Heating and providing a home with hot water are the most important factors for creating comfortable conditions for residents. In many cases, the best solution is a long-burning double-circuit solid fuel boiler. Such devices are reliable and easy to use.

A long-burning double-circuit solid fuel boiler is needed to create comfortable conditions.

Features of a long-burning double-circuit solid fuel boiler

The installations are mini-boiler houses that effectively cope with both heating the premises and providing consumers with hot water.

Due to the low cost of fuel and versatility, these units are often used for installation in country houses, cottages and dachas.

Device

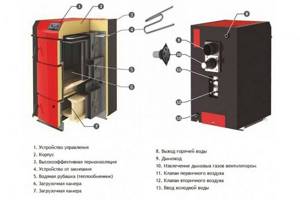

The combined type heating unit consists of the following components:

- metal body covered with thermal insulation;

- working chamber in which solid fuel is burned;

- ash pan for collecting combustion products;

- capacitive heat exchanger of the heating system;

- built-in coil of the hot water preparation circuit;

- air supply and draft regulators;

- automation systems ensuring safe operation of the installation;

- pump for circulating water in the heating circuit;

- fan for supplying air to the firebox and removing combustion products.

Construction of a solid fuel boiler.

Household models of solid fuel heat generators are made of strong, durable materials.

The uninterrupted operation of the unit is controlled by automation, which helps prevent emergency situations.

Principle of operation

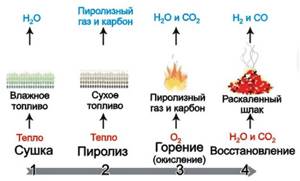

Thermal energy is generated through the gradual combustion of solid fuel. The reaction takes place in the combustion chamber. The increased operating time is due to the design features of the device. The fuel does not burn immediately. It smolders slowly with low oxygen content in the work area. Under such conditions, the pyrolysis reaction occurs. Organic fuel decomposes into coal and a mixture of flammable gases, which are burned in a separate chamber.

The released energy is spent on heating the coolant in the heating circuit. The built-in coil prepares water for domestic needs. To monitor the main operating parameters - temperature and pressure - thermometers and pressure gauges are provided. Unlike classical boilers, in long-burning units the fuel is burned almost completely. The smoke contains no toxic compounds that decompose in the afterburner into water vapor and carbon dioxide.

Differences from single-circuit

Installations with one circuit can only be used for space heating. They have a single heat exchanger. Double-circuit units are used both for heating a home and for preparing hot water. For this, an additional built-in coil or storage boiler is used. This complicates the design and increases the cost of such devices.

A double-circuit boiler is used for heating and preparing hot water.

The operating principle of this type of heating equipment

A lot has already been said in various materials about what the operating principle of long-burning solid fuel heating equipment is based on. The achieved effect is due to a fundamentally different method of fuel combustion in the combustion chamber. Due to the multi-stage combustion process, complete burnout of the fuel mass loaded into the boiler is ensured. In this case, wood gas is released in large quantities, which does the main work of heating the coolant.

For reference: the units operate on the basis of pyrolysis, the process of generating volatile flammable compounds obtained from wood as a result of exothermic reactions. During the smoldering process of fuel, wood (pyrolysis) gas is formed, which, when interacting with hot air, ignites. This technique is also called gas generators.

* The operating principle of boiler equipment is relatively clear; let’s figure out how a double-circuit autonomous solid fuel boiler works at home. Let's look at its main functions. The presence of two circuits in the system provides heating in the house and hot water supply. Boiler water circulates in the first circuit, which disperses throughout the pipeline, supplying heat to the heating radiators. The second circuit is designed to remove waste coolant back to the boiler for subsequent heating. The detector sensors installed on both circuits react sensitively to the slightest change in the set coolant temperature, giving signals to the control panel. Accordingly, the automation activates a mechanical device that regulates the air flow in the combustion chamber of the heating device.

Advantages and feasibility of installation in a residential building

Installing a solid fuel boiler is an effective and simple way to organize heating for a cottage or summer house. This option is especially convenient for buildings that are not connected to the gas supply system. Electrical installations, although convenient and reliable, are expensive to maintain due to high tariffs. It is more profitable to use them as a backup option.

Solid fuel devices are cheaper to maintain. They are able to work on wood, coal, and waste from the wood processing industry.

The use of such boilers is a justified and economically feasible solution if the house is located in a non-gasified area. In this case, long-burning double-circuit units will be the best choice for installation in a cottage or country house.

Such devices have a number of important advantages:

- low fuel costs;

- ease of installation, maintenance and repair;

- reliability and long service life of equipment;

- high energy efficiency;

- the ability to work in autonomous mode without connecting to the mains.

Installing a solid fuel boiler is justified.

Advantages and disadvantages

The main disadvantage of double-circuit boilers is the dependence of the operation of the device on humans. Today, a large number of fully automated stations with a mechanized method of fuel supply have been developed. However, budget products still depend on the person.

Relatively recently, another drawback that homeowners often encountered was regular overheating of the coolant. Modern devices are connected to a safety group, which prevents an emergency from occurring, since pressure is released when the coolant boils. Additionally, three-way valves can be installed, which add cold water to the heating medium and constantly equalize the heating temperature .

The advantages include no need for registration, reliable operation and ease of installation. To properly connect the boiler, you simply need to follow the manufacturer’s recommendations and SNiP requirements.

Any device comes with connection instructions, which take into account design features and various nuances.

Modern boilers can operate for up to several days after one fill of fuel. Stations with automated fuel supply can operate without stopping throughout the entire heating season, providing heating and hot water. Universal devices, in addition to solid fuel, can use gas and electricity. All these features explain why double-circuit boilers are so popular in the domestic market.

Selection criteria: what to look for

Consumers are offered a large number of models of heating installations, which differ in design features and technical characteristics.

Type of fuel used

Modern heating units can operate on various types of fuel:

- firewood;

- coal;

- wood processing waste;

- wood briquettes;

- pellets.

Modern heating boilers run on coal and wood.

Wood-burning machines are unpretentious and inexpensive. Often such models can operate on other types of fuel after minor modifications. To ensure efficient operation of the installation, it is necessary to use dried fuel.

Compared to wood, burning coal releases more thermal energy. It is economically feasible to use the fuel in regions where this type of mineral resource is mined. It is better to use coal. Unlike brown, it burns longer and has a higher calorific value.

Many boiler models are capable of operating on various waste from the woodworking industry: chips, shavings and sawdust. Unlike firewood, this fuel has low humidity and takes up less storage space.

Pellet boilers are the most convenient and energy efficient. They work on compressed and specially prepared wood pellets. An important advantage of pellets is the ability to install a hopper for automatically loading fuel into the boiler.

This solution automates the operation of the unit. The main disadvantage is the relatively high cost of wood pellets.

Combustion principle

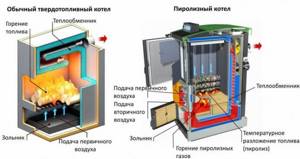

In heat generators, 2 types of fireboxes are most often used.

Pyrolysis boilers are equipped with two chambers. In the first, solid fuel slowly smolders in the absence of oxygen, forming flammable gases. In the second chamber, the pyrolysis products are burned. This scheme is characterized by high efficiency and increased operating time. Organic fuel burns completely, producing steam and carbon dioxide. There are no harmful emissions into the atmosphere.

Pyrolysis boilers have two chambers, so they have high efficiency.

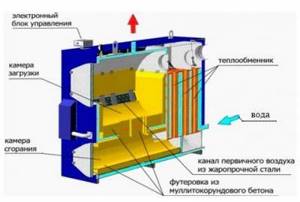

Top combustion boilers can operate on one load of fuel for up to 10-12 hours. The device is an elongated cylindrical body that is installed on the floor in a vertical position.

Firewood or other combustible material is laid in layers along the entire height. The air is supplied through a pipe that rests on the top layer of fuel. The reaction occurs only in the upper part. As the fuel burns out, the working area gradually moves from top to bottom. This method allows you to achieve economical consumption of firewood and control the intensity of the oxidation reaction.

Heat exchanger material

Cast iron and heat-resistant steel are used to create the primary heat exchanger. These materials have good thermal conductivity and high strength. Cast iron is resistant to corrosion and can easily withstand temperature overloads. The material heats up quickly and is able to accumulate thermal energy for a long time. Cast iron is fragile, so during installation and transportation, care must be taken to avoid falls or strong impacts on the structure.

Steel heat exchangers easily withstand water hammer and are lighter. This metal is cheaper and is more often used in inexpensive models. Steel boilers are easier to install. Metal is susceptible to corrosion, and products made from it have a shorter service life.

Power

The parameter is selected based on the volume of the heated room. For 10 sq. m must have at least 1 kW of power.

The boiler power is selected based on the area of the room.

If you plan to install the device in a poorly insulated room or the building is located in a cold climate zone, it is recommended to provide a margin of 20-30% of the minimum value. However, it is not advisable to use heating installations with excess power.

This can lead to increased fuel consumption or reduced service life due to the constant operation of the boiler at insufficient load.

Types of boilers based on combustion principle

The combustion principle significantly affects the efficiency and efficiency of the device. In solid fuel systems, the most common fireboxes are gas-generator and top-burning.

Gas generators

Pyrolysis or gas generator boilers have two combustion chambers. In the first: the fuel, due to the low supply of oxygen, smolders and releases flammable gases, which are then burned in the second chamber.

This system provides very high efficiency due to maximum combustion of all fuel. Waste in the form of ash is quite insignificant here.

Top burning

Top combustion boilers have one firebox. Often such a cauldron can be recognized by its cigar-shaped shape. The firebox can take up about half its length. The principle of combustion in it is realized by supplying oxygen from above. Thus, only the upper part of the bookmark burns, and the lower part, due to the lack of oxygen, cannot burn. As it burns out, the air is supplied lower and lower, until the entire load is completely burned. This method allows you to use fuel economically and regulate combustion.

What is the difference

Both systems allow you to increase combustion duration. The first is due to the afterburning of the resulting gases, the second is due to limiting the uncontrolled combustion of the entire stash.

These systems differ in design and combustion process. The gas generator has two furnaces, and, accordingly, two stages of combustion: the actual filling and the resulting combustible gases. The top combustion furnace has one chamber and one long and economical combustion process.

Famous manufacturers and best models

When choosing a device model, it is recommended to first consider the products of the most well-known companies that develop and manufacture heating equipment.

Karakan 16TPEV-3 16 kW

Inexpensive but reliable device with an open combustion chamber. The unit is capable of operating on all types of fuel: wood, coal, briquettes. Features of the model are a deep firebox and the presence of a hob. The efficiency is 75%. The unit is suitable for heating a room up to 160 square meters. m. Mechanical type control. The heating circuit operates in energy-independent mode. The primary heat exchanger is made of steel. To heat water for domestic needs, a built-in heating element with a power of 9 kW is provided.

Karakan 16TPEV-3 16 kW is a boiler with an open combustion chamber.

Dragon TA-GV-15

A 15 kW installation is suitable for heating a house or cottage with a total area of up to 150 square meters. m. The model is easy to use and highly efficient. The efficiency of the installation is 88%. The large volume of the firebox allows the device to operate on one load of fuel for up to 6-10 hours.

The pyrolysis type boiler is equipped with an open combustion chamber and an improved fuel afterburning system. The heat exchanger is made of heat-resistant steel. Mechanical type control is used. No electrical connection required. It is possible to additionally install a burner for liquid fuel. The disadvantage of the Dragon TA-GV-15 is the high cost of the product.

Wirbel ECO-CKB 20

The combined energy-independent heat generator has a power of 20 kW. Open type working chamber. For the preparation of domestic hot water, a built-in storage tank with a volume of 65 liters is provided. The heat exchanger is made of furnace steel. Firewood, coal, and pellets can be used as fuel. Additional installation of gas and liquid burners is possible. Disadvantages - high cost, difficulty in maintenance due to the low prevalence of the model.

Wirbel ECO-CKB 20 is a combination boiler.

Trajan T-15-2KT

The unit of the Russian manufacturer has a power of 15 kW. Despite its small size, it has a spacious combustion chamber with a volume of 80 liters. The pyrolysis type device allows you to achieve high efficiency, reaching 85%, and reduce fuel costs. Coal and wood can be used as fuel. Trayan T-15-2KT is a non-volatile heat generator and does not require connection to the electrical network. The heat exchanger is made of steel.

How to increase efficiency

To increase the efficiency of a double-circuit boiler, you can use the following tips and recommendations:

- Increasing the inertia of the heating system due to the use of a larger diameter of pipes connecting the boiler to the heating radiators. As a result, the volume of the coolant becomes larger due to which the heating and cooling time increases.

- Inclusion of a heat accumulator in the heating system, which allows the accumulation of excess heat generated by the boiler during the combustion of fuel. This allows you to significantly increase the efficiency of the boiler and reduce fuel consumption during its operation.

- The use of mechanical or electronic devices to automatically regulate the boiler power and maintain the specified heating temperature of the coolant.

- Installation of thermostatic valves on heating radiators that limit the flow of hot coolant into them, which ensures that the required temperature is maintained in the room.

It should be taken into account that using a TT boiler in the warm season only for the purpose of heating water for the hot water system is irrational and economically unprofitable. Therefore, it is best to provide your home with hot water in the summer using a separate water heater.

The best option in this situation would be to use a separate thermally insulated storage tank (boiler) for hot water, connected to an additional DHW heat exchanger of the boiler and having an additional electric heating function.

This ensures fuel savings and a stable supply of hot water to the home, regardless of the volume of its consumption at any time of the year.

Operating rules

Heating units are complex devices with a high hazard class. The unit must be installed and operated only in accordance with the requirements and instructions of the manufacturer.

Ways to Increase Productivity

There are a number of methods that can significantly increase the efficiency of the installation.

Experts recommend periodically cleaning the unit.

Experts in the operation of heating systems recommend:

- Take time to prepare the fuel. Do not use undried firewood or damp coal.

- Ensure reliable ventilation of the room where the equipment is installed. Most solid fuel boilers use an open combustion chamber, so it is necessary to provide an uninterrupted flow of oxygen.

- Optimize the heating system of the room. To do this, you need to correctly calculate the number of radiators and the diameter of communications, as well as use the collector distribution of the coolant.

- Clean the unit periodically. Combustion products should be removed from the ash pan and ventilation lines should be cleaned.

- Check and, if necessary, improve the thermal insulation of the room. By sealing cracks and holes, you can greatly reduce your home heating costs.

- Use fuel that has increased energy efficiency. At the same time, it is not always economically justifiable to use the cheapest fuel. Thus, pellets, when burned, release more thermal energy than wood and coal.

- Install additional heat preservation equipment. For this purpose, thermal accumulators are often used. They are buffer containers filled with water. Circulation is provided by an electric pump. It takes water from the tank and supplies it to the boiler. There it heats up. The liquid is then returned to the storage tank. After the fuel burns out, the water container slowly cools, maintaining the air temperature in the room.

Nuances of operation

Be sure to read the accompanying documentation. The efficiency and performance of equipment can be influenced by a number of factors that at first glance seem insignificant.

It is worth noting that most manufacturers strictly recommend that installation be carried out by specialists, since in some cases, deviation from this requirement can lead to loss of warranty, and in the worst case, to serious breakdowns and accidents.

After installation, regularly inspect the perimeter of the harness for leaks.

Equipment is often sensitive to fuel quality. Cast iron boilers are the most unpretentious, while steel boilers can burn out when using high-temperature fuels

Therefore, it is important to follow the manufacturer’s recommendations when choosing fuel

Any boiler, even one equipped with various types of self-cleaning systems, requires regular maintenance and cleaning of both ash and soot.

How to increase productivity

The economic and actual efficiency of the boiler depends not only on its initial characteristics.

To improve your performance, take the following measures:

- Use high-quality and dry fuel. Wet firewood will take up some of the energy for drying, and household waste will lead to contamination of the heat exchanger and chimney.

- Take the time to clean regularly.

- Ensure a stable flow of air into the room where the boiler is located: there is no fire without oxygen.

- Reduce heat loss from heated rooms. You can especially identify problem areas using a thermal imager.

- Install auxiliary equipment: for example, a heat accumulator.

Additional equipment and its installation lead to increased costs; not only a buffer tank will be required, but also a circulation pump, but it is worth it. The heat capacity of water is quite high: 1 liter of water, cooled by 1 degree, can heat 1 m³ of air by 4 degrees.

The principle of operation of the battery is quite simple: the pump takes cold water from the tank, drives it through the boiler heat exchanger and returns it back. This happens until all the water is heated. After all the fuel has burned out, the tank is completely filled with hot water. Thermal insulation of the tank allows you to keep the water hot from several hours to a day, so the resulting heat can be used for a fairly long period of time.

Video

Detailed explanation of the operation of the boiler and buffer tank, features of installation of shut-off valves:

Service Security

Heat generators running on solid fuel are safer than gas and electric devices. There is no danger of the flame coming off in the burner and no risk of short circuit in the wiring. Solid fuel boilers do not require connection to the electrical network and can operate autonomously.

The automation and control systems provided by the manufacturer block the access of air to the furnace if the permissible operating parameters of the equipment are violated. After this, the combustion process stops on its own.

Solid fuel boilers are safer than gas boilers.

When operating the equipment, the following safety requirements must be met:

- do not cut off the air supply to the working chamber;

- use only the types of fuel specified by the manufacturer;

- do not light a boiler with an empty heating system;

- provide ventilation in the room where the device is installed;

- Do not operate the unit if the smoke exhaust is faulty or there is insufficient draft;

- remove flammable items away;

- close the firebox door during operation;

- Do not carry out repairs or maintenance after igniting the fuel.

Comparison with electric and gas boilers

Many people who build a house away from the city are faced with the choice of installing an autonomous solid fuel, gas or electric boiler.

In order to compare these options with each other, you will need to consider three important parameters: connection cost, service safety and ecology.

Connection cost. Although a solid fuel boiler is not cheap, its operation has the lowest cost indicators among all compared models.

The cost of a gas boiler is much cheaper than a solid fuel one, but in order to connect it you will need numerous permits from state supervisory authorities.

For this purpose, they will require the owner to provide a gas supply project, perform installation work to install the boiler and meter, and also pay for the connection.

Today, according to conservative estimates, it will take 600 thousand rubles and more to supply gas to a house, perform installation work and obtain an operating permit. Installing an electric boiler will cost much less, but it’s also not cheap.

In most cases, such a connection will require changing the power of the power supply line to 380 V. This will also require significant financial investments for the reconstruction of in-house electrical networks and coordination with the distribution zone.

However, it is not a fact that the electricity supplier will agree to replace the technical conditions. A solid fuel boiler does not require any approvals, and the funds spent on the purchase of boiler equipment will pay off in 2-3 years, while connecting to the gas network and installing a new power line no earlier than in 6-9 years.

Service security.

Everyone knows that gas boilers are the most dangerous, since if there is a violation in operation and the flame breaks away from the burner, an explosive mixture can be created in the house.

Electric boilers pose a danger due to the possible occurrence of fires in cable lines during overloads. In addition, an explosion of the steam-water mixture in the heat exchanger may occur if the circulation of the coolant is disrupted.

Any boiler needs to be serviced on time. Photo source: termo-star.ru

A solid fuel double-circuit boiler is also a source of a fire hazard, but the reality of its occurrence is much lower.

Since all structural components of the boiler unit are designed in such a way that the device is non-volatile. The built-in automatic protection, if the permissible parameters of the boiler operation are violated, shuts off the air supply to the firebox, after which the combustion process stops. In addition, today pallets are the safest fuel.

Ecology.

Here, in the first place are electric boilers, which have no emissions into the atmosphere at all, followed by solid fuel double-circuit long-burning boilers, and the list is completed by gas boilers, with the largest CO emissions.

Taking into account all the listed features of the types considered, we can conclude that the most convenient and easiest to operate is an electric boiler, followed by a gas unit, and a solid fuel unit is inferior to them in terms of these requirements.

But in terms of the cost level of the generated thermal energy, the best option is a solid fuel pyrolysis boiler, followed by a gas unit and the list is completed by an electric boiler. The heat cost of the latter unit is several times higher than that of a solid fuel unit.

Cost of basic options for solid fuel boilers

Solid fuel boilers are produced to operate on various types of fuel. The most commonly used wood species are pellets made from pressed wood chips and various types of coal.

The cost of boilers is from 30 to 200 thousand rubles. Photo source: avtokotel.ru

Recently, with the advent of biofuel from wood and agricultural waste, many users have switched to burning it in heating boilers. There are models that can run on any of these types of fuel.

The price of such modifications of heating units very much depends on the metal of the combustion chamber - cast iron or steel.

Wood-burning boilers today can be purchased for 55 thousand rubles. Coal units from 40 to 80 thousand rubles. Long-burning pellet double-circuit solid fuel boilers are the most expensive from 120 to 200 thousand rubles.

Negative aspects of long-burning double-circuit TT boilers

The main disadvantages are:

- high requirements for fuel quality;

- the need to allocate space for storing fuel reserves, which takes up a large volume;

- the inability to organize automatic supply of fuel to the firebox in inexpensive models that burn wood and coal;

- the need for regular maintenance - removing ash, cleaning ventilation lines;

- lack of automation responsible for controlling the water temperature in the heating circuit;

- inertia of the installation - the boiler cannot be turned off until the fuel burns out.

Principle of operation

Double-circuit boilers are universal appliances. They can heat houses and provide prepared hot water

, heated to a certain temperature. Their design is quite complex, there are many additional components and modules, because the finished design should be as compact and functional as possible. This is precisely what distinguishes double-circuit boilers, both gas and solid fuel.

The most complex structure is gas equipment, which, in addition to the burner and heat exchanger, contains gas units, security systems, piping, various sensors and fans. All this makes the equipment difficult to maintain and repair. As for double-circuit solid fuel boilers, they are much simpler. In them we will find:

Construction of a solid fuel boiler with two circuits: heating and hot water.

- Burner – classic or pyrolysis;

- Double heat exchanger;

- Additional pipes for water supply and intake.

A wood or wood gas burner produces heat that warms the coolant circulating through the heat exchanger. This heat exchanger contains tubes responsible for heating the incoming water from the water supply. Since direct contact with hot metal is excluded here, this scheme allows you to get rid of scale

– the temperature here is insufficient for its formation.

Some boilers are designed differently - the flame passes through the middle of a cylindrical heat exchanger, which first heats the heating circuit. The hot water supply circuit in such units is located on top of the heating circuit. This approach ensures that there is no overheating of water in the DHW preparation system.

Thus, there are no three-way valves or other complex components here, which is already a definite plus. As soon as you open the tap, hot water immediately begins to flow from it. Moreover, it is too hot, since adjusting the temperature in the DHW circuit in a double-circuit solid fuel boiler is very problematic - especially if it does not have a combustion control system.

You can count on a more or less stable water temperature in the hot water supply circuit only in pellet models. But gas and liquid models cope best with this.

Long-burning solid fuel double-circuit boilers are equipped with spacious combustion chambers that can accommodate a large amount of solid fuel. Some models can work up to 12 hours from one bookmark

. The record holders are pellet devices that operate on compressed wood pellets - they can be equipped with extremely capacious bunkers that ensure continuous combustion for 7-10 days.

User reviews

Anatoly, 48 years old, Voronezh:

“I am the owner of a summer house. There is no gas in our area and there is no prospect of it in the near future. I had to install a solid fuel boiler. I chose the universal Karakan model, equipped with a second circuit for heating water. I burn with wood. I've been using the unit for almost 2 years. There are no problems yet."

Vasily, 30 years old, Ryazan:

“I have been using the Trayan T-15 device for more than a year. Reliable and easy to maintain unit. Large firebox, can be heated with wood up to 55 cm long. Installed it myself. Works good".

Nikolay, 61 years old, Penza:

“I bought a Dragon TA-15 six months ago. The model is not cheap, but it is worth the money. I use pellets, it turns out cheaper than firewood. I like the built-in hot water tank. During operation, I have not identified any problems yet.”

Review of popular models and their costs (minimum 7, can be presented in a table)

It is not difficult to buy a double-circuit solid fuel boiler; the cost depends on the degree of automation, brand and configuration. The table shows models from foreign and domestic manufacturers of approximately the same power in ascending order of cost.

| Hephaestus | Mozyrselmash | Trajan | |

| Hephaestus KSTGV-20 | Mozyrselmash KS-TV-16 | Trayan TB-20-2K | |

| Power | 20 kW | 16 kW | 20 kW |

| Heating area | 200 m² | 160 m² | 160 m² |

| Fuel | solid fuel | solid fuel | solid fuel |

| Efficiency | 80,0 % | 85,0 % | 85,0 % |

| Nutrition | autonomous operation | autonomous operation | autonomous operation |

| The combustion chamber | chimney | chimney | chimney |

| Boiler type - combined (wood/gas) | |||

| Price | 21,000 rub. | 22,000 rub. | 55,000 rub. |

| Dakon | Virbel | Wiesman | |

| Dacon FB2 20 | Wirbel EKO-CKB 20 | Wiessmann Vitoligno 100-S | |

| Power | 20 kW | 20 kW | 25 kW |

| Heating area | 150 m² | 160 m² | 250 m² |

| Fuel | solid fuel / when connecting a boiler | solid fuel | solid fuel |

| Efficiency | 78,0 % | 91,0 % | 92,0 % |

| Nutrition | autonomous operation | 220v | 220v |

| The combustion chamber | chimney | chimney | chimney |

| water overheating sensor | water overheating sensor | air vent | |

| built-in boiler (65 l) | |||

| Price | 89,000 rub. | 180,000 rub. | 180,000 rub. |

| Kiturami | |

| Kiturami KRP-20A | |

| Power | 24kW |

| Heating area | 192 m² |

| Fuel | solid fuel/pellets |

| Efficiency | 92,6 % |

| Nutrition | 220v |

| The combustion chamber | chimney |

| Equipment | remote control unit |

| circulation pump | |

| water overheating sensor | |

| liquid freezing sensor | |

| hopper 160 kg | |

| Price | 300,000 rub. |

Prices for the Kiturami KRP-20A boiler

Kiturami KRP-20A