Parameters for choosing a solid fuel boiler

Efficiency

Power is valuable as a parameter only in relation to efficiency, and in this case it fluctuates widely and depends on the type of unit and combustion material.

1. Traditional devices have an efficiency of about 80%,

2. pyrolysis – approximately 90%,

3. long burning – about 85%.

Type of fuel

The type of fuel is of great importance, and it can be very diverse:

1. Coal;

2. Pellets;

3. Briquettes;

4. Firewood;

5. Coke;

6. Peat.

When burning fuel, ash is formed, which needs to be cleaned: from coal - every day; from wood - weekly; from briquette - monthly.

Heat exchangers of products are:

1. Cast iron;

2. Steel;

3. Copper.

Purpose

The devices are:

1. Single-circuit - designed exclusively for a heating system with the ability to connect an indirect heating boiler;

2. Double-circuit - designed for heating and hot water supply.

Electricity dependence

Devices are also divided according to the criterion of dependence on electricity. Models that operate without electronics, are loaded manually, and circulate water without a pump are considered autonomous.

Fuel supply method

Fuel supply is:

1. Manual;

2. Automatic.

In the case of automatic fuel supply, a hopper is used from which only small materials are loaded: pellets and coal. Logs are thrown into the firebox only by hand.

Top double-circuit boilers

To independently regulate heat and supply hot water, building owners abandon single-circuit units. Models with two circuits have become popular due to their positive characteristics; the practicality of such devices can be noticed after the first day of use.

The best wall-mounted gas double-circuit boilers

Bosch Gaz 6000 W WBN 6000-24 C among the rest for its optimal design; it is suitable for most buildings.

Bosch Gaz 6000

Multi-stage protection will ensure excellent safety, and the copper heat exchanger can surprise with its service life, designed for 15 years. German quality is undeniable, which is why the product of this company has become famous all over the world.

Lemax PRIME-V32 is produced in Taganrog; the model is capable of organizing decent heating and hot water supply even in two-story buildings. Heat dissipation is at a high level, and operation in the most difficult technical circumstances will be a good addition, you can completely rely on it.

Lemax PRIME-V32

The best double-circuit floor-standing gas boilers

I advise you to choose equipment for the heating system and hot water supply, regardless of the device model, but pay attention to companies such as:

- Vaillant.

- Viessmann.

- Baxi.

- Protherm.

- Siberia.

By giving preference to the above brands, each owner will be able to choose products that best suit his needs. Floor structures equipped with two circuits will ensure autonomy and can create a cozy atmosphere in any home.

Types of water heating devices

All modern heating boilers used in private houses and apartments are divided into groups according to the following criteria:

- consumed energy carrier – natural gas, electricity, solid fuel, etc.;

- by installation method - floor and wall;

- in terms of functionality - single-circuit and double-circuit, the latter additionally heats water for hot water supply;

- need for electrical connection - dependent and non-volatile.

We propose to consider boiler installations, dividing them according to the main criterion - the energy carriers used. Existing types of devices:

- gas;

- solid fuel;

- electrical;

- diesel;

- combined, otherwise multi-fuel.

Now we will analyze each group separately, covering in detail all the disadvantages and advantages of boilers.

Other Features

Boilers vary in installation method. They can be wall mounted or installed on the floor. Wall-mounted equipment has less power compared to floor-standing models. It is clear that the large dimensions of powerful devices lead to an increase in their mass. Floor-standing units are designed for heating large facilities, such as clinics, kindergartens, and cottages with several floors. Such heating equipment takes up a lot of space, since in addition to the boiler it is necessary to install:

- circulation pump;

- expansion tank providing stable pressure inside the system;

- security block.

The benefit of using floor-standing models is the ability to provide large facilities with heat and hot water supply. Wall-mounted units are capable of heating small private houses. Floor-standing and wall-mounted boilers can operate on one of the types of fuel:

- gas;

- coal;

- peat;

- electricity;

- liquid fuel.

The heat exchanger in a floor-standing boiler can be made of steel or cast iron. The latter work longer and do not rust.

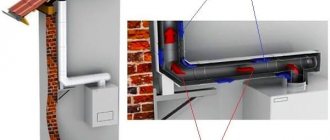

All parts and devices that ensure the process of heating water in the system are installed under the body of wall-mounted models:

- heat exchanger;

- heater (burner);

- mini pump;

- small expansion tank.

Wall-mounted samples are cheaper and do not require a separate boiler room. They are quite enough to heat houses with an area of up to 100 square meters. m.

Electric boilers for heating a private house

Electric heating boilers are designed to heat houses not connected to gas mains. They cannot boast of being economical, but in some cases they are the only available option for organizing heating - not everyone is ready to carry around firewood and coal, or endure the subtle smell of diesel fuel throughout the house. As for electrical equipment, it is environmentally friendly and unpretentious.

Electric boilers are divided into heating elements, electrode and induction. They differ in the principle of heating the coolant and are characterized by high efficiency. The lack of gasification and the inability to install other types of boilers makes electric boilers ideal equipment for heating private homes. Let's look at the features of certain varieties.

Tenovye

Electric heating element boilers are a timeless classic. The most common heating elements are installed inside them, heating the coolant. Next, the heat enters the pipes and is transferred through radiators to the rooms. These devices have minimal dimensions and are excellent for heating private homes. Power is supplied from single-phase and three-phase networks - depending on the power of the equipment. Heating element boilers boast high efficiency and ease of installation. They are controlled by external or built-in automation modules.

Classic heating element boilers have a couple of disadvantages. The first of them is the low reliability of heating elements. They often fail and even cause fires. They are also characterized by high inertia - their own heating and subsequent heating of the coolant takes time (due to this, part of the electricity is wasted). However, cheapness and simplicity are the factors that ensured the popularity of heating element boilers.

If you want to purchase reliable, unpretentious equipment that does not require frequent maintenance, turn your attention to heating element electric boilers.

Electrode

Heating private houses using electrode boilers allows for some efficiency - its figure is 10-20%. It is achieved due to the design features of the electrode equipment and the automation systems used. These devices have an extremely simple design - two electrodes are installed inside, to which alternating current is supplied. This ensures direct heating of the coolant. Here is a list of the advantages of electrode boilers:

- Fast heating of the coolant;

- More intense circulation;

- Possibility of using salt additives to increase the efficiency and efficiency of equipment;

- Compactness;

- Almost complete fire safety.

In the list of disadvantages, we can include demands on the quality of the coolant - if its electrical conductivity changes, the efficiency of the heating system may drop.

Electrode boilers are suitable for those who are pursuing efficiency and are willing to put up with some of the disadvantages inherent in electrode (ion, ion exchange) models. Fire safety is ensured by natural cessation of operation in the absence of coolant.

Induction

Induction heating boilers, which have many advantages, are not particularly widespread. They are large in size and require stable supply voltage. But scale does not form in them (as in heating element models), and they do not require a balanced coolant (like induction models). Heating of the coolant here is carried out due to electromagnetic induction created by powerful coils and special electronic equipment.

Such heating can be called direct, since the coolant is heated directly in the metal pipe, which is the core of the coil. The prices for induction boilers for heating a private home are steep, so they cannot be called an ideal solution for home use.

Type of fuel used

A gas boiler

Gas-powered units are now the most popular, since in most cases they provide the most favorable heat. If, of course, you can connect to public networks. A very significant factor is the convenience of blue fuel, its purity and waste-free nature. Such equipment operates without human intervention around the clock.

Boiler room with gas heat generator

When there is no mains nearby, gas heat generators can be connected to cylinders or gas holders and get the same consumer benefits. It is enough just to replace the burner or reconfigure the existing one. True, the pleasure will not be so cheap, because the cost of liquefied propane-butane will be about 5 times higher.

A separate topic is condensing boilers. They are designed in such a way that they use the full potential of the fuel, collecting heat also from heated water vapor, which usually flies away along with the smoke. There is no need to be surprised at the seemingly fantastic efficiency exceeding the one hundred percent threshold. When the methodology for its calculation was developed, this technology still seemed unrealistic. The cost of condensing boilers is quite high, but against the backdrop of rising gas prices, the investment is justified. Stable fuel economy will be 10 percent or more.

Solid fuel heating devices

In those regions where specific raw materials are not in short supply, heating a house with a solid fuel boiler can compete with main gas in its economic indicators. At least they are guaranteed second place.

Solid fuels are:

- firewood,

- coal,

- coke,

- peat,

- briquettes,

- pellets.

Yes, this is not entirely clean. Yes, you will have to frequently load fuel and remove ash. But there are also wood-fired pyrolysis boilers, which can operate all night on one bed, or pellet units, whose battery life depends only on the capacity of the bunker.

Pellets are very convenient, but not always cheap

Electric heat generator

This is also a fairly common solution. Primarily due to the fact that such boilers can be quite easily installed and even easier to operate. For example, there is no need to deal with the problem of smoke removal (in the absence of one), or to ensure air flow to the device. Electric boilers for heating a private home are silent and compact, there is no dust or odors from them. Moreover, better controllability is available to the consumer.

Both heating elements and electrode models have a fairly high efficiency, but efficiency is still not their strong point. Electric heating is about 10 times more expensive than main gas heating; it definitely holds the anti-record. It seems that energy is always available - here is an outlet, plug in, but the traditional problem is the lack of free power to power a unit designed for several kilowatts. And don't forget about power outages.

This is under the casing of the heating element boiler

Liquid fuel equipment

Such heat generators mainly burn diesel fuel, although there are boilers that run on kerosene, oil, fuel oil, and waste oils. Mixtures of diesel fuel with gas or diesel fuel with oil are also used. Most liquid fuel boilers have a “standard” design; if you replace the burner, they can operate on gas, mains or liquefied. Although all of them are more economical than electric ones, heat will cost several times more than heating a house using mains gas. Obvious disadvantages include the mandatory use of a fuel storage container, as well as the need for strict control of the quality and temperature of the fuel. The issues of noise and unpleasant oil smell, at least for modern units, are controversial.

Universal multi-fuel boilers

The ability to switch to different types of energy allows us to feel more confident, especially if we need to heat a country house. As a rule, the same firebox is used for this, only it is necessary to perform certain manipulations with the burner:

- It is completely removed if you need to use firewood (in pellet boilers).

- They install other nozzles when connecting a gas boiler from cylinders.

- They change the burner to switch from gas to diesel.

- Install a “mounted” burner for burning gas or diesel fuel in the chamber of a solid fuel boiler.

Some models use several separate combustion chambers designed for different types of fuel. Many solid fuel boilers are equipped with heating elements that allow you to maintain the temperature set by the coolant, or protect the system from defrosting when no one is in the house.

Using a combi boiler

Advantages and disadvantages of electric boilers

Electrical equipment used to heat the coolant of autonomous heating systems has a number of advantages.

- Unlike gas and solid fuel units, electric ones do not use an open fire source during operating heating mode. The design of electrical equipment provides for heating the coolant through the influence of physical processes by special boiler elements caused by the influence of electric current.

- The absence of burners and flames allows electric boilers to be fireproof if the electrical wiring is installed correctly. For the same reason, there are no harmful emissions into the atmosphere, unlike their “brothers” that use fossil resources.

- When connecting a gas main used for heating, it is necessary to comply with a whole list of technical conditions that will be presented by the gas workers servicing the territory of the household. At the same time, the low price of gas for years to come will be reflected several times in the cost of design documentation and pipe laying. And the availability of electricity does not require any approvals.

- For solid fuel and sometimes gas boilers, a special boiler room is required, equipped with all the necessary attributes of fire safety and technological equipment. The compactness of electrical units allows heating devices to fit into the interior of any living room.

- The design of electrical equipment is quite simple to control and operate. The operating mode of heating the coolant does not require control. Using simple power buttons, set the desired parameters. Further participation of the consumer in the operation of the boiler occurs if it is necessary to adjust the set parameters.

- Low price and no need for storage facilities for solid or liquid fuel are also advantages of electric boilers.

Installing electrical equipment also has disadvantages:

- The high cost of electricity and the lack of technical ability to heat large cottages.

- The use of electric boilers is effective in closed circuits of heating systems, and this will entail alteration and increase in cost of existing intra-house lines. The operation of electrical equipment with natural circulation or an open expansion tank leads to a decrease in thermal power, and therefore the relevance of the application.

In addition, installation of an electrical unit often involves the installation of additional elements:

- circulation pump to create a closed circuit;

- voltage stabilizer with high sensitivity to changes;

- replacing the coolant with a chemically neutral one, with a certain resistivity, for electrode boilers;

- replacing radiators, because hydrogen sulfide can form in the water, which destroys aluminum.

The best long-burning solid fuel boilers

Stropuva Mini S8 8 kW

Bright solid fuel boiler with a safety valve, power 8 kW. Suitable for heating a room of 80 m2. The fuel burns for up to twenty hours, the temperature is enough for the whole night.

Characteristics:

- type of device - solid fuel boiler;

- type of combustion - long;

- contours - single-circuit;

- power - 8 kW;

- area - 80 m2;

- placement - floor;

- energy independence - yes;

- control - mechanics;

- combustion chamber - open;

- fuel - firewood, wood briquettes;

- safety valve - yes;

- thermometer - yes;

- weight - 145 kg;

- price - 53,000 rubles.

Advantages:

- compactness;

- long burning;

- ease of use;

- reliable handles;

- does not require power supply;

- robust design.

Flaws:

- high price;

- heavy weight;

- it is difficult to wash off carbon deposits from the cladding;

- Not very convenient for loading firewood.

ZOTA Topol-22VK 22 kW

A high-quality solid fuel device with a power of 22 kW, which is enough to heat an area of 220 m2. Convenient loading consists of two sections for storing firewood.

Characteristics:

- appliance - solid fuel boiler;

- contours - single-circuit;

- power - 22 kW;

- placement - floor;

- control - without control panel;

- fuel - coal, coal briquettes, firewood, wood briquettes;

- thermometer - yes;

- weight - 128 kg;

- price - 36,860 rubles.

Advantages:

- various types of fuel;

- long burning;

- economical consumption;

- convenient operation;

- reliable design.

Flaws:

- heavy weight;

- no control panel.

ZOTA Topol-16VK 16 kW

A decent model of a solid fuel boiler with two sections for storing fuel. Designed for heating a small private house or workshop of 160 m2.

Ensures long burning of wood or coal.

Options:

- unit - heating boiler;

- fuel - coal, firewood, coal and wood briquettes;

- power - 16 kW;

- placement - floor;

- control - without control panel;

- Efficiency - 75%;

- thermometer - yes;

- weight - 108 kg;

- cost - 30,100 rubles.

Advantages:

- heats up quickly;

- gives uniform heat;

- quality materials;

- long burning;

- possibility of laying briquettes;

- easy control.

Flaws:

- high price;

- heavy weight;

- no control panel.

ZOTA Topol-32VK 32 kW

Reliable solid fuel unit with a power of up to 32 kW. Capable of heating an area of 320 square meters. It is possible to install an additional heating element and connect external control.

Excellent for a country house, ensures long burning of fuel.

Characteristics:

- type of device - solid fuel boiler;

- number of circuits - one;

- power - 32 kW;

- area - 320 m2;

- installation - floor;

- energy independence - yes;

- control - mechanics;

- Efficiency - 75%;

- fuel - coal, coal briquettes, wood briquettes, firewood;

- thermometer - yes;

- connection of external control - yes;

- weight - 143 kg;

- price - 40,370 rubles.

Advantages:

- fast heating;

- reliable assembly;

- simple controls;

- opportunity to purchase a burner;

- economical fuel consumption;

- stylish design.

Flaws:

- heavy weight;

- high price.

Stropuva S30 30 kW

A full-fledged solid fuel boiler with a power of 30 kW for heating a room of 300 m2. Equipped with thermometer and safety valve.

Made of high quality steel, the material does not become red-hot when the boiler heats up.

The only boiler that continues burning for up to 31 hours.

Characteristics:

- appliance - solid fuel boiler;

- power - 30 kW;

- area - 300 sq.m.;

- placement - floor;

- control - mechanical;

- contours - one;

- non-volatile - yes;

- combustion chamber - open;

- Efficiency - 85%;

- material - steel;

- fuel - firewood, wood briquettes;

- thermometer - yes;

- safety valve - yes;

- weight - 257;

- price - 89,800 rubles.

Advantages:

- long burning;

- uniform heat;

- fast heating;

- quality materials;

- presence of a thermometer;

- economical fuel consumption.

Flaws:

- high price;

- heavy weight;

- bulky.

Types of boilers

Electric devices for autonomous heating are suitable for heating rooms with a total area of up to 100 sq. m. meters. The limitation is related to the maximum permitted power of electrical networks connected to private households.

This type of boiler absorbs a large amount of electricity; they are installed in homes remote from gas mains. In addition, in houses with an eclectic heating system, other, cheaper heat sources may exist in parallel.

Heat supply running on diesel fuel is cheaper. The disadvantage is that you have to constantly keep a fuel tank filled with fuel next to your house. These boilers, like gas-fired equipment, are designed to heat very large rooms.

Gas boilers are economical, reliable and easy to operate. When burned, gas emits the least amount of combustion products; it is considered an environmentally friendly fuel. They can only be installed in houses connected to a central gas supply system.

Brands of gas boilers powered by electric ignition are not beneficial for owners of country houses and private households located in areas where electricity is often cut off for long periods of time. Such a device may cause the system to defrost.

Solid fuel equipment operates on one or more types of fuel:

- wood;

- coal;

- peat;

- fuel briquettes.

Solid fuel boilers are capable of heating rooms with a total area of no more than 60 square meters. m. If the house is large, then two devices will have to be installed in it.

Important! Solid fuel devices are in demand where there is no central gas supply system. They allow residents of small settlements to heat rooms without stoves or fireplaces.

Solid fuel boilers have disadvantages:

- To avoid smoke from entering living spaces, separate rooms are allocated for boilers, which are equipped with chimneys.

- To ensure continuous combustion, you need to constantly add fuel.

- You need to have a large supply of fuel near your home.

Which heating boiler is better to choose?

Before purchasing a boiler, you should decide on the type of fuel that will be used, since the main part of the operating costs is its cost. If you have not yet decided which heating boiler to choose, check out their main characteristics.

A gas boiler. The cheapest and most common fuel is gas. The amount of heat generated during equipment operation exceeds similar indicators for other types of fuel. Gas is burned in the firebox with virtually no residue, which is also a big plus. Gas boilers are equipped with meters that can be used to control fuel consumption. The equipment is not subject to corrosion and has a long service life.

Boilers with modeling burners are modern devices equipped with burners that allow you to smoothly change the power of the device, leaving the efficiency value unchanged. The amount of fuel in the combustion chamber in such units changes due to changes in the amount of air and aerodynamic resistance. The fuel is completely burned in the chamber thanks to simulating liquid fuel burners with preheating. The burners are also called “blue flame burners”. The blue flame is obtained as a result of heating the fuel by the reverse gas flow.

When choosing a boiler for your home, do not forget that gas boilers cannot be used everywhere, since gas lines are not laid everywhere. In addition, in new settlements, gas pipelines are installed only some time after the start of construction.

Diesel boiler. The units do not depend on centrally laid pipelines, but at the same time they are expensive. In addition, it is necessary to equip a special place for storing diesel fuel reserves. For this purpose, a room is allocated inside the boiler room or special holes are dug outside the house.

During operation of a diesel boiler, the fuel evaporates and its vapors burn. The sulfur emissions formed during this process settle on the walls of the boiler. Therefore, diesel-powered units, as a rule, are made of cast iron, which produces much less condensate. The boilers are equipped with an automation system that saves energy.

Solid fuel boiler. Before choosing a boiler, keep in mind that a solid fuel unit requires a lot of effort and time. It is necessary to load fuel frequently, and since the combustion efficiency is low, the boiler efficiency is about 60%. After combustion, soot remains and the unit must be cleaned. In addition, solid fuel needs to be stored somewhere, and this is a fairly large area.

Electric boiler. The operating temperature can be easily controlled; in some models it is possible to switch the boiler to an economical operating mode. But the equipment has one important drawback - it is uneconomical. Another disadvantage of the unit is the inability to use it during power outages. This problem, however, can be easily solved by installing an emergency power supply in the house.

Basic criteria for choosing boilers

Hundreds of foreign and domestic manufacturers offer thousands of models of heating equipment. It is not easy for an unprepared buyer to navigate all this variety of products. I want it to be cheaper and the quality to be high.

All heating boilers differ in the type of fuel and are divided into the following categories:

- solid fuel (processing firewood, peat, pellets, coal);

- liquid fuel (units running on diesel fuel);

- gas (regular and condensing);

- electrical (requiring electricity supply);

- universal (using either gas or electricity).

Before choosing an option, it would be a good idea to do a little analysis and find out which energy carrier is profitable to use in your region. Then you need to decide how safe, reliable and comfortable the boiler should be in terms of every penny invested in it.

You need to choose one or another type of heating equipment after first familiarizing yourself with the advantages and disadvantages of each of them.

In order not to make a mistake and not waste your hard-earned money, you need to carefully consider the process of choosing equipment. To do this, it is necessary to take into account a number of nuances that significantly affect the final result.

When choosing a boiler you should:

- understand in detail the advantages and disadvantages of each type of boiler;

- calculate the optimal heating power for your home;

- decide on the number of circuits;

- choose the location where the equipment will subsequently be placed.

The maximum permissible dimensions and weight depend on the future location of the boiler. After all, for a small room it is not advisable to choose a heavy cast iron unit.

The choice of heating equipment must be approached responsibly. This is the only way to buy high-quality equipment that will last for many years.

Selecting heat generator power

The performance of the heating device must correspond to the heat loss of a particular house on the coldest days of winter. Ideally, it is necessary to make thermal calculations. A simpler way is to choose a boiler such that for every 10 square meters of the building there is 1 kW of power. It should be noted that this formula is suitable for cottages that are well insulated. A reserve of 15-20 percent will not hurt, but heat generators that are too powerful, operating in a clamped mode most of the time, will produce an efficiency below the nominal one and consume excess fuel.

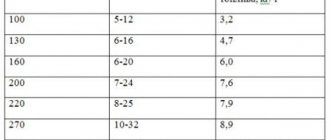

This table will help you navigate the performance of heat generators

Pair of gas boilers installed in cascade

How much power do I need?

The power of a heating boiler is determined not only based on the area of the house. The calculation takes into account: ceiling height, thickness and material of walls, quality of insulation, location of the boiler and other parameters. Offhand, you can focus on this ratio: 1 kW for every 10 m². A specialist will help you make an accurate calculation.

To calculate the approximate boiler power, use a simple formula:

1 kW = 10 m².

For independent calculations, you can use the professional engineering program VALTEC.PRG. It takes into account a lot of parameters and allows you to accurately calculate heat loss for any home. The program is free and can be downloaded from the official website. There are also training videos with calculations using specific examples: one, two, three and four.

Which boiler to choose for heating a private house

1. Boiler for a city house

In private homes, any of the boilers discussed above are installed, but the specific choice is made based on the circumstances.

For large facilities located within the city, the most rational option would be to connect a floor-standing single-circuit boiler to the gas pipeline and additionally arrange hot water supply using an indirect heating boiler.

In smaller private dwellings, you can install the same unit, but a double-circuit wall-mounted one with a closed firebox. In addition, it is better to choose a cast iron heat exchanger. If the water is soft, then use a steel bithermal one. When comfort plays a role, and money does not matter, you can choose an electric device.

2. Boiler for a country house

In the case of a house located outside the city, the options are the same, but if it is possible to connect to the highway. Otherwise, a good alternative is a solid fuel boiler, the fuel for which is selected based on the prices of coal, coke, firewood, pellets, briquettes in a particular region.

So how do you choose a boiler for heating a private house?

To make it easier to navigate when choosing, let's systematize the information. Let's look at the most typical requirements that influence the choice of boiler type:

- The most economical heating. The cheapest heating options are wood/coal and gas. Next come pellets, liquid fuel and electricity. In general this is true, but the situation greatly depends on the region. In some places electricity will be cheaper, in others liquid fuel will be cheaper. In general, you have to count.

- Degree of autonomy. The most automated are gas, electric and pellet units. They can be left at work unattended. Liquid fuel ones require a little attention. The least automated are solid fuel ones. To keep your home warm, you need to choose the right boiler for heating a private home.

- Difficulty connecting. The most difficult thing is with the registration and connection of gas. There may be problems with allocating power for electric heating - not all substations have a reserve. With the rest, everything is simple: the main thing is to follow the recommendations for safe installation.

If you take into account the availability and affordability of fuel, making your choice is not difficult.

Date: September 25, 2021

Features of single- and double-circuit boilers

When thinking about how to choose the right heating boiler for your home, special attention should be paid to such a characteristic as the number of circuits. Single-circuit technology is intended exclusively for heating the coolant circulating through heating pipes.

A single-circuit boiler is designed to serve only one system: either hot water supply or heating. If it is not possible to install a double-circuit unit, it is permissible to use no more than two boilers in one boiler room, regardless of their floor or wall-mounted design

In this case, to heat tap water you will have to additionally install a boiler. Yes, a single-circuit boiler is convenient, but the disadvantage of this solution is its high cost - you will have to buy not only heating equipment, but also a boiler. Moreover, both devices will take up a lot of space.

As for the double-circuit boiler, here the heating equipment and water heater are assembled into a single structure. Thanks to this structure, you can solve two problems at once, while purchasing only one unit.

In addition, in the absence of hot water, the coolant can be redirected to the second circuit and used alternately - to heat the house and to provide hot water supply.

Operating principle of single-circuit equipment

Single-circuit heating equipment is most often used by owners of luxury country houses. In essence, a single-circuit boiler is the same water heater, but supplies water to the heating system.

The operating principle of this type of equipment is based on burning fuel in a special compartment and heating the liquid. The heating main is connected to the outlet where the hot coolant enters. Next, the water begins to circulate through the pipes and heat the rooms.

The final stage of circulation is the flow of waste coolant back into the boiler through the inlet pipeline.

If you do not need to provide hot water supply, then it is better to give preference to single-circuit boilers

The cost of a single-circuit boiler may be more than a double-circuit system. Even despite less functionality, this type of equipment is less expensive to install, easier to operate and more energy efficient.

Single-circuit equipment is suitable for those buyers who want to spend money once and buy reliable equipment that does not require special care. This type of boiler will be the ideal and only right choice when there is no need for hot water supply in the house.

Design specifics of a dual-circuit unit

A double-circuit boiler is a system where, in addition to the primary heat exchanger, there is an additional one designed to heat water and then supply it to the water supply system. The movement of the coolant is controlled using a three-way valve. It directs the heated water either to the DHW circuit or to the heating system.

It should be noted that in the first case, the coolant will be supplied only if the hot water tap has been opened. The peculiarity of such heating equipment is that while the tap responsible for supplying hot water is open, the system does not work.

If you have a large family and some of its members like to take long showers, then the rooms may become cool. Manufacturers solve this problem by installing a storage water heater in their boilers.

The disadvantages of the double-circuit boiler design include the need for careful and attentive maintenance. This is due to the fact that the secondary heat exchanger can become overgrown due to the use of water containing organic and mineral particles suspended in it, and the small diameter of the pipes.

If you plan to actively consume hot water, then installing a double-circuit boiler is not the best solution. After all, then the house will not be heated well. You should only think about installing this system in a small house or apartment, where there is not enough space to organize a full-fledged boiler room.