The design and construction of private residential buildings is a responsible, labor-intensive process that requires compliance with the sequence of work, taking into account all technological parameters.

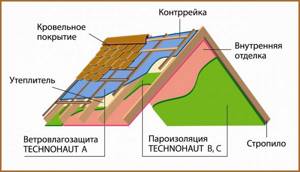

To create the most comfortable conditions for living, an optimal level of microclimate in the premises, it is necessary to ensure that the walls of frame or any other buildings, regardless of their design, are equipped with a vapor barrier, thermal insulation layer, and also take care of wind protection (wind insulation) of the house.

Proper wind protection for a frame house

The frame structure of houses has recently become popular in private, individual construction.

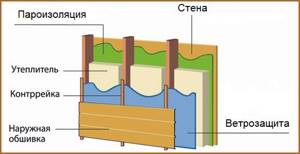

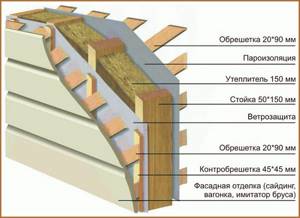

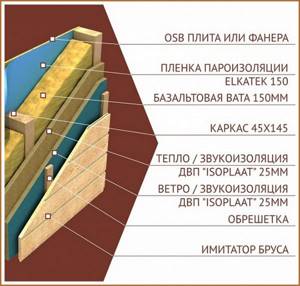

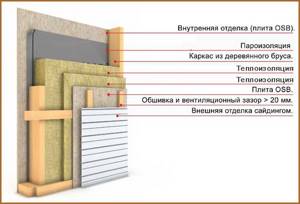

The walls of frame buildings consist of several layers, each of which performs certain functions and takes on part of the load. Insulation materials reduce the heat loss of frame walls, provide additional heating of the premises, frame risers evenly distribute the loads of all elements of the construction site, form a load-bearing frame, the outer cladding creates a reliable protective layer, stabilizes the structure of frame buildings, wind protection protects the walls from blowing gusts of cold winds.

In addition to the windproofing layer, the walls of frame houses are equipped with thermal insulation materials, a layer of vapor and waterproofing is installed, and the external cladding of each wall is performed. The top layer of insulation must be covered with a vapor barrier, for the arrangement of which roll fabrics (membranes) are used. If you neglect this aspect, the insulation will begin to get wet if atmospheric moisture enters, the walls will begin to freeze, which will lead to an increase in heat loss.

Ventilation gaps

When installing wind protection for the walls of frame houses, a special ventilation (air) gap is made. It is created using vertically attached bars and exterior trim.

The question may arise: is it possible to attach the trim directly to the windproof film? Many builders do this, saving on the purchase of additional materials.

The benefit here is only apparent. Indeed, water seeps in capillarily and in small quantities. Without ventilation, it will accumulate, spoiling the insulation array. The gap is created for a practical purpose: to prevent condensation from entering the surface of the membrane. Even if moisture seeps into the film, ventilation holes located on the top and bottom of the wall will help it escape. It is especially important to have wind protection when finishing with siding - this material does not have vapor permeability. The presence of a gap makes the wall dry, reducing its thermal conductivity. This means that the heat in the house will escape outside very slowly, preventing it from cooling down.

Here is one of the air gap options:

Wind protection functions

It is worth noting that strong gusts of cold winds can blow through any types of building materials that are used in the construction of any construction projects. Therefore, if you neglect wind protection, the walls will let in cold from the outside, give off heat from the premises, the house will become blown from all sides, which in turn will lead to additional costs when heating it. The main functions of windproofing include:

- ensuring an optimal level of microclimate;

- prevents walls from freezing during the cold season of the year;

- active protection of the structure from penetration of atmospheric moisture;

- protection of building walls from blowing;

- ensuring the unimpeded escape of steam from inside the house through the insulating elements of the building.

Bottom line

To make it comfortable to live in a private and individual building, you need to ensure an optimal level of microclimate. This requires a careful approach to the design stage. Calculate all layers of walls in a frame structure. Much attention should be paid to the insulation and windproof layer. It is recommended to do all work only from high-quality building materials.

If the arrangement is done with your own hands, then all activities must take place in a certain strict sequence. When choosing a windproofing material, you should take into account its ability to be vapor permeable. The absence of this characteristic will lead to the walls getting wet and freezing in winter.

Wind protection of walls in a frame house

To ensure wind insulation (waterproofing) of frame buildings, innovative materials are used - special membranes (rolled building materials) and polyethylene protective films that block and prevent the free penetration of air into houses, but do not prevent vapors from escaping through the “pie” of frame walls. In most cases, wind protection is installed on the outer surface of the walls, with the exception of finishing the walls of building structures using the “wet facade” type.

In the case of external wall finishing using the “wet facade” technology, the windproof layer is a thick layer of plaster mortar, which will protect the facade from the harmful effects of atmospheric factors. That is, windproofing membranes are initially installed on top of OSB boards, after which they proceed to finishing work (installation of siding panels, finishing walls with cement-plaster mortars, clinker tiles, wood panels, brickwork).

A ventilation gap is formed between the layer of wind protection and the external finishing of the facades of buildings using lathing or leaving a gap of 20-25 cm from the brickwork to the frame wall. The ventilation gap is necessary to protect against the formation of condensation in the cold season.

Installation of wind protection for frame buildings

Windproof films are produced in rolls, the thickness of which is 1.5 meters, have a high degree of resistance to tears, damage, and a long service life. Installation of wind protection for the walls of construction sites must be carried out taking into account all technological construction rules. Installation of windproofing materials is carried out after the final installation of the thermal insulation layer and before finishing finishing work.

All work is performed in accordance with the following sequence:

- Perform calculations and determine the required amount of windproofing material to be used.

- Install the insulating layer.

- Windproofing membranes are installed.

- They are fixed.

- Install the guide rails, leaving a ventilation gap.

- Finishing and facing work is carried out on the external surface of the walls of the frame structure.

Do-it-yourself wind protection for a frame house

At the initial stage, a layer of insulation is installed, laying a layer of mineral wool (mineral boards) between the frame supports, preventing the formation of cracks and gaps between them. At the next stage, windproofing membranes are installed, laying them with the pattern facing outward. To cut the material to the required length, use sharp large scissors or a stationery knife.

All joints are taped with reinforced construction tape. Installation of rolled material is carried out in a horizontal position from top to bottom, with an overlap, which is marked with dotted lines. The overlap width is 100 mm. You must not allow the material to sag or form bubbles, which can cause damage to the film during finishing, decorative and cladding work. For reliable fixation of windproofing membranes, a construction stapler and special plastic dowels with “disc-shaped” caps are used.

Before installing the support posts, the counter slats are treated with a layer of antiseptic solutions to improve their practical and performance characteristics. Install the support rails, not forgetting the need to provide a ventilated gap, which should be at least two to three centimeters, taking into account the thickness of the beams used. After installing all the necessary layers, they proceed directly to carrying out external cladding work on the wall surface. Finishing is carried out using the selected type of building materials.

High-quality wind protection for houses

At the design stage of the structure, it is necessary to carry out all the necessary calculations in order to know the required amount of building materials that will be used in arranging the “pie” of the frame wall. At the same time, the structural features of the structure, the total area of the facility, weather and climatic factors of the region, and the number of floors are taken into account.

When choosing a building material for windproofing, it is very important to pay attention to the operational, quality and technical characteristics and properties. As already noted, wind protection should prevent contact of the insulation with unfavorable environmental factors, while simultaneously protecting the walls of the building from wind blowing. It is especially important to consider wind insulation when constructing wooden houses.

Self-installation of wind protection

Thermal insulation is inseparably linked with the wind insulation of the walls, so it is very important to install the sheets of building materials so that their seams do not coincide, and all joints are securely taped with construction tape. If you doubt your competence, use the services of professional craftsmen who will carry out the construction of frame walls in accordance with all the rules and install steam and waterproofing layers.

Any mistakes when carrying out work on arranging the “pie” of frame walls can lead to a deterioration in the microclimate in the premises, getting the wall wet, and loss of heat-insulating properties, which in turn will reduce the level of comfort in the house.

Floor insulation

In warm regions where the temperature does not drop below zero, insulation is not necessary. In the middle zone, an uninsulated floor will entail large losses for heating the house, so it is necessary to provide for the installation of thermal insulation.

The optimal material for this is mineral wool - it is non-flammable, has extremely low thermal conductivity, is not damaged by rodents and is easy to install due to its compressive ductility. The only drawback of this material is its tendency to get wet and thus loss of thermal insulation ability. Therefore, the insulation layer must be protected with a vapor-waterproofing and windproof film. You can use Izospan.

If insulation with insufficient density is selected, a subfloor made of unedged boards treated with bioprotection must be hemmed under the joists.

- The vapor barrier film is laid across the joists so that it sag and allows insulation boards to be laid between them. The joints of the strips are glued with tape, and the film is secured with a stapler.

- Insulation boards are placed between the joists, trying not to leave gaps. If the insulation is laid in two layers, it is necessary to move the second layer halfway across the slab to cover the joint of the first.

- A waterproofing film is placed on top of the insulation, which will help avoid getting wet if liquid leaks inside the house. The film is secured with staples.

Floor insulation with mineral wool

Wind protection of a frame house using films

When choosing a material, as well as immediately before laying it, you need to pay attention to the quality indicators and structure of the materials. On one side the film has a smooth surface, the other side has a fleecy surface. Manufacturers apply company logos or inscriptions on the smooth surface of products for reference. The film is installed with the fleecy side facing the insulation, and the smooth surface should be located towards the outside of the wall being covered.

The advantages of windproof films include:

- non-toxic, non-flammable material; high quality and performance parameters (elasticity, strength, resistance to adverse factors, frost resistance);

- ease of installation. If necessary, you can arrange windproofing for the frame walls of a building yourself;

- affordable price;

- long service life;

- the possibility of installing the film, both at the initial stage of construction of the building, and during the process of repair work;

- preventing air filtration from the outside, ensuring the heat-insulating properties of the building structure.

In addition to providing windproofing for walls, windproof membranes are used when arranging the roofing system of houses and insulating floors before finishing them with decorative materials. Windproof films of the following brands have high quality criteria: “Izospan”, “Ondulin”, Tyvek, Yutavek (85, 95, 135, 115).

Windproof films Ondutis

- withstands temperature changes (from minus 40 to plus 80 degrees);

- not subject to the harmful effects of ultraviolet radiation;

- provides additional thermal protection of the structure;

- allows steam to pass through;

- the material is environmentally friendly, non-flammable;

- has a long service life.

Ondutis A-120 provides reliable protection of the building structure from the penetration of moisture and cold air, and reduces the heat loss coefficient.

They are used to provide wind protection for brick, concrete, and wooden walls in houses, roofing structures, and insulation of attic floors. installation is carried out before finishing finishing work (external cladding) in ventilated facades of multi-storey buildings. Can be used as temporary wind protection for walls for two to three months.

Types of materials

What wind protection should I choose for a frame house? To answer this question, you should carefully examine your options. Here is a list of the most common:

- Izospan is a vapor and moisture protective film. Non-woven material is created according to modern standards and is durable. Izospan, used for windproofing walls, is available in several versions. Depending on the type, they have a different number of layers. The degree of possible membrane tension also varies. The wide temperature range of use allows the material to be used in any region of the country. The membrane does not emit toxic smoke when heated.

- Wood fiber boards additionally soundproof the building. The flexible material fits tightly to the walls, preventing them from becoming saturated with moisture. The pores in the wood structure remove condensation out, preventing its accumulation. To keep the slabs dry, they are coated on all sides with paraffin.

- The OSB board strengthens the building frame. The material has low vapor permeability, so in this case it is necessary to have a vapor barrier using a special film. Facade types of drywall. They are made from natural ingredients and are therefore environmentally friendly. Drywall is resistant to sudden temperature changes, fireproof and vapor permeable. It is easy to cut and install. The material has a long service life.

- Fiberboard slabs are a mixture of cement, wood shavings and liquid glass. The insulation is characterized by environmental friendliness, a high degree of thermal insulation and sound absorption. Fibrolite is not afraid of either moisture or fire. Drying after getting wet, the slab returns to its original state. Fiberboard weighs little, so it is easy to saw and install.

- Eps boards made from pressed polystyrene are resistant to water, chemical compounds and rot. During the entire period of operation they do not change shape and do not shrink. When used, a rigid base is obtained that strengthens the overall structure of the wall.