Date of publication: January 30, 2020

One of the key stages in creating a heating system in a country house or country house is the installation and installation of a chimney. The chimney is responsible for the safe and high-quality removal of combustion products from heating equipment operating on combustible fuel - boilers, stoves, fireplaces and stoves. The fire safety of the entire house, as well as the efficiency of heating units, directly depends on the quality of both the chimney itself and the method of its installation. This article will discuss the advantages and disadvantages of constructing a smoke exhaust route in one way or another.

Differences in the designs of external and internal smoke exhaust ducts

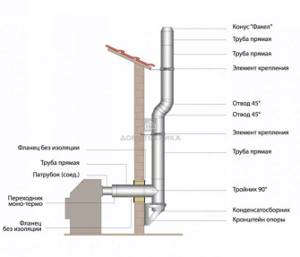

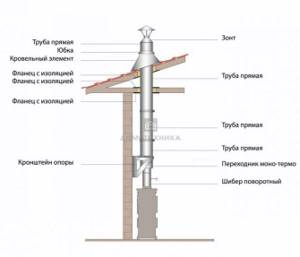

The differences between the two installation methods lie in the location of the smoke exhaust pipe. Thus, a chimney installed inside the building is located inside the house and passes directly from the heating device upward - along the walls of the room and above: through the ceiling to the second or third floor and further through the attic floors and the roof of the building. Thus, the chimney originates at point A - on the heating equipment pipe, and ends at point B - on the roof of the house. The internal chimney, as a rule, has a strictly vertical design. But, due to the peculiarities of the layout and technical plan of the structure, the smoke exhaust route may have various displacements, turns, bends, and bypasses of supporting structures.

The external chimney also originates from the heating device, but its main part is laid along the external facade of the house. A small section of the beginning of the pipe from the stove or fireplace is led to a hole in the wall, which leads directly to the street. Next, the pipe runs strictly vertically along the facade wall of the building and ends at the required elevation above the roof. In the case of installing an external chimney, various displacements, turns and detours are also possible, if required by the configuration and structure of the building facade, roof and the building as a whole.

Both options for installing a channel for removing combustion products - inside and outside the building - are actively practiced in suburban housing construction, and have their own advantages, features and disadvantages. It is worth adding that these two options for installing a chimney are used both for private residential buildings and for bathhouses and saunas.

Advantages of placing a sandwich pipe inside the house

Let's return to the main question - where is it better to install a chimney: inside or outside the building.

We think you've definitely come across buildings with a pipe coming out of the roof. That is, the chimney is located inside the house. This option is considered a classic, and we will start with its advantages.

- Minimum heat losses and condensation Installing a chimney in the house helps the flue gases cool much less, because

the heat is not given off to the cold street. Which, in turn, reduces the occurrence of condensation and other unpleasant consequences (clogging and clogging of the pipe, destruction of the chimney walls, etc.). It is under such conditions that the sandwich pipe exhibits all its best qualities. Read more in our article “What you need to know about sandwich chimneys”.

Fig 2. LAVA sandwich chimney inside the house

- Stable traction due to the absence of bends. The fewer bends in the pipe, the better the traction. Namely, good draft is the main task of any chimney.

- Reliability and durability The chimney will last much longer, because... indoors, he is not afraid of either gusts of wind that can tear off the pipe, or precipitation. The reliability of the structure is also ensured by more reliable fastening to roof structures and a reduction in the protruding part of the pipe.

- More warmth in the house Due to the fact that part of the pipe runs inside the house, the house will be warmer. As they say, it’s a small thing, but it’s nice.

- We do not violate the thermal insulation of the walls of the house. This operational advantage is an indisputable advantage, because no need to make additional holes in the walls.

- The design is cheaper. There is no need to spend money on a tee, brackets, more powerful fasteners, etc. In addition, non-insulated elements can be used in heated rooms, which also saves the family budget.

- No complicated installation To install a chimney inside a building, you most likely will not need scaffolding, but only a simple ladder, which can be found in every household.

- Easier to maintain If the chimney is located inside the building, you can inspect it in any weather conditions.

- Beautiful appearance Agree, a pipe from the roof looks much more attractive than a pipe along the facade of the building. Although we will leave this point at your discretion, as the taste and color...

Designing a chimney at the initial stages of construction or installing it in an already finished house?

Important! In order to avoid additional costs of money and time, as well as to achieve the highest quality of the smoke route, it is recommended to include the hearth and smoke channel in the engineering design of the house at the initial stages of construction.

The diagram of the smoke duct, developed before the construction of the main frame and structures of the house, allows you to comply with all the required fire and operational safety standards, select the most suitable location for the stove or fireplace, and also immediately calculate all the costs and actions along the smoke exhaust route. Unfortunately, most often the fireplace, stove, boiler and chimney begin to be installed after the house or bathhouse is built. This entails significant risks and completely unnecessary expenses.

We list the main disadvantages of this approach:

- the need to remodel many structures in the house

- the need to dismantle newly constructed rafters and floors

- the need to cut membranes, vapor barrier at home

- the need to create the necessary openings in the walls, floor and ceiling, on the roof

- often: the need to develop a smoke route design based on an existing layout, which entails frequent turns of the chimney, which increases its cost and reduces efficiency

- the need to dismantle some structures

- the need for new repair work in places where structures have been dismantled and the integrity of walls and ceilings has been damaged

- often: the inability to fully implement compliance with all fire safety standards due to the features of the finished layout and load-bearing structures, which entails the risk of a fire in the future

Drawing up a plan for the passage of the pipe from the heating device to the roof ridge at the initial stages of construction allows you to install a smoke exhaust route during the construction of load-bearing and related engineering structures of the building. This approach significantly reduces the cost of funds, and also allows you to install heating equipment and a chimney in compliance with all fire safety standards and requirements.

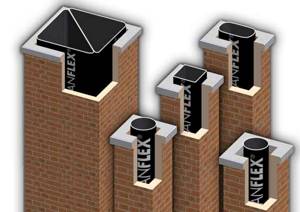

External chimney along the facade of the building: advantages

An external chimney is a chimney whose main area is located on the street. Only a small horizontal section of pipe remains in the house, connected to the heating device. In the vast majority of cases, this method of organizing a smoke route is resorted to when the smoke channel was not provided at the beginning of the construction of the house. In order to avoid labor-intensive and costly processes of reconstruction and adaptation of internal structures to the smoke route, the pipe is simply brought outside.

Advantages of an external chimney:

- easy installation

- simple design

- higher fire safety

- no possibility of smoke and carbon monoxide entering the room

- good traction with the ability to adjust it

- saving useful living space

- the possibility of installing a smoke exhaust route at any stage of building a house, or after its completion

Disadvantages of an external chimney:

- hypothermia of the chimney in winter and difficulty in lighting the fireplace

- low draft in the cold season

- supercooling of flue gases, which provokes the formation of condensation on the internal walls of the pipe

- constant risks of damage to the chimney structure by snow and wind

- violation of the appearance of the building facade

- heat losses

- the need to use expensive fasteners due to the large loads placed on the smoke duct in bad weather

Operation report

After two more experiments in operating the stove, it became clear that everything was fine and working.

But there are several disadvantages: 1. If the stove is not cleaned from the inside, the hairdryer is sucked in with coals and other debris through the grill, so it is better to choose a hair dryer not with a large grill, but with a fine mesh. 2. If the hoods and boiler are turned on in the house, then no draft is created from the hairdryer; it is necessary either to turn it all off to reduce the influx, or to open the window briefly during kindling so that the influx goes through it. Enjoying the fireplace every day has become a habit.

The third drawback: if you heat it for a long time, the stove warms up the room very much; after all, it actually turns out to be a “potbelly stove” in a tile. For the author, it’s enough to lay down three medium-sized birch logs “for a light and to warm up a little”; it burns for an hour and a half. If there are six logs, then it becomes too hot to be in the room.

Internal chimney through the roof: advantages

A chimney installed indoors from a heating device upward through the floors and roof is called internal and is most widespread. The main thing in this matter is to plan such a smoke removal route in advance, at the very initial stages of building construction.

Advantages of an internal chimney:

- the most stable and good traction

- absence of external factors that can damage the structure

- insulation of the chimney and, accordingly, eliminating the possibility of overcooling of smoke and gases with subsequent formation of condensate

- independence from climatic and weather conditions

- no wind load

- no heat loss

- no violations of the integrity and insulation of the external walls of the building

- longer service life

- the possibility of saving on fasteners, since they can be used to fasten the structure of the house itself, and also use inexpensive fasteners due to the absence of load on them by external factors

- easier installation and maintenance

Disadvantages of an internal chimney:

- violation of the tightness of the roof and the need to dismantle some load-bearing structures in cases where the chimney route was not included in the original house construction plan

- higher level of fire hazard due to the location of the pipe inside the house

- the need to insulate all areas where the pipe adjoins the walls and where the pipe passes through the ceiling, ceiling and roof

- use of useful living space

- risk of smoke in the room if the pipe is damaged

Attention! When organizing a smoke exhaust system inside a house, it is important to pay special attention to insulating all surfaces and pipe passages.

When pipes are heated, the surrounding areas, especially those made of flammable materials, may begin to smolder or catch fire. It is strongly recommended not to skimp on the quality of insulating materials and to install them in accordance with all established rules. You should also maintain safe distances between the chimney and surrounding areas of walls, ceilings or roofs.

Chimneys: types, features

The chimney is an engineering system combined with stoves, heating boilers and fireplaces. The pressure difference that occurs at its inlet and outlet occurs naturally in the system. There are different classifications of chimneys.

Depending on the material of manufacture, chimneys are distinguished:

- brick;

- metal;

- ceramic;

- asbestos;

- polymer.

Expert opinion

Borodin Vasily Platonovich

Stove mason, specialist in fireplaces, stoves and heating systems

Conventionally, all existing types of chimneys are divided into two large groups: straight and complex channels.

The first type of structure is made in the form of a straight pipe. The advantage of this type of chimney is that it provides good draft, the disadvantage is large heat losses. Complex structures are equipped with additional channels. As smoke passes through them, it heats up the walls of the chimney, which become an additional radiator of heat in the room.

The classic version of chimneys is a brick structure. It has a number of advantages, the main one of which is high heat capacity. Such chimneys are the safest to use, have a long service life, have mechanical strength, but cannot be installed only on certain models of modern heating boilers, stoves and fireplaces. They require the construction of simpler and more mobile chimneys.

Steel single-circuit chimneys

The structures look like pipes made of stainless steel. In some cases, galvanized iron is used to make single-circuit chimneys for heating boilers and fireplaces. The wall thickness of smoke channels of this type starts from 0.6 mm. This is not enough to ensure a long service life of the structure. It often burns out. The service life of such chimneys rarely exceeds 10 years.

Despite these disadvantages, steel and galvanized single-circuit chimneys are popular among owners of country houses.

Contribute to this:

- quick and simple installation of the structure;

availability of the material and its relatively low cost;- light weight.

Thanks to the smooth inner surface of the pipes, soot does not accumulate in them. Such structures do not require a foundation.

Among the significant disadvantages of steel or galvanized single-circuit chimneys:

- lack of insulation;

- poor heat capacity;

- difficulties in joining with roofing material.

Expert opinion

Borodin Vasily Platonovich

Stove mason, specialist in fireplaces, stoves and heating systems

When installing a direct chimney, special gaskets are installed between it and the roof. Such structures can also be displayed through walls.

Steel double-circuit chimneys

The main difference from single-circuit structures is the presence of two walls. A heat-resistant insulating material is placed between them. The structures can be joined closely to the roof. Most often, chimneys of this type are used for side exit devices.

Ceramic chimneys

The structures consist of a ceramic pipe and thermal insulation material. The shell for the ceramic pipe is a tube made of cellular concrete. Most often, the latter has a square cross-section.

The advantages of the design include:

- ease of installation;

- high degree of fire resistance of the structure;

- long service life;

- smooth inner surface.

The chimney is assembled according to the design type. The outer walls of the pipes hardly heat up. A minimal amount of soot accumulates inside the chimney. The main disadvantage of ceramic pipes is their high cost.

Asbestos chimneys

Single-wall structures have a high degree of thermal stability. Chimneys are a straight pipe with a round cross-section and an internal rough surface. Can be installed on stoves and fireplaces that have an upper smoke exhaust channel.

Among the advantages of asbestos chimneys:

- low cost;

- light weight;

- fire resistance.

Despite all the advantages, asbestos chimneys have many disadvantages. The main one is the low degree of mechanical strength. Condensation can accumulate in these types of pipes. The chimney can only have a straight vertical shape. Very often it has to be cleaned of soot.

Polymer chimneys

The cheapest design, not particularly reliable. Can be used as a temporary solution. Suitable only for connection to gas boilers. Despite this, polymer chimneys have their advantages.

Among the advantages:

- low cost;

- smooth inner surface;

- light weight.

Expert opinion

Borodin Vasily Platonovich

Stove mason, specialist in fireplaces, stoves and heating systems

Polymer pipes are often used to repair old brick chimneys. They are simply inserted into the existing structure.

External and internal chimney: do it yourself or with the help of professionals?

On the Internet you can find numerous diagrams for connecting external and internal pipes, their designs and fastening methods. But installing a chimney with your own hands is always a big risk. Since it concerns fire safety, property safety, life and health of the residents of the house, it is recommended to use the services of trusted specialists.

Carrying out installation work by professionals has the following advantages:

- preparation of a work plan taking into account all technical features of the structure

- guarantee for work performed

- guarantee of high quality assembly and installation

- guarantee of compliance with all required standards, including those established by law

- taking into account all the nuances and features of the smoke exhaust system

- high efficiency of work

- fire safety guarantee

Full range of design and installation services

carries out a full range of work on the design, installation and commissioning of smoke removal routes of any level of complexity, length and design. The company’s installation department specialists will prepare a detailed technical work plan, taking into account all the nuances of the structure, its design and layout, as well as taking into account the personal needs and wishes of the customer. Drawing up a plan is possible both at the initial stages of construction and in finished buildings.

The project plan is drawn up with an accurate calculation of the cost of both all work and the required chimney elements, which is undoubtedly convenient for the customer. After approval of the project, a team of specialists arrives at the client’s site and promptly carries out high-quality installation of the smoke exhaust system, followed by commissioning. A big advantage is testing and a full check of the functionality of the heating and smoke exhaust system upon completion of the work. The client receives long-term guarantees of the quality of the constructed smoke removal system, installed in accordance with all fire and operational safety rules and regulations.