The ball valve is mounted on pipelines through which water, gas and heat are supplied. The main purpose of this device is to regulate or completely cut off the movement of a liquid or gaseous medium with the formation of absolute sealing.

The reliability and unpretentiousness of the design determine its widespread use both on industrial pipelines and on pipelines in the residential sector.

Design features

A ball valve is a valve with a valve having a spherical configuration.

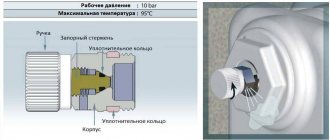

Let's look at the main components of this design.

- Device body. It is produced in one piece (by welding) or collapsible. The first version of the devices is non-repairable. Collapsible modifications can be repaired, but have a more complex structure, greater weight and price, compared to products that have a one-piece body design.

- Valve ball. It is produced in a floating or stationary version. The diameter of its passage hole can coincide with the nominal diameter of the valve or be smaller.

- Movable spindle mechanism , through which movement is imparted to the locking mechanism in the shell.

- Removable handle. It can be implemented in the form of a lever or a flywheel.

- Rings. The seal between the shell and the polished ball valve is provided by end rings made of fluorine-containing synthetic polymer (PTFE).

The structure of the ball valve is reliable and simple. The metal ball valve located in the valve shell has a through hole along the flow line. Rigid fixation of the rod and ball forms an axis of rotation located at 90 degrees relative to the flow line.

The supply of liquid medium occurs when the center line of the hole in the spherical valve and the center line of the flow are aligned. When the rod is rotated 90 degrees, the axes will become orthogonal to each other, and the ball will block the feed.

Design and principle of operation

The body of the shut-off device is a piece of pipe expanded in the middle part. The extension contains a seat made of sealing material, inside of which there is the main element - a ball, also known as a valve or plug.

The ball can rotate freely inside the seat. It has only one through hole in the shut-off valve.

Control devices and valves that redirect flow may have 2 or 3 holes. If the tap is used to regulate the pressure of hot or cold water, then there are two holes, if the device is a mixer, then there are three holes.

The ball valve is activated by turning a lever to which a ball valve with a hole is connected through a rod. By rotating the hole relative to the axis of the pipeline, we open/close the passage of the medium or partially let it through

The principle of operation is very simple: when the axis of the hole in the ball is aligned with the axis of the faucet body, water will begin to flow out of it.

Those. when the plug is deployed so that its hole coincides with the direction of the pipeline, as if continuing it. In this position, the flow of liquid, steam, gas passes through the pipeline, including through the tap, freely.

When the ball valve is turned 90º, the passage for water, steam, gas is blocked by the side on which there are no holes. In this position, the flow of the medium stops completely, because it rests against the solid wall of the valve.

However, with this simple device you can regulate the flow parameters. When turning 45º, for example, the flow will only be blocked by half.

To control the ball, a rod connected to a lever is used. There are o-rings on both sides of the rod. The hole in the body through which the rod passes is also equipped with a washer and an O-ring.

The single-lever ball mixer is equipped with a valve with two holes for the passage of cold and hot water and another hole for the exit of a mixed stream

Ball valves are made of brass or various grades of steel. Brass devices are considered more reliable, their service life exceeds 10 years. Steel products are very rarely used in everyday life; they are mainly used for industrial pipeline systems.

More recently, manufacturers began to produce cranes whose body is made of high-strength plastic. Unlike brass, such devices are not subject to corrosion and are much cheaper.

The only disadvantage of plastic products is that they cannot be used for hot water.

All o-rings are made of high-density rubber; these are the “weakest” points of the faucet, which cause leaks, but are easily replaced using a regular repair kit

These taps are most widely used in everyday life. A feature of their design is that the ball is not rigidly connected to the stem and can move under the influence of water, pressing against the sealing ring, thus sealing the tap.

A floating ball is used in mechanisms whose nominal size does not exceed 20 cm. Such devices are installed in internal water and heat supply systems. Almost all domestic and imported household faucets also have a floating ball mechanism.

The design of the valve body with a floating ball can be either welded or dismountable. Sealing elements can be of different hardness. Small household appliances are usually collapsible and have soft seals.

Floating valves are installed on pipelines with a diameter of up to 200 mm with constant movement of the working medium. The ball, under the pressure of the medium, is pressed against the sealing rings, sealing the fittings

There are valves in which the locking element is fixed on the axis of the stem, and the seals are pressed against the ball using tightening bolts or springs. To facilitate closing/opening, the trunnion is equipped with bearings.

This design is the most reliable, but due to its high cost it is used extremely rarely in everyday life and usually in the most critical areas of the water supply system.

Types of valves

Depending on the design characteristics, ball valves come in several types.

- Straight-through. The main characteristic feature is low hydraulic losses. Mostly they are installed to regulate the supply of liquid medium to heating systems.

- Walkthroughs. Gas straight-through valves and valves for liquid media are mounted on a straight section of pipe and are designed to completely stop the flow of incoming media.

- Angular. Installation of corner devices is carried out on the bend of the pipeline system. The function of the valves is to block (cut off) the incoming flow.

- Three-way or mixing. Mounted on systems when there is a need to mix two streams of incoming liquid medium having different temperatures.

Disadvantages and advantages

Like any building element, plumbing ball valves have disadvantages and advantages.

Among the advantages are:

- Relatively light weight;

- The length of the structure is small;

- Convenient to install;

- The quality matches the price;

- Tightness.

Among the disadvantages of the design are:

- Good torque indicator for turning the lever;

- If you open it abruptly, hydraulic shocks occur in the pipe;

- It is necessary to open and close it at least once a week to prevent the ball element from sticking in the pipe;

- The fragility of the seal when operating above 150 degrees.

To understand which ball valves are best to choose for water supply, understand the features and types.

Fastening methods

Based on the fixation technique, ball valves are classified into the following types.

- Coupling (threaded). The threaded type mechanism is usually used in private water supply systems of small diameter (no more than 65 millimeters), for gas and for heating systems or liquid media. The sleeve valve is distinguished by its ease of installation. To install the device, given that the pipes are threaded in advance, there is no need for specialized tools or highly qualified specialists.

- Flanged. Devices mounted using specialized elements (flanges) are mainly used for installation on industrial pipelines with a diameter of 50 millimeters or more. Such a device is more durable and sealed.

- Welded. Mounted on metal water pipes by welding. The fixation of such a valve is the most reliable, however, installation of the device requires certain qualifications. For the most part, welded valves are installed on industrial gas pipelines where high sealing is required.

- Combined. They are connected to pipes using various methods. Products of this type are endowed with multifunctionality and are used in a variety of communication systems with the following connections: flange connection plus welding, threaded connection plus welding, and others.

Water ball valve sizes, thread types and operating pressure

Ball valves for water are classified not only by the type of thread, material of manufacture, operating pressure and environment.

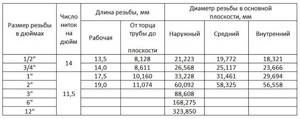

Another important parameter is the diameter of the internal passage. The most popular designs used by craftsmen when installing water pipes have an internal passage diameter of ½ or ¾ inches. In terms of standard measurement, this is 15, 20 or 25 mm. Much less commonly used are ball valves for water with an internal passage diameter of 1 inch or 1 ¼, 1 ½ and 2 inches.

A ½-inch diameter water ball valve is more than sufficient for plumbing in a house or apartment. In this case, the diameter of the tap corresponds to the diameter of the pipe. If the heating system has a circulation pump, then you need to take a ball valve for water with a diameter of ¾ inches.

Homes also have heating systems with natural circulation. They must be mounted from pipes and taps of larger diameter, at least 40-50 mm.

To find out the diameter of a water ball valve, you need to find the DN marking on it. If the ball valve says DN25, this means that the diameter of the internal passage is 25 mm or ½ inch.

The thread on a ball valve can be internal or external. In plumbers' jargon, the internal thread is a nut, and the external thread is a fitting. If the tap has external threads on both ends, then it is called a “fitting-fitting”, if there is an internal thread on one side and an external thread on the other, then it is called a “nut-fitting”, etc.

Another important parameter indicated on the ball valve is operating pressure. It is marked with the letters PN, the unit of measurement is atmosphere.

The PN25 marking indicates that the maximum permissible pressure in the system on which the valve will be installed is 25 atmospheres. Practice shows that when installing a central heating system, you can use PN16 taps, which are also suitable for installation on gas and electric boilers and radiators.

Choice

The structure of the ball fittings must be selected in accordance with the parameters of the pipeline and the work being performed.

Ball devices for structures transporting liquid and gaseous substances are sold by all companies that supply pipes. Among the entire mass of manufacturers, companies such as Rehau, Valtec, Lavita and AS Gruppe can be distinguished. The products of these companies have been on the market for a long time, they have been tested in practice by a huge number of users and do not raise questions regarding quality.

One of the main differences between high-quality devices and their unreliable prototypes is the metal from which the case is made. When choosing a ball valve, first of all, pay attention to the shell of the device - it should be made of leaded brass brand CW617N. Inexpensive Chinese products are often made from recycled brass, which may contain additives that are hazardous to humans. You should not ignore this circumstance and, if necessary, ask the seller for a hygiene certificate and a sanitary-epidemiological certificate for the product.

It is also necessary to focus on shut-off and control valves, since in order to reduce the cost of goods, brass is often replaced with ordinary iron, which rusts over time. During operation of such a product, due to corrosion of the locking mechanism, the sealing of the valve may be broken, which will lead to a break in the water supply system.

When choosing a ball valve, it is better to inspect the surface of the valve ball. The sphere should shine like a mirror and be impeccably glossy (the surface of the ball is processed using diamond grinding). All of the above indicates the high quality of the device. If the surface of the shutter ball has a dull shine, a matte coating, or even has roughness, then this indicates that this is a counterfeit. This will affect the throughput of the device in the open state, and specific noise will occur when the liquid medium moves.

What characteristics of gas boilers exist?

There are heating units that consume only main gas, while others operate on both natural and liquefied fuel. The main technical characteristics of gas boilers are as follows:

- Location: floor, wall and parapet.

- Number of circuits: single-circuit and double-circuit.

- Type of ignition: electric ignition and piezo ignition.

- Burner type: atmospheric, pressurized, diffusion-kinetic.

- Type of traction: forced or natural.

- Heat exchanger material: cast iron, copper, steel.

- Combustion chamber: closed and open.

- Type of coolant: plain water and with the addition of antifreeze.

- Power.

Which boiler is better - wall-mounted or floor-mounted?

The main difference between floor-standing and wall-mounted boilers is the heat exchanger. For the former, it is more massive and is usually made of cast iron or high-alloy steel. A cast iron heat exchanger is easier to damage, but it can last for many years if used carefully. The steel element is stronger and weighs less.

Floor-standing boilers are large in size, their power can reach 3000 kW or more.

Wall-mounted boilers often have a heat exchanger made of copper or steel - they have a shorter service life. They are convenient to place in residential areas, as such units are compact in size and operate quietly.

How do single-circuit units differ from double-circuit units?

Single-circuit boilers are intended only for heating rooms without the ability to heat water.

Double-circuit ones are capable of both heating a home and providing hot water supply.

Note! Double-circuit gas boilers are designed in such a way that when the hot water supply is started, the power of the unit will be directed to heating water

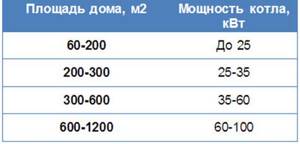

Boiler power

One of the main indicators of heating units is power. It determines whether your home will be warm and comfortable. The power indicator should be selected based on the estimated area that is planned to be heated and possible heat loss. They can be calculated using the formula:

Q = k • V • ΔT, where

Q – heat loss, kcal/h;

V – room volume, m³;

ΔT – maximum difference between the air temperature outside and inside the building in winter, °C;

k is the heat transfer coefficient of the house, which depends on the material of the walls (k = 0.5-1 – insulated structure, k = 1-2 – brickwork in two layers, k = 2-3 – brick wall in one layer, k = 3-4 – plank house.

Knowing the heat loss, calculate the required boiler power:

M= Q • k, where k is the safety factor, which ranges from 1.15 to 1.2.

When choosing boiler power, the following factors should be taken into account:

- The need to heat water. If you plan to purchase a double-circuit boiler and actively use hot water supply, you should increase the estimated power by 20-30%. It is known that when heating water, 70-80% of this indicator is spent.

- Water hardness - it affects the amount of scale on the surfaces of the heat exchanger. Significant limescale accumulations lead to a decrease in the productivity of the boiler. To avoid this, you should regularly clean the unit of scale, as well as soot and soot. The first cleaning is usually carried out after 2-3 years, but this period may vary depending on the quality of the water and the intensity of work.

Which type of combustion chamber should I choose?

As already mentioned, there are gas boilers with open and closed combustion chambers. The first type consumes oxygen, which supports the combustion process, directly from the room. Combustion products go there too. Therefore, an open chamber requires a chimney and high-quality ventilation. Such units are mainly installed in specially equipped boiler rooms.

Note! An open combustion chamber is a feature of floor-standing boilers with a power of over 35 kW. For units with a closed combustion chamber, air supply and smoke exit occur via a coaxial chimney

It consists of two pipes, one of which is located inside the other. Through one of them, air enters the boiler, and through the other, combustion products are forced out. Mainly wall-mounted boilers with a power of less than 35 kW are equipped with closed combustion chambers

For units with a closed combustion chamber, air supply and smoke exit occur through a coaxial chimney. It consists of two pipes, one of which is located inside the other. Through one of them, air enters the boiler, and through the other, combustion products are forced out. Mainly wall-mounted boilers with a power of less than 35 kW are equipped with closed combustion chambers.

What are ball valves for gas

These are shut-off devices that can ensure a complete shutdown of the supply of any type of gas if necessary. They must not allow leaks through elements of their design. The passage of gas when the valve is completely closed is also excluded.

For greater clarity, let’s look at their design and features using the example of gas taps from the Italian company FADO.

Quality

FADO gas ball valves differ from other manufacturers in the way they are produced. The hot stamping method is used to produce the brass body. This technology has advantages over injection molding.

During the stamping process, the brass self-seals. This guarantees the absence of serious defects in the metal of the case. These include air bubbles and leaks. Such flaws can lead to cracks, delaminations and inevitable gas leaks.

Classic series tap with two internal threads (BB)

The material used is high-strength brass CW 617n (LS59-1). It has the necessary properties for all types of processing. This allows you to perform stamping, turning, threading and other operations with high quality.

According to technical standards, not every tap can be used for gas. To do this, he must have the appropriate permits.

Ball valves for gas from FADO are provided with the necessary international certificates. They confirm the possibility of using these products in gas supply systems.

Design features

The taps are produced in two series – Classic and New. Their design guarantees compliance with all safety requirements when using gas. This is, firstly, ensuring the tightness of the shutter.

Secondly, the presence of a rotation limiter and open-closed position indicators. Thirdly, they are sealed with respect to the external environment.

FADO ball valve for gas NEW series with BB thread

In many ways, they repeat the design of water taps. However, you need to understand and respect their interchangeability. The gas tap can be installed on the water supply system. It is not allowed to install a water tap on gas.

Differences from designs for water

Ball valves for gas from FADO have a longer body length. Accordingly, a larger number of threads are cut here. There are seven of them on gas disconnect devices, and six on water disconnect devices. This ensures a more reliable and tight connection between the gas tap and the pipeline. Reduces the risk of gas leakage.

The valve stem seal is made of Viton material. It is completely gas-tight and has increased temperature resistance (up to 650 o C). This is a fire safety requirement so that the valve does not leak gas when it gets heated.

The rod is sealed in the form of two rings mounted on it. They are not pressed with a clamping nut (as in a water tap). It's simply not in the design. By this feature, you can distinguish a gas tap from a shut-off device for other purposes.

To do this, just look under the control knob. If you see a clamping nut there, then this is not a FADO brand gas valve.

The control knob is yellow. All FADO gas ball valves are not repairable. This is not a sign of low quality, but a condition of safety.

Single lever mixer

The ball, or, as it is also called, cartridge, mixer appeared relatively recently and has become widespread. This is a convenient and simple element. Water adjustment is carried out by turning and raising or lowering the only control element - a lever, a handle. The mixer is controlled by a cartridge device. These are quite easy to use water taps. There are many sizes and shapes - it’s easy to choose a product to suit any room design. The minimum pipe size for water supply is 1/2 inch. Sometimes communications with a cross section of 3/4 inch are used. However, for mains there are pipes up to 12 inches in diameter.

Among the disadvantages, it is worth noting that in the event of a malfunction, only replacing the cartridge will help, and it is not always possible to find a compatible cartridge with an installed mixer

When choosing, pay attention to the weight of the crane. The lighter it is, the worse the quality

You should definitely look at the equipment, the materials from which the mechanism is made, and the quality of the parts. It is better to choose a brass faucet or a chrome faucet. A stainless steel ball element quickly loses its attractiveness.

Peculiarities

So, special ball valves have recently been used in gas pipelines. These devices are designed to completely shut off or open the gas flow. The peculiarity of these devices is contained in the locking mechanism, which is made in the shape of a ball with a through hole. Moreover, the diameter of the hole coincides with the diameter of the pipeline (see also the article “Where and how is a high-pressure valve used”).

To block the flow, the ball is rotated so that the hole is perpendicular to the pipeline, i.e. it must be rotated 90 degrees. The locking mechanism is controlled using a lever. Tightness is ensured by rings made of soft and durable materials.

Differences from plumbing fittings

It must be stated that the external difference between a gas tap and a water tap is that the lever is yellow and not red.

There are much more structural differences:

- They have a more durable body, which is made of special types of steel or brass with a high copper content.

- They have a longer connecting thread.

- The locking mechanism is made of very durable chrome-plated or nickel-plated material.

- The rod is made of particularly durable polymer material.

- These taps can withstand greater pressure than taps.

- O-rings are stronger and provide a better seal.

Note! Despite the fact that the price of gas taps is higher, they cannot be replaced with water fittings, since the savings can be very expensive. But it is not permitted to use gas shut-off valves instead of water valves.

In general, the only difference between a gas tap and a water shut-off valve is the increased level of tightness. The remaining issues are not so serious in domestic gas pipelines. Based on this, in principle, any valve that meets tightness class “A” can be used for a gas pipeline.

Features of application

In most cases, shut-off valves for gas pipelines are installed in the kitchen, i.e. where gas equipment is used. Moreover, a separate valve is installed for each source of consumption.

For example, in buildings and apartments where gas stoves and water heaters or boilers are installed, I install separate gas taps for stoves and for other devices. In addition, usually one non-specialized valve is installed at the inlet, which allows you to completely shut off the gas supply.

Differences from plumbing fittings

The water tap is painted red. The gas valve differs from the water tap in the appearance of the lever, which is yellow instead of red, as well as in a number of design features:

- long connecting thread;

- more durable housing and locking mechanism;

- ability to withstand high pressure;

- the presence of strong and sealed rings.

Despite the fact that a standard gas faucet is more expensive, it cannot be replaced with water fittings, since such savings may lead to the replacement of the main elements of the system as a result of an accident.

The reliable brass body of the gas ball valve is not subject to corrosion processes

Types of ball gas valves

In addition to the fact that the shut-off valves under consideration differ in diameter, the differences lie in the installation method. The following types of devices are used much more often in gas pipelines:

| Threaded (coupled) | They have a small diameter. In most cases, these products are used in domestic gas pipelines. The connection to the pipeline, as you might guess from the name, is made using a threaded connection. |

| Flanged | They are used in external gas pipelines of enormous diameter. The connection is made using the flange method using bolts. Like threaded ones, these devices are collapsible, i.e. they can be dismantled and then reinstalled. |

| Welded | Like flanged ones, they are used for external gas pipelines. Their diameter can range from 10 to 70 millimeters. The connection to the pipeline is carried out by welding. Accordingly, this installation option is non-removable. The advantages of such products include complete tightness and high reliability. In addition, welded shut-off valves do not require maintenance, i.e. tightening flange connections. |

Advice! In addition to ball valves, there are also plug valves. However, they are less reliable and durable, which is why they have recently been used very rarely.

Characteristics and material of manufacture

In the production of die-cast cases, an alloy of aluminum and silicon is often used.

Various models are made from the following materials:

- bronze;

- brass (often decorated with galvanic coating);

- copper;

- cast iron;

- alloy steel;

- plastic (polypropylene or polyethylene).

The classification of water supply devices is standardized by GOSTs 19681-94 and 25809-96. Characteristics depend on several parameters:

- Bandwidth. There are 3 groups of mixers with parameters 40-50%, 70-80%, 90-100%.

- Tightness class, permissible pressure. Class 1 provides pressure up to 1 MPa, class 2 – up to 0.63 MPa.

- Noise level. Mixers are divided into 3 groups: up to 20 dB, 20-30 dB and more than 30 dB.

- Temperature conditions. Taps are available for cold and hot water (up to 75°C).

Each product is accompanied by technical documentation, which indicates the parameters.

Manufacturers

Gas pipelines are one of the most important systems for providing housing. Based on this, the selection of all its elements, as well as shut-off valves, requires special attention.

You need to buy products only from well-known, well-established manufacturers.

In particular, it is possible to give preference to cranes from such Italian companies as:

- Bugatti;

- FIV;

- Valtec;

In addition, the products of the following companies are of good quality:

- Dungs - Germany;

- Profactor - Germany;

- Broen Ballomax – Poland;

- Efar – Poland;

- LD – Russia.

Advice! You should not take the most inexpensive gas valve, since there are many low-quality fittings from China on the market, which do not always meet all the requirements for gas shut-off valves.

Conclusions and useful video on the topic

As you can see, choosing and replacing a gas valve is not such a difficult job. And in order not to expose yourself and your neighbors to danger, you should treat the process responsibly. Even such a small detail as a tap for gas pipes in an apartment plays an important role in general gas communications.

How to choose a high-quality gas valve will be discussed in the following video:

Please tell other visitors to our site whether you have ever had to deal with choosing and replacing gas valves. Perhaps there are subtleties that we did not mention in this material? Leave your comments, share your experience, ask questions - the contact block is located under the article.

Features of replacing a gas tap

Of course, every shut-off valve can fail; for example, gas taps are not insured against failure. If a malfunction of this device is detected, it must be replaced immediately.

Let us immediately declare that doing this work with your own hands is not allowed! But, some actions will still need to be performed independently.

So, the instructions for replacing this shut-off valve are as follows:

- First of all, it is necessary to tell about the problem to experts from gas work or a personal organization that holds a license to perform similar work.

- After this, you need to purchase a new faucet from a specialized store. You must first measure the diameter of the pipeline so as not to make a mistake when choosing a product.

- When the experts arrive, prepare a technical passport and a gas supply contract. A technical passport is needed to make notes on the work performed.

- After this, you need to light the gas on the stove and turn off the central valve. Leave the burner until it completely extinguishes, so that all the gas leaves the pipeline.

- Upon arrival of experts, it is necessary to open a couple of windows in order to create a draft in the room. This is necessary in case of a gas leak.

- Upon completion of the work, work together with experts to diagnose the installed shut-off valves for leaks.

- At the end of the work, it is necessary to give the workers a technical passport and ask them to make a note in that direction.

Advice! It is possible to identify a gas leak using soap foam. It must be applied to the connection points between the device and the pipeline, and to the valve itself. If a soap ball forms in some place, it means that the shut-off valve is letting gas through.

Upon completion of work, leave the windows open for another 15-30 minutes, which will ensure complete ventilation of the room.

General operating rules

The basic rules for operating a gas tap are quite simple and predictable. The tap closes by turning the handle 90 degrees clockwise, and opens by turning it 90 degrees, but counterclockwise. If the handle is perpendicular to the axis of the faucet, this indicates that it is closed. The parallel position of the handle means that the tap is open.

The working environment passing through this valve should not contain overly hard elements or solid impurities that could damage the polished surface of the bolt ball. If solids can still get into the ball valve, a strainer should be installed in front of the ball valve.

The ball valve itself must be periodically opened and closed so that it can later be easily turned in any direction.

It is allowed to open and close the gas valve only using the factory-made handle, and it is prohibited to extend it by any means.

The ball valve should be operated using a standard handle. There is no need to use special levers for these purposes that can lengthen this handle. Opening and closing the tap should be done as slowly as possible to avoid water hammer.

The pressure and temperature at the installation site of the ball valve should not be higher than the operating pressure. Most designs do not allow the use of ball valves with the same temperature and pressure ratings.

The ball valve requires periodic cleaning of rust and dust, as well as tightening of the threads. In accordance with the manufacturers' recommendations, this should be done once every six months.

When installing pipelines, a pipe fastening design is provided that excludes the possibility of external mechanical influence on the valve, taking into account axial, radial or torsional loads.

Repairs and maintenance of a ball valve under pressure are prohibited. For full operation, the required section of the pipeline must first be cleaned. When cleaning the system, the ball valves need to be opened and closed several times.

We connect the gas stove with a flexible hose

Several years ago in Russia it was allowed to connect gas stoves in an apartment only with a rigid connection, for example, Hans stoves. Therefore, in many apartments, gas supply was carried out using metal pipes with bends and brackets. Such structures are highly reliable structures, however, they also have a number of disadvantages. For example, if you need to carry out repairs, it is impossible to move the slab from a certain place. To solve this problem, it is better to connect the gas stove using a flexible hose. There are also quite a lot of them in our time. Therefore, let's figure out which one he considers the best, and which one is better not to use or to use, but last.

According to instructions from crane manufacturers, any repair work, including replacement of the device, is prohibited from being carried out independently without the necessary skills.

Ball valves: selection and installation instructions

The ball valve is mounted on pipelines through which water, gas and heat are supplied. The main purpose of this device is to regulate or completely cut off the movement of a liquid or gaseous medium with the formation of absolute sealing.

The reliability and unpretentiousness of the design determine its widespread use both on industrial pipelines and on pipelines in the residential sector.