Long gone are the days when a person needed to build a fire to heat his home, maintain it by being on duty around the clock and throwing wood on the fire. The civilized world has already emerged from the caves of the primitive communal system; people live in comfortable apartments and private houses with a central or individual heating system.

Over the past half century, heating equipment has changed a lot not only in appearance, but also in functional purpose. Modern models of radiators (batteries) have an aesthetic appearance and are made of various materials: cast iron, bimetal, aluminum.

The need to replace old cast iron batteries may arise due to major repairs, remodeling, or replacement of failed radiators.

How much does one section weigh?

For many builders, the term “cast iron heating radiator” is associated with a heavy structure. Indeed, on the construction market you can find a huge number of heating devices in question, and their weight varies over a fairly wide range. According to experts, the heating radiator section, which was used during the Soviet Union, has a mass of just over 7 kilograms. If water is poured into this container, the weight of the section will increase to 8.6 kilograms.

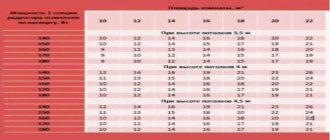

At that time, a standard heating radiator consisted of 6 sections, which means that the weight of each battery without water was within 43 kilograms . If we take into account that the thermal power of each of the individual sections is within 170 watts, then two such radiators will be needed for a room with a total area of 20 m2.

Connecting sections in a cast iron radiator

Modern analogues of cast iron heating devices have much less weight than the batteries that were used during the Soviet era. For example, the weight of a single section of a Czech heating device is 3.8 kilograms. This container contains 800 milliliters of water, which increases the weight to 4.6 kilograms.

If we take into account the thermal efficiency of each section within 140 watts, then for a room with a usable area of 20 square meters you will need 14 such sections. With detailed calculations, one can easily determine that the weight of such a device is 40% less than the mass of its Soviet counterpart.

Is it worth replacing cast iron batteries with bimetallic ones?

The issue of replacing cast iron batteries with bimetallic analogues should be approached with particular seriousness. The fact is that the first heating devices have many useful characteristics:

- Long period of operation - at least 50 years;

- Corrosion resistance;

- Possibility of heating indoor air at a minimum coolant temperature of 55 degrees;

- High thermal inertia.

Bimetallic radiator

As we can see, cast iron heating radiators, despite their significant weight and unpresentable appearance, perform their functions perfectly. People who replace cast iron batteries with bimetallic heating devices have the goal of camouflaging the batteries in the general environment.

The second reason for changing radiators is considered to be automation of the heating process and cleaning the system of contaminants. It should be noted that during operation, cast iron batteries become clogged with dirt, which leads to uneven heating.

Comparison of cast iron and bimetallic heating radiators

The coolant of the central heating system is not clean and neutral. In addition to chemical indicators, the liquid contains sand and pebbles. These abrasive elements have a destructive effect on both bimetallic and cast iron appliances, reducing their service life.

Which batteries heat better: cast iron or bimetallic?

The heat transfer readings of cast iron and bimetallic radiators are approximately the same, but there are differences. The former take a very long time to heat up, but cool down much longer compared to the latter. This saves you when accidents happen in winter and the heating is turned off to fix the problem. Cast iron models can retain heat for a long time. The thermal power of one section is 100-160 W.

Cast iron appliances heat the room using both convection and radiation methods. This ability allows objects located close to heating sources to heat up.

The results of measuring heat transfer with a thermal imager show the ability of cast iron structures to retain heat longer

Bimetallic radiators heat up very quickly. They also cool down quickly. Heating occurs according to the principle of convection, the radiative ability of heating interior items in the room is minimal. This is one of the disadvantages of a bimetallic heating device. Heat transfer power 150-180 W.

Which batteries hold pressure better?

The central heating system can rupture any radiator, because the pressure in it is not stable and water hammer occurs. Workers sometimes neglect the rules and turn on the valves of the circular pump not smoothly, as required by the instructions, but quickly. The pressure increases sharply and the devices burst. Residents of high-rise buildings (especially in buildings with more than five storeys) should give preference to devices with good pressure retention.

Attention! Experts recommend installing bimetallic radiators, as they can withstand up to 50 atmospheres, depending on the model.

Cast iron elements can withstand up to 9-12 atmospheres. If there is a strong water hammer, the radiators rupture.

Products with a monolithic core can withstand up to 100 atmospheres

Comparison of maximum coolant temperature

The temperature of the coolant in the central heating system is not stable. Temperature changes from warm to hot often occur. Cast iron radiators can withstand liquid heating up to 110 0C. Bimetallic elements – up to 130 0С. With sudden changes, steel makes cracking sounds.

Durability and service life

Cast iron appliances can operate for over 50 years. Proper care significantly extends their service life. Periodic flushing of the system and timely minor repairs extend the serviceability to 100 years and beyond.

The service life of bimetallic heating elements is set by manufacturers at 20 years for sectional ones and 25 years for monolithic models.

Easy to install

Installation of cast iron radiators is complicated by the weight of the devices. In addition to weight, it is necessary to consider a mounting system that will be able to support the mass of models. The brackets are made of high-strength steel. It is also necessary to take into account the reliability of the walls. Lightweight materials, such as drywall or gypsum panels, are not able to withstand such a load. Therefore, they either strengthen the walls with metal corners, or build a support from reliable building materials that can withstand heavy loads.

High-strength steel brackets for installing heating devices are an important fastening element

Modern manufacturers also produce floor radiators. When installing such structures, experts recommend making sure that the floor can support the weight of the devices.

The bimetallic heating structure is convenient to install. One person can handle the installation. Radiators are lightweight and do not require reliability of building materials.

Radiator cost comparison

Cast iron heating products are much cheaper than bimetallic ones. The cheapest section costs from 300 rubles, and the bimetallic section costs 500-700 rubles. Modern manufacturers offer artistic cast iron radiators. Their cost is high and varies around 2000 rubles.

Appearance comparison

Cast iron radiators come in 2 types: classic and artistic. The former look unattractive and require periodic painting. Artistic models with sinuous injection molding patterns can decorate the interior of a room, but this increases the cost of the products.

Bimetallic models have a ribbed-shaped shape.

External differences between cast iron and bimetallic heating devices lie in the shape of the sections and the presence of artistic elements

These types of radiators are classified as sectional. The length and height of the section is selected by the buyer from the options offered by the manufacturers. Usually the second parameter is 35-150 cm, and the depth is up to 50 cm. In accordance with the required heated area, the number of sections is selected, it is possible to modify the design.

Bimetallic models cannot be changed.

Which batteries are better - cast iron or aluminum?

Cast iron heating radiators need no introduction, which cannot be said about heating devices made of aluminum. To determine which of these types of devices is better, we will describe the advantages and disadvantages of each of them.

The advantages of cast iron batteries include:

- Resistance of the material to corrosion. According to experts, cast iron is not afraid of abrasive substances such as sand and other debris. It is also not destroyed by acids;

- Such devices are low in cost and have high thermal output;

- Such products can last up to 50 years.

Modern cast iron radiators

Despite the significant number of advantages, the described devices also have disadvantages. The main disadvantages of heating devices made of cast iron:

- Possibility of water hammer and disruption of the system;

- Insufficient thermal conductivity of the material;

- Ugly appearance, although modern analogues are very attractive, but their price is high.

Today, aluminum heating radiators are very popular among consumers. They have small dimensions and weight compared to analogues. When using aluminum radiators, automatic heating control becomes possible.

The disadvantages of the described devices include low corrosion resistance and limited strength of the products. The service life of such devices will depend on the degree of purification of the coolant. The optimal acidity level should be between 7 and 8 pH.

Aluminum radiator

There is no clear answer to the question of which batteries are better. Here everyone chooses according to personal preferences. Recently, more and more users are leaning toward aluminum radiators, because such devices are much lighter and more compact than their analogues.

How to make the right choice

Cast iron products are suitable for private and residential buildings up to five floors. In high-rise buildings, very high pressure can occur, which can lead to rupture, so bimetallic models are chosen.

Aesthetically, classic cast-iron models look ugly, but when designing a room, decorative grilles are often used to hide the appearance of radiators.

When purchasing, experts recommend paying attention to the following characteristics:

- heat transfer quality;

- frequency of performing necessary preventive maintenance to extend the service life of heating devices;

- lifetime;

- pressure retention;

- aesthetics.

How to rinse at home

In country houses, the heating system often loses its efficiency. This happens through poor heat transfer, as well as as a result of debris settling on the walls of the batteries. The coolant heated to a high temperature affects the inside of the radiators, where scale and rust settle. The presence of blockages leads to poor heating of the building.

The main reasons for flushing batteries are:

- Uneven heating of the radiator over the entire plane, when the upper part of the sections is hot, but the bottom of the tank remains cold;

- Warming up the heating system to the required temperature takes longer than usual;

- Increased fuel consumption.

To independently flush heating devices, aluminum or cast iron radiators, you need to drain the water and unscrew the radiator from the system. Removing blockages or flushing occurs using clean water with the addition of acetic acid, special cleaning agents or caustic soda.

Battery before and after washing

It is advisable to carry out the work in the bathroom to prevent liquid from spilling onto the floor. At the same time, a mesh is installed in the bathroom drain hole to collect large contaminants. Pre-placed rags will help prevent damage to the container's coating.

At the initial stage of work in cast iron radiators, all plugs are unscrewed, and water heated to a boil is poured into the resulting holes. Next, shake out the heating device and drain the liquid and debris.

Next time, water with the selected cleaning agent is poured into the radiator. After this, close all the plugs, knock on the device with a wooden hammer, shake it and pour out the water. Similar operations are carried out until clean liquid flows from the holes.

Heating element for cast iron battery

A heating element mounted in a cast iron radiator allows you to warm up the room when it is not possible to start the heating system in the usual way. The heating element itself is nothing more than a metal pipe with a spiral sealed in the middle. When installing a heating element in a cast iron radiator, you can achieve optimal temperature values in a small room: garage, kitchen, greenhouse or any other outbuilding.

Heating element for radiator

The main advantages of electric heating elements:

- Possibility of installation in a battery made of cast iron and other materials;

- Automatic control of water heating temperature;

- Using a heater as the main heat source;

- Easy to install.

Anyone can install the described device. The heating elements are equipped with temperature control mechanisms and overload protection. The heater just needs to be installed in the radiator socket and connected to a power source. Before operating the heating element, the heating system must be completely filled with water or another type of coolant.

The heater in the radiator must be in a horizontal position. It usually works in two modes. If the device is used in the system as the main heating source, then the room will warm up to the set temperature, and a special thermostat will maintain the temperature at the specified parameters.

Connection to a cast iron battery

If the heating element is used in a country house or in an auxiliary room, then the main task of the heater will be considered to be minimal heating of the system to protect against freezing. In this case, the device is set to minimum power.

What to consider when choosing batteries

If you look at the descriptions on manufacturers’ websites or listen to salespeople in stores, all devices, of course, are equally beautiful. This radiator is good, but this one is the same, only different. In order to understand all this monotonous diversity, it is worth considering this:

- Water quality in the heating system

. You can find out about it from the management company. For example, it is useful to pay attention to the pH indicator - acid-base balance. If it is below nine points, as in most Russian houses, then you can safely install aluminum batteries. If it is higher, water can have a destructive effect on aluminum and it is better to play it safe and choose bimetallic or steel panel radiators. In both of these devices, steel that is resistant to high pH comes into contact with water. - Heat transfer of the device.

Or, more simply put, the amount of heat it releases into the room. Batteries that seem identical at first glance, even those made from seemingly the same material, can have different heat transfer. It's all about the surface area of the radiator, the thickness of the metal and its thermal conductivity. Of course, you can’t tell by looking at it, so you need to look at the technical data sheet of the device and look for the maximum heat transfer rate. For example, for one section (95 millimeters deep) of a bimetallic battery it is 170–185 W/kg, and for an aluminum one it is 185–195 W/kg. - Pressure

that

the radiator can withstand.

Russian heating systems, as you know, suffer from frequent pressure drops, and although most modern devices cope with this, it would not be superfluous to check the indicator. On average, this parameter in central heating systems fluctuates around 10 atmospheres. Exactly the same operating pressure for steel panel radiators. For aluminum and bimetallic ones it is higher - up to 20 and 35 atmospheres, respectively. - Availability of a certificate.

This is a point that has become mandatory since June 2021, when mandatory certification of heating devices was introduced in Russia. All batteries must be tested in laboratories to confirm safe operation and compliance with GOST. The absence of a certificate is a sure sign of a low-quality radiator. - Manufacturer reliability.

Here, the period of operation on the market is important, and for foreign brands, the presence of an official Russian representative office. An advantage will be insurance, which guarantees reimbursement of expenses if the device turns out to be defective. In general, batteries produced at European and Russian factories have decent characteristics. But it is better to refrain from buying Chinese-made products, because they often turn out to be of poor quality.

Life time

The first mention of a cast iron battery dates back to 1857, when the famous Russian engineer Franz Sangalli made the first cast iron radiator from a piece of pipe. A special feature of his invention were protruding fins, which were used to remove accumulated heat. After some time, the appearance of the cast iron radiator changed, it took on the appearance of an accordion.

For a long time, heating devices made of cast iron were the main ones in civil and industrial buildings in Russia. One of the advantages of cast iron radiators is their long service life. According to experts, such a battery can be used for 50 years, but this requires periodic maintenance of the system. It consists of washing the sections and replacing the gaskets between the blocks.

Vulnerability to water hammer

But this is really a big drawback of cast iron batteries. Cast iron only seems so invulnerable - in fact, this metal is quite fragile. Even if they believed GOST, radiators made of such metal must withstand a pressure of 1.5 MPa, but under one condition - if it turns out to be short-term.

Timati personally invited the first participant to “Bachelor”: this is Dasha Pogadayeva

Got “beauty injections”: how Bozhena Rynska’s face changed after the procedure

Abandoned children for whom he does not pay child support. Who was Anastasia Makeeva's fiancé?

However, if the pump is started abruptly and there are no compensators, the pressure may significantly exceed the permissible value. In such a situation, the battery may become unusable - it will crack.

What is the price

The cost of cast iron radiators will depend on the overall dimensions of the product, manufacturer and brand. The oldest model of domestic production is considered to be MC 140. A separate section of such a battery costs an average of 340 rubles per piece, the price depends on the markup of resellers and the region.

Also, cast iron batteries from foreign manufacturers (Italy, Czech Republic, Spain, Turkey) are supplied to the domestic market. Such devices differ from domestic ones in various respects. For example, the capacity of the section of the Czech Termo battery is almost two times smaller - 800 milliliters, while the domestic MS 140 holds 1.4 liters of water.

Radiator Nostalgia (retro) in the interior

The price of one section of foreign cast iron radiators in rubles is as follows:

- Brand Kiran 92/500 – from 335 rubles;

- Manufacturer Viadrus termo 500/95 – no less than 450 rubles;

- Company Nostalgia (retro) 500/180 – from 2120 rubles;

- Demrad 350 brand – no less than 400 rubles per section.

How to paint

If it is not possible to replace old cast iron batteries with more modern heating devices, many people repaint the radiators in the desired color. The entire painting process can be divided into several stages:

- Selection of paint;

- Surface cleaning;

- Paint application;

- Drying the product.

To treat such surfaces, it is recommended to use alkyd dyes, heat-resistant varnish with the addition of bronze or aluminum powder. In addition, for such work you can use water-based paint, to which you can add various pigments to obtain the desired color.

At the initial stage of work, working tools are prepared and the surface of heating devices is cleaned. This can be done using a wire brush, coarse sandpaper or an angle grinder equipped with a special attachment. To facilitate the work, special solutions are used that help destroy the old coating.

The washing liquid is applied to the surface using a brush. After leaving for a certain time indicated on the solvent packaging, the old layer of paint will begin to wrinkle and peel off. The coating can be removed with a small metal spatula. The final cleaning of the battery is carried out using a metal brush.

At the next stage of work, the radiator is thoroughly cleaned with sandpaper and primed, which will help the paint adhere better. The best type of primer is considered to be the GF021 brand; it is suitable for any type of dye.

Next, a layer of paint is applied using a paint brush. The composition is applied carefully from top to bottom. For better coloring, the dye is applied in several layers. In this case, you need to take a break between the stages of applying the coloring composition.

How to disassemble

To disassemble cast iron radiators we will need the following tool:

- Bulgarian;

- Chisel and hammer;

- Pipe wrench of the required size;

- Hacksaw for cutting metal;

- Metal brush.

Radiator dismantling is usually carried out in the summer, when the heating system is turned off. Before starting work, drain the water from the pipelines and unscrew the nuts at the radiator mounting points. If it is impossible to unscrew the control nuts, then the supply lines are cut off using a grinder.

Sometimes it can be very difficult to disassemble a cast iron radiator

To disassemble a cast iron radiator, we install the device on the panel, unscrew the blind plugs and unscrew the threads that hold the individual sections of the radiators together. To unscrew the necessary nipples, we determine the length of the key with a special chalk mark.

When unscrewing the battery, insert the key alternately into each section. Between the nipples in the upper and lower parts of the heating device, a gap of no more than 5 millimeters must be maintained. If you do not adhere to this rule, the radiator may become skewed, which will lead to jamming of the threads.

When dismantling old batteries with stuck threads, the attachment points of the sections are treated with a blowtorch or autogen. Subsequently, a key is inserted into the joining points and the nipple is turned half a turn. Sticky fittings and plugs are unscrewed in a similar way.

Sometimes corrosion damages the nipple so much that it cannot be turned with a wrench. In this case, the joints of the sections are cut with a grinder or a hacksaw. The remaining nipples are heated and turned out, and the threads are cleaned with a metal brush.

Many people think that replacing a heating radiator is a simple fad that should correspond to fashion trends. But this is not true at all. Replacing the radiator is a necessity. And all for the reason that today there are heating elements that give off heat much better than previous materials. In this case, the heat supply can be independently regulated. It is because of these reasons that it is recommended to gradually get rid of old cast iron radiators and install more modern ones.

Reasons for the necessary replacement

The following reasons should push owners to replace the heating radiator:

- A small number of radiators are located in the required area. Because of this, the room is not heated properly.

- No thermostat.

- Poor space heating.

- The heating system model has long been outdated and has become unusable.

- The presence of corrosion on the radiator, various damage in the form of cracks and system leaks.

All these factors lead to the fact that the temperature in the space is constantly low, and there is simply no way to regulate the indicators yourself. There is also a high probability that sooner or later the neighbors below will be flooded. As a result, considerable amounts of honestly earned money are paid for heating, but there is no heat at all. Of course, it is recommended to replace the heating radiator in the spring or summer, when the entire house is turned off. But if it is not possible to wait, then this procedure can be performed during the heating season. But then the whole house will have to be turned off from heating for a while. To prevent your neighbors from being doused with boiling water, you should ask qualified specialists for help.

This is the only way to change the heating radiator without any problems and in the shortest possible time. Modern models of heating elements weigh significantly less than older ones. In addition, they have a high level of heat transfer and a stylish design appearance. The problem may also be that there may be an air lock or a blockage inside the radiator. Also, the temperature supplied to the room may simply be insufficient. You can find out this from locksmiths or the housing office. They are probably aware of how powerfully the boiler room supplies heat to the room.

Why change batteries?

The Lifehacker Telegram channel contains only the best texts about technology, relationships, sports, cinema and much more. Subscribe!

Our Pinterest contains only the best texts about relationships, sports, cinema, health and much more. Subscribe!

There are five reasons why you should do this.

- The batteries are leaking.

There is nothing to think about here: if even a few drops of water appear on the radiators, they need to be changed. Because sooner or later the drops will turn into a stream that will flow to the neighbors. And then, instead of spending several thousand rubles on buying a battery, you will have to shell out tens of thousands to repair your own and neighboring apartments. - It's cold inside.

If you wear wool socks every October and don't take them off until May, it makes sense to replace your radiators. Maybe the radiators currently in the apartment do not warm the rooms enough. This means that it is worth replacing them with devices with higher heat transfer. Perhaps the radiators are designed to warm the rooms to the standard 19–21 °C, and the residents are too thermophilic. Then it’s worth buying larger batteries to better warm the apartment. - The radiators look shabby.

This is familiar to everyone who had classic cast-iron radiators in their apartment, whose paint sooner or later began to peel off. But relatively new radiators can also lose their presentable appearance, for example, if the manufacturer saved money and painted them with only one layer. Or after repairs, chips and remnants of building materials appeared on them. All this reduces the reliability of the devices: where the paint has chipped, rust appears faster and a leak forms over time. - It is planned to modernize the heating system . If 10 years ago adjusting the temperature in a room using a window was considered normal, today there are more technologically advanced methods. For example, automatic thermostats or remote control of heating in an apartment via a smartphone are rapidly gaining popularity. Cast iron radiators and convectors, which once seemed like the crowning achievement of engineers, hardly fit into such systems, so they are replaced with more modern heating devices.

- The interior is being updated . Including after buying an apartment. This is probably the most common reason for replacing radiators. Sometimes old appliances simply don't visually match the new design of the rooms. And some apartment owners believe that if they are going to do any renovations, they should change everything down to the batteries.

Materials for the production of modern radiators

Instead of cast iron radiators, you can install the following models:

- Made of aluminum.

- Of steel.

- Made of copper.

- Bimetallic.

The radiator, which is made of aluminum, usually has a small weight, but at the same time a stylish design, good thermal conductivity and heat dissipation. The disadvantage is that it is necessary to constantly maintain the pH of the water in the system, as well as sensitivity to pressure changes. They are absolutely incompatible with copper pipes. Radiators made from steel also have good heat transfer and low weight, and they also have a fairly reasonable cost. But they cannot be left without fluid in the system and they are susceptible to corrosion, which is a significant drawback. Over time, the coating may peel off, and they also do not withstand water hammer.

But bimetallic radiators are the most popular. They have increased heat transfer, are resistant to pressure changes and can last for many years. They are not subject to corrosion, have an attractive appearance, and are also quick and easy to install. But such pipes are expensive and at first you will hear some crackling in the system due to the steel and aluminum.

It should be remembered that before changing, it is best to consult with a specialist so that the choice is ideal.

Reinforced polypropylene pipes are suitable for heating, but if the question is about using them in an apartment, then you will have to ask your housing and communal services about this issue.

There is a classic option, cast iron batteries for aesthetes, which look quite attractive in the photo.

Heating time

Cast iron batteries take a long time to heat up - yes, many people may really not like this, especially when it’s cold outside and you want to warm up as quickly as possible.

But let's be completely honest: is this a minus? Of course no. Everyone understands perfectly well that they will only have to endure it once - then the heat will begin to circulate through the pipes.

True, in houses equipped with individual heating, the situation may be different.

With all this, cast iron radiators have an undeniable advantage. Metal not only takes a long time to heat up, but also takes a long time to cool down. This means one thing: when the aluminum or bimetallic radiator is already cold, the cast iron one will maintain heat.

Celebrities who post very strange things on their Instagram

What does Konstantin Solovyov’s wife look like, for whom he left his children and wife

They are afraid to use it: Europe is reluctant to use the AstraZeneca vaccine

Is it worth replacing cast iron batteries with new ones? 5 years 3 months ago link to post #1307

|

I think it’s worth changing if the old cast iron batteries don’t heat well due to being clogged. Taking them apart, washing them, reassembling them and putting them back in place is not worth the candle. You also need to change to bimetal if it is too hot and the radiators are not adjustable. And of course, if you decide to install a heating meter. Then change it, but not with pure aluminum ones - they are of little use for centralized heating. Bimetallic - the best option - cast iron inside, aluminum outside. True, if you reduce the water supply to them, thereby reducing the pressure, they will quickly clog if the water is too hard.

And so, if you are satisfied with everything except the appearance, you can, for example, cover the cast-iron “accordions” with decorative modern grilles. Well, or decorate it, as in the photo “for aesthetes.” But this, I think, is probably expensive.

Dimensions and weight

The massiveness of cast iron batteries is another argument because of which people refuse them. Many people are confused by the fact that such radiators need additional hooks for support - not everyone wants to drill holes in the wall for them.

KamAZ celebrates the 45th anniversary of the release of the first truck in the series

Snow fence: an ice wall has appeared in the UK (photo)

How to Clean an Iron: Unexpected Uses for Regular Aluminum Foil

If the large size of the battery, which does not fit everywhere, can still be considered a minus, then you should definitely not pay attention to the significant weight. It only causes inconvenience to those who install heating elements. This factor does not affect everyone else in any way.

Is it worth replacing cast iron batteries with new ones? 5 years 3 months ago link to post #1315

|

In old apartment buildings, simply replacing old batteries with new ones may not give anything, I know this from my own bitter experience. A couple of years ago I decided to change the cast-iron batteries in my apartment in the Khrushchev-era building built in 1962 (the batteries had never been changed), because... the temperature of the house's batteries was 20 degrees less than the temperature of the coolant at the entrance to the house.

I purchased Czech-made cast iron batteries, installed them in the summer, and waited for the heating season. In October, when the heat came on, the problem of cold sections remained. Then I started talking to my neighbors downstairs, and it turned out that they had the same problem. Together we decided to replace all the risers in the entrance next year; by the following summer we had collected the necessary amount, hired a team of plumbers and in two days replaced the old metal risers with plastic ones. When the plumbers sawed off the old pipes, they showed me their internal cross-section; the diameter of the passage was slightly thicker than a match! The rest of the space was filled with dark brown deposits, i.e. there was practically no circulation of coolant in these pipes (and this despite the fact that the heating system in our house is flushed every year before the start of the heating season).

Now it’s just Africa in my apartment, although my neighbors who haven’t changed the batteries are a little cooler. In general, the problem of cold batteries needs to be solved in a comprehensive manner. This is, of course, expensive, but a small consolation can be the fact that the old sections can be scrapped, slightly reducing the overall costs.

|