- ensure optimal temperature inside the building and

- reduce heating costs.

In our review of heating system control units you will learn:

- When is it advisable to install a weather control unit - examples and calculations

- How does the heating control unit work?

- The main advantages of installing an automated heating control unit

- How to install an automated heating system control unit

- Effective use of automated metering units

- conclusions

Automated heating control unit

How it works

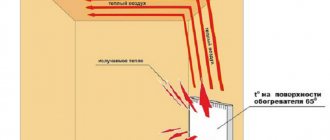

The operating principle of the heating system control unit is very simple:

When the outside temperature drops, for example to -20 °C, the heating control unit supplies more heat to the rooms, thereby maintaining the indoor temperature at the required level, for example +20 °C.

And vice versa.

When the outside temperature rises, for example to +5 ° C, the weather control unit, as it is also called, supplies less heat to the premises.

Thus, heat consumption is reduced, and the temperature in the rooms remains at the level we need, for example, +20 ° C and does not increase to +28 ° C, as often happens during sudden warming.

The temperature does not rise to +28 °C

And scientifically speaking, the weather control unit is designed to ensure and maintain the required coolant temperature in the supply pipeline, depending on the outside air temperature.

Our advantages:

- We carry out a full range of works on design, installation, maintenance of central and individual heating points!

- We have been installing and constructing ITP for more than 15 years!

- Own customer service - 24 hours;

- Warranty for work performed – 1 year;

- Availability of our own spare parts warehouse;

- Experienced specialists who have been trained by manufacturers and have appropriate certificates;

- Our company is the official authorized service center of the De Dietrich company, a service partner for the repair of BAXI, UNICAL, Viessmann boilers.

- We have a SRO certificate for this type of work;

- Employees have Rostechnadzor certification for industrial safety at gas distribution and gas consumption facilities and a third or fourth clearance group for electrical safety. They annually pass exams and receive permits to perform gas-hazardous work at ROSTEKHNADZOR.

Our specialists are ready to install, construct or reconstruct ITP and central heating substations of any complexity. The price is calculated individually for each object.

You can consult and agree on the cost of work by calling us by phone +7

The main advantages of installing an automated heating control unit

As we have already said, the goal of this energy-saving measure is to optimize the consumption of thermal energy in the building, namely:

- significant reduction in costs for heat supply to buildings and structures,

- improving the quality and reliability of heat supply,

- automatic control of heat supply to buildings and structures,

- the possibility of remote control of coolant parameters and operating modes of heat supply equipment,

- the ability, without additional costs, to reconfigure the operation of the heating system, for example, after insulating facades, replacing windows, renovating a building,

- automation of the thermal energy consumption metering system.

As practice shows, an automated control unit (ACU) allows saving about 25% - 37% of thermal energy and providing comfortable living conditions in each room.

What are the needs of an accounting structure?

The heat assembly is assembled at the entrance of the pipeline into the building to produce the following functionality:

- Stabilization and testing of coolant operation along with energy;

- Stabilization and testing of heating infrastructures together with hydraulics;

- Reading and archiving thermal fluid indicators (many parameters);

- Financial settlement between subscribers and the heat energy developer, following verification of the acquired values;

Its key significance is considered to be the transformation of the parameters of the internal heat carrier and monitoring of heat energy consumption. Its purpose? Following the coolant entering the converter or the customer’s heater, the heating unit reduces both p and t.

When is it advisable to install an ACU - examples and calculation of the payback period

Let's look at 3 examples of installing a metering unit and calculate the payback period for this event.

All examples are from real life and are based on energy surveys that we have carried out.

And so, we have three administrative buildings (offices):

- Building 1 with an area of 1300 m2

- Building 2 with an area of 4800 m2

- Building 3 with an area of 18,500 m2

All three buildings are located in Moscow.

Here are the main results of installing the heating system control unit:

| Area, m2 | Total heat consumption for the heating period before installing the ACU | Total heat consumption for the heating period after installing the ACU | Reducing heat consumption Gcal | Cost Gcal thousand rubles. (2018) | Savings during the heating period, thousand rubles. | |

| Building No. 1 | 1 300 | 340 | 266 | 74 | 2,0 | 148 |

| Building No. 2 | 4 800 | 550 | 418 | 132 | 2,0 | 264 |

| Building No. 3 | 18 500 | 4 400 | 3 720 | 680 | 2,0 | 1 360 |

As can be seen from the table, installing a heating control unit helped reduce heat consumption during the heating period by:

- Building No. 1 – 74 Gcal,

- Building No. 2 – 132 Gcal,

- Building No. 3 – 680 Gcal.

Such a significant difference in consumption reduction is mainly due to:

- size of buildings (area and number of storeys)

- number of operating hours,

- appointment.

The following table shows:

- heat savings during the heating period (based on the cost of 2 thousand rubles per Gcal)

- cost of installation and assembly of the heating control unit and

- payback period.

| Savings during the heating period, thousand rubles. | Cost of automatic control unit (equipment and installation) | Simple payback period years | |

| Building No. 1 | 148 | 1 556 | 10,5 |

| Building No. 2 | 264 | 1 856 | 7,0 |

| Building No. 3 | 1 360 | 2 000 | 1,5 |

The main conclusion that we can draw from calculating the payback period of an automated control system

It is advisable to install an automated heating control unit in buildings with significant consumption of thermal energy and in buildings with overheating.

In small buildings and buildings with low thermal energy consumption, an automated heating control unit will pay for itself for a very long time or may never pay off.

In small buildings, it is more advisable to inspect or install elevator units, as well as install a system of balancing valves on the main risers of the heating system.

Heating system control unit

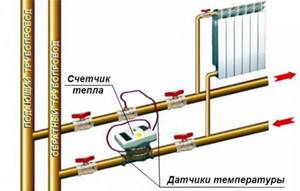

Is it possible to install a heat meter in an apartment?

The supply of thermal energy is paid according to the readings of the installed common building meter, which is made as follows: the total amount is divided between apartments in proportion to their area.

Not everyone is happy with this method, because... Some consumers have insulated their walls and installed energy-saving windows, while some continue to live with old wooden ones. Because some people have insulated their homes and invested in minimizing heat loss, it is unfair to charge them the same rate as everyone else.

Because of this, many consumers are interested in the possibility of installing individual metering devices. Their installation does not require OSBB registration and other bureaucratic red tape. The main task in this case is to develop a project, that is, a plan for the location of the equipment, install the device, and coordinate all your actions with the supplier of this service. Unfortunately, such pleasure is not available to most consumers, and here’s why.

Heat metering implies that it comes from a single source, but in most apartments there are several of them due to the vertical distribution. Because of this, it is necessary to install a device on each riser, which is quite expensive and it will be much cheaper to continue paying according to the old scheme.

The option of redoing the vertical wiring is quite complex and unpromising, since it may cause an imbalance in the system. Only apartment owners in new buildings with horizontal wiring can install an individual apartment meter without any problems.

Owners of apartments with a horizontal heating system can install a device that matches the diameter of the pipes supplying coolant to the apartment. If you have a certified project, a certificate for the meter and other documentation, the heat meter can be registered with the management organization and you can pay for services upon delivery.

Not long ago, overhead meters appeared on the market; they read the heat expended by each radiator. They are quite cheap and almost anyone can purchase a device for each radiator. Another issue is that many suppliers will not want to recognize these devices for charging purposes and may refuse to register them.

Why is it more profitable to install ACU in buildings with high heat consumption?

The heating control unit costs approximately the same for large and small buildings (the difference in the cost of equipment and installation is 20%-30%).

At the same time, in a large building you can save 5-10 times more thermal energy than in a small building.

In our example we see:

- The heating control unit pays for itself in 10.5 years in building No. 1, with an area of 1,300 m2 and a heat consumption of 340 Gcal before installing the ACU.

- The same unit pays for itself in 1.5 years in building No. 3, with an area of 18,500 m2 and a heat consumption before installing an ACU of 4,400 Gcal.

Our analysis and calculation are not universal.

They only give you a basic understanding of which buildings make the most sense to install automated heating control units.

We recommend calculating the feasibility and payback period of the heating control unit individually for each building, based on specific circumstances and conditions.

Help with TP maintenance from many companies

Companies have been operating in the market of technical infrastructures and communications for a large number of years. One of the key types of services provided by organizations is equipment and technical guarantee of various heating stations. Organizational professionals have many years of experience in this field.

All activities are carried out taking into account the standards for technical support of engineering equipment of central heating centers, which detail the list and sequence of activities. The security contract is formed with subscribers on personal terms. This is roughly how all work is done.

How to install an automated heating system control unit

There is no fundamental change in the building's heat supply scheme when installing an automated heating system control unit (ACU).

Unlike elevator units, which are installed on each section of the house, the ACU is installed, as a rule, one per building.

The control unit is connected after the thermal energy metering unit.

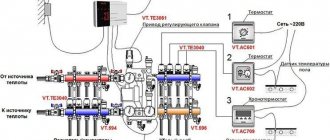

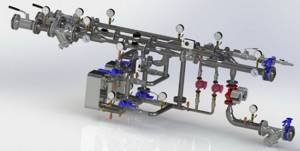

The weather control unit includes the following elements:

- control element,

- control valve with actuator,

- circulation pump,

- outside air temperature sensors,

- room temperature sensors.

The control element of the weather control unit allows you to manually change the settings that determine the operating mode of the heating system and allow you to maintain different temperatures in the building at different times.

For example, in administrative buildings on weekends and holidays, the air temperature inside can be reduced to +12 °C.

On weekdays the temperature can be increased to +18 °C.

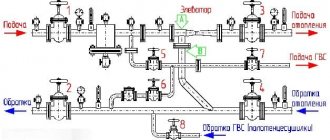

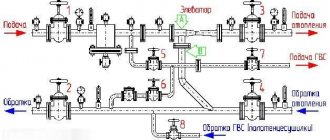

The diagram and general view of the automated weather control unit are presented in the figures below.

The scheme provides:

- automatic switching between the main and backup pumps if one of the pumps fails,

- the possibility of introducing a flexible schedule for regulating indoor air temperature, taking into account night time, weekends and holidays for the entire heating season,

- mandatory control of the return coolant temperature,

- maintaining a temperature schedule.

The temperature of the heating system is regulated by changing the valve capacity and mixing network water using a circulation pump.

During operation, the controller:

- periodically polls the coolant temperature sensors, the indoor air sensor (if there is one) and the outdoor air sensor,

- processes the received information and

- generates control signals that command the actuator to open or close.

The control action from the controller changes the opening value of the flow area of the control valve.

In the absence of an indoor air sensor, the main control priority is maintaining the temperature schedule.

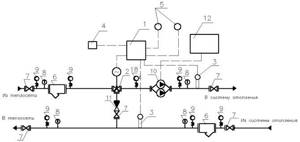

Operating principle of the elevator heating unit and diagram

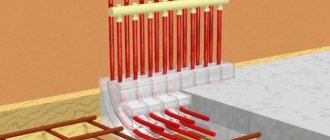

With the help of an elevator, the temperature of the superheated water drops to the calculated temperature, after which the prepared coolant is sent to the heating devices. The operating principle of the elevator unit is based on mixing superheated coolant from the supply pipeline with cooled water from the return pipe.

The diagram of the elevator assembly below clearly shows that the elevator performs 2 functions at once, which makes it possible to increase the overall efficiency of the heating system:

- Works as a circulation pump;

- Performs mixing function;

Elevator unit diagram

The advantage of the elevator is its simple design and, despite this, high efficiency. Its cost is low. It does not require an electrical connection to operate.

It is worth mentioning the disadvantages of this element:

- There is no possibility of regulating the outlet water temperature;

- The pressure difference between the supply and return pipelines should not fall outside the range of 0.8-2 Bar;

- Only accurate calculation of every detail of the elevator guarantees its efficient operation;

Today, elevators are still widely used in heating units of residential buildings, since the efficiency of their operation does not depend on changes in thermal and hydraulic conditions in heating networks. In addition, the elevator unit does not require constant supervision, and to adjust it, it is enough to select the correct nozzle diameter. It is worth remembering that the entire selection of elevator unit elements should be trusted only to specialists who have the appropriate permits.

Elevator diagram

Effective use of automated metering units

The use of ACU is most effective:

- in large buildings with significant heat consumption,

- in houses connected to city heating networks,

- in buildings with insufficient pressure drop in the central heating system and where the installation of central heating pumps is mandatory,

- in buildings with decentralized hot water supply and central heating.

Elevator heating unit - what is it? Scheme and principle of operation

No one will argue that the heating system is one of the most important life support systems of any home, both a private house and an apartment. If we talk about apartments, centralized heating often predominates in them; in private houses, autonomous heating systems are most often found. In any case, the design of the heating system requires close attention. For example, in this article we will talk about such an important element as the elevator heating unit, the purpose of which is not known to everyone. Let's figure it out.