According to professionals, replacing heating batteries with gas welding is the best option if there is a need to change them or simply expand the system. Unfortunately, nothing lasts forever, and even such a durable thing as a heating radiator will sooner or later fail. Therefore, the property owner has to solve two problems at once - which radiator to choose and how to change it.

Both the first and second problems will be solved by experienced professionals who work in our company.

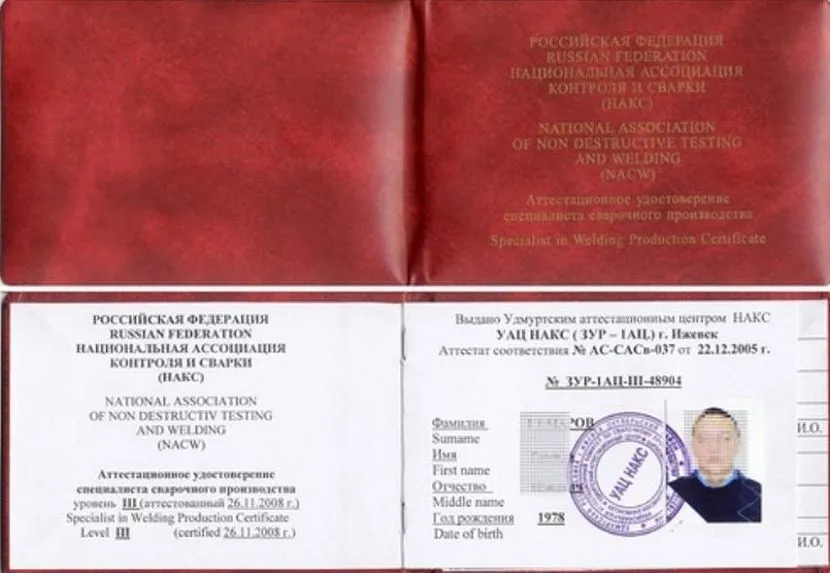

Replacing heating radiators using welding should be carried out exclusively by a specialist with the appropriate qualifications, specialized education and many years of experience. These are the specialists who work in our company, so replacing batteries with gas welding is carried out with consistently high quality and reliability.

Our craftsmen work exclusively with high-quality equipment, so the welds are reliable and durable, which meets safety requirements.

Replacing batteries with gas welding guarantees high-quality seams!

The appearance of new proposals on the heating equipment market prompts the population to think about replacing old batteries with new heating radiators.

In order to carry out the replacement, it is important to correctly determine how the installation of heating radiators will be carried out. There are many options by which the work can be done, but the most effective is to use gas welding

This is due to the fact that replacing batteries with gas welding has many advantages such as:

- Increased reliability. Provided that the work is completed by a highly qualified craftsman, the resulting seam will be reliable, thanks to which it can serve ideally for many years. In addition, the weld seam will not require additional attention, as is observed when performing installation using pre-mounted joints. This is due to the fact that the connection point does not have an additional seal, which, as a rule, is not durable in operation.

- Neat appearance. After the welding work is completely completed, the seam remains almost invisible, so it does not spoil the external design of the room and can remain in the open.

Only an experienced technician should be trusted to install heating radiators, since the efficiency and economy of the heating system will depend on the quality of the work performed. The craftsmen of our company are able to install radiators using gas welding efficiently and accurately.

| 1 | Replacement visit | PC | for free |

| 2 | Consultation and estimate | PC | for free |

| 3 | Purchase and delivery of materials | PC | for free |

| 4 | Replacement of batteries with gas welding from 20 pcs. | PC | 2500 |

| 5 | Replacement of batteries with gas welding from 10 pcs. | PC | 3000 |

| 6 | Replacing batteries with a gas welder from 4 pcs | PC | 3500 |

| 7 | Replacing batteries with a gas welder from 2 pcs | PC | 4000 |

| 5 | Replacing one battery with gas welding | PC | 5000 |

The advantage of replacing batteries with gas welding

Welding is a special process in which molten metal is poured between the edges of parts heated to a certain temperature.

It is important to note that the edges are heated to a temperature required by the technology and the characteristics of the material itself

Gas welding work is carried out to weld metal parts of various shapes; in addition, welding is used to eliminate defects from a metal surface, regardless of its shape and size.

Gas welding work to replace batteries consists of:

- preparatory part;

- welding (applying a seam);

- eliminating cracks and cavities from the surface of a metal part;

- smoothing seams (if necessary).

Only specially trained specialists are allowed to perform gas welding work, since only they are able to weld metal surfaces together as correctly and efficiently as possible.

How to replace heating batteries with gas welding

As already noted, with the help of gas welding it is possible to install heating radiators with the highest quality and reliability. The main explanation for this is that the metal edges of the pipe and radiator are connected by molten metal, which is formed as a result of melting the filler wire. Using gas welding, you can easily and most importantly quickly connect steel pipes to a radiator, the outer diameter of which does not exceed 100 millimeters. The fastening points (weld seam) are reliable and able to withstand high operating pressure in the system, which eliminates the possibility of a breakthrough. It should also be noted that the seam made by the master looks very neat compared to fittings and other available

Safety regulations

Work involving the use of open flames and explosive components is classified as fire hazardous. For this reason, when performing them, generally accepted safety standards must be strictly followed. Possible types of violations and consequences during gas welding work:

- Explosion of gas or acetylene cylinders;

- thermal injuries;

- harmful effects of harmful fumes and dust;

- effects on vision;

- possibility of ignition of flammable materials.

With the advent of new highly efficient heating devices on the market, many users of heating systems have a desire to replace their outdated cast iron radiators with new modern bimetallic devices. In order to carry out an effective replacement, you need to professionally decide on the choice of installation option. Today, many different methods of connecting heating equipment are practiced, but a particularly effective one is to resort to gas welding.

Replacing batteries with gas welding guarantees high-quality seams!

The emergence of new proposals on the heating equipment market prompts the population to think about replacing old batteries with new heating radiators

In order to carry out the replacement, it is important to correctly determine how the heating radiators will be installed. There are many options by which the work can be done, but the most effective is to use gas welding

This is due to the fact that replacing batteries with gas welding has many advantages such as:

- Increased reliability. Provided that the work is completed by a highly qualified craftsman, the resulting seam will be reliable, thanks to which it can serve ideally for many years. In addition, the weld seam will not require additional attention, as is observed when performing installation using pre-mounted joints. This is due to the fact that the connection point does not have an additional seal, which, as a rule, is not durable in operation.

- Neat appearance. After the welding work is completely completed, the seam remains almost invisible, so it does not spoil the external design of the room and can remain in the open.

Only an experienced technician should be trusted to install heating radiators, since the efficiency and economy of the heating system will depend on the quality of the work performed. The craftsmen of our company are able to install radiators using gas welding efficiently and accurately.

| 1 | Replacement visit | PC | for free |

| 2 | Consultation and estimate | PC | for free |

| 3 | Purchase and delivery of materials | PC | for free |

| 4 | Replacement of batteries with gas welding from 20 pcs. | PC | 2500 |

| 5 | Replacement of batteries with gas welding from 10 pcs. | PC | 3000 |

| 6 | Replacing batteries with a gas welder from 4 pcs | PC | 3500 |

| 7 | Replacing batteries with a gas welder from 2 pcs | PC | 4000 |

| 5 | Replacing one battery with gas welding | PC | 5000 |

The advantage of replacing batteries with gas welding

Welding is a special process in which molten metal is poured between the edges of parts heated to a certain temperature.

It is important to note that the edges are heated to a temperature required by the technology and the characteristics of the material itself

Gas welding work is carried out to weld metal parts of various shapes; in addition, welding is used to eliminate defects from a metal surface, regardless of its shape and size.

Gas welding work to replace batteries consists of:

- preparatory part;

- welding (applying a seam);

- eliminating cracks and cavities from the surface of a metal part;

- smoothing seams (if necessary).

Only specially trained specialists are allowed to perform gas welding work, since only they are able to weld metal surfaces together as correctly and efficiently as possible.

How to replace heating batteries with gas welding

As already noted, with the help of gas welding it is possible to install heating radiators with the highest quality and reliability. The main explanation for this is that the metal edges of the pipe and radiator are connected by molten metal, which is formed as a result of melting the filler wire. Using gas welding, you can easily and most importantly quickly connect steel pipes to a radiator, the outer diameter of which does not exceed 100 millimeters. The fastening points (weld seam) are reliable and able to withstand high operating pressure in the system, which eliminates the possibility of a breakthrough. It should also be noted that the seam made by the master looks very neat compared to fittings and other available

A question that sooner or later faces almost every resident, be it an apartment in an apartment building or their own home in the private sector.

Among the variety of existing types of heating batteries and methods of their installation, it is difficult to make the right choice without special knowledge and experience in this area.

Therefore, whether the heating batteries will be replaced using gas welding or a threaded method, and what type of radiators to use, is best decided together with qualified specialists. If replacement and installation work is performed poorly, there is a high risk of costly property damage.

Argon arc welding

Argon arc welding (also known as TIG welding) is a welding method using a tungsten electrode and argon shielding gas. Tungsten electrodes belong to the class of non-consumable electrodes, which means that they do not directly participate in the formation of the seam, but only allow the metal to melt. Due to the molten metal, the seam is formed. And argon gas performs a protective function. It protects the welding zone from the penetration of oxygen, which deteriorates the quality of the seam.

This method is good for welding thin-walled gas pipes. To weld steel gas pipes, set the welding machine to constant current and select electrodes whose diameter matches the thickness of the pipe.

Installation technology.

Let us consider in detail the technology of installation with steel pipes, as the most common case. There are two options here, welding or threading. The optimal technology is gas welding, since in comparison with threads there are no vulnerabilities in the form of slips, without which no installation on a threaded connection is possible. In short, pipes usually always leak, since they are subject to loads from thermal expansion, and installation with a large number of fittings does not look as attractive as a welded solid steel pipe.

Details in the photo of the installation of the radiator on the thread and our modification with gas welding.

As for gas welding in comparison with electric arc welding, gas welding has 3 advantages:

— the ability to correct inaccuracies in the installation of builders by heating and bending fragments of the riser using a gas burner.

— absence of slag inside the pipe, narrowing the cross-section.

- no sparks from molten metal.

Disadvantages of using welding for heating installation

The use of gas welding is often very profitable, but it has certain disadvantages:

- Relatively large heating area during operation. If you do not take the necessary protective measures, nearby furniture, walls or ceilings may be damaged. To avoid such consequences, you need to remove flammable objects from the work site and cover the rest with protective material.

- When gas welding is carried out, harmful substances are released into the air. Therefore, it is necessary to use personal protective equipment at this time.

- To perform welding work, you must have the appropriate qualifications and obtain a work permit. If the welding is done by a professional, then he must have a permit.

The permit is given by the fire service and has a limited validity period. It is necessary to ensure that the welding machine is in good working order, and that personal protective equipment is used.

After welding, traces remain on the pipes Source tehkomfort.rf

Installation of a cast iron battery Source tehkomfort.rf

Basic steps for replacing batteries

To dismantle radiators in an apartment with an open heating system, you must obtain permission from the local housing office and heating networks. Separately, you need to coordinate the modernization of the design, for example, if you plan to move the batteries to another location, add or remove several sections.

Welding work, as already mentioned, is allowed to be carried out only by specialists with clearance and professional education - independent initiatives can result in a hefty fine. Therefore, we will consider the main stages of the upcoming repair to avoid unpleasant surprises.

Carrying out preparatory work

To begin with, it is worth minimizing the possible consequences of the operation of the gas welding machine. Furniture close to radiators must be removed or covered from possible damage. Also protect the area of the floor and wall adjacent to the battery.

Then the water is drained from the heating system. If we are talking about a private house or other room with autonomous heating, a special tap is used, which must be provided for during the design.

In an apartment with central heating, you cannot turn off and drain the coolant from the system yourself - you should call a specialist from a service organization. Next, you need to disconnect the expired radiators. The easiest way to do this is with a grinder.

But even here you will need good skill in working with tools, because in order to connect new heating devices with a minimum of effort, it is important to make a neat and even cut

Assembling a new structure

Next, the new radiator is packaged. If you want to save on the services of craftsmen, it is quite possible to do this work yourself.

Required materials and tools:

- Set of nuts (for radiators).

- American ball valve.

- Mayevsky crane.

- Adjustable wrench.

- Packing paste.

- Sealant (linen or fum tape).

To assemble the battery, you need to seal the nuts, treat them with paste and screw them onto the pipes at the joints. The radiator layout is completed by installing the taps.

An “American” is installed on the side of the connection with the heating system in order to be able to block the access of the coolant to a specific battery. From above, on the opposite side from the pipe entrance, a Mayevsky tap is screwed in with a wrench, with the help of which it will be possible to remove “plugs”, releasing air accumulations from the system.

Gas welding connection

The assembled radiator is suspended in place of the old battery using special fasteners, and the evenness must be checked with a building level. Before starting welding, thoroughly clean the ends of the elements to be joined from dirt, dust and degrease.

Next, the inlet and outlet pipes are welded with a adjusted slope, which helps prevent the formation of air pockets. To do this, the connecting section is heated with a burner, while simultaneously using filler wire to fill the gaps between the fragments of the system.

The type of seam and heating rate are chosen by the master, based on the wall thickness, pipe material and other professional nuances.

Seam cleaning and finishing

After the work of a gas welder, the pipes look unaesthetic: black marks and stains are unlikely to decorate the interior. But this is a fixable matter.

To process the welding site, you need to follow the following algorithm:

- Clean the pipe with 3 or 4 grit sandpaper. If the welder does not work carefully, there may be a thick bead at the joint, which some try to level with the same grinder. But you shouldn’t do this - you can damage the strength properties of the seam.

- Dust the pipe - wipe with a damp and then a dry cloth.

- Degrease with white spirit.

- Coat with anti-corrosion primer in 2 layers.

- Paint with heat-resistant enamel also in 2-3 steps (the lighter and more transparent the paint, the more layers may be needed to mask the black color).

Of course, all painting work should be carried out before connecting the system, on cold pipes. If the batteries were replaced during the heating season, you need to shut off the access to the coolant and wait until the system cools completely.

You can decorate only the pipes or the entire structure complete with the radiator. The color is usually chosen white, silver, bronze or to match the tone of the walls. But for some interior styles, you can also use a contrasting shade, for example, dark chocolate, glossy black or spectacular red.

You can open the system and fill the circuit with coolant only after the paint has completely dried.

Battery selection

The quality of heating depends not only on the installation, but also on the correct choice of radiator. It is important that it provides exactly the required amount of heat. If there is not enough of it, the residents will freeze. If there is a lot, there will be discomfort due to the heat, and energy for heating will also be wasted uneconomically.

When selecting equipment, you need to determine the most suitable material and take into account how many sections there should be in the radiator. It must be taken into account that the power of one is indicated in the technical documentation.

The simplest method of calculation is the following. It is necessary to take into account the area of the room. For a ceiling height of 2.40-2.65 m, the number of square meters must be multiplied by 100 W. The resulting value must be divided by the power of one section. This way you can determine their number.

The use of welding ensures a reliable connection Source tehkomfort.rf

A small radiator was suitable for this room Source tehkomfort.rf

The required value can be found in the documentation. If this is not possible, use the standard value of 170 W. If there is a need for rounding, this will need to be done upward.

In apartments with high ceilings, it is more advisable to use a different calculation method. Here you need to determine the volume of the room. To find out, it will be enough to multiply the area of the room by the height of the ceilings. The result obtained is multiplied by a coefficient corresponding to the type of building. For a panel one it is 41 W, for a brick one - 34. By dividing the calculated value by the heating power of one section, it will be possible to obtain their number.

The result will be approximate. For a more accurate accounting, you need to take into account the following:

- Features of the climate in the area where the housing is located.

- The presence of a balcony or loggia in the room.

- The number of windows available, as well as the method of glazing them.

- Number of floors, as well as the location of the apartment.

- The location of the radiator in the room and the use of a decorative screen for it.

- Use of external or internal insulation.

The most popular are radiators made of steel, aluminum, cast iron, copper, and bimetallic.

When carrying out work, you need to move the furniture to the side Source tsaritsyno.online

Choosing heating radiators to replace

Types of radiators

After a detailed review of the Technical Conditions (TS), you can begin to select models of radiators and batteries. Currently, there are many types of components for heat supply on the market, and it is difficult to immediately navigate this variety.

Can heating pipes in an apartment be replaced with new ones made of a different material? Yes, if its technical operational parameters comply with the specifications

There is a list of main characteristics that you need to pay attention to first:

Heat dissipation or rated power. They may be larger or smaller than older batteries

It is important that the capacity is approximately the same. This will affect the cooling of the coolant and, as a result, the temperature distribution throughout the house;

Maximum temperature and pressure

The first parameter is not particularly important. However, replacing heating radiators in an apartment with gas welding should only be done for those models whose maximum permissible pressure is equal to the same indicator for the central system. Usually it does not exceed 6 bar. But you need to take into account the possibility of water hammer;

Connection method.

Design of bimetallic radiators

An important point is the battery material and design. They will largely determine the characteristics described above and will affect the difficulty of replacing heating batteries in the apartment.

Traditionally, cast iron radiators were installed in apartment buildings. They are characterized by durability and reliability. However, high heating inertia and mass are their disadvantages. Therefore, to replace heating batteries in an apartment in winter, other types of heating devices are chosen:

- Bimetallic radiators. They differ from aluminum ones in the presence of steel or copper pipelines through which the coolant flows. Manufacturers increased the maximum possible pressure in this way. The vast majority of bimetallic radiators are sectional, which allows you to choose the rated power.

- Panel metal. Refers to the budget option. They are non-separable. They are characterized by the ease of replacing heating batteries during the heating season, since the radiator has a relatively small mass.

Aluminum batteries do not have the proper technical qualities for installation in a centralized heating system. Therefore, their installation is not recommended. In addition, replacing heating radiators with gas welding will be difficult due to different materials for making pipes and batteries.

You can assemble a bimetallic radiator yourself, but only if you have a special key. It can be rented.

Carrying out repairs

If the homeowner realizes the need to replace the radiators, then he will have to do it himself or invite a professional to do the work. In the latter case, you will need to take the following steps:

- You need to choose a suitable specialist and ensure his arrival. He will study the situation on the spot, take the necessary measurements and draw up a work plan. You can get recommendations from your specialist on choosing suitable radiators for replacement.

- To understand what radiators and pipes are needed, and to choose the right equipment, it is important to understand how the heating system works, the advantages and disadvantages of various designs. Using existing knowledge and expert advice, the necessary equipment is purchased.

- Before replacing heating batteries with gas welding, it is necessary to ensure the dismantling of the existing structure. It is best to do this shortly before installing new equipment. Before work, you need to shut off the water supply. In a situation where repairs are being carried out in an apartment building, you will need to contact the Housing Office for this.

- The technician determines the exact location and begins installation. Next comes the replacement of equipment and installation of welding radiators.

- When the replacement is completed, it is necessary to test the reliability of the equipment. To do this, you need to turn on the water supply. The tenant or master does not have the right to do this on their own. To check the quality of the work done, you need to contact a housing office employee.

The efficiency of the updated heating system will be determined not only by the quality of the specialist’s work, but also by the correct choice of pipes and radiators.

Certificate required to work as a welder Source portaltepla.ru

How to obtain work permits?

Only professional gas welders who have a document confirming their education in this specialty are allowed to install heating batteries using gas welding. In addition, the welder must have a valid fire safety permit. It is advisable that the specialist has experience (excellent, if many years) in carrying out gas welding work. The quality of the final result is also affected by the equipment used, which must not only be in good working order, but also meet established safety requirements.

Gas welding work is carried out in special clothing, in special glasses with a protective shield that prevents the eyes from catching “bunnies,” as experienced welders say. We must not forget about gloves that protect the skin of the hands from the effects of negative factors.

Mandatory equipment for a gas welder includes protective equipment such as goggles, a shield, and work gloves. All listed items are intended for gas welding work.

Please note that at the moment in apartment buildings there is a ban on carrying out gas welding work without obtaining permission from the authorized bodies. Violators of this legal norm face a significant fine.

How to legally change the heating in an apartment

Replacement of radiators in an apartment must be carried out with the consent of the management company. To do this, you need to write an application to the chief engineer of the management company, requesting consideration of the possibility of replacing the radiator for certain reasons.

If the management company agrees, you will have to order a heating system reconstruction project from an organization that has SRO approval. Next, the chief engineer of the management company approves the project or sends it to an interdepartmental commission. After the MEC, the chief engineer takes over again. Next, to replace the pipe, you hire an organization with SRO approval (even if your relative is a certified welder, he will be able to replace the radiator in the apartment only if he has a welder’s certificate and a fire safety permit). Copies of all documents are kept in the management company.

Welder's certificate

If refused, you can go to court or insist that the management company fulfill its duties, including replacing the heating system in an apartment building.

This is interesting: Which pipes to choose for heating: which options are better and why?

Materials and tools

Installation of a radiator installation is possible if the necessary components are available. Thus, the manifold of any block of the product is made with a G1 internal thread (1 inch), in addition, on the left edge there is a left-hand thread, and on the right - a right-hand thread. This counter-direction of the turns serves to combine the nodes into one battery through the use of a nipple. Therefore, several adapters will be required to allow the transition to a standard right-hand thread, which in most cases is used for eyeliner sizes of 1⁄2 or 3⁄4 inches. In another way they are called futorki or transition plugs. The size of the internal connecting diameter depends on the tubular product that will be used for the liner.

Basically, only two inputs work, and the remaining 2 must be muted. For this purpose, a standard plug (plug) with an external thread that matches this adapter is suitable. The best option for a plug would be a sample with a strong O-ring seal that does not require additional winding. The “set” of a plug and a plug can be replaced with a standard blind plug with a suitable left- or right-handed 1G thread.

As a rule, one pair of plugs (4 in total) is not installed. Experts recommend replacing the upper manifold plug with a Mayevsky valve, which is a simple device that will help free the battery from accumulated air before the heating season or during maintenance. This device is located diagonally to the supply pipe, in the case of a double-sided bottom connection. The faucet comes with a key that helps release the air. This component is necessary for safety reasons so that a small child cannot turn on the tap and flood the apartment.

These materials are sold both separately and as ready-made installation kits. This set consists of two pairs of pass-through plugs, one plug, and a Mayevsky tap with a key. Additionally, in some kits you can find brackets to hang the installation on the wall (3 medium batteries up to 10 blocks will require three brackets). Components are sold for pipe sizes 1⁄2 and 3⁄4 inches. Installation measures, carried out in accordance with all requirements, include disconnecting the device from central heating for preventive, repair purposes, and when replacing. Therefore, you should buy two standard ball valves of a coupling connection with a union nut - “American”, which will facilitate future procedures associated with servicing the device.

If there are specific features of the heating circuit that involve the possibility of installing control devices (if the thermal output of a centralized heating system is excessive or the need to fine-tune autonomous devices), standard ball valves are replaced with other elements. For example, a thermal valve with a thermostatic head can be installed on the supply pipes. They are produced in straight and angular models, depending on the methods of connecting pipe fittings to the heating structure.

Correct balancing and maximum output of generated heat will be ensured by a control valve installed at the outlet. To preserve the settings, you should install a block tap whose adjusting screw (for a screwdriver or hexagon) is closed with a plug. Let us add that you can use a ready-made thermostatic kit suitable for installation with a thermal valve, balancing valve, or thermostatic head.

Replacing heating batteries using gas welding

Replacing heating batteries with gas welding is still in higher demand today than using a threaded connection for this purpose. And almost every specialist who has dealt with welding and understands the principles of operation of the heating system will be able to explain the reason for this state of affairs.

The main role here is played by the features of domestic heating systems, especially those used in apartment buildings. The fact is that during their operation a heat carrier under high pressure is used. And it is this factor that can have the most negative impact on a threaded connection. During operation of the heating system, the nut on such a connection may become loose, and this can lead to an accident, which will reduce the economic advantages of the threaded connection not just to zero, but will put them in the negative, since such an accident will not cost without the cost of repairing your own apartment and for the renovation of the neighbors' apartment below. And you shouldn’t forget about such a factor as the discomfort associated with repairing a heating system, which can fall into disrepair due to a weak threaded connection at the most inopportune time.

By the way, experts who prefer gas welding to a threaded connection agree that gas welding requires more time and effort during installation than a threaded connection. But is this such a big advantage if this approach puts the strength and reliability of the entire system into question? As for the ease of dismantling the system, this advantage of a threaded connection is rather doubtful. As you know, the heat carrier inside the pipes is under high pressure and can reach high temperatures, so the nuts during operation of the system can simply “stick” and then unscrewing them becomes very difficult - in most cases you have to resort to the same cutting of pipes as and when dismantling a heating system for the assembly of which welding was used.

So, let's summarize:

- The use of a threaded connection when installing requires less time, money and effort on the part of workers.

- Gas welding provides greater reliability of the connection (as a rule, the strength of the weld in most cases exceeds even the strength of the pipes themselves) - which means that an unexpected breakthrough of the heating system at the joint is completely excluded. In addition, a welded connection is more aesthetically pleasing and inconspicuous in appearance than a threaded one.

Of course, in this case it is up to the owner of the apartment or house to choose. For example, if we are talking about the heating system of a private house, which has to be regularly disassembled in order to clean the pipes from the inside, then a threaded connection may be more preferable. But for a heating system in an apartment building, it is, of course, better to use a welded joint, which has higher reliability and, therefore, durability. It is not for nothing that today a threaded connection when installing a heating system in apartments of monolithic new buildings is simply prohibited, and the only way to connect pipes into a single whole is welding.

Why is gas welding better than the threaded method?

I would like to highlight the following features of these works:

- When making threaded connections, fittings, nuts and other bulky structures are used, which do not look very aesthetically pleasing. Carefully welded seams become unnoticeable after painting.

- The strength of the welded joint is high, which eliminates the possibility of a leak in the system.

- Welded fastening is indispensable in heating circuits with high pressure, since the threaded connection simply cannot withstand the load.

- The absence of seals, which are a mandatory element of a threaded connection, eliminates the possibility of a pipeline breakthrough due to their wear.

- The final cost of the work, including the purchase of materials necessary to replace batteries, when using gas welding will be lower than when using the threaded connection method.

Gas welding is inferior to the threaded fastening method in terms of time required for dismantling and installation work. Taking into account all the pros and cons, we can summarize that the threaded fastening when replacing batteries is most suitable for private homes.

A few words about gas welding

Gas welding of heating is a process during which the edges of the metal parts of the heating system to be connected are heated using special equipment. This causes molten metal to form between them. As it cools, it creates a strong, inextricable connection between the parts that were welded together.

The peculiarity of gas welding is that it can be used for metal parts of absolutely any size and shape. As a rule, gas welding work includes the following actions:

- The parts are prepared for welding.

- They perform welding work using different types of welding seam - ceiling, horizontal, vertical.

- If necessary, the applied and cooled seam is boiled in weak places, cracks are welded on the parts.

- Weld seams are cleaned.

Replacing radiators with gas welding is in high demand today. Almost any specialist who understands the principles of operation of the heating system and has dealt with welding can explain the reason for this. Here the nuances of domestic heating systems, especially those used in apartment buildings, are important. Their operation involves the use of a coolant under high pressure.

This factor, when the system constantly experiences pressure on all its elements, in combination with possible water hammer, can have a detrimental effect on other types of connections. In the event of an accident, the economic advantages of other methods of replacing batteries will not only be reduced to zero, but will develop into the costs of repairing the living space of the neighbors below and your own apartment. The troubles associated with repairing a heating system that failed at the wrong time should also not be forgotten.

Experts who prefer gas welding agree that it requires more effort and time during installation, but gas welding is characterized by greater reliability and durability of the connection. The strength of the seam after welding, as a rule, exceeds the strength of the pipes that were welded. This indicates that a sudden breakthrough of the heating system along the seam is completely excluded. In addition, a welded connection looks invisible and more aesthetically pleasing. Therefore, gas welding is considered the most effective and optimal option for connecting radiators and heating pipes for an apartment or country house.

Depreciation of equipment

The use of metal options is in most cases reliable and convenient, but it also has important disadvantages. If you do not change the heating equipment. Over time, the inside of the pipes gradually becomes overgrown, reducing the diameter and making it difficult for the coolant to pass through.

This happens because the water contains impurities that settle on the walls. This process proceeds very slowly, but over many years it will lead to a decrease in the flow of coolant and a deterioration in the quality of heating.

The coolant circulates in the heating system under high pressure. Over many years of operation, it can significantly deform the threaded joints. When using gas welding, this problem does not exist.

The deposits inside pipes and radiators are hard and almost impossible to clean. If they are located in the radiator, then due to its complex shape it is difficult to access them. The only way to fix the heating is to replace pipes and radiators.

The use of taps is mandatory Source 1-teplodom.ru

The process of replacing batteries in welding

If you intend to replace old radiators with batteries of a different type or change the number of sections, this must be agreed with the management company. You must also provide documents confirming that the work will be performed by a qualified welder. Self-dealing is punishable by a large fine.

Preparatory work

First of all, nearby furniture is removed from the welding site, and adjacent sections of the wall and floor are covered with non-flammable material. A specialist from the housing office is called in to shut off the heating and drain the water in an apartment building. In private houses and autonomous heating systems, a drain valve is provided for such cases. Then, using a grinder, the old batteries are dismantled. The pipes leading to the radiator must be cut straight so that there are no difficulties when installing a new one.

Assembling a new heating system

You can assemble and install a new heating battery yourself without calling a specialist. To do this you need to stock up:

- a set of nuts (for the battery);

- two ball valves;

- Mayevsky crane;

- investment paste;

- sealant made of flax or fum tape.

Before tightening, the nuts are treated with paste, and a sealant is wound around the threaded connections. Ball valves are installed on the supply and return pipes. They are necessary to disconnect the radiator from the heating system in emergency situations. On the other side of the battery, the Mayevsky tap is screwed in at the top. Air pockets, which often form in central heating systems, will descend through it.

Ball valves are required to be installed to shut off the radiator in emergency situations

Gas welding

The completed battery is placed in place, hanging on special mounts. To prevent air from accumulating inside, the installation of heating radiators is carried out according to the building level. Dirt is removed from the ends of the elements being connected and degreased. The supply and return pipes are connected to the radiator at an angle to prevent air pockets from forming. To prevent coolant circulation from being disrupted when closing the taps, a jumper from a pipe of slightly smaller diameter is welded onto the radiator between the supply and return.

Welding is performed by heating the joint with a torch while simultaneously feeding filler wire. Melting, it fills the gap between the ends. Ideally, the material of the filler wire should be the same as that of the pipes or as similar in composition as possible. The best results are obtained when working with an acetylene torch. The use of methane and propane is permitted provided that their combustion temperature is twice the melting temperature of the filler wire. The heating rate and type of weld are determined by the welder depending on the thickness of the wall and the material being welded.

Stripping and painting

At the welding joints, black marks and streaks form. To remove them, treatment is carried out followed by staining in the following order:

- The surface of the pipes is cleaned with sandpaper No. 3 or 4. If welding beads remain on the seams, they cannot be removed with a grinder, as the strength of the connection will decrease.

- Dust is removed from the cleaned areas first with a damp cloth and then with a dry one.

- Solvent degreasing is carried out.

- Treated with two layers of anti-corrosion primer.

- Heat-resistant enamel is applied in 2 - 3 layers so that the blackness does not show through.

Pipes and radiators are painted when they are cold. Therefore, if pipes are replaced in winter, the heating will have to be turned off. The color is chosen in accordance with the design of the room or a contrasting option.

Preparatory stage

It includes a series of sequential actions aimed at preparing the room for the installation of new radiators.

Coordination with neighbors in an apartment building to disconnect the riser

Coordination is established with those who live on the floors above and below in an apartment building. This is done to carry out a complete change of supply pipes.

A proposal is being made to purchase transition fittings and pipes for neighboring batteries using our own funds.

This is a reliable way to eliminate the need to replace heating sources in the future.

If the dialogue with the neighbors does not work out, then the riser is cut off at floor level and under the ceiling. Then, in your own room, you switch to a reinforced polypropylene pipe.

Dimensions

Performed in case of successful negotiations with neighbors. Measured:

- the diameter of the outlets from the radiators of neighbors on the upper and lower floors;

- the length of the pipeline to connect neighbors from both floors;

- pipe length in your own room;

- the length and diameter of the pipe running through the ceilings.

Purchase of new radiators

After taking the main measurements, an estimate for the purchase of materials is calculated.

Batteries are produced in 4, 6, 8, 10 sections. If necessary, their number can be changed up or down.

When purchasing “bare” radiators, you will additionally need to purchase 1 right lower blind plug and 2 left adapters with a transition to a certain diameter.

In addition, in order to subsequently be able to bleed air from the system during its startup, it is necessary to have a right-hand passage plug for embedding the Mayevsky valve. Gaskets are purchased for all plugs.

To turn off the radiator in order to remove and wash it, American taps are used. When they are closed and there is a need to turn on the heating system with the battery removed, a polypropylene tap is used.

To connect to neighboring radiators, a PPR end cap with a diameter of 2.2 cm and an external thread of 2 cm is used.

Attention! The propylene pipe must be reinforced

Preparing tools

An important part of the preparatory stage before replacing the battery is the availability of all the necessary tools:

- pencil for marking;

- adjustable and gas wrenches;

- roulette;

- concrete drill for attaching the radiator to the wall;

- construction level;

- soldering iron for soldering pipes;

- grinder using a metal disc;

- ladder (in case it is necessary to cut external threads on a pipe at floor and ceiling level).

Types of welds and joints

Depending on the relative position of the pipes, they are connected:

- end-to-end, when the ends are adjacent to each other;

- in a T-bar, if the pipes are arranged in the shape of the letter T;

- at an angle when it is necessary to change direction by 45 or 90˚;

- overlap by flaring the end of one pipe and putting it on the other.

Depending on the possibility of access to the joint, the connection is made:

- With a horizontal seam, if a vertical section of the pipeline is being installed.

- Vertical when the pipeline is in a horizontal position.

- Ceiling when the joint is welded from below. Such a seam has to be applied during repair of the heating system when replacing the damaged area.

- Pipes are welded bottom when installing new systems, when it is possible to rotate them so that the electrode is on top of the joint.

Pipe welding methods

For welded pipe joints, three methods are most often used:

There are three types of electric arc:

— manual using consumable electrodes;

— using a semiautomatic device in a carbon dioxide environment, the arc is created by a refractory electrode, and filler wire is used for the surfacing layer;

- under a layer of flux, it is applied to rolled products with protective coatings.

- Electroslag, due to the thick layer of slag, the seam does not oxidize.

- Gas, heating is provided by burning acetylene entering the working area from the burner.

There are also contact, ultrasonic, thermomechanical welding.

Gas welding

The method is applicable in field conditions, when pipelines are laid far from power sources or when pipes cannot be welded by electric welding: the rolled products cannot be turned or twisted when forming a connection. The filling of seams with gas is higher than with electric arc. The metal is less exposed to temperature, and the risk of internal stresses in the metal is negligible.

When welding pipes with gas, acetylene or a gas generator is used; the temperature in the working area is higher when bottled acetylene is burned. UTP grade filler wire is fed so that it rests on the hot metal. For butt joints of 3 mm walls, edge cutting is not required; for thick-walled rolled products, the edges are cut at an angle.

Galvanized is mounted using HLS-B flux, the oxygen concentration in the gas mixture is increased. After work, additional anti-corrosion protection of the seams is not carried out.

Manual arc welding method

To properly weld a pipe using electric welding, you need to take into account the technology. The number of penetrations depends on the thickness of the rolled product; the composition of the electrodes and coating is selected according to the type of rolled product. When welding large-diameter pipes, before applying the next layer, scale is knocked off the metal and the joint is forged. The direction of surfacing is changed - even seams are made opposite to odd ones. Much depends on the first connection; it is done slowly; when checking the roller, the metal is checked for cracks. If defects are detected, a section of an uneven seam is cut out, and a new one is created in its place with an offset of 15 to 30 mm. For the finishing layer, choose electrodes with thick coating.