How to flush the heating system in a private house

Chemical system cleaning

Chemical washing involves the use of special preparations that may have:

- biological origin;

- chemical origin.

The biological product purification technology is highly effective and environmentally friendly. The action is based on the principle of introducing microbiological agents into the heating system, after which deposits are broken down. This technology does not require disassembling and turning off the entire heating system of the house.

An undoubted advantage of chemical cleaning with biological products is the possibility of painless use in old heating systems. Cleansers are made on a water basis; the preparation serves to separate dirt from the walls. The desired cleaning result is achieved after a few days.

The advantages of this technology are:

- no need to turn off the heating system;

- Possibility of use in old heating systems;

- high efficiency and achievement of the desired result in a few days;

- safety;

- no negative impact on the pipe material.

The mechanism of chemical flushing is the effect of the drug on the contamination of the heating system of the house and cleans it by dissolving sediments and scale. Chemicals act on deposits, which are subsequently removed from the heating along with the liquid flow.

The cost of a chemical reagent depends on the composition and reputation of the manufacturer. The most popular drugs are:

DOCKER TERMO

The cost for 1 liter is 180 rubles; the drug cannot be used for aluminum.

Metalin

The price for 1 liter is 105 rubles; the drug cannot be used for non-ferrous metals.

Master Boiler Power

The price for 0.6 kg is 475 rubles, the drug has no contraindications for use.

Compositions of the SP-OM brand

They have no contraindications for use and can be used with aluminum and non-ferrous metals. The main advantage of the SP-OM brand washing liquid is the ability to use it for washing systems containing polymer components, non-ferrous metals and aluminum. SP-OM is also relatively harmless when draining the used solution. Each SP-OM grade is intended for use with certain metals and under certain conditions. More detailed information about the application and brands of the SP-OM composition can be found on the website https://spomcom.ru/

Significant disadvantages of the method include the difficulty in independently selecting the correct volume of the drug. The possibility of using chemicals is complicated by the fact that in most cases the components of the heating system are made of different materials. Chemicals have varying degrees of impact on metal or polymer materials. In most cases, preference is given to the method of mechanical action on contaminants in the heating network.

Physical cleaning methods

Physical cleaning methods are:

- hydrodynamic flushing;

- pneumohydropulse washing.

For hydrodynamic washing you will need special equipment, including special nozzles and thin hoses.

The cleaning mechanism consists of supplying water under pressure to a nozzle, which is responsible for generating thin jets of water.

The advantage of hydrodynamic flushing is considered to be its effectiveness, but in practice the method is used quite rarely due to its high cost.

Cleaning using the pneumatic-hydropulse flushing method is an effective means of combating contaminants in the heating system. For better cleaning, it is recommended to carry out the procedure several times. The essence of the method is to create increased pressure, due to which dirt breaks off from the walls.

Operating principle

Special reagents are used to clean heating units and closed heating systems. The solution is pumped into boilers and pipelines using a pump to flush heat exchangers, where, under the influence of an acidic environment, solid deposits are softened, as well as rust, deposits and scale are peeled off, with further dissolution and removal of residues. Alkaline washing decomposes growths of biological origin. It is used only in certain, specific cases.

The cleaning process is carried out using a hydrochemical method. The reagent solution is forced to circulate within a closed loop due to the operation of a chemical pump. Deposits are dissolved and washed away without compromising the integrity of the structural material from which the heating system, heat exchanger, connecting units and sealing gaskets are made. The rapid movement of the cleaning solution occurs under pressure, which prevents the formation of stagnant areas.

The technology for washing heat exchange equipment is quite simple, but requires attention and accuracy, as it is associated with chemical compounds harmful to humans. Work must be carried out wearing rubber gloves, protective clothing and goggles. The room should be well ventilated. The boiler, boiler or other equipment should be disconnected from gas, water and electricity.

The flushing unit with pump is connected to a previously emptied system or heat exchanger, following the manufacturer's instructions. Prepare a reagent solution by diluting the liquid in water according to the description on the label, and then heat it to the desired temperature (30-40 degrees). Warm liquid will help remove deposits faster. Next, the chemical solution is poured into the container and the pump is turned on, switching the washing unit to circulation mode.

The process of washing heat exchangers is carried out until sediments and contaminants are completely dissolved. Reusable test kits included with the equipment help determine the effectiveness of cleaning. The period of time required to remove growths is usually from two to six hours and depends on:

- heat exchanger dimensions;

- power of the treatment plant and pump performance;

- degree of pollution.

At the final stage, the heat exchanger is washed with a solution that neutralizes the acid residue.

After finishing work on cleaning heat exchangers and radiators, additional surface treatment is carried out, called passivation. For these purposes, another reagent is used that forms a thin but durable oxide layer on metal walls, protecting the material from corrosion. But you should be aware that for equipment made of aluminum, such a protection option is not allowed.

Another important step in flushing heat pipes, radiators, boilers and heat exchangers is the neutralization of the reagents used in their cleaning. Rinsing the solution directly into the sewer without pre-treatment is strictly prohibited! A crystalline powder that is poorly soluble in water or a special liquid is added to the spent reagent to bring the acidic environment to acceptable pH levels. In some cases, it is possible to replace the neutralizer with a large volume of tap water, which is mixed with the reagent before draining.

For branched networks, more efficient washing installations are used, and for simple circuits of short length or household boilers, it is enough to use low-power equipment. Washing units are professional equipment, so they are not cheap. Some companies offer to rent installations with pumps, but for high-quality flushing it would be wiser to invite specialists from specialized service companies who have sufficient experience in carrying out the work.

Hydrodynamic type of flushing

The heating flushing scheme in this way involves active action of water on scale and deposits. This happens thanks to a stream of water, which is directed under extreme pressure to the desired area.

Water is supplied through special nozzles of the required size and diameter. This type of washing is more expensive than chemical washing, but the result is much more satisfactory.

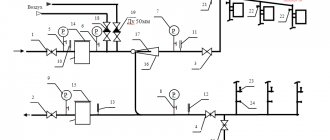

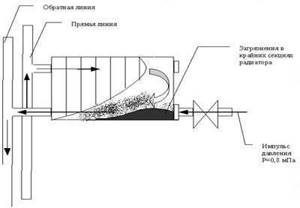

Scheme of using the hydrodynamic method of cleaning the heating system. Click to enlarge.

This type of flushing is best suited for batteries made of cast iron. Removing scale from cast iron using chemicals is very problematic due to the properties of the material itself, and sometimes even impossible.

However, the hydrodynamic system does an excellent job in such cases.

Another undoubted advantage is the environmental friendliness of such washing, since no acids or solvents are used. But only water.

To achieve the desired effect, specialists must have a special mechanism that will create a pressure of two hundred or more atmospheres.

Naturally, all scale is removed solely by exposure to water. No additional liquids or reagents are needed.

But here, too, everything is not as simple as it seems. Before flushing using this method, you must take the radiator to a service center. There it will have to be treated with a special liquid so that the layer that needs to be removed becomes softer and more pliable.

Only after this can the walls be treated with a jet of water operating under pressure. Using this method, you can remove almost everything: grease, scale, rust, dyes, carbon deposits, etc.

Pumps for washing heat exchangers PUMP ELIMINATE (Italy)

This pump with high power and performance is used to clean heating systems, water heaters, heat exchangers from scale and deposits. It is efficient and easy to operate.

The pumps are equipped with a flow inverter, which allows for faster cleaning. The unit consists of an acid-resistant working mechanism, a polyethylene tank, hoses and a flow direction switch. The body of the device is made of reagent-resistant plastic.

Download technical specifications of Pump pumps for cleaning heat exchangers:

teh_harakt_pump_eliminate_25.doc teh_harakt_pump_eliminate_v4v.doc teh_harakt_pump_eliminate_190.doc

General diagram of pump operation

Before cleaning the heat exchanger, a special solution is prepared. The required proportions of water and chemicals are specified in detail in the instructions.

The resulting volume of solution is poured into the equipment tank, then heated to the temperature indicated by the technology or immediately supplied to the system by a flushing pump.

Next, the installation is connected to one of the heat exchanger circuits, the pump is turned on, and the product is introduced into the system. Depending on the size of the system and the degree of contamination, the solution circulates, washing each plate within three to five hours.

Then the pump switches to reverse flow mode and removes accumulated contaminants from the system along with the spent flushing agent.

Products 1 - 30 of 47 Home |

Prev. | 1 | Track. | End

When the system should be cleaned

The system will require an initial flush after installation to remove any remaining flux or pipe joining material, as well as any metal particles such as swarf left over from recent installation or changes to the piping.

If the system is properly maintained, well designed, and regularly treated with a corrosion inhibitor, unscheduled flushing is unlikely to be required unless significant changes are made to the system.

However, not all of these requirements are common and sludge can build up in the system very quickly. Here are a few clues that indicate that sludge has already begun to accumulate in the heating system:

- cold “spots” on the bottom of radiators;

- parts of the heating circuit that do not heat up correctly;

- Excessive noise (bumps, clicks, pops) made by the boiler when it heats up.

The heating circuit should also be thoroughly flushed before installing a new high-efficiency condensing boiler, as the heat exchangers in such boilers are particularly susceptible to damage from contaminants in the heating system.

General information

Before cleaning, you should check the system to determine its configuration. You also need to determine the “age” and general condition of the components in order to select the required system flushing mode. For example, the procedure may remove corrosive debris blocking openings in radiators, which can lead to coolant leaks. If there is any doubt as to whether the system will withstand any cleaning methodology, replacement or repair of the relevant components will be required before proceeding.

Cleaning procedure

There are several ways to clean a system and there are a number of cleaning products on the market designed to help flush heating systems. Many products are designed to be added to the circulating water some time before flushing and help mobilize contaminants prior to flushing. Here you need to follow the instructions from the manufacturer of these products.

Basic flushing procedures:

- Powerflushing.

- Overpressure flushing.

- Flushing with a circulation pump

Positive pressure flushing is probably the most effective procedure (although it is important to check the boiler manufacturer's instructions to determine whether flushing the system using the boiler in the heating circuit is acceptable). Powerflushing is also an effective method for cleaning heating systems, especially those containing high levels of black magnetite sludge. Powerflushing is also an effective method for cleaning heating systems, especially those containing high levels of black magnetite sludge.

Powerflushing is also an effective method for cleaning heating systems, especially those containing high levels of black magnetite sludge.

Please note that with all methods, changing the direction of coolant flow will help remove debris that could otherwise remain in the system and cause it to fail.

Preparation

Before flushing with any method, there are several general preparation steps. Typically these involve adding a suitable detergent to a running heating system and letting it sit for some time before actually flushing. The cleaner is usually flushed (while hot) from the system and the system is primed to begin the final flushing process.

Before flushing, you may also need:

- Turn off all electrical controls and electrically isolate the system.

- Avoid supplying cold water to the central heating system.

- Manually close all heating circuit vents.

- For systems with open ventilation, close or temporarily connect the open ventilation and cold water supply to the supply and expansion tanks.

- When draining a vented system, the collection tank may have quite a large portion of floating sludge. It must be removed to prevent it from being drawn into the pipeline.

- Mark the operating position of any shut-off valves or other control valves, and then open all valves fully.

- Remove all thermostatic radiator valve (TRV) heads to ensure maximum flow through the valves.

- Set any diverter or zone valves to their manual open position.

- Where check valves are present, they must be closed, bypassed or temporarily removed, otherwise this will prevent flow reversal.

How is cleaning carried out?

- Connection of pumping unit;

- Preparation of a chemical solution to remove deposits (dilution, heating);

- Filling the pump container with the required amount of water so that the pump body is completely immersed in it during operation and adding the reagent according to the required concentration

- Starting the installation.

Important!

During operation of the installation, the lid must be open to remove the generated gases.

- Directly flushing the system - reverse

(changing the direction of flow in manual/automatic mode).

Important!

The washing process is accompanied by the active release of gases, and an “air lock” may form, slowing down or even completely stopping the cleaning process. By changing the direction of flow of the washing reagent - Reverse, we are able to swap the supply and return of the washing solution, pumping out the “boiling” liquid and accumulated gases into the tank of the pumping unit, thereby eliminating the “air lock” effect.

- The descaling process can be considered complete when bubbles stop appearing in the return hose (this means the reaction is complete) and the solution in the tank remains acidic (if the solution is not acidic, this means that the initial concentration of the reagent is not enough, in which case it will need to be added to solution). acidity can be determined using PH strips. Most often, service providers, based on their experience, determine the degree of contamination and the required concentration.

- Draining and disposal of used waste fluid

Important!

The recycling process is the removal of residual acidity in the solution; this problem can be solved either with the same neutralizer or with a recycler. Recycling with a neutralizer will be more expensive. It is more convenient to purchase a special recycling reagent

Compressor for washing: means and equipment, reagent

When choosing equipment, familiarize yourself with the characteristics and features of the heating circuit

Pay attention to the size of the heating system and how many heating devices are installed in it

There are other parameters that affect the compressor installation.

Often, specially prepared coolant is poured. In this case, the pipeline will remain in normal condition for a long time. But this happens rarely, and usually ordinary running water is poured in, containing salts of microelements, which gradually settle on the walls. A simple example is a kettle with scale that has formed.

In addition, silt and dirt accumulate inside, and rust forms. A number of problems arise:

- Reduced heating quality. Since salt layers have low efficiency, they become an obstacle to the transfer of thermal energy to radiators.

- Due to the reduction in the internal diameter of the pipes, the passage of coolant becomes less intense.

- Any type of pollution helps reduce the operating period of heating.

After such problems occur, coolant circulation deteriorates. This is reflected in a decrease in air temperature in the heated room.

The best preventive measure to combat this problem is regular cleaning of the circuit. Cleaning methods:

- Using chemical reagents that can dissolve dirt and scale.

- Jets of liquid supplied under high pressure wash away the plaque on the inside.

- Using the hydropneumatic pulse method.

Compressor for hydropneumatic flushing of the heating system

The compressor is connected using hoses. First, a thorough analysis of the structure is needed to identify areas that are severely affected by layers.

Then the compressor operating mode and cleaning method are selected.

Hydropneumatic flushing is performed in the following ways:

- Filling the circuit and supplying compressed air under pressure. After the procedure is completed, the drain valve opens.

- Flow-through method: water is supplied continuously.

In order to protect the receiver from liquid entering it, a check valve is used.

The device is turned off and dismantled. The results are checked: a small section of the pipe is cut off, with a clean inner coating.

Models are top sellers

Popular brands of washing equipment:

- Ropuls. The compressor cleans heating appliances, water pipes, heated floors and solar collectors. Among the advantages is the disinfection of drinking water.

- Rockal. Small heating cleaner (no more than 300 l).

- Cillit-Boy. Universal equipment: with its help, heating circuits, hot water supply and hot water supply pipes, drinking water pipelines and the “Warm Floor” system are freed from dirt. Controlled by an electronic module.

The supply of compressed air with liquid is under pressure. This loosens all the accumulated layers.

How to flush your heating system

Before you start washing, you should prepare the necessary materials and tools for work. Since special equipment for cleaning pipes is quite expensive, and their use requires certain knowledge, you can purchase cheaper material.

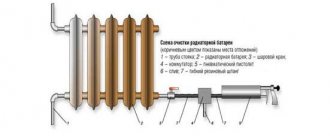

For self-washing you will need the following material and tools:

- A container for draining liquid from pipes.

- Rags, old rags.

- Keys.

- Gas-burner.

- Kerosene lamp.

- Hose to match the diameter of the hole in the pipes.

- Iron brush.

After all the material has been prepared, you can begin to wash the battery.

Rent of washing cleaning equipment

| WE OFFER EQUIPMENT WASHING UNITS FOR RENT | |

| Using this pumping station, you will be able to service a hot water boiler, remove lime deposits from the heat exchanger, and also perform comprehensive maintenance of heating systems, air conditioning systems, chiller refrigeration systems, vertical industrial water heat curtains, water boilers and other equipment requiring servicing, underfloor heating system , water heat pumps, industrial reverse osmosis systems. Our pumping station has pump protection against dry running, as well as automatic pump control, which makes it more practical and convenient when working on cleaning heat exchange equipment. IN CASE OF ANY DIFFICULTY, OUR SPECIALISTS CAN GO TO YOUR SITE AND CARRY OUT MAINTENANCE WORK. | |

| CHEMICAL CLEANING OF THERMAL POWER EQUIPMENT | |

| TECHNICAL CHARACTERISTICS OF THE PUMP GEL BOY C 190 |

| Electric motor 220 V – Hp 0.75 | |

| Connected power W 559.5 | |

| Head height, max. m in.st. 22 meters | |

| Max, circulation rate 150 l/min (9000 cubic meter per hour) | |

| Protection type IP 54 | |

| Capacity volume 100 liters | |

| Amount of acid to be filled, max, l Measuring lines | |

| Temperature, max. 50°C | |

| Empty weight 14 kg | |

| Centrifugal pump | |

| RENT FULL SET 15,000 TR with VAT PER DAY | Overall dimensions, Width 53 cm x Height 72 cm |

| Number of hoses 2 pcs. | |

| Connection inches 1 Inch (25mm) | |

| With additional equipment - a complete set of washing equipment may include: | |

| 1. Installation for washing heat exchange and boiler equipment2. A device for measuring the pH of a solution, range 0-14 ph - for measuring the pH of the washed solution3. Pump for pumping chemical liquids from a canister4. Consultation in the selection of a reagent, neutralizer, passivator, etc. | |

| HYDRODYNAMIC CLEANING OF THERMAL POWER EQUIPMENT | |

| Compressor for flushing Rothenberger Ropuls drinking water systems with a pulsating water-air mixture in accordance with EN 806 and DIN 1988 part 2, as well as dirty floor heating systems and water heaters. | |

| TECHNICAL CHARACTERISTICS ROTHENBERGER ROPULS (ROPULS) |

| Pipe connection: R 1″ Geka coupling | |

| Maximum pipe diameter: DN 50/2″ | |

| Maximum water flow: 5 m3/h | |

| Maximum water pressure: 7 bar | |

| Maximum water temperature: 30°C | |

| Protection degree: IP 22 | |

| Oil separation rate: 99.9% | |

| Particle filtration: 0.3 micron compressor | |

| Maximum operating air pressure: 8 bar | |

| Motor power: 1.5 kW | |

| Power: 230 V - 50 Hz | |

| Dimensions (H x W x D): 630 x 380 x 340 mm | |

| RENT FULL SET 15,000 TR with VAT PER DAY | |

| PORTAFLOW 220A LIQUID FLOW METER | PORTAFLOW 330 LIQUID FLOW METER |

| PRINCIPLE OF OPERATION OF THE DEVICE: When ultrasound is transmitted through a liquid, the speed of sound propagation in the liquid increases slightly if the sound is transmitted in the same direction as the flow, and decreases when propagating in the opposite direction. Therefore, the difference in the time of sound propagation over the same distance in the forward and reverse directions will be directly proportional to the speed of fluid flow. | |

|

|

| RENT FULL SET 15,000 TR with VAT PER DAY | RENT FULL SET 15,000 TR with VAT PER DAY |

| Read more >>> | Read more >>> |

| PRESS TONGS FOR METAL-PLASTIC PIPES VALTEC (VALTEC) | LASER INFRARED THERMOMETER -50 ~ + 280 |

|

|

| FULL SET 500 TR PER DAY | FULL SET 150 RUB PER DAY |

| Read more >>> | |

| SALE OF NEW EQUIPMENT 1500 TR | |

| DEVICE FOR MEASURING PH SOLUTION RANGE 0-14 PH | PUMP FOR PUMPING ACID TO ALKALI FROM A CANISTER |

| |

| FULL SET 100 RUB PER DAY | FULL SET 300 RUB PER DAY |

| SALE OF NEW EQUIPMENT 800 RUB | SALE OF NEW EQUIPMENT 1500 TR |

How to choose washing equipment

- It is recommended to choose a device with a small reserve of pressure power and flush tank volume

- Productivity affects the flushing speed. If the heat exchanger is large, then the difference in the flushing speed becomes noticeable; for small heat exchangers the parameter is not so important.

- The volume of the rinsing tank affects convenience. For example, if the heat exchanger is 200 liters, then we need 200 liters of cleaning solution (since not all pumps have dry-running protection)

- Connection diameter . For a connection distance >100mm, either a compressor unit is required (for example, the X-pump series from Pipal), or an installation that has the appropriate connection cross-section. Adapter kits are also available for connecting hoses to the water supply and heat exchanger ports. Ask managers.

- reverse are considered the most effective , since this allows you to completely remove scale and wash off reagents (reverse is a change in the direction of flow) Automatic reverse - a button for switching the direction of flow

- Manual reverse - a valve for switching the flow or manual reconnection of hoses (see the installation passport)

Equipment types

Timely cleaning of the system allows you to get rid of problems such as rust, scale and sediment. There are several types of heating system flushing equipment used for varying degrees of system blockage.

Hydroflushing

This method involves supplying compressed air and water to the heating system. High pressure and frequent pulses allow small air bubbles, which actively fill a separate section of the system, to quickly and effectively separate deposits on the walls.

To achieve maximum effect, cleaning takes place in separate, relatively small areas (for example, one riser). Before starting the cleaning process, you should determine the amount and speed of water required for cleaning, as well as the amount and level of air pressure. When making calculations, it is necessary to take into account both the length of the section of the system selected for flushing and the diameter of the pipes used in this section.

Hydroflushing of heating systems can be carried out in two ways - flow and filling. The flow-through method involves completely filling the heating system with water. In this case, the air collector valve must be open. After the system is filled as much as possible, the valve closes and the compressor begins supplying compressed air to the system. Hydropneumatic flushing of heating systems ends when exclusively clean water without impurities begins to flow from the open pipe. For further operation, the system must be cleared of the water-air mixture.

First of all, the area of the system selected for cleaning should be filled with water. Next, the air collector valve closes. After this, the supply of compressed air begins through the second valve. You should first check the level of contamination - the duration of the air supply depends on it, as well as on the length of the area being cleaned. After stopping the air supply, it is necessary to close the shut-off valves. Next, the mixture of water and sediment formed in the system should be drained into the drainage. After using this method, the system must be flushed several times with water.

Pipeline flushing technology using a pump

To remove scale from the walls of the heat exchanger using a pump, you must perform the following steps:

- Connect the flushing pump to the heating circuit.

- Prepare a solution of the required concentration according to the instructions. The aggressive chemical is carefully diluted with water in the required proportion.

- Start the washing process. The solution is pumped into the system, after which for some time it circulates through the pipes and heat exchanger with periodic changes in the direction of movement.

- Make sure that the process is complete, then drain the flushing fluid and neutralize it.

- The neutralized substance can be discharged into a regular household sewer, as it becomes safe for the environment.

- Rinse the heat exchanger to remove any remaining solution.

- Passivate heat exchanger surfaces to protect against corrosion.

- Turn off the pump - flushing is completed, the pipes are free of accumulated deposits.

The process takes several hours, after which the original heat exchange is restored. Such cleaning does not require large expenditures, and it prevents wasteful loss of coolant.

Devices used

Pipeline cleaning can be done in different ways, and a specific unit is selected for each of them. The price of some devices can be quite high, since their efficiency is at the proper level. Some work can be done with your own hands using inexpensive tools.

Hydrodynamic installations

The main equipment is water jetting machines that supply liquid under high pressure. With their help, it is possible to eliminate deposits in pipelines with a diameter of 20 mm and above. The high efficiency of the method is achieved through the use of special nozzles.

Compact size water jet.

Hydrodynamic technology for removing scale and other contaminants is considered the most gentle, since when carrying out work inside the communication system, excessive pressure is not created. This operation is completely safe for installed elements.

Its features are discussed below:

- The advancement of the nozzle is ensured by jet thrust, which is created under the action of high-pressure water flows coming out of the holes in a special nozzle.

- This installation for flushing heating systems works most effectively when using high-performance nozzles. Their choice should be made depending on the nature of the blockage.

- For the most difficult jams, chain carousels and rotary tips are used. The resulting traffic jams in the communication network are successfully removed using punching nozzles.

This is what the pressure cleaning nozzle looks like.

Pneumohydraulic units

The main device is a compressor for flushing the heating system or a pump, which allows the accumulation of compressed air and a sudden release at a certain point in time. In this situation, purification is performed by creating a kinetic impulse in a liquid medium. The swirling water removes deposits from the surface of the pipeline.

The pneumohydraulic design has a special container designed for compressed air, which is usually pumped by a compressor. However, a special pump can also be used to flush the heating system. It is a cylinder equipped with a piston.

One side of the device is in contact with air, and the other with water.

A unit for pneumohydraulic flushing is demonstrated.

- At the very beginning, the device is connected to the heating elements through a switch and adapter hoses.

- After this, water is poured into the system, which enters directly into the cylinder of the main device, moving the piston to its original position.

- Next, the cylinder is charged until the required pressure is created.

- At the main stage, a shock wave is created using a piston, which makes it possible to clean the pipes.

Mechanical impact devices

In this case, flexible shafts with a drive are used, on one side of which metal brushes are placed. The tool that rotates the rod is usually a drill.

The following are instructions describing the procedure for carrying out the work.

The flexible shaft is presented in assembled form.

- At the initial stage, the system is prepared for cleaning activities. The coolant is completely drained, the pipe fittings are unscrewed in the right places.

- A structure is being assembled that will mechanically remove scale and other contaminants from pipelines. A metal brush of suitable size is attached to one end, and a drill to the other.

- Gradually, the flexible shaft is introduced into the interior of the conductive elements of the system. When the device rotates around its axis, scale will fall off the pipe walls.

Electrohydraulic devices

The operating principle of such installations is based on the fact that a coaxial cable is inserted into the liquid medium, which is connected to a high-voltage pulse device. The device creates repeated electrical discharges with a frequency of 1 to 10 Hz. Thanks to this, accumulated deposits are destroyed.

Example of an electrical installation.

Many models of cleaning equipment of this type are capable of cleaning pipelines whose diameter ranges from 10-100 mm. Additional devices may be supplied with the equipment.

Methods for cleaning the heat exchanger of a gas boiler

There are two main types of flushing the heat exchanger of a gas boiler - with and without disassembling the unit. To disassemble the equipment, you will need tools. Which ones specifically - it depends on the design of the heating equipment. In some cases, it is impossible to remove the heat exchanger at all, but you can gain access to it by removing some of the parts.

Before starting work, you should prepare the equipment:

- Disconnect the boiler from all power sources, drain the water from the system and expansion tank. To drain the coolant, special fittings must be provided. If this is not the case, then you will have to turn off the water supply to the house, and then drain it from the system into pre-prepared basins and buckets.

- When there is no water left in the system, you can begin to disassemble the equipment. First, remove the front of the housing to gain access to the heaters. If the boiler is double-circuit, then the second circuit heater is located closer, the main one is further away. To remove it, you need to disassemble the combustion chamber.

- Construction parts are usually dirty. It is advisable to wash them outside with special compounds that remove soot and carbon deposits. If there are no such products, you can take traditional household chemicals that are used for cleaning stoves - gels, cleaning pastes, etc. They should be used only in extreme cases, since even the most aggressive household chemicals cannot remove carbon deposits as efficiently as specialized ones, but they can damage materials.

- The inside of the unit elements can be washed with a strong aqueous solution of citric acid. It does not corrode metal, but removes plaque and lime deposits well. Most often there is a lot of scale. It is impossible to cope with it by half measures. In this case, you will need equipment for washing the heat exchangers of gas boilers. You can make a simple installation with a circulation pump with your own hands.

There are three main ways to clean boilers: manual, hydrodynamic, and chemical washing of boilers. Let's look at them in more detail below.

Option #1: DIY manual cleaning

Manual cleaning is called cleaning of boilers without the use of special mechanisms. You will only need simple tools that are found in almost any home. The boiler must be partially disassembled to gain access to the heat exchanger and remove it. Next, you should decide how best to remove the dirt - mechanically or using chemical solutions.

If you decide to remove plaque mechanically, you should stock up on a scraper, brush and vacuum cleaner to remove small particles of deposits. If you plan to chemically descale boilers, you can use a citric acid solution, or even better, buy a specialized product.

The MasterBoiler and SVOD TVN Professional brands have proven themselves well. They come in different forms. There are liquids that do not require special preparation before use, and powders. When using, you should carefully read the instructions. Some formulations foam, and you need to be prepared for this.

How to clean a gas boiler from scale? Almost all compositions are suitable for removing calcium carbonate deposits, while only certain preparations cope with iron oxide deposits. When purchasing a product, it is important to make sure that it is intended specifically for those types of deposits that are typical for a particular boiler. Among the popular preparations that remove iron oxide plaque, we recommend SVOD TVN Extra.

Advice. When disassembling and cleaning the boiler, try to be extremely careful so as not to damage the parts. When installing them in place after manipulation, check the tightness of each connection.

Option #2: chemical washing

Boosters are often used to flush boilers. These are special installations that pump liquid into the heat exchanger channels. You can make a booster for washing heat exchangers with your own hands by connecting a circulation pump so that it drives the acid solution, washing the equipment from the inside.

A good flush may take up to 10 hours if the channels are very dirty, but usually it takes much less time. Cleanliness indicators: carbonate and iron deposits completely disappear, and the internal surfaces of the channels shine. To neutralize the residues of acidic preparations, special compounds are used; they are poured into a booster to wash the heat exchangers at the end of the procedure.

Option #3: hydrodynamic cleaning

Hydrodynamic flushing of boilers and heat exchangers is similar to chemical flushing, since it also uses pumps and acid solutions. The main difference is that the liquid is pumped under high pressure. Sometimes preparations with abrasives are used as cleaning agents.

Since deposits are destroyed by water hammer, the procedure itself is quite dangerous. If the pressure is higher than permissible, the pipes may be damaged, and their repair will cost a significant amount. It’s better not to take risks and entrust this work to professionals.

Hydroflushing

The process itself is based on simultaneously supplying water and air under pressure to sections of the pipeline. The resulting mixture cleans the heating system due to the many pulses that the compressor produces to flush the heating system.

Small bubbles form, which gradually destroy various deposits on the walls of pipelines.

Pipes before and after cleaning

Methods

Flow-through. The return and supply pipelines are first filled with water, with the valve on the air collector open. After filling the pipelines, the valve is closed and compressed air is supplied. The air and water mixture is supplied to the pipelines simultaneously (see also the article on hydropneumatic flushing of the heating system). Flushing ends when clean water begins to flow through the nozzle. The water is then drained into the drain. This method is used for flushing hot water supply and heating systems;

Fillings. This method has some consistency in actions. First, the pipelines are filled with water and the valve is closed. Compressed air is supplied to the second pipe for twenty to twenty-five minutes (depending on contamination and pipe diameters). After the air supply is stopped, the shut-off valves are closed and the water is drained through the drain pipe. At the end, the system is washed a couple of times with clean water.

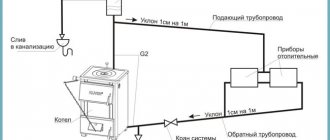

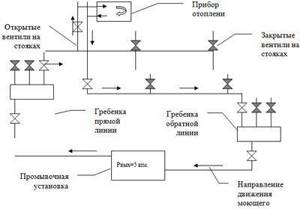

Typical scheme for carrying out work

Heat exchanger flushing frequency

The frequency of cleaning heat exchangers is specified in the operating instructions that come with the product. Most manufacturers recommend doing this every 2 years. However, if water saturated with lime is used, a thick layer of plaque can boil in just one heating season, even if the boiler has a stainless steel circuit. When a filtration system is installed in the harness, the procedure can be carried out at intervals of 4-5 years. Water needs to be changed annually, as it changes its structure and acquires properties that are aggressive towards metal.

It is best to calculate the required frequency of cleaning the heat exchanger experimentally. After the end of the heating season, you need to disassemble the boiler, remove the circuit and assess its condition. The plaque will tell you how long it will take for its thickness to reach a critical state.

How often do you clean the heat exchanger in a gas boiler?

The frequency of cleaning the heat exchanger depends primarily on the type of coolant and the design features of the unit itself. It is least common to service single-circuit boilers in heating systems that use purified water as a coolant. To keep them in good condition, it is enough to carry out preventive maintenance once every 4 years.

If untreated water circulates in the system, the boiler should be flushed once every 2-3 years. If the water is hard, then the cleaning regime is once every 2 years. The secondary heat exchanger of a double-circuit boiler must be washed with the same frequency, because unfiltered tap water with impurities flows through it.

Most often, maintenance is required for equipment in heating systems where antifreeze is used as a coolant. It should be washed at least once every 2 years. In addition, you have to monitor the expiration date of antifreeze and replace it in a timely manner. Otherwise, the efficiency of the system will decrease and heating costs will increase.

When cleaning heat exchangers, pay attention to the appearance of the boilers and nozzles and, if necessary, carry out repair work. You should also monitor the condition of chimneys and clean them of soot in a timely manner. These simple measures extend the life of heating equipment and prevent breakdowns.

Tips/Tricks

To increase the cleaning effect, bleach is added to the input. This allows you to disinfect not only water, but also the inner surface of the pipes.

During self-washing, the technician needs to keep in mind that radiators and pipelines are washed separately from the boiler. If communications have a complex, branched structure, cleaning is carried out separately for each circuit.

For preventive purposes, the water is softened, but if this is not possible, the heating system is regularly flushed. Without maintenance, the system quickly deteriorates, and then the owners will have to replace all communications.

How to choose the optimal flushing pump?

Modern washing equipment is represented by units with a variety of functionality. The main manufacturers that have earned the approval of the international market are German factories (Rems, Rothenberger), Italian concerns (Manta Ecologica) and American (RIDGID). But, despite the high quality of each device, it is short-sighted to buy a flushing pump without assessing its operational capabilities. When choosing the optimal model, experts advise studying the specification of the unit.

- For the private sector, preventing and eliminating deposits in the system is a big problem. Utility workers stand guard over the apartment building. In a cottage, the costs fall on the homeowner. The Ridgid DP-24 or DP-13 descaling flushing pump will help the owner deal with the annual problem on his own.

- Inexpensive pumps from Rothenberger compete with compact “Americans”. The popular Rocal and Romatic washing devices do an excellent job of removing scale in installations with a capacity of 300 liters. At the same time, the technical characteristics of Rothenberger and Ridgid units allow the equipment to be used for commercial purposes.

- In the Pump Eliminate model line, professionals will find devices for removing scale from heat exchangers. Any flushing pump from Manta Ecologica is distinguished by high productivity and good throughput. A wide price range and variety of functionality mean you can purchase a unit that meets different tasks.

- Ropuls compressors from Rothenberger are devices on a different scale. They allow you to buy a flushing pump in conjunction with many additional options. In addition to their direct specialty, the units sanitize water pipes, are suitable for testing pressure in the system, and even for connecting pneumatic tools.

- A separate category is pressure testing devices with hydropneumatic pumps. REMS units open up wide scope for the work of specialized enterprises.