Maintenance of Protherm gas boilers - all included!

An integrated approach to heating is profitable

Protherm heating boilers are reliable, safe and stable in operation, subject to proper operation and regular maintenance.

The manufacturer recommends doing it at least 2 times a year. Otherwise, you risk finding yourself without heating or hot water at the most inopportune moment due to a dirty filter, Protherm gas burner or boiler breakdown. We invite you to protect yourself from surprises and entrust the comfort in your home to Servicepoint service specialists. Our Protherm boiler technicians have manufacturer certificates and are certified to work with gas equipment. Maintenance of Protherm boilers is a service of our service center. We professionally repair and service Protherm gas boilers of any model (Bear, Cheetah, Panther, etc.), double-circuit and single-circuit, floor-mounted and wall-mounted.

Get more information about the service of Proterm boilers - leave a request on our website.

Cleaning the boiler heat exchanger in Moscow and the Moscow region

Professional cleaning and flushing of the heat exchanger - at your home with a guarantee!

Do you want to extend the life of your boiler? Do you want to live warm and with hot water? When was the last time you cleaned your boiler heat exchanger?

Hurry - cleaning the boiler heat exchanger from VashKomfort! High-quality cleaning and flushing of the boiler heat exchanger in a private house in Moscow and the Moscow region on the day of your call! Extend the life of your boiler and your home will be guaranteed to be warm.

When is cleaning required?

There is no specific schedule for the frequency of cleaning the boiler heat exchanger in a private boiler room.

This is due to such parameters as:

- heat exchanger material

- boiler operating conditions

- boiler operating mode

- type of fuel used

- quality of fuel used

- coolant used

- quality of coolant preparation.

The main signs of the need to clean the boiler heat exchanger:

- the boiler has been in operation for more than 3 years

- you notice an increase in fuel consumption

- drop in coolant temperature at the outlet although the adjustments remain the same

- your gas boiler's heating cycle time has increased

- the temperature of the hot water from your hot water boiler has dropped

- the pressure in the DHW system has decreased

- The heating system at home no longer heats up evenly

Heat exchanger for solid fuel boiler

Gas boiler heat exchanger

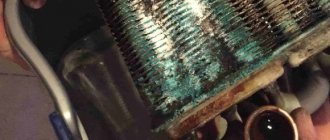

Clogged heat exchanger of a double-circuit boiler

Regular maintenance of the boiler heat exchanger:

- increases the period of efficient operation of the boiler

- increases the service life of the heating system

- prevents increased fuel consumption

- cheaper than boiler repair or replacement of parts

- stable and guaranteed heat in your home!

Why you should contact us

- a master for cleaning and flushing heat exchangers VashKomfort was trained and trained at the centers of equipment manufacturers - BOSCH

,

Ferroli , PROTHERM

,

Conord

,

LEMAKS

,

ARISTON

,

OCHAG

,

VAILLANT

,

Siberia

(Siberia),

NAVIEN

,

Baxi

,

Buderus

(

Buderus

),

Beretta

(

Beretta

) ,

ZOTA (Zota)

,

KARAKAN

,

BUDERUS

(

Buderus

),

KMCH

(

Kirov Plant OJSC

),

PROTHERM

(

Proterm

),

LEMAX

(Lemax), - Departure within Moscow and the Moscow region is FREE!

- we issue a guarantee on work

- pensioners 5% discount on cleaning solid fuel boilers

- 24/7 technical support - always in touch with the client!

- “Emergency plumber departure” for you

- Slavs

Our experienced staff can perform procedures such as:

- cleaning the heat exchanger from soot

- cleaning the boiler heat exchanger from resin

- cleaning the heat exchanger from carbon deposits

- mechanical cleaning of the heat exchanger

- dry cleaning of boiler heat exchanger

- combined cleaning of boiler heat exchangers

We have all the necessary tools and reagents. YourComfort cleans solid fuel boilers throughout Moscow and the Moscow region. Travel to the neighboring region is possible.

Prices for cleaning and flushing heat exchangers

| Service | Works | Price |

| Cleaning the heat exchanger of a single-circuit gas boiler | Washing the heat exchanger (dry cleaning of the gas boiler heat exchanger) Starting and setting up the boiler. | 5500 rub. |

| Cleaning the heat exchanger of a double-circuit gas boiler | Washing the heat exchanger (dry cleaning of the gas boiler heat exchanger) Starting and setting up the boiler. | 7400 rub. |

| Cleaning the condensing boiler heat exchanger | Washing the heat exchanger (dry cleaning of the heat exchanger of the condensing boiler) Starting and setting up the boiler. | 5500 rub. |

| Cleaning the heat exchanger of a solid fuel boiler | Washing the heat exchanger (dry cleaning of the heat exchanger of a solid fuel boiler) Starting and setting up the boiler. | 7800 rub. |

| Cleaning the heat exchanger of a pyrolysis boiler | Washing the heat exchanger (dry cleaning of the heat exchanger of the pyrolysis boiler) Starting and setting up the boiler. | 7400 rub. |

| Cleaning the heat exchanger of a pellet boiler | Washing the heat exchanger (dry cleaning of the heat exchanger of a pellet boiler) Starting and setting up the boiler. | 8500 rub. |

| Cleaning the heat exchanger of an oil-fuel boiler | Washing the heat exchanger (dry cleaning of the heat exchanger of an oil-fuel boiler) Starting and setting up the boiler. | 8500 rub. |

Do you already have an estimate? Send it to us.

What does servicing of Proterm boilers include?

Professional, fast, reliable

- Diagnostics.

Our technician will check the operation of the ventilation and the entire heating system (tightness of connections, boiler protection, etc.). He will decipher all Protherm boiler error codes and fix problems according to service instructions. - Cleaning Protherm boiler elements.

The technician will clean the boiler burner and filters. If this is not possible, a replacement will be made. This is a mandatory stage of servicing a Protherm gas boiler. - Replacement of parts.

If faulty parts are found during diagnostics, our specialist will replace them. The Servicepoint warehouse has everything you need. - Setting up a Protherm boiler.

After eliminating all problems, the technician will configure the boiler operating modes using the Protherm control unit. - Checking the operation of the automation.

Upon completion of the work, the technician will check the operation of the automation systems, the operation of the regulator and temperature sensor of the Protherm heating boiler.

After the service, the technician will make a note in the passport of the Protherm gas boiler.

Do you want to conclude a contract for maintenance and repair of the Proterm heating boiler? Leave a request on our website.

Methods for flushing the heat exchanger of a gas boiler

Mechanical (manual) cleaning

The simplest, but also the least effective method, great for minor blockages. External cleaning of the heat exchanger fins is carried out with any convenient tools: a toothbrush and other hard brushes, a spatula, a scraper, a cable. Be careful not to remember or break the plates that are vulnerable to strong mechanical stress.

Rinsing in a container with solution.

After rough external cleaning, the heat exchanger must be placed in a container with a solution of hydrochloric or citric acid (a proportion of 100-200 grams per 10-20 liters of water is sufficient), you can use any descaling agent. The heat exchanger must be left to “acidify” in the solution for 30-40 minutes, after which the remaining scale must be carefully wiped off. Also try, as far as possible, to clean the coil through which the coolant moves from the inside. It is better to use a special steel brush as a cleaning agent.

Dry cleaning

It involves pumping more aggressive chemicals through the heat exchanger using a circulation pump connected to the heat exchanger pipes.

So, how to flush the heat exchanger of a gas boiler:

1. Citric Acid – Citric acid washing is the most common DIY method. 2 standard bags of 100 grams per 10-12 liters of water are enough. It is better to use warm water (50-70°C).

2. Thermal Agent Active is a well-known universal and effective liquid for washing heat exchangers of heating equipment from scale, limescale, salt and other deposits. The concentrate is diluted in a ratio of 1 to 9; to increase efficiency, it is better to use water heated to 40-50°C.

3. STEELTEX Cooper - is also one of the most effective products, but is recommended only for use for cleaning heat exchangers made of steel, aluminum and other light alloys. The concentrate contains corrosion inhibitor additives. Diluted in proportion with water from 1:6 to 1:10, depending on the degree of contamination.

4. Detex concentrate liquid – contains effective biodegradable surfactants, designed for washing steel, cast iron and copper heat exchangers of modern boilers. Diluted to achieve a concentration of 2-5% (200-500 ml per 10 l).

5. Hydrochloric acid – effective for severe scale, used in a concentration of 2-5%. It is important not to overdo your concentration.

We recommend using 10 liters of solution, this will be enough for stable pumping through any heat exchanger. A hose connected to the heat exchanger is placed in a container with a solution (canister, durable container, plastic bucket). Next, on the other side of the heat exchanger, a hose is connected to the circulation pump and, finally, a hose goes from the pump to a container with a solution, as low as possible to the bottom or hermetically mounted into the bottom of the container. As a result, the solution circulates between the canister and the heat exchanger.

The duration of pumping is 30-40 minutes, after which the heat exchanger must be thoroughly rinsed several times with ordinary running water.

Hydrodynamic flushing

To carry out cleaning, it is not necessary to disassemble the boiler and remove the heat exchanger. However, only specialists can carry out the process, since special equipment and strict adherence to safety precautions are required.

The principle of hydrodynamic flushing consists of running a special liquid through the system under high pressure using special equipment - a booster. For greater effectiveness, the liquid contains abrasive substances.

An important point is the pressure during flushing, which should be as high as possible, but in no case exceed the maximum permissible limits of the most vulnerable elements of the system. Usually the most vulnerable element is the heat exchanger itself, the maximum permissible operating pressure of which in many models is 1.5-2 bar.

However, the method is the most effective: abrasive particles clean sediments on the internal walls well, and the high speed of water movement washes the coil to its original appearance.

Why is it profitable to entrust Servicepoint heating boiler maintenance?

5 reasons to sign a contract

| Unlimited number of emergency trips | The agreement with Servicepoint provides for an unlimited number of emergency trips. Call us whenever you need help! |

| Security Guarantee | We comply with safety requirements when working with gas equipment. You don't have to worry about the safety of property or negative consequences when working with gas. |

| Confidence in the stable operation of the heating system | Regular maintenance will ensure that your heating system is in good working order. |

| Professional advice | Do you have any questions about operating your gas boiler? Call us. We will answer all questions and give recommendations. |

| 30 minutes for a technician to visit | No hot water in the house? Call us at any time and in 30 minutes the specialist will be with you. |

Do you want to use our services? Leave a request.

Rinsing and descaling

The procedure for removing scale from the internal heat exchange surfaces of gas boilers is performed in two ways: with and without removing the heat exchanger. If you intend to regularly clean and flush your heat generator, then it is more advisable to choose the second option. Each time disassembling the boiler to remove the heat exchanger is quite a troublesome task. Yes, and the designs of heaters are different, some need to be laid out almost by screws.

To wash the boiler without disassembling it, you will have to make a washing installation - a booster - with your own hands. It is a 15-20 liter container, filled with a washing solution, with connected hoses. Their ends are connected to the supply and return pipes of the heat generator and turn it on for heating. Circulation is provided by a separate pump, the same as in the heating system. It’s even better when the farm has a reversible pump to periodically change the direction of liquid flow.

In a booster for a bithermic heat exchanger, you should not use a water pump; it is better to find a circulation pump for heating

Advice. Place a mesh filter on the hose supplying the solution from the booster to the heating unit so that the scale does not circulate in a circle. It is possible that during washing it will have to be cleaned several times.

Before flushing the main heat exchanger of a gas boiler, you must perform the following operations:

- Reduce the pressure in the network to zero using a special valve (these are found in some boilers) or a Mayevsky tap on the nearest radiator;

- disconnect the heater from the system and empty it;

- check if your unit model has a built-in mud trap, remove and clean it.

A few words about how you can wash the heat exchanger of a gas boiler. The most popular folk remedy, safe for all elements of the heat generator, is a solution of citric acid and vinegar. According to reviews from users of a well-known forum, 9% vinegar or citric acid, dissolved at the rate of 20 g per 1 liter of water, works well. If necessary, the concentration can be increased.

In addition, there are many commercial products available for sale intended for chemical cleaning of heat exchangers (for example, Antiscale). The washing time is indicated on the product packaging, and when working with citric acid, the duration of the process depends on the degree of contamination and can take from 1 to 3 hours.

Advice. If a reversible pump is not available, then during operation periodically swap the hoses, starting the fluid flow in the opposite direction. If there is reverse flow, the heating must be turned off.

After finishing washing, fill the container with ordinary purified water and rinse the unit from chemicals and remaining dirt, and clean the mud trap again.

Servicepoint - we are always on your side!

Get extra privileges

- Personal expert.

Upon conclusion of the contract, a personal manager will be assigned to you. He will monitor your every application and will always be in touch. - Savings when ordering services.

We will give you a privilege card, with which you can save when ordering our services.

24/7 call center.

You can call us at any time of the day or night, on any day, including holidays and weekends. We will immediately begin working on your application.

How to flush the heat exchanger of a double-circuit boiler

The method for removing scale from the DHW tract depends on the type of heat exchanger installed in your heat generator. There are only two of them:

- bithermal, it combines heating of the coolant and water for hot water supply;

- secondary heater made of stainless steel.

It is better to clean units with a bithermic heater using a booster, since removing such a unit can be quite difficult. Hoses leading from the tank are connected instead of cold water supply and hot water outlet, after which the circulation pump and the boiler itself start. The heating temperature should be limited to 50-55 degrees.

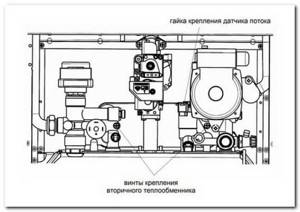

If a double-circuit boiler has a secondary heat exchanger, in most cases it can be removed. Unscrew the front panel, release the control unit and move it to the side. The plate heater for DHW is located at the bottom of the gas boiler and is secured with 2 bolts. Unscrew them, disconnect the pipes and remove the heat exchanger. Next, immerse it in a pan with a solution of citric acid and boil on the stove, which is described in detail in the video:

How to remove the secondary DHW heat exchanger of a Baxi Eco gas boiler

The plate DHW heat exchanger of a BAXI Eco boiler can be easily removed using a screwdriver as follows:

- Close the taps at the boiler inlet of heating water and cold water.

- Drain heating water only from the boiler through the drain valve.

- Drain the water from the DHW system.

- Unscrew the two screws (directly in front of you) securing the DHW heat exchanger and remove it (see figure).

The BAXI Eco boiler is equipped with a cold water filter. To clean the filter, proceed as follows:

- Turn off the tap at the cold water inlet to the boiler.

- Drain the water from the DHW system.

- Unscrew the nut on the water flow sensor block (see figure).

- Remove the water flow sensor unit along with the filter.

- Remove dirt.

In BAXI Eco boilers, I also recommend cleaning the NTC temperature sensor of the DHW system and its location from limescale.

Removing scale by pouring a cleaning solution into the heat exchanger

Watch the video that shows how to remove and descale the secondary plate heat exchanger of a DHW gas boiler "Ariston".

Here, to remove scale, a cleaning solution is poured into both cavities of the heat exchanger. To increase the efficiency of the process, it is recommended to place the heat exchanger filled with liquid in a container in a water bath and maintain it at a temperature above 60 °C for at least 1 hour. Then the heat exchanger cavities are washed under a strong stream of water from the tap.

This simple method is recommended for removing thin deposits.

To fill all the cavities of the secondary DHW heat exchanger of a wall-mounted gas boiler, approximately 0.25 liters of cleaning solution will be required.

The chemical reaction of scale salts with acid produces carbon dioxide. Therefore, the release of gas bubbles can be observed from the openings of the heat exchanger.

If the gas evolution stops, then the chemical reaction has stopped. This can happen in two cases, either there are no more scale salts in the heat exchanger, or there is not enough acid to continue the reaction with the scale remaining there. The acid concentration in the solution gradually decreases as it reacts with scale salts.

If there are doubts about completely descaling the heat exchanger, I recommend rinsing the heat exchanger with a strong stream of water and pouring a new fresh portion of acid solution into it. Repeat the entire cleaning process. If you see that gas bubbles have reappeared, then you didn’t do it in vain.

Forced circulation of the solution in the heat exchanger removed from the boiler

And from the following video you will learn how to remove a bithermic heat exchanger using the Nova Florida boiler as an example.

In this option, the heat exchanger removed from the boiler is connected to a pumping unit, with the help of which the cleaning solution is forced to circulate through the heat exchanger channels. The bithermal heat exchanger has a complex channel configuration.

During the cleaning process, it is recommended to change the direction of movement of the solution in the heat exchanger.

This cleaning method allows you to quickly and efficiently remove significant scale deposits from a heat exchanger with a curved channel shape.