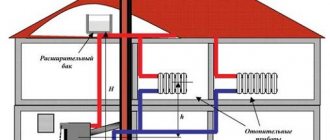

When starting to install a heating system, it is necessary to calculate the volume of liquid, because this parameter is considered the main one when choosing a boiler. Only the optimal volume of coolant allows you to effectively warm up the house in the winter season. This indicator is affected by the dimensions of the pipes. When using a circulation pump, it is permissible to choose pipelines of a smaller diameter. This allows you to increase the number of heating radiators.

When choosing pipes of increased diameter at the boiler's maximum power, the coolant is underheated. This is due to the fact that the working fluid has time to cool before it reaches the extreme point of the heating system, and this is additional material costs. According to earlier calculations, for every kilowatt of boiler power, 15 liters of liquid will be needed. Based on this, a detailed calculation of the volume of water in the heating of a private house is carried out.

Selection of coolant

Water is most often used as a working fluid for heating systems. However, antifreeze can be an effective alternative solution. Such a liquid does not freeze when the ambient temperature drops to a critical level for water. Despite the obvious advantages, the price of antifreeze is quite high. Therefore, it is used mainly for heating small buildings.

Filling heating systems with water requires preliminary preparation of such a coolant. The liquid must be filtered from dissolved mineral salts. For this purpose, specialized chemical reagents that are commercially available can be used. Moreover, all air must be removed from the water in the heating system. Otherwise, the efficiency of space heating may decrease.

Features of selecting a circulation pump

The pump is selected according to two criteria:

- The amount of pumped liquid, expressed in cubic meters per hour (m³/h).

- Pressure expressed in meters (m).

With pressure, everything is more or less clear - this is the height to which the liquid must be raised and is measured from the lowest to the highest point or to the next pump, if the project provides more than one.

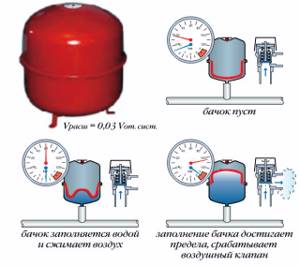

Expansion tank volume

Everyone knows that liquid tends to increase in volume when heated. To prevent the heating system from looking like a bomb and leaking at all the seams, there is an expansion tank into which the displaced water from the system is collected.

What size tank should I purchase or make?

Everything is simple, knowing the physical characteristics of water.

We multiply the calculated volume of coolant in the system by 0.08. For example, for 100 liters of coolant, the expansion tank will have a volume of 8 liters.

Let's talk about the amount of pumped liquid in more detail.

Water consumption in the heating system is calculated using the formula:

G = Q / (c * (t2 - t1)), where:

- G – water consumption in the heating system, kg/sec;

- Q – amount of heat compensating for heat loss, W;

- c is the specific heat capacity of water, this value is known and equal to 4200 J/kg*ᵒC (note that any other coolants have worse performance compared to water);

- t2 – temperature of the coolant entering the system, ᵒС;

- t1 – coolant temperature at the outlet of the system, ᵒС;

Recommendation! For comfortable living, the temperature delta of the coolant at the inlet should be 7-15 degrees. The floor temperature in the “warm floor” system should not be more than 29 ᵒ

C. Therefore, you will have to figure out for yourself what type of heating will be installed in the house: will there be radiators, “warm floor” or a combination of several types.

The result of this formula will give the coolant consumption per second of time to replenish heat loss, then this indicator is converted into hours.

Advice! Most likely, the temperature during operation will vary depending on the circumstances and season, so it is better to immediately add 30% of the reserve to this indicator.

Let's consider the indicator the calculated amount of heat required to compensate for heat losses.

Perhaps this is the most complex and important criterion, requiring engineering knowledge, which must be approached responsibly.

If this is a private house, then the indicator can vary from 10-15 W/m² (such indicators are typical for “passive houses”) to 200 W/m² or more (if it is a thin wall with no or insufficient insulation).

In practice, construction and trade organizations take the heat loss indicator as a basis - 100 W/m².

Recommendation: calculate this indicator for a specific house in which a heating system will be installed or reconstructed. For this, heat loss calculators are used, with losses for walls, roofs, windows, and floors being calculated separately. These data will make it possible to find out how much heat a house physically releases into the environment in a specific region with its own climate regimes.

We multiply the calculated loss figure by the area of the house and then substitute it into the water consumption formula.

Now you need to deal with the issue of water consumption in the heating system of an apartment building.

General calculations

It is necessary to determine the total heating capacity so that the power of the heating boiler is sufficient for high-quality heating of all rooms. Exceeding the permissible volume can lead to increased wear of the heating device, as well as significant energy consumption.

The required amount of coolant is calculated according to the following formula: Total volume = V boiler + V radiators + V pipes + V expansion tank

Boiler

Calculating the power of the heating unit allows you to determine the boiler capacity indicator. To do this, it is enough to take as a basis the ratio in which 1 kW of thermal energy is enough to effectively heat 10 m2 of living space. This ratio is fair in the presence of ceilings whose height is no more than 3 meters.

As soon as the boiler power indicator becomes known, it is enough to find a suitable unit in a specialized store. Each manufacturer indicates the volume of equipment in the passport data.

Therefore, if the correct power calculation is performed, there will be no problems with determining the required volume.

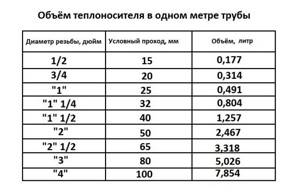

Pipes

To determine the sufficient volume of water in the pipes, it is necessary to calculate the cross-section of the pipeline according to the formula - S = π × R2, where:

- S – cross section;

- π is a constant equal to 3.14;

- R is the inner radius of the pipes.

Having calculated the cross-sectional area of the pipes, it is enough to multiply it by the total length of the entire pipeline in the heating system.

Expansion tank

You can determine what capacity the expansion tank should have by having data on the coefficient of thermal expansion of the coolant. For water this indicator is 0.034 when heated to 85 °C.

When performing the calculation, it is enough to use the formula: V-tank = (V system × K) / D, where:

- V-tank - the required volume of the expansion tank;

- V-syst - the total volume of liquid in the remaining elements of the heating system;

- K – expansion coefficient;

- D – efficiency of the expansion tank (indicated in the technical documentation).

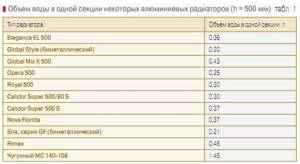

Radiators

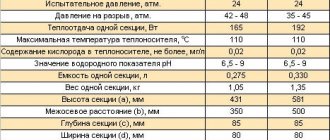

Currently, there is a wide variety of individual types of radiators for heating systems. In addition to functional differences, they all have different heights.

To calculate the volume of working fluid in radiators, you must first count their number. Then multiply this amount by the volume of one section.

You can find out the volume of one radiator using the data from the product technical data sheet. In the absence of such information, you can navigate according to average parameters:

- cast iron - 1.5 liters per section;

- bimetallic - 0.2-0.3 l per section;

- aluminum - 0.4 l per section.

The following example will help you understand how to correctly calculate the value. Let's say there are 5 radiators made of aluminum. Each heating element contains 6 sections. We make the calculation: 5 × 6 × 0.4 = 12 liters.

How to correctly determine the type of heating boiler and calculate its power

In the heating system, the boiler plays the role of a heat generator

When choosing between boilers - gas, electric, liquid or solid fuel, pay attention to the efficiency of its heat transfer, ease of operation, and take into account what type of fuel predominates in the place of residence

The efficient operation of the system and a comfortable room temperature directly depend on the power of the boiler. If the power is low, the room will be cold, and if the power is too high, fuel will be wasted. Therefore, it is necessary to choose a boiler with optimal power, which can be calculated quite accurately.

When calculating it, you must take into account:

- area of the heated room (S);

- specific boiler power per ten cubic meters of room. It is set with adjustments taking into account the climatic conditions of the region of residence (W spec.).

There are established specific power values (Wsp.) for certain climatic zones, which are for:

- Southern regions - from 0.7 to 0.9 kW;

- Central regions - from 1.2 to 1.5 kW;

- Northern regions - from 1.5 to 2.0 kW.

Boiler power (Wbot) is calculated using the formula:

W cat. = S*W beat. / 10

Therefore, it is customary to choose the boiler power at the rate of 1 kW per 10 kW. m of heated room.

Not only the power, but also the type of water heating will depend on the area of the house. A heating design with natural water movement will not be able to effectively heat a house with an area of more than 100 square meters. m (due to low inertia). For a room with a large area, you will need a heating system with circular pumps, which will push and accelerate the flow of coolant through the pipes.

Since the pumps operate in non-stop mode, they are subject to certain requirements - noiselessness, low energy consumption, durability and reliability. On modern models of gas boilers, the pumps are already built directly into the housing.

Eventually

As you can see, calculating the heating capacity comes down to calculating the total value of the four above elements.

Not everyone can determine the required capacity of the working fluid in a system with mathematical accuracy. Therefore, not wanting to perform the calculation, some users act as follows. To begin with, fill the system to approximately 90%, after which the functionality is checked. Next, the accumulated air is released and filling continues.

During operation of the heating system, a natural decline in the coolant level occurs as a result of convection processes. In this case, there is a loss of power and productivity of the boiler. This implies the need to have a reserve tank with working fluid, from where it will be possible to monitor the loss of coolant and, if necessary, replenish it.

Water volume of the coolant in the pipe and radiator, how is it calculated

The water volume or heat carrier in a wide variety of pipelines, for example, low-pressure polymer ethylene (HDPE pipe), polypropylene pipes, metal-plastic pipes, profile pipes, is important to know when choosing some equipment, especially an expansion tank. For example, in a metal-plastic pipe with a diameter of 16 per meter of pipe 0.115 g

coolant

For example, in a metal-plastic pipe the diameter is 16 per meter of pipe 0.115 g. heat carrier.

Did you know? There is no faster way. And why do you actually need to know this until you are faced with a choice, for example, an expansion tank. Knowing the volume of coolant in the heating system is necessary not only to select an expansion tank, but also to purchase antifreeze. Antifreeze is sold undiluted to -65 degrees and diluted to -30 degrees. Once you know the volume of coolant in the heating system, you will be able to purchase an equal amount of antifreeze. For example, undiluted antifreeze needs to be diluted 50*50 (water*antifreeze), which means with a volume of coolant equal to 50 liters, you will need to purchase only 25 liters of antifreeze.

We recommend for you a form for calculating the volume of water (heat carrier) in the water supply and heating radiators. Enter the length of a pipe of a specific diameter and instantly find out how much coolant is in this section.

Water volume in pipes of different diameters: performing calculations

Once you have calculated the volume of coolant in the water metering unit, however, to create a complete picture, and specifically to find out the entire volume of coolant in the system, you will also need to calculate the volume of coolant in the heating radiators.

Volumetric calculation of water in pipes

Volumetric calculation of water in a heating radiator

Water volume in certain metal batteries

Now it certainly won’t be difficult for you to calculate the volume of coolant in the heating system.

Volumetric calculation of the coolant in heating radiators

In order to calculate the entire volume of the coolant in the heating system, we also need to add the water volume in the boiler. You can find it out in the boiler passport or take approximate numbers:

floor boiler - 40 liters of water;

mounted boiler - 3 liters of water.

A brief guide to using the calculator “Volume calculation of water in a wide variety of pipelines”:

- in the first list, select the pipe material and its diameter (it can be plastic, polypropylene, metal-plastic, steel and diameters from 15 - ...)

- in another list we write the footage of the selected pipe from the first list.

- Click “Calculate”.

“Calculate the amount of water in heating radiators”

- in the first list, select the interaxial distance and what materials the heating device is made of.

- enter the number of sections.

- Click “Calculate”.

Heating 'target=»_blank»>')

3.1.General information

The heat demand of heat-using consumers varies depending on meteorological conditions, the number of people using hot water in domestic hot water supply systems, and the modes of air conditioning and ventilation systems for heating units. For heating, ventilation and air conditioning systems, the main factor influencing heat consumption is the outside air temperature. The heat consumption supplied to cover the loads of hot water supply and technological consumption does not depend on the outside air temperature.

The technique of changing the amount of heat supplied to consumers in accordance with their heat consumption schedules is called a heat supply control system.

There are central, group and local regulation of heat supply.

One of the most important tasks in regulating heat supply systems is calculating operating schedules for various load control methods.

Regulation of the heat load is possible using several methods: changing the temperature of the coolant - a qualitative method; periodic shutdown of systems – intermittent regulation; change in the surface of the heat exchanger.

In heating networks, as a rule, central quality control is adopted for the main heat load, which is usually the heating load of small and public buildings. Central qualitative regulation of heat supply is limited by the lowest water temperatures in the supply pipeline necessary to heat the water entering the hot water supply systems of consumers:

for closed heating systems - at least 70°C;

for open heat supply systems - at least 60°C.

Based on the data obtained, a graph of changes in the temperature of the network water is constructed depending on the outside air temperature. It is advisable to perform a temperature graph on a sheet of A4 graph paper or using Microsoft Office Excel. The graph determines the control ranges based on the break point temperature and describes them.

2.3.2

.

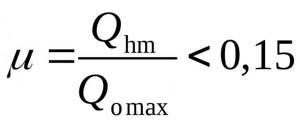

Central quality regulation for heating load

Central quality regulation for heating load is advisable if the heat load for housing and communal needs is less than 65% of the total load of the area and with the ratio

.

With this method of regulation, for dependent connection schemes of elevator heating systems, the temperature of the water in the supply

and reverse

highways, as well as after the elevator

during the heating season is determined by the following expressions:

(2)

The calculation was made for value No. 1. For all others, the calculation was made using the formula proposed above; the results are listed in Table 3.

(3)

The calculation was made for value No. 1. For all others, the calculation was made using the formula proposed above; the results are listed in Table 3.

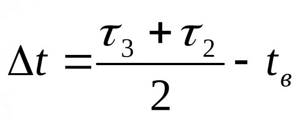

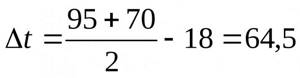

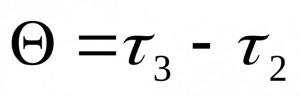

where t

— calculated temperature pressure of the heating device, 0 C, determined by the formula:

, (4)

Here

3 and

2 - calculated water temperatures, respectively, after the elevator and in the return line of the heating network, determined at

(for residential areas, as a rule,

3 = 95 0 C;

2 = 70 0 C);

— calculated temperature difference of supply water in the heating network

=

1 —

2 (5)

=110-70=40

- calculated temperature difference of network water in the local heating system,

(6)

n (usually

t

n = +8; 0; -10;

t

nr v;

t

nro) determine

01;

02 ;

03 and build a heating graph of water temperatures.

To satisfy the hot water supply load, the water temperature in the supply line

01 cannot be lower than 70 0 C in closed heating systems. To do this, the heating schedule is straightened at the level of the indicated temperatures and becomes a heating-domestic one (see example solution).

Outdoor air temperature corresponding to the break point of the water temperature graphs t

n ", divides the heating period into ranges with different control modes:

in range I with the range of outside air temperatures from +8 0 C to t

n “group or local regulation is carried out, the task of which is to prevent “overheating” of heating systems and unnecessary heat losses;

in ranges II and III with the range of outside air temperatures from t

n » to

t

nro central quality regulation is carried out.

Table 3 - Temperature graph

| Outside air temperature, tnr | Coolant temperature |

Types of radiators

The most popular among the total number of convectors are three types:

- Aluminum radiator;

- Cast iron battery;

- Bimetallic radiator.

If you know which convector is installed in your home and are able to count the number of sections, then making simple calculations will not be difficult. Next, calculate the volume of water in the heating radiator

,

table

and all necessary data are presented below. They will help to calculate as accurately as possible the amount of coolant in the entire system.

| Convector type | Average water volume liter/section |

| Aluminum | |

| Old cast iron | |

| New cast iron |

Bimetallic

Aluminum

Although in some cases the internal heating system of each battery may differ, there are generally accepted parameters that allow you to determine the amount of liquid placed in it. With a possible error of 5% you will learn that one section of an aluminum radiator can contain up to 450 ml of water

It is worth paying attention to the fact that for other coolants the volumes may be increased

Cast iron

Calculating the amount of liquid that fits in a cast iron radiator is a little more difficult. An important factor will be the novelty of the convector. New imported radiators have significantly less void space, and due to their improved structure, they heat no worse than the old ones.

The new cast iron convector holds about 1 liter of liquid, the old one will hold 700 ml more.

Bimetallic

These types of radiators are quite economical and productive. The reason why filling volumes may change lies only in the features of a particular model and pressure variation. On average, such a convector is filled with 250 ml of water.

Possible changes

Each battery manufacturer sets its own minimum/maximum permissible standards, but the volume of coolant in the internal tubes of each model may change due to pressure increase considerations. Typically, in private homes and new buildings, an expansion tank is installed on the ground floor, which allows the liquid pressure to be stabilized even when it expands when heated.

Parameters also change on outdated radiators. Often, even on non-ferrous metal tubes, growths form due to internal corrosion. The problem may be impurities in the water.

Due to such growths in the tubes, the amount of water in the system must be gradually reduced. Taking into account all the features of your convector and the general data from the table, you can easily calculate the required volume of water for the heating radiator and the entire system.

The circulation pump is selected based on two main characteristics:

G* - flow rate, expressed in m 3 / hour;

H - pressure expressed in m.

*To record coolant flow, manufacturers of pumping equipment use the letter Q. Manufacturers of shut-off valves, for example, Danfoss, use the letter G to calculate flow. In domestic practice, this letter is also used. Therefore, within the framework of the explanations of this article, we will also use the letter G. But in other articles, going directly to the analysis of the pump operation schedule, we will still use the letter Q for flow rate.