cause of the breakdown. Sometimes the self-diagnosis system displays an error code:

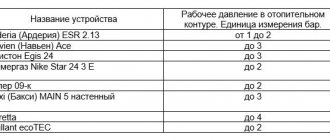

- E01 for " ";

- E02 for ;

- A03 for " ";

- 01 for ;

- F20 for " ";

- 16 for etc.

But if this does not happen, the problem can be identified by external signs.

What causes overheating:

- Clogged filters;

- Air accumulation;

- The heat exchanger is clogged with scale;

- Problems with the circulation pump;

- Failure to comply with regulations for the premises where the equipment is installed.

Why the boiler boils: causes and troubleshooting

Overheating of equipment is unsafe for both residents and the heating system, so it is important to diagnose the problem at the first sign and make the necessary changes to the functionality. Experts emphasize that it is important to take into account the type of working unit.

Most common situations

The most common source of the problem is an air lock in one of the nodes. It is necessary to carefully examine the entire system, focusing on the circulation of hot water. If a warm liquid comes from a pipeline instead of a hot one, it means that this is where an accumulation of air has formed. It is necessary to bleed excess air from the system using bleed valves. If this problem was not detected during the inspection, most likely the cause of the boiling lies directly in the functionality of the boiler.

Overheating of a boiler based on a gravity heating system can be caused by insufficient coolant circulation in the circuit. In this situation, you should place the expansion tank at the highest point in the house, in which case an additional load will be placed on the boiler and the required heated resource will be directed to it.

Experts recognize the most practical method of solving the problem as installing a circulation pump and equipping the heating system with a mixture circuit. Both types of devices allow you to reduce the load on the functionality of the heating device; cooled water will be added to the network. The boiler will receive return flow, which will provide natural cooling.

Causes of boiling in different types of boilers

In addition to insufficient circulation and airing, gas devices suffer from clogged filters: the latter need periodic cleaning or replacement. If exfoliated scale particles clog the duct, knocking and clicking sounds may be heard; here you need to clean the unit with special chemicals. Overheating can be caused by prolonged stagnation of the system and subsequent abrupt start-up (it is necessary to ensure preliminary testing of the ventilation engineering).

Actions relevant when a gas boiler is boiling:

- checking the complete circulation of the coolant and filters;

- monitoring the serviceability of radiator taps and the circulation pump;

- chimney draft control;

- cleaning the heat exchanger.

Solid fuel boilers overheat due to incorrect correlation of their power with the parameters of the room being served. The problem of increasing pressure in equipment caused by turning off the circulation pump is also often recorded.

Steam boilers seriously depend on the presence of liquid in them: due to the low level, the walls overheat, and an emergency situation occurs. Here you should stop supplying fuel, wait until the device cools down and add the working medium.

Why does an electric unit boil?

- scale clogging;

- a malfunction of the thermostat, causing the heating element to function even after the temperature increases;

- membrane malfunction;

- insufficient coolant;

- circulation pump failure;

- The return flow regulators are not open.

Overheating can be prevented by introducing a buffer tank that prevents the boiler from boiling; excess thermal energy will be directed into it. An uninterruptible power supply will allow you not to be afraid of turning off the control units and the pump. An additional circuit for a solid fuel boiler will allow for timely cooling. Experts also recommend periodically inspecting and maintaining (cleaning) the ventilation system.

When the boiler is turned on, the water boils. what to do

Water in a heating boiler may boil because the rate of heating in the boiler exceeds the rate of heat transfer in the home heating system. This can happen for several reasons:

insufficient coolant circulation rate or its absence; insufficient amount of coolant (water) in the system - most often happens in open systems with an expansion tank; excess power of the heating boiler compared to the total power (heat transfer) of the heating radiators of the house, taking into account losses - in the absence of a system for regulating the draft (power) of the boiler; improper installation of the heating system.

If the coolant circulation rate is insufficient, the heated water does not have time to release the heat received in the boiler into the system and can heat up in the boiler to the boiling point. This can happen in heating systems with natural coolant circulation if the correct pipe installation slopes are not observed or, less often, if their diameter is insufficient. With a forced circulation system, this can happen if the circulation pump is not selected correctly, is faulty, does not work, or there is no electric current supplied to it.

Also, the water in the boiler may boil if for some reason there is not enough water in the system and air has entered it. If you have a heating system with natural circulation and a conventional expansion tank, this sometimes happens and in this case you just need to add water. Depending on the design of the heating system, sometimes it is necessary to bleed air from the system or some part of it (in the absence of an automatic valve).

To increase the circulation of water in the heating system, it is necessary to remodel the heating system or, best of all, install a circulation pump. Even with not entirely correct pipe slopes or in their absence, the circulation pump will provide the necessary circulation.

Water in the heating system can also boil if the installed boiler’s power is much higher than the heat transfer power of the entire system, especially if there is no or malfunction of the automatic regulation (draft) air supply system. In this case, it is necessary to install a semi- or automatic draft control system, replace the boiler (if it is homemade without a draft control system) or increase the number or power of radiators. Also, as an option, you can install an indirect water heater (boiler) in the system, which will take part of the heat from the system to heat water and serve as a kind of heat accumulator.

OBI sells a special liquid (like ANTIFREEZE for a car) specifically for heating systems in private homes—I recently saw it at OBI at Belaya Dacha

Good day. You urgently need to call heating system repair technicians. We had the same problem last year. We ourselves could not solve it, we called these masters https://toutletoutim.fr/

The cauldron is boiling

Why is the heating boiler boiling?

Last winter I had a misfortune. The heating boiler leaked. The time has probably come for him. For ten years it worked flawlessly, and then from the blower, at first little by little, and then more and more, it began to pull out raw slag. Everything would be fine, change the boiler, and that’s all. But it's winter outside. The frost is in the thirties, so I had to add water to the system every day. And so he lived until spring. At the beginning of March I purchased a new boiler. I spent a long time choosing from different options and finally settled on the Krasnoyarsk boiler “Dymok”, with a power of 18 kW. I won’t go into details about replacing the boiler, that’s not what I’m talking about.

After starting up a new boiler, I encountered the following problem: the boiler is boiling. I started researching this issue in more detail. An old boiler of approximately the same power did not boil. And this is the conclusion I came to.

Why is the boiler boiling?

The first reason is that there is an air lock somewhere in the system. I went through the entire heating system, determined where the hot water reaches, and then warm water goes further. Air was released through the plugs. It's gotten better, but the boiler is still boiling.

The second reason that I noticed is that the boiler heats the water very quickly, and I have a large heating system. There are approximately 20-25 buckets of water in the entire system

I don't have a circulation pump. It’s just hard for the boiler to quickly disperse such an amount of water.

The expansion tank is connected to the system at the highest point, above the boiler. The hose connecting the heating system to the expansion tank was quite short and connected the heating supply pipe and the tank almost in a straight line. And as a result, it turned out that it is easier for the boiler to push boiling water into the expansion tank than into the heating system.

To solve this problem, I extended the hose so that it now hangs below the level of the supply pipe, and even forms a loop. Now the hot water needs to go down, go through the loop and only then get into the expansion tank. It’s easier to go up into the heating system.

Of course, I did not completely eliminate the boiling problem. Still, a circulation pump is needed. But now the boiling occurs in very short intervals. As soon as it begins to boil, you can immediately hear the characteristic sound of water moving in the pipes. A new portion of water boils and starts moving again

This is how I solved the problem when the boiler boils.

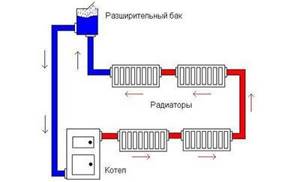

The main difference between open or gravity systems (OS) and closed ones is that in the OS the coolant communicates with the surrounding air in an open expansion tank.

The coolant is in the system under atmospheric pressure, there is no excess pressure.

A simple look at the problem.

The expansion tank plays an important role in the cooling system. Its main function is to dampen pressure fluctuations in pipelines that arise as a result of an increase (decrease) in the volume of antifreeze during heating (cooling). Thanks to the presence of such a container, mechanical loads on system elements are reduced, water hammer and the appearance of air locks are prevented.

In fact, the tank replenishes the lack of fluid in the lines during cooling and serves to receive excess fluid when heating. Structurally, it is made in the form of a plastic sealed container.

A mandatory part of the design is a safety valve for releasing excess pressure into the atmosphere.

When antifreeze heats up, it expands, filling the free space of the tank, and the evaporation rate increases. This leads to an increase in pressure in the volume. An increase in pressure above a threshold value triggers the built-in valve.

The only situation when antifreeze is thrown out of the expansion tank is when the valve fails to perform its assigned functions.

Principle of operation

Schematically, the OS heating circuit can be represented as a long vertical ring. One side of the ring

- with hot water (supply riser from the boiler to the boiler),

the other side

- with cold water (riser with return from the radiators). The density of a hot coolant is less than that of a cold fluid - water expands when heated.

Consequently, the weight of water and the pressure of the water column in the cold part of the circuit will be higher than the weight of water and the pressure of the column in the hot leg.

According to the law of communicating vessels, the liquid will tend to balance the pressures - to move from the cold branch to the hot one.

Since the circuit is such a closed ring, circulation or gravity flow of the coolant occurs.

- The supply riser is maximally insulated along its entire height.

- The boiler is located as far down as possible from the last radiator.

- The circuit has a container for releasing the excess volume of heated coolant

- an expansion tank (to ensure a reduced density and low pressure of the water column in the heated branch).

With natural circulation

During natural circulation, the coolant moves under the influence of the circulation pressure Pн

(in mm water column):

Pn=H x (cold - phot).

- H

- height difference between the boiler and the last radiator, m; - phol

- density of water in the cold return riser,

kg/m³

; - phot

- density of water in the hot supply riser,

kg/m³

.

During circulation along the circuit, the coolant spends part of the pressure to overcome the hydraulic resistance of pipes, radiators, and shut-off valves. Therefore, when designing an operating system, materials with low hydraulic resistance

so that their total does not exceed the design pressure

Pn

(do not block the system).

Important! The OS coolant contains air, which is mixed in the expansion tank. To remove air, pipes are made with a slope of at least 3-5 mm per p.

m. pipes.

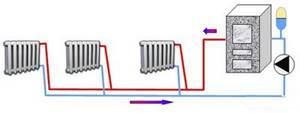

With circulation from a pump

To increase the natural pressure, a circulation pump is included in the OS circuit.

There are two pump insertion points

to existing OS:

- On the return pipe in front of the boiler.

The expansion tank is reconnected to the return pipe in front of the pump (in the suction zone). - On the upper supply pipe

immediately after the expansion tank connection point.

Reference!

The pump insertion point is equipped

with a bypass

with a reed check valve.

Single-pipe

A single-pipe system with natural circulation is made only with upper coolant distribution.

All radiators in the riser of a single-pipe OS are connected in series - the output of one battery is connected to the input of another.

- Small number of pipes.

- Easy to install.

- The system is unbalanced

- the top batteries are hot, the bottom batteries are cold. To equalize the temperature regime, lower radiators are installed with a large number of sections. - Impossibility of thermoregulation

due to high resistance of control valves.

Installation of an open heating system: photo

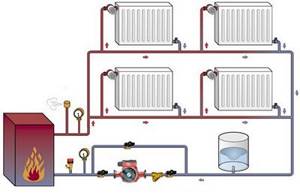

Before installation, it is necessary to perform a radiator calculation, a hydraulic calculation of the circulation pressure, develop an installation diagram, and draw up a list of materials and components.

Photo 1. Heating gas boiler of steel color, floor type, installed in a room with all equipment.

The OS consists of the following elements:

- Heating boiler - gas or solid fuel.

- Pipes.

- Expansion tank.

- Radiators.

- Fittings (taps, boiler piping, valves).

- Circulation pump (optional).

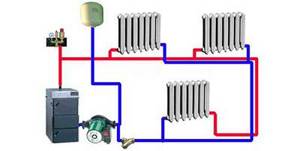

Photo 2. A circulation pump embedded in the pipes increases the efficiency of the entire heating system.

- The slope of the pipes of horizontal supply and return beds is at least 3–5 mm per linear meter.

- Use pipes with a diameter of at least 30 mm.

- The volume of the expansion tank is 15% of the total coolant volume.

Photo 3. Expansion tank made of metal, mounted under the ceiling of the attic of a private house.

Scheme

The diagram, drawn to a convenient scale on a sheet of graph paper, should indicate:

- Dimensions of the rooms where the OS pipes pass.

- Pipe layout diagram.

- Placement of radiators, boiler (providing the required height difference between the boiler and radiators), expansion tank, pipe fittings.

- Dimensions of pipe blanks.

- Elements for fastening pipes to building elements.

- Prepare a set of necessary tools (depending on the selected pipe material).

- Install the boiler and boiler equipment in accordance with the boiler operating instructions.

- Make an expansion tank and install it in the attic.

- Install the vertical riser.

- Install radiators in the rooms.

- Carry out the final installation of pipes connecting all elements of the system.

- Insulate the expansion tank.

- Fill the system.

- Check the system for leaks.

- Perform a test run.

Expansion tank for OS

Any open homemade metal container or flask with the required volume of at least 15% of the total coolant volume in the system can serve as an expansion tank (ER).

RB performs the following functions:

- Serves as a buffer tank to accommodate excess coolant that occurs due to expansion of the liquid when heated in the boiler.

- Provides atmospheric pressure in the system.

- It is the element through which air bubbles leave the system. The rise of air bubbles is ensured by the slope of the pipes.

Installation recommendations:

- The installation of a vertical riser from the boiler should be made of a steel pipe with a diameter of 40–50 mm.

- The size of the remaining pipes is the larger, the better (less hydraulic resistance).

- It is best to use cast iron radiators.

- Try to minimize the number of turns of pipes and shut-off and control valves.

- Use only full bore ball valves.

Features of installation in a private house

- Small area (no more than 150 m²).

- Presence of an attic.

- Possibility of installing the boiler low in relation to the last radiator.

What to do if the water in the tank boils quickly?

If it is discovered that the water is boiling quickly, you need to carry out the entire set of emergency stop actions for the boiler (listed in the operating instructions) as quickly as possible to avoid destruction of the equipment.

Then you need to figure out the reasons.

If the water boils when the boiler is first started, then it is necessary to check the hydraulic calculation and the correct selection and installation of all elements.

If the water boils after some time after normal operation, then you need to check the following parameters:

- coolant level in the system (need for replenishment);

- boiler performance;

- normal operation of the check valve (if there is a pump with a bypass);

- normal operation of the expansion tank.

Expansion tank

Located in the attic. Since the attic is usually an unheated room, the tank must be insulated, otherwise the water in it may freeze in winter. The tank compensates for temperature fluctuations in the water level. In addition, sometimes water in the system can boil (this happens if you start heating the boiler too quickly), and the bubbles significantly increase the volume. This is what the excess volume in the expansion tank is for.

It is advisable to provide for the possibility of draining excess water from the tank when it overflows. To do this, water can be discharged either into the sewer or simply onto the street.

It should be borne in mind that water from an open system evaporates. Therefore, it is necessary to replenish the system with water. This can be done manually, periodically climbing into the attic and adding water, or you can make an expansion tank similar to a toilet - with automatic topping up of water.

But they rarely do this. Usually they just use a container.

It is better to close the top of the tank with a lid so that less water evaporates.

Preventative measures and prevention of overheating

Measures to prevent and prevent emergency situations include the following:

- Install an additional circuit to cool a boiler that runs on solid fuel. In a double-circuit boiler, when the coolant increases, the liquid can be cooled due to the water supply system.

- Installing a buffer tank, it will prevent the boiler from boiling, take on excess temperature, and can also store heat for the heating circuit.

- You need to install an uninterruptible power supply. If there is a power outage, the uninterruptible power supply will automatically turn on, energy will come from the battery, and the system will continue to operate.

- Periodically clean the ventilation system.

Expansion tank device

Structurally, this container is very simple. The material used is translucent plastic. Also, a sensor can be additionally built into the tank, which signals the driver about a critical decrease in the coolant level.

The top of the tank is closed with a lid in which a valve is installed to regulate the pressure. If the pressure in the system increases, then the valve operates.

Also on the wall of the tank there is a level indicator in the form of o and “maximum”, allowing you to control the liquid level

It is important to understand that on a cold engine the level should not fall below the minimum. It is also not allowed to exceed the maximum level

As for the tank cap with the valve, it seals the container hermetically on a cold internal combustion engine. However, when the engine reaches operating temperature and the coolant heats up, the pressure in the cooling system and in the tank naturally increases.

If the pressure rise reaches an average of 120 kPa, the valve opens. When the pressure drops to an average of about 83.4 kPa, the valve closes. This operation of the valve is necessary in order to avoid rupture of pipes, damage to the radiator, etc.

At the same time, after the engine cools down, the pressure in the system begins to drop, the volume of coolant decreases and a vacuum is created. When the pressure drops, on average, below 3 kPa, the inlet valve of the expansion tank opens to take in air. As a result, the pressure difference is leveled, and the missing volume of liquid is compensated from the tank.

Heating devices

In systems with natural circulation, you can use only radiators, as well as thick pipes as radiators (they have less hydraulic resistance).

But, alas, you cannot use convectors - natural circulation simply will not flow through them.

To summarize the above, an open system is a thing of the past. Slow heating, high inertia of the system, a large amount of soluble air, bulky pipes, and low efficiency make it unattractive for modern heating systems. So it is used in extreme cases - for example, in areas where electricity is often cut off.

The most popular now are closed systems with forced circulation of coolant, two-pipe or collector-beam.

Let's analyze the situation when water boils in a heating boiler, and it turns off in emergency mode due to overheating of the coolant. Let's look at several types of boilers and the common causes of this problem in them.

Low circulation rate

So, if the coolant circulates too slowly, the coolant will not fully transfer the resulting heat and, as a result, the water in the boiler will boil. This applies only to those systems in which there is natural circulation of liquid, and the angle of inclination or diameter of the pipes is chosen incorrectly.

Note! In systems with forced circulation, this happens only in cases where the pump power is too low or it has completely failed.

An open heating system with natural circulation has a number of features

- There is a lot of dissolved air in the system, which can lead to corrosion of internal metal elements in the system.

- Great inertia of the system. After turning on the heating, the house heats up slowly. The system must be warmed up gradually, otherwise the water will simply boil in the boiler, while it will still be cold in the radiators.

- The house warms up evenly

- Large temperature difference between supply and return

- Fuel consumption is higher (low efficiency) than in a closed system with a circulation pump

- Independence from electricity

- The system is simple, there is practically nothing to break in it. Fairly simple installation.

- Aesthetically not very good, because... large diameter pipes are used, and sometimes pipes of increased diameter are used as radiators

- The system is quite cumbersome

- Antifreeze cannot be used in the system.

- The water from the system gradually evaporates, so it must be added periodically. It is advisable to install automatic topping up.

- The boiler must be installed at the lowest point of the system. The best place is in the basement, or in some kind of recess.

- The expansion tank is installed at the highest point of the system. If you install it in the attic, it must be insulated.

- Quiet operation due to the absence of a circulation pump

But nevertheless, this system has been successfully used and is used when installing heating in small private houses with a height of 1 or 2 floors.

Let us describe the entire system in order:

The main causes of heating and methods for eliminating them

The temperature of the device and pipeline should be in the same range and approximately equal. If the difference between the temperature of the supply device and the pipes is large, this indicates that the circulation pump is overheating.

The malfunction of any technical device is caused by certain reasons, this also applies to pressure equipment. Below are the main reasons that cause increased heating of the device.

Incorrect installation

This is a fairly common cause of equipment overheating. There may be an incorrectly drawn up heating project or errors made directly during installation work or the use of low-quality materials.

Such errors can lead to displacement of the axis relative to the horizontal axis, resulting in the risk of air entering the heating system. This error appears immediately after the start of operation.

Clogged system

The unit may overheat due to clogged pipes and other heating parts. The flow of working fluid through pipes can lead to the formation of rust and scale. Over time, dirt is deposited on the internal walls of the pipeline. As a result, the internal diameter of the pipeline decreases. Because of this, the device must expend more force to push the coolant through clogged pipes. This leads to overheating of the unit.

This problem can be eliminated by cleaning the heating. To do this, you can use caustic soda; it is poured into the system for one hour.

Foreign body

Foreign particles that are in the piping system can enter the electric drive over time. They can block the operation of the motor and thus cause the windings to burn out. This can be avoided by performing periodic preventative maintenance. The frequency of maintenance is indicated in the operating manual of the circulation unit. During maintenance, the engine is cleaned of foreign particles. If dirt is not removed, or removal of contamination is impossible, the electric motor will have to be replaced over time.

Insufficiently lubricated bearings

Lack of lubrication leads to accelerated bearing wear. The result of this is engine jamming. In this case, the engine will have to be dismantled and sent to a specialized workshop for repairs.

Low voltage in the network

As a rule, devices operate on a voltage of 220 V. Low voltage will sooner or later lead to the unit becoming air-filled, causing it to fail.

Overvoltage

Increased voltage can cause the windings to burn out. To eliminate this problem, you can install an uninterruptible power supply, which will ensure a stable supply of electricity. If the motor is running smoothly, the impeller may become hot due to the high resistance that occurs in a pipe that is too narrow. This problem can be solved by increasing the diameter of the pipeline.

Insufficient pressure

Overheating may be caused by an error made when installing the device in its place. For example, the motor was connected incorrectly. In this case, the direction of movement will be disrupted. Low pressure can also be caused by the fact that a liquid with a viscosity greater than that allowed by the technical characteristics of the device is moving through the pipeline.

To eliminate this problem, at the first sign of its manifestation, you will need to check the cross-section of the inlet pipe, set the required device parameters and remove deposits on the filter of the pipe installed at the inlet.

Stopping after start

This problem occurs when the phases in the terminal box are connected incorrectly or the fuse is not pressed tightly enough (there is no contact in the fuse). To eliminate this defect, you will need to remove the fuse and clean the contacts.

Boilers with automatic ignition.

Water circulation in the heating circuit is disrupted.

Due to the slow movement of the coolant in the heating system, the water in the heat exchanger overheats and the boiler stops in emergency mode. The speed of fluid movement in the system can be affected by decreased performance or breakdown of the pump, contamination of the filter installed on the “return” of the heating circuit, or improper operation of the three-way valve.

The performance of the circulation pump is reduced due to contamination of the turbine blades or internal cavity.

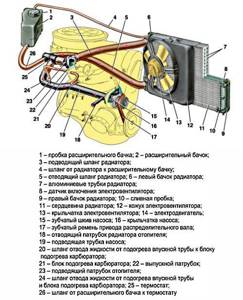

Photo 1 – circulation pump module of a gas boiler with automatic ignition.

To revise it you need:

- Stop smoothly by moving the water temperature regulator knob to the extreme zero position and wait until the process is completed, turn off the power to the boiler.

- Remove the front part of the housing.

- Determine the installation location of the pump.

- Close the shut-off valve (No. 2, No. 3, No. 4 photo 2) of the supply, return, and cold water supply lines.

- Drain water from the boiler through the drain valve and leave it in the open position.

- Loosen the pump fasteners until air enters the circuit to drain residual fluid from the system.

- Remove the mount, power plug and remove the module (engine with turbine).

- Clean the blades, internal cavity and rubber seal of the mechanism from dirt.

- Assemble the pump.

- Open the cold water supply tap.

- Open the feed tap slightly to check the tightness of the hydraulic part of the boiler.

- Open the flow and return valve.

- Fill the system with water to a pressure of 1 bar.

- Turn on the boiler in circulation mode to remove air.

Photo 2 is an example of heating system pipe routing.

In boilers with electronic control, if the pump breaks down, the corresponding fault code will be displayed on the dashboard, which is deciphered using the boiler passport or electronic catalogs posted on the manufacturer’s website.

Checking and cleaning the filter:

- Smoothly stop the boiler.

- Using the taps (No. 1, No. 2) installed in front of and behind the filter, turn off the water supply.

- Using the filter drain valve, remove water from the isolated area.

- Unscrew the flask and clean the mesh catcher.

- Assemble all filter components.

- Open previously closed valves.

- If system pressure decreases, recharge the circuit.

- Turn the boiler to the venting position.

Checking the three-way valve.

In double-circuit wall-mounted gas boilers, switching from the heating mode to the hot water supply position is carried out using a three-way valve. It consists of a servo drive (motor with gearbox), rod, rubber seals, valve and body with inlets and outlets. A malfunction of this device can lead to a cessation of coolant circulation and, as a result, overheating of the heat exchanger occurs.

To check the condition of the three-way valve, it is necessary to smoothly stop the boiler and de-energize the system. Check the serviceability of the engine, and to do this, connect ohmmeter probes to the power terminals. If it shows 80 - 300 Ohms, then the engine is working, and if there are other readings (0 or 1), then it is faulty.

The three-way valve may not switch due to jamming of the drive gearbox, or due to deformation of the valve itself. If malfunctions of the valve are detected, it is replaced with a serviceable one or undergoes revision.

How to restore boiler operation

If the equipment overheats, do not delay repairs. There are times when a gas boiler explodes, so fix the problem as soon as you notice it.

Blockage and airiness of the system

If water stagnates and does not circulate in the circuit, this leads to boiling. You can hear the liquid inside gurgling. Turn off the device and wait until the coolant cools down. Often the filters are valved on both sides so you don't have to drain all the water from the system. Turn on the taps, remove and wash the filters.

If the strainer is very clogged, dip it in a solution of citric acid. Additionally, you can clean the part with a soft brush.

Filters that are worn out and cannot be cleaned should be replaced.

An air lock slows down the movement of the fluid or stops it altogether. How to deal with this:

- Open the Mayevsky taps - they are on every radiator. Place containers under them first;

- You will hear air hissing out of the circuit. Then water can flow. Do not close the taps immediately. Wait until the liquid is drained and all the air is released;

- Repeat the procedure until the air lock is completely eliminated.

Scale deposits

Magnesium and potassium salts are deposited on boiler parts when heated above 55 degrees. Most of the scale deposits in the heat exchanger because the liquid circulates and heats up in it. As a result, the passages in the tubes narrow, the pressure decreases, and water boils in the assembly. This leads to overheating and damage to the heat exchanger.

To clean the unit, remove it. The most effective way is to connect a pump to the unit and pump it with the reagent. After this, the radiator is washed with running water, dried and installed in place.

At home, the radiator is placed in a metal container with warm water. A solution of citric acid is poured into the coil. The container is placed on the stove, where it warms up for half an hour.

To prevent scale formation, install magnetic filters. Their cassettes only need to be changed once a month, but they soften the water well.

Problems with the pump

When turning on the boiler after a long period of inactivity, you need to check the pump. Its parts could stick and the holes could become clogged. Clean and replace faulty parts.