The design of the hood and its principle of operation

The principle of organizing a kitchen hood with a conventional ventilation duct

The operating principle of a kitchen hood is similar to a vacuum cleaner. A fan rotating inside the device draws in air, thereby creating a low-pressure zone in front of the housing. Air currents rush towards it, collecting fumes, dust and masses waste during the breathing process of people on their way. Since hoods are located directly above the stove, combustion products, evaporations and fatty secretions enter them. If the food burns, the equipment will absorb the smoke, preventing it from spreading throughout the apartment.

The hood is designed simply, but functionally:

- Frame. Serves to accommodate parts and mechanisms. Has different colors and sizes. Made from stainless steel, plastic or black enameled iron.

- Input filter. It is a dense grille located behind the front or bottom panel. Designed to trap fat and soot.

- Electrical engine. It is used to rotate the propeller and is manufactured in a sealed casing that prevents moisture from getting inside. Some manufacturers install two low-power motors that make less noise.

- Fan. Today, drum-type products are more often installed, which are more efficient than axial ones.

- Lighting. Made from 220 V lamps or 12 V LED boards powered by a stabilizer. Designed to illuminate the hob.

- Air duct. They are a pipe that drains pollution to the street or into the common shaft of an apartment building. There are no air ducts in recirculation-type devices; the air is passed through mechanical filters on the top of the housing.

The retail chain offers a wide range of household appliances. To make the right decision, you should study the features of the product, as well as the processes that occur when the kitchen hood operates.

Additional amenities

Hoods may also differ in their control features. The standard option is a hood with a button panel : more modern models include slider speed switches. Touch-sensitive exhaust technology with an electronic display is more convenient to use and has the additional advantage of cleaning the housing from dirt.

The hood control type can also be remote . Turning the device on and off, as well as changing modes during operation, is carried out either using the remote control or through voice commands.

Both manual and automatic control processes are convenient if you have chosen a retractable kitchen hood with a slider panel or a model with the ability to adjust the tilt angle.

Both horizontal and vertical hoods are distinguished by their diversity in design. In addition to the main material, chrome steel, glass or wood can be used.

In addition to the decorative properties, pay attention to the size of the equipment itself : some stylized interiors will look more harmonious when using a large hood, while others require greater conciseness and the installation of compact hoods.

Remember! Hoods of different sizes differ in maximum power and noise level during operation. Study the technical documentation before choosing the appropriate model.

The next difference between hoods is their functionality. Modern devices are equipped with an auxiliary timer, an automatic shutdown mode, a sensor that signals when filters are dirty, the ability to adjust the brightness of the backlight, and also have many other additional functions .

After studying photos of types of hoods and understanding what kind of kitchen hoods there are in terms of work characteristics and appearance, you can choose the best model for your kitchen.

Variety of exhaust devices

Manufacturers produce kitchen appliances in various options in terms of design, size, appearance and placement methods.

According to the principle of operation, devices are divided into the following types:

- Flow-through. The drawn-in contaminants are fed into the general ventilation system or through a separate channel and discharged to the street through a hole in the wall.

- Recirculation. The air is forced through filters and returned to the room.

Based on the type of installation, products are divided into the following categories:

- Mounted. Hung on the wall directly above the stove. They have a horizontal bottom panel.

- Built-in. Depending on the model, they are attached to a shelf above the stove or next to the hob.

- Hanging. Installed on the ceiling, air ducts can be masked with suspension or tension systems.

By design, hoods are divided into the following types:

- Smooth. They are a rectangular structure located parallel to the floor.

- Inclined. The filter is tilted and opens by opening the decorative front cover.

- Dome. They are the most powerful, since large motors and fans can be installed in a large case.

- T-shaped. They belong to the category of hanging products. Installed above the work surface located in the center of the kitchen (island type).

Manufacturers produce products whose body has a natural steel sheen, painted white, brown or black. There are models decorated with patterns, ornaments and paintings.

Control type

For your information! In the modern household market you can find devices with several types of control:

- touch – the device is operated by sliding your finger across the surface of the screen. The option is considered quite convenient and in terms of cost belongs to the mid-price segment;

- push-button – the classic option that most models are equipped with. Devices with push-button control are affordable and easy to use;

- remote – designed to control an electrical appliance using a remote control or smartphone. Thanks to this, the user does not have to go to the kitchen to turn on the device, being distracted from his work.

Instructions for using the hood

You can use the hood in the kitchen without any age restrictions or any other criteria. The device is completely safe and reliable in all respects. With durable mounting brackets, the product can support the weight of a child or large pet.

Rules for using devices:

- Do not screw the cable to the gas riser, as induction may cause fire.

- Use the equipment only with filters connected or with air ducts removed.

- The inclusion of engine modes is gradual, starting from “1”. Introducing maximum draft can cause a backflow effect into the room.

- Regular cleaning of the coarse filter or replacement of output filters in recirculation type devices.

- Discharge ventilation ducts only into designated shafts. When the draft changes, combustion products may enter adjacent rooms.

When washing the device or replacing filters or lamps, unplug it from the mains. The possibility of electric shock cannot be ruled out.

Features of air duct installation

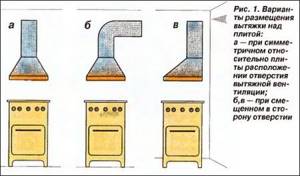

Correct selection of the hood, pipes, and connecting elements may not give the desired result if an error is made when installing the air duct to the ventilation shaft.

For high-quality operation of the exhaust equipment, you need to know how to connect the hood, and also take into account the following points:

- The piping assembly should be as straight as possible. Bends and deflections are not allowed. When using a corrugated air duct, you need to stretch it.

- It is necessary to use sealant to seal connections with pipes and adapters.

- In places where the duct bends, the diameter should exceed the cross-section of the corrugation itself. If this requirement is violated, the pressure will decrease, and hence the quality of operation of the entire exhaust system.

- A pipeline 3 meters long will effectively perform its functions - no more, without turns or bends. If a turn is necessary, its angle must be obtuse.

- When laying through a wall, adapters must be used to protect the pipeline from damage.

- Long corrugated pipes should be fixed every 1-1.5 m. This prevents them from bending and swaying when the hood is on.

- At the junction of the pipe being laid and the ventilation shaft, it is advisable to install a special lattice frame equipped with a check valve and a flange for fastening the edge of the air duct. The principle of operation is as follows - when the hood is turned off, air circulates freely through the grille, while the valve is open. When the device is turned on, the valve closes, preventing contaminated air from entering the room.

We recommend that you read: Equipment for cleaning ventilation in apartment buildings

You need to know that the throughput of the exhaust equipment drops by 10% with each turn of the pipeline at an acute or right angle. With several bends, the system is ineffective and operates with large overloads. If turns cannot be avoided, you should buy a device with more power, and also increase the nominal cross-section of the pipeline.

Installation Rules

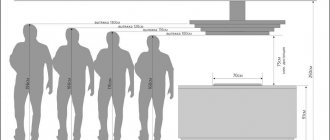

When installing a hood, the following rules must be observed:

- reliability of fastenings is 2-3 times higher than the calculated weight parameters of the devices;

- distance from the sink - at least 50 cm;

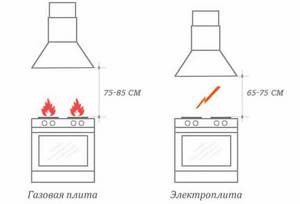

- height above the stove - 70 cm from electric and 80 cm from gas;

- a separate outlet to disconnect the device for maintenance;

- horizontality necessary for correct operation of the motor;

- correspondence of the cross-section of the air duct to the exhaust pipe and its power.

Equipment must be built in taking into account the strength of the cabinet, which is used as a supporting structure.

Preliminary calculations

Before making a kitchen hood with your own hands, you will have to perform some calculations. First, calculate how much air needs to be purified. This parameter depends on the size of the room.

Calculate the volume of the kitchen by multiplying the length by the width and height. Then the resulting result is multiplied by a special coefficient from the SNiP tables.

In a house with a gas stove, a coefficient of 20 is used (it is believed that gas pollutes the air more, since additional combustion products are released), with an electric stove - 12.

The resulting number indicates the required extraction capacity in cubic meters per hour. Thus, the formula is obtained:

P = (a × b × c) × K

Then they move on to calculating the electrical part. As a rule, all household units consume no more than 1 kW/h and require wires with a cross-section of 2.5 square meters. mm, used in apartment lines, so they can be freely connected to simple household sockets.

There is no need for separate grounding for the hood. However, in new buildings a separate two-core wire is installed directly under the ventilation.

The dimensions of the air ducts do not require complex calculations. They must comply with one simple rule: be no larger than the ventilation hole of the common house duct.

When designing, the pipe must be laid with a minimum number of turns. Each angle reduces the performance of the hood.

Advantages and disadvantages of kitchen hoods

Benefits of installing and using a kitchen hood:

- elimination of unwanted odors;

- removal of moisture, fats and smoke;

- preventing contamination on furniture, walls and ceilings from fumes:

- reducing the risk of gas poisoning if the autonomous heating boiler malfunctions.

Disadvantages of the decision to use a hood in the kitchen:

- expenses for the purchase and installation of equipment;

- regular replacement of filters;

- quite loud noise during operation;

- time and effort for cleaning, washing and replacing consumables.

The hood is an important part of the housing ventilation system, without which it is impossible to achieve a normal level of sanitary standards.