Currently, the gas burner is certainly one of the most common types of heaters. They have found wide application in various fields. Gas burners are mainly used for heating small rooms, warehouses, garages, and construction sites. Such heaters are also very popular among tourists and fishermen for heating tents and cooking, especially in places where it is not possible to light a fire. Their advantages are obvious - lightness, compactness, ease of use, good heat transfer, do not smoke, no gas smell.

Infrared radiation allows you to create a warm, cozy atmosphere and a feeling of comfort.

Gas burners come in different types and capacities. Based on power, burners can be divided into low-power burners up to 2000 W and high-power ones – more than 2000 W.

Runs on liquefied or natural gas.

The design differences lie in the method of attachment to the cylinder: on the cylinder itself or connected with a special hose.

To connect the latter you will need a hose, a reducer and clamps.

The burner heating element has a high heating temperature and should be positioned with the radiating surface straight up.

There are burner models equipped with a gas control system that will turn off the heater if the wick goes out.

When choosing, it is necessary to take into account the area of the heated room, its warmth and wind insulation.

An infrared gas burner is an excellent choice for heating a garage, greenhouse or any industrial premises. These devices are among the most cost-effective.

It was originally planned that they would be used in country houses where access to other heating sources is limited. Nevertheless, due to their high efficiency, they began to be used even where there is a stove or other heating.

IR burner - what is it?

Infrared ceramic gas burner is widely used due to its high efficiency and heat output. They run on natural gas supplied from a centralized network or cylinder.

Such installations are characterized by low weight, which means high mobility. In their design, they can have two different types of emitter: metal or ceramic.

Such burners are perfect for heating domestic premises; they can be used outdoors and in other places with good ventilation.

INFRARED GAS BURNER Prometheus

Technical name:

SMALL-SIZED INFRARED GAS BURNER GI-2.3

The infrared gas burner GI-2.3 is designed for heating domestic premises (dachas, retail outlets, construction trailers, greenhouses) in the cold season, as well as heating food in the field (hiking, etc.), heating the crankcase of a car engine in winter conditions.

The main distinguishing feature from competitive analogues is the use of a ceramic infrared burner (Germany) as an emitter, which ensures long service life, uniform flame spread inside the emitter (without flashing), the absence of an open flame and, as a result, operational safety.

Infrared gas burner emitter

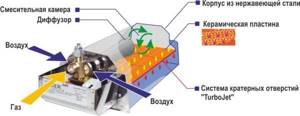

A solid ceramic radiating panel is used as a radiator, with a specially designed hole shape that promotes complete and most efficient combustion of gas.

A one-piece specialized emitter (as opposed to one glued together from several elements not intended for such use) emits heat from the entire area and is not subject to possible destruction from temperature changes. The special shape of the emitter holes allows gas to be burned with minimal release of harmful combustion products, which makes it possible to use an infrared burner in domestic premises.

Technical characteristics of the gas infrared burner GI-2.3

| No. | Indicator name | Standardized values |

| 1. | Rated thermal power, kW | 2,30 |

| 2. | Gas consumption, g/hour | 180-190 |

| 3. | Nominal gas pressure at the burner inlet, Pa | 2940 |

| 4. | Temperature of the radiating surface of the burner, ºС | 800-900 |

| 5. | Content of carbon monoxide in combustion products, by volume, no more than, % | 0,02 |

| 6. | Overall dimensions, mm length X width X height | 255 X 150 X 100 |

| 7. | Weight, kg | 1,4 |

The designated service life of the infrared burner is 10 years.

Certification of infrared burners

The infrared gas burner has certificates of compliance with GOST R requirements and a fire safety certificate. You can view the certificates in the section “Certificates for gas burners”

Infrared burner equipment

The infrared gas burner is supplied to the consumer in individual cardboard packaging, complete with a spare nozzle for natural gas and a stand for utensils.

Advantages and disadvantages

The infrared gas burner is a compact and simple device. Each person can connect it independently without any problems in a few minutes.

The advantages of an infrared gas burner include the following characteristics:

- high reliability - the design of the unit is quite simple, so the likelihood of breakdown is minimal;

- emitters can last a long time, and the device’s lifespan exceeds thirty years;

- the small dimensions of the hiking emitters make it easy to put them in a travel bag;

- profitability - GII has low gas consumption, so such devices are more profitable than electric options, especially when constantly heating large rooms;

- these units are among the safest heating devices;

- high heating efficiency.

Of course, this device also has its disadvantages.

These include the following:

- presence of open fire;

- the operation of the device is based on the combustion of oxygen, so it is advisable to use it in well-ventilated areas;

- The main disadvantage of the unit is the smell from the heater.

Heaters: For home

Ballu BIGH-55

I bought it for a country house. I use gas from a cylinder. Economical consumption and good heat transfer are very pleasing. I don't regret buying it. A stove and firewood would cost more

During the construction of a country house, one of the main tasks facing the owners is to make their stay as comfortable as possible. And the arrangement of heating plays a significant role here, because this is the main component of comfort and coziness. Let's consider why a gas heater is increasingly being chosen as a heating device for a summer residence, its advantages and features of use in a residential building.

A gas heater can be the main or additional source of heating in a country house

How the device works

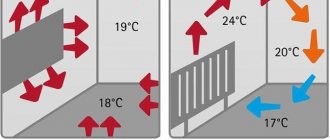

The device operates in the infrared wavelength range. For this type of radiation, the air is transparent, so the radiation does not heat it. Only surrounding objects that absorb infrared rays are heated, as a result they become a source of heat.

Due to the peculiarities of the device’s operation, it turns out to be very effective in large spacious rooms compared to other heaters, for example, an electric boiler.

Such devices make it easy to heat rooms with high ceilings, since energy is not wasted on heating the air.

The source of infrared rays in the device is a ceramic perforated panel. It heats up to the required temperature, at which it begins to emit electromagnetic waves.

Smooth adjustment of the infrared burner allows you to customize it for each specific task. Due to their high efficiency, such devices are perfect for installation in open areas of cafes, on verandas, in gazebos and in large workshops.

Among other things, the heater provides protection against gas leakage. For these purposes, a special valve is installed. This element has a sensitive thermocouple. If wind or any other external influence extinguishes the flame, the gas supply will stop.

Information regarding the operating principle of the device is provided solely for familiarization and understanding of the basic operation of the burner. Making a homemade heating boiler with an infrared burner is highly not recommended.

The fact is that even in the simplest units, which are not very expensive, there are many sensors that monitor the operation of the boiler.

A backdraft sensor must be installed to prevent the flame from blowing out, an overheating sensor, gas leaks, a temperature sensor that regulates the temperature of the coolant, and a thermostat.

In order for all of the above elements to work effectively in tandem, it is necessary to correctly write a control program for the microcontroller. Even a person who understands programming will need several weeks of intensive work on the software.

It is worth noting that the above are only the tasks that need to be solved to organize the boiler control. Calculating the thermal part can be completely overwhelming work. There are many subtleties in this matter, the consideration of which is necessary.

Among other things, it is worth keeping in mind that not a single gas service will allow you to connect uncertified gas equipment. And this is correct, because the cost of error in this matter is too high.

Moreover, it is better not to “get inside” even into factory devices without appropriate training.

Operating principle of a gas ceramic heater

Gas ceramic heaters are small-sized heating equipment powered by mains or liquefied gas. They are focused on heating rooms and open areas using infrared radiation - it does not heat the air, but warms the surrounding objects, which begin to emit heat. The main advantage of such devices is that they cope well with heating large rooms.

The operating principle of a ceramic infrared heater is that it heats the objects around it, not the air.

Ceramic heaters running on mains or bottled gas are actively used in dachas - there is no central heating here, so summer residents have to rely only on autonomous heating. Heating with electricity is fraught with high costs, since electrical equipment is characterized by gluttony. As for gas heaters, they use cheaper fuel.

Ceramic gas heaters for summer cottages are distinguished by their versatility. They can heat:

- country houses;

- outbuildings (sheds, garages, poultry houses, etc.);

- open areas (country yards, playgrounds);

- semi-closed areas (gazebos, verandas).

That is, unlike many other heating devices, they are truly universal equipment with which you can heat anything. Neither heat guns, nor convectors, nor any other heating devices can boast of such versatility.

Gas ceramic heaters are mostly self-contained equipment. They are very rarely fed from gas mains - most often the source of fuel for them is gas cylinders of various designs. These can be small liter or one and a half liter compact cylinders, or capacious refillable cylinders with a capacity of up to 27-30 liters.

If necessary, gas cylinders used to operate kitchen stoves can be connected to gas ceramic heaters. They are connected through reducers that reduce gas pressure.

The device of a gas ceramic infrared heater.

The operating principle of gas infrared heaters is clear from their design. Burners are installed inside them, which heat ceramic heating elements (emitters). The ceramics begins to generate infrared (thermal) radiation that is sent into space. Reaching surrounding objects, it begins to heat them, and they, in turn, begin to emit heat.

Advantages of gas heaters:

- high heating efficiency - they work well even in large rooms (including those with high ceilings);

- low gas consumption - allows you to make heating less expensive;

- versatility in use - you can heat any rooms and open areas with them;

- ease of transportation - they are easily transported from place to place.

There are also a couple of disadvantages:

- such devices (like any heating equipment) are characterized by low safety - their improper operation can lead to a fire or explosion;

- the need for good ventilation - such devices burn oxygen and emit combustion products that require removal.

Thus, such gas-powered equipment requires extremely careful handling and compliance with safety regulations.

How do infrared heaters work?

Unlike the traditional concept of heating a room, where the main principle is based on the fact that the air is heated first, infrared heating systems propose to heat not the air, but the plane itself and the objects in the room. Heated objects give off their heat, as a result of which the air heats up and a stable temperature is maintained in the room.

Compared to gas heating systems, IR heating is more efficient, and, as advertising says, this heating method saves quite a lot of electricity, but this is only in comparison with conventional radiators, which consume a lot of electricity.

The new, “revolutionary” principle of heating rooms with infrared “plates” actually involves surface heating, in other words, contact heating, which the average consumer was actually familiar with before. Take, for example, heated floors or heated windows in a car - all this is the infrared heating method, popularized in our time, which has replaced the usual convection.

Kinds

Heaters are divided into several main types. Each type has features, advantages and disadvantages.

Fan heaters

A fan heater is a heating device that operates on the principle of heating an air flow passing through a heating element using a fan. This device is suitable for you if you do not need to use it to maintain a constant temperature, but sometimes you need to quickly heat the air.

The main advantage of this type of heating device is cost. There are models on the market that cost up to a thousand rubles. Of course, cheap low-power models will not work as the main source of heat, but they can serve as additional heating during the off-season. In addition, a fan heater is used instead of a conventional fan to cool hot air in summer.

Floor-standing

In floor-standing models, heated air is directed upward, evenly distributed throughout the room. This type of heaters is considered the most effective. Such heaters are equipped with a safety system that stops the operation of the device if it falls or overheats.

Wall mounted

A massive type of heater that resembles a split system in appearance. The wall heater is installed in a free place, for example, below, near the floor. The air in such models flows from bottom to top, so you should not install them under the ceiling.

Ceiling

Ceiling heaters, due to their location, are able to cover the largest amount of space in the room. Models of this variety, as a rule, have an attractive design, therefore, in addition to the heating function, they have a decorative function.

Oil radiators

An oil radiator is a compact device that is designed for use in a limited area. However, thanks to its mobility, the device can heat the entire living space.

Advantages and disadvantages

The advantages of this type of heaters are their safety, reliability, noiselessness, price and lack of odors. Disadvantages include a long heating time and relatively large weight, which, in turn, is compensated by wheels for movement.

Design features

Oil heater - is a structure with an oil container and a heating device. When the radiator is turned on, the oil inside heats up and transfers its heat to the body, which heats the space around it.

Electric convectors

The essence of a convector is to distribute heat evenly throughout the room. The convector is a heating element in a housing with a slot-shaped hole at the bottom and blinds at the top. In turn, heaters in convectors are divided into dry, needle and monolithic.

Dry

Dry convectors are affordable and serve mainly for additional heating. Dry convectors are able to operate in a small area. They are not recommended to be used as the main heating element, as they increase air toxicity.

Needle

The needle heater is a plate with a chromium-nickel filament. Such a device is characterized by high heating temperature and low thermal inertia. The advantage of this type is its affordable price on the market.

Monolithic

This type of heater uses a nichrome filament with a dielectric. It is located inside a solid aluminum body. Monolithic heaters are silent and last a long time. Their design minimizes excess heat loss.

It works on the principle of transferring heat through infrared radiation directly to surrounding objects. The heat absorbed by objects, in turn, heats the air around it.

What are the benefits of infrared boilers?

It is problematic for many people to completely change the heating system in their home, but it is possible to use combined methods of heat transfer, thanks to the fact that you can install an infrared heating boiler.

The principle of its operation is based on the fact that an infrared plate is built into the boiler, which increases the efficiency of the boiler and the efficiency of its operation. Moreover, such plates allow you to use gas more economically, although it is difficult to imagine a heating system that is more profitable than gas. Compared to gas boilers, even infrared heating consumes more energy.

A boiler with a built-in infrared burner does not require additional air supply, which prevents a decrease in the level of moisture in the air and the release of flue gases. This boiler operates in semi-autonomous mode and heats the room faster than usual.

Tips on how to choose gas heaters for the garage and cottage

A good gas heater cannot be cheap. It is better to give preference to more expensive European products over the cheapness of domestic and Chinese devices.

Listen to users and experts.

It doesn’t matter whether you are going to buy a gas ceramic heater or a convector for your summer house, read the reviews about the device. In most cases, it is in practical use that the manufacturer’s shortcomings are revealed.

Study the technical characteristics and efficiency of the device.

Gas is one of the cheapest types of fuel, but its cost is growing every year

It is important to choose an economical but effective heater, the maintenance and refueling of which you can afford. All technical characteristics are indicated in the technical data sheet of the product

Electric boiler

Electric heating is an expensive and unaffordable pleasure for many, and installing an infrared water heating boiler in your home is problematic for many due to the cost of electricity. However, boilers with infrared heating elements inside save a lot of electricity due to the low energy consumption of heating elements in principle.

Infrared boilers work in the same way as conventional ones, the only difference being that the heat transmitter is water, which most effectively heats the room and retains heat. It is important to note that the internal heating elements are practically not in contact with the liquid, which makes them operational for quite a long time, but you should still choose a boiler with replaceable parts, since after a couple of years of operation they often fail.