Currently, many consider solid fuel water heating boilers to be obsolete, but under certain conditions a full-fledged heating system cannot operate without them.

Coal and firewood are the main types of fuel for solid fuel boilers. Long-burning devices for heating a private home can increase the effect of an autonomous operating process, since human intervention is required once every 2-4 days.

Types of solid fuel boilers

Solid fuel boilers are manufactured only with a floor-mounted installation option; they can be designed to burn only one type of fuel, like classic units, or for different types of fuel, like pyrolysis and pellets.

The devices are often produced as single-circuit ones, but in most versions they have the ability to turn on an external boiler for indirect DHW heating. In addition, modern solid fuel boilers are equipped with electric heating elements to maintain the temperature of the internal heating circuit at night or in the absence of residents of the house.

Classic

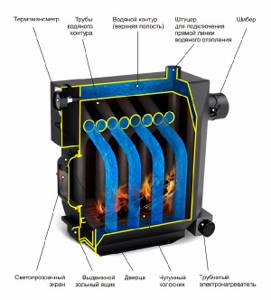

These modifications of the units are already more than two hundred years old and they have a traditional design. They are equipped with a combustion and ash chamber, a capacitive heat exchanger in the form of a water jacket and a smoke ventilation system.

Such units operate on any solid fuel. They are ineffective because they do not have developed heating surfaces. This leads to large heat losses in them with flue gases, of the order of up to 20%.

In addition, they do not have automatic fuel supply; fuel is filled manually every 2-3 hours. The units operate with natural exhaust of flue gases into the atmosphere; the combustion process is controlled manually, through an air supply control valve.

The heating circuit is connected to the in-house heating system, which operates on the principle of natural circulation. Typically, the power of such units is not high; they are capable of heating houses with an area of no more than 150 m2.

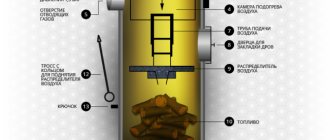

Pyrolysis

The normal functioning of units of this class occurs in the generation mode based on smoldering fuel with the release of volatile substances. In heating engineering, such a technological process is called pyrolysis.

As a rule, wood is used as energy carriers. Under the influence of high temperatures and air deficiency, they split into gaseous volatile substances, which burn in the pyrolysis chamber, generating thermal energy, which is transferred through the heat exchanger to the heating coolant of the heating circuit.

To implement the pyrolysis process, the firebox is divided into 2 working chambers. In the main stage, the fuel smolders, releasing flammable gases that burn out in the afterburning zone at a temperature of 1200 C, enriched with secondary air.

Peletnye

Such boilers burn specially prepared fuel - pellets in the form of granules obtained during the processing of industrial and agricultural waste: sawdust, plant fragments and peat.

They are characterized by low humidity and a very high calorific value and a certain fluidity, which makes it possible to organize the automatic supply of fuel to the boiler without human intervention.

The boilers are equipped with an automatic ignition and combustion process control system, which results in high efficiency indicators - efficiency up to 92%. The units are capable of heating rooms with a large area - 1000 m2. They are environmentally friendly because they ensure complete combustion of harmful substances in the fuel.

Principle of operation

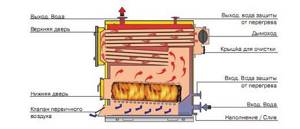

This unit is a direct combustion boiler, that is, fuel is burned in it in the most common, uncomplicated way. The resulting ash is poured into the ash chamber, from where it must be removed periodically.

The most convenient to maintain are boilers in which the manufacturer has installed a pull-out tray in the ash chamber.

Fuel loading and ash removal are carried out traditionally - through the corresponding doors in the housing. The difference from conventional solid fuel heaters is the increased size of the firebox and the presence of a water heating tank. Note that boilers of this type are not double-circuit. Here, rather, we are talking about an indirect heating boiler (and partly direct), built into the boiler body.

Operating principle of the boiler

But indirect heating here is not entirely ordinary. As is known, in indirect heating boilers, heat is delivered to the heated medium using water or other coolant fluid (oil, antifreeze), which fills the heating circuit. In a water heating boiler, thermal energy is transferred using air: inside the water heating tank there are tubes connected to a heat exchanger installed in the firebox, and this entire system is essentially empty, that is, it is filled with air that circulates in it.

At first glance, such a solution may seem strange, because we are accustomed to seeing water as a coolant, the heat capacity of which is 800 times greater than the heat capacity of air. But everything falls into place if we remember that the intensity of heat transfer depends not on heat capacity, but on the temperature difference. Air, due to its low heat capacity, heats up faster than water, which means it will give off heat more actively. Since all components are located inside the boiler body, there is no heat loss, so there is no need to use a coolant with a large heat capacity.

The location of the tank affects the efficiency of the water heating system. The best performance is demonstrated by boilers in which the hot water tank is located above the firebox, and not on the side of it. This is explained by the tendency of heated air to rise.

Solid fuel boiler

Boilers equipped with a fan can operate longer on one load of fuel than those without one. This system works as follows:

- The user sets on a special panel the temperature that must be maintained in the water heating tank, after which he closes the firebox door (in such models it is sealed) and starts the fan installed in the air duct connected to the firebox.

- As soon as the temperature sensor detects the heating of the water to the desired temperature, it will send a signal to the controller and it will turn off the fan. In this case, the so-called gravity damper in the air duct will lower under its own weight (it opens only during operation of the fan - by the air flow), so that the oxygen supply to the firebox will be completely blocked. This will cause the fire to die out, but the coals will remain - the boiler will go into standby mode.

- When the water cools down, the sensor will signal the controller again and it will start the fan. The latter will fan the coals in the firebox and the fire will flare up there again.

Thanks to this scheme, the operating time on one portion of fuel can be extended from 4 hours to 8–10.

The higher the boiler fan is located, the better: blowers installed near the floor draw dust, which clogs the air duct and causes slagging in the firebox.

Automation and piping of wood-burning boilers

As already mentioned, the boiler power can be adjusted only by changing the amount of oxygen supplied. This system works most efficiently and accurately in pyrolysis-type mine boilers using wood or briquettes.

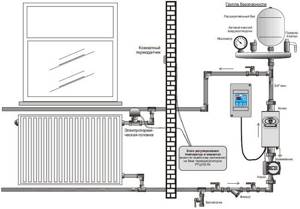

The main automation complex includes an electronic control unit, a fan, an electrically driven draft regulator and a thermocouple tightly wound to the supply pipe. All these components are sold both individually and in sets for a specific boiler model. On average, all automation costs about 4-5 thousand rubles

We would like to separately mention the importance of having protection against falling dampers and sealing grooves on loading and inspection hatches, the chimney, and the draft stabilization system

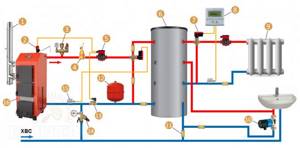

For solid fuel boilers, a number of other types of protective devices are provided, installed in the hydraulic piping. Among the absolutely mandatory ones are a circulation pump and protection of the firebox from overheating - a safety group for relieving excess pressure

Please note that the outlet of the relief valve must be turned towards the wall or equipped with a hose so that when activated it does not injure anyone present. Safety requirements may require the installation of a chimney bleeder valve to stabilize draft and combustion; it is mounted immediately at the outlet of the boiler or immediately before the final vertical section. Connection diagram for a solid fuel boiler with a heat accumulator: 1 - chimney; 2 — thermostat; 3 - security group; 4 — air separator; 5 - circulation pump; 6 - heat accumulator; 7 - three-way mixer; 8 — weather-dependent automatic; 9 — heating radiator; 10 - circulation pump; 11 - check valve; 12 — expansion tank; 13 — protection against dry running; 14 — make-up valve; 15 — overhead temperature sensor; 16 - solid fuel boiler

Connection diagram for a solid fuel boiler with a heat accumulator: 1 - chimney; 2 — thermostat; 3 - security group; 4 — air separator; 5 - circulation pump; 6 - heat accumulator; 7 - three-way mixer; 8 — weather-dependent automatic; 9 — heating radiator; 10 - circulation pump; 11 - check valve; 12 — expansion tank; 13 — protection against dry running; 14 — make-up valve; 15 — overhead temperature sensor; 16 - solid fuel boiler

For cast iron boilers, it is practiced to install a two-way valve that mixes water from the hot outlet to prevent cold water from entering the heated firebox. When installing a heat accumulator, a three-way electric valve is added, which starts the supply of heat to the tank only after the main composition has warmed up. Control is carried out based on the return temperature, the additional circuit is turned on 7-10 ºС before the cut-off temperature is reached. In this aspect, control units with a PID controller are most preferable.

Types of hot water boilers

Like all solid fuel units, water heating devices and traditional boilers have their own specific power parameters. Models of heating devices operating on coal are more powerful. The power range on different units in this case varies within the following limits:

- for low power equipment 4 kW – 65 MW;

- average power devices 70 kW – 1.8 MW;

- high-power boilers, starting from 1.8 MW and above.

Units running on wood are weaker than their “coal counterparts”. In this case, the power of hot water boiler models ranges from 4 kW to 1.3 MW. It should be noted that wood-burning equipment has a large combustion chamber for a larger one-time fuel load. In such devices, high combustion intensity is achieved and there is virtually no underburning of the fuel mass.

In order to prevent the accumulation of small residues of unburned fuel, the boiler design has a rotating chamber at the exit from the main combustion chamber.

Note: Water heating units that use wood as the main fuel are usually loaded manually. The cleaning and cleaning of this equipment is no less costly and difficult. Removal of slag and ash components is carried out manually.

In addition to dividing heating equipment by type of fuel, water heating boilers should be divided by the method of coolant circulation. The most commonly used ones include the following:

- boilers with natural circulation;

- forced circulation technology;

- equipment that uses a combined circulation option;

- direct-flow hot water boilers.

In the first case, we are talking about heating units, where the circulation of boiler water is carried out due to different densities of the liquid. In the second case, we can talk about coolant circulation caused by the operation of an electric pump. In combined units, both the first and second options are used, depending on the technological need. The latter option includes heating devices, where there is a forced direct flow of the coolant towards the outlet.

High-power hot water boilers are equipped with fans that force air into the combustion chamber. Such models, as a rule, are equipped with smoke exhausters for balanced draft and are placed in separate rooms equipped with fire-fighting equipment.

Design features, classification by temperature and method of execution

The hot water boilers found on the shelves today have a relatively identical design. Significant differences lie in specific manufacturers (they are both foreign and Russian), as well as in the maximum power of the equipment.

If we talk specifically about design features, then from this point of view, boilers can be gas-tube (or, as they are also called, fire-tube) and water-tube. Let's take a closer look at each of the categories.

- Fire tube models. Their distinctive feature can be considered the presence of special tubes through which heated combustion products of energy carriers move. As for the operating principle of such equipment, it is based on the use of automated burners equipped with blower fans. Thanks to the smoke tubes, the water outside them is heated. It is worth noting that such models are almost never used in everyday life.

- Water tube models. They are characterized by special boiling tubes through which the coolant moves. And fuel combustion products are used to heat these tubes. Water-tube boilers warm up quickly enough, you can easily adjust them if the loads change. In addition, the operation of this equipment also involves the possibility of serious overloads. As for the explosion hazard of these boilers, it is at a fairly low level.

Note that the low-temperature operating mode provides for fairly economical fuel consumption, but at the same time condensation appears on the surface of the device, which can negatively affect materials in contact with the products of combustion of energy resources. For this reason, extremely stringent requirements are placed on the materials used in the production of boilers.

Units that generate superheated water are characterized by a long service life and high reliability. During operation, they make virtually no noise, and waste emissions are minimal. These units are also equipped with convenient and simple control systems. They are installed quickly and do not require labor-intensive maintenance.

DIY making

It’s easy to make a simple hot water boiler yourself. Here's what you need to consider:

- The choice of firebox material should take into account what type of fuel you plan to use. Coal is characterized by a much higher combustion temperature than wood, so sheets for making a coal boiler firebox should be thicker - thin steel will quickly burn out.

- The ideal material is special heat-resistant boiler steel. In second place is alloyed heat-resistant steel with additions of chromium and molybdenum, for example, grades 12ХМ or 12Х1МФ. If you plan to use ordinary steel, then it should have a grade lower than steel 35. In steels of higher grades, when heated, a hardening effect occurs, as a result of which they become brittle.

Kits consisting of a fan, a temperature sensor and a controller are available for sale (for example, from the Polish company KG Elektronik), with the help of which it is easy to organize forced air supply into the firebox (see above for the description of the operation of a boiler with a fan).

Electric hot water boilers - features and reasons for popularity

Such natures are very popular in Russia. They are produced by many manufacturers - both Russian and foreign. These boilers make it possible to provide housing not only with heat, but also with heated water, regardless of whether there is a centralized hot water supply in your area.

Electric boilers have a simpler design than, for example, gas boilers and do not require regular maintenance. Moreover, they are easy to operate and cannot explode

What can we say about such an important parameter as environmental safety?

Design features of electric hot water boilers

Such devices consist of the following elements:

- heat exchanger (it is a container in which an electric heating element is built);

- automation (necessary to maintain the required temperature in the room, but without direct human participation);

- closet.

Typically, not only ordinary water, but also non-freezing liquid can act as a coolant (this option is more preferable). Such boilers can also be divided according to the type of heating element used.

- Models with tubular heating elements. Such elements are filled with a special conductor that heats up when in contact with electricity. Capable of permanently heating running liquid, but subject to connection to an electrical network. Tubular heating elements are used in cases of combined heating. Who doesn’t know, during the day such systems operate from a heating device using liquid/solid energy or gas, while at night, when the cost of electricity decreases, they keep the house warm using it.

- Models with electrodes. Electrode-type units heat the liquid through an ion flow that forms between the electrodes (this is written in the description). The main advantage is the absence of heating elements, but due to the fact that the most important component of the circuit is the coolant, it must be properly prepared. Salt must be added to the liquid in a certain amount to obtain the desired concentration.

Factors that ensure efficient operation of the device

There are several requirements that must be met for the hot water boiler to operate efficiently.

Before describing the main design and technical characteristics, it is worth highlighting several main indicators that affect the quality of work, which are considered general and are suitable for any device.

These include the operating diagram of the hot water boiler and parameters such as:

- Equipment manufacturer.

- The quality of the device and its elements.

- Availability of a warranty period for operation and maintenance of equipment.

To operate efficiently, you need to pay special attention to the firebox. It must have a sufficient volume to burn the entire volume of loaded fuel.

According to experts, this parameter is an important calculation indicator that determines the total amount of mechanical fuel.

Which boiler is better

When considering long-burning solid fuel boilers, the rating of the best on the Internet or from the mouth of a representative selling them will be somewhat ambiguous. There are numerous ratings of solid fuel heating boilers for private homes, which are compiled based on different criteria. For example, sales volume on the market, owner surveys, expert assessments of reliability and efficiency specialists. But to say unequivocally that some model is “the best” is at least incorrect. If only because of the different operating principles and subjective approach when choosing boiler equipment.

Russian boilers are simple but reliable, and are considered by specialists to be among the best in their class in terms of price/quality ratio. Source poc.ledikycora.ru.net

If energy independence, low price and unpretentiousness to the type of fuel are important, then this should be a traditional boiler design with natural draft. And in this case, you can limit yourself to choosing among domestic manufacturers, such as ZOTA, Burzhuy K or Lemax.

And for lovers of comfort, and simply busy people who have little time to care and maintain their heating system, we can recommend pellet boilers.

A pellet boiler, even in a compact form, is capable of operating autonomously for a long time. Source www.opcgate.ru

But even with this division, there are also additional criteria. For example, according to one of the specialized online publications, the rating of pellet heating boilers for a private home looks like this:

Boilers with water circuit

Today, it is possible to ensure the operation of the heating system and heat water for domestic needs using just one device - a boiler with a water circuit.

This device is a regular heating boiler in which a boiler is installed. The latter, as in the case of a hot water boiler, can be located both above the firebox and on the side of it.

The simplest and at the same time the most famous representative of this category of equipment is titanium.

The heat exchanger located inside the firebox is connected to the heating circuit, as a result of which the coolant is pumped through it - now water. Part of this coolant is supplied through a separate branch to a heat exchanger installed inside the boiler, due to which the water in the boiler is heated.

In order for a heater to supply heat to two systems at the same time, it must have significant performance. Therefore, developers use various design solutions to ensure complete combustion of fuel and assimilation of the maximum possible amount of energy released.

To maximize heat transfer from a solid fuel boiler, use only well-dried fuel.

Types of solid fuel boilers

Now we will consider the existing types of solid fuel boilers, applying to them the selection criteria indicated above. So, at the present time the following types of heating units are offered on the market:

- traditional, direct combustion;

- pyrolysis;

- long burning;

- pellet

From the point of view of low cost of equipment, the best choice is traditional boilers using wood or coal. In a budget version, they are non-volatile, since the automation in them works without connecting to electricity. This is very important when using a gravity heating system with a solid fuel boiler. As for ease of maintenance, a traditional heat generator needs to be frequently loaded with firewood (once every 4-5 hours at maximum operating mode), harvested, and cleaned out the combustion chamber and ash pan. That is, you will have to devote a fairly large amount of time and put a lot of effort into heating the house.

It is also necessary to take into account the fact that heating in a wooden house with a solid fuel boiler will require the construction of a separate warehouse for firewood or coal. Its dimensions are approximately calculated in this way: the thermal energy consumption for the season is calculated and divided by the calorific value of the fuel, multiplied by the boiler efficiency value (in fractions, not percentages).

For example, in a temperate climate zone, heating a private house with an area of 100 m2 requires spending approximately 21,000 kW of thermal energy per season. If you heat with wood, then you need to take their calorific value, equal to 4.5 kW / kg, and multiply by the efficiency of the unit (0.75 for a traditional boiler), and then divide the total requirement by the resulting value: 21000 / (4.5 x 0.75) = 6222 kg or 6.2 tons. In simple words, this is 1 Kamaz of firewood, and for this volume you need to plan a storage area or at least a shed.

Fuel types

The term “solid” speaks for itself.

This is what boilers happily consume, giving in return the benefits of civilization in the form of warmth and comfort.

- Hardwood.

- Charcoal and coal.

- Pellets (granules from wood waste).

- Briquettes made from wood chips and sawdust, cones, peat.

The last point is easy to organize with your own hands if you collect forest gifts nearby and use a simple press.

Separation based on combustion principle

The photo shows the device of a pellet boiler.

The most popular types of devices are:

- Traditional boilers.

- Analogues of long burning, where combustion occurs from top to bottom (and not from bottom to top, as in conventional ones). They are convenient because the frequency of fuel filling occurs less frequently (up to once a day).

- Pellet units, with automatic placement of granules into the chamber.

- Gas generator (pyrolysis) devices. The increased efficiency is due to the use of heat from the released gases, which is not the case in the types listed above.

How to choose the right boiler connection diagram

In order to keep the house warm, it is not enough to know what heating schemes are available with a solid fuel boiler. Craftsmen who have been creating heating systems for many years give the following recommendations:

- When creating a drawing of a heating circuit for a solid fuel boiler, you should first familiarize yourself with the types and operating principles of such heat generators. This can be a constant or long-burning heater, a pyrolysis or pellet unit, or a buffer. Each of these devices has its own operating criteria, which may be disadvantages for some, and advantages for others.

- To get an ideal heat supply scheme, you need to be able to combine the functioning of the boiler with the tank, since this element accumulates thermal energy. This is justified by the fact that the element heating the water can change its temperature in the range from 60 to 90 degrees. There is no constant indicator. Since solid fuel boilers are inert devices, this distinguishes them favorably from gas, diesel and electric analogues.

- When choosing a heating scheme, you need to objectively assess the risk of power outages. If there are frequent power outages in the area, then a system with a water pump will not only not pay for itself, but may quickly fail. Therefore, it is better to choose a type of heating with natural circulation.

- When choosing a piping, it is worth considering in advance the safety lines between the boiler and the tank. They are located at the points of the inlet and outlet pipes so that they are as close as possible to the water heater. Also, to achieve maximum effect, you need to try to keep the distance between the boiler and expansion tank to a minimum. But it is no longer possible to install safety valves or taps here.

- If a scheme with a pump was chosen, then it is installed on the return pipe, as close as possible to the heat generator. Thus, even if the lights are turned off and the pump stops working, the water will continue to move along the circuit, that is, minimal heat will be retained. The device must be installed along a bypass route. Only then will it be possible to disconnect it from the network (if necessary), and shut off the circuit itself using taps.

- There is such a thing as bypass. These are jumpers with taps that are placed between the supply line and the return pipe. This arrangement facilitates the return of “extra” hot water when the volume changes through the thermostat.

- A stainless steel valve must be installed in the chimney pipe. Since there is moisture in the smoke, albeit in small quantities, it is this that can provoke the destruction of the internal part.

Tying is a process that deserves special attention. Therefore, they design and install it only if they have complete confidence in their abilities. Nikolay Avramenko, 51 years old

Energodar

Nikolay Avramenko, 51 years old, Energodar

Having read the article, I would like to add my note. The topic of operational characteristics of solid fuel boilers was touched upon here. It was indicated that they have such a feature as high inertia. I would like to say that this phenomenon is not typical for pellet boilers. This is due to the fact that such devices have a burner that receives wood pellets in portions. Therefore, when the supply of raw materials stops, the flame immediately goes out. Although such boilers are not so cheap.

Anton Abramov, 29 years old, Omsk

At one time, I was interested in the work of solid fuel boilers, as they offered me a position related to this area. I would like to leave a few words about the thermostat and its regulatory features. You need to understand that when a certain temperature is set, for example, at 85 degrees, even though the damper is closed, the burning and smoldering continues. Because of this, the water still heats up a couple of degrees, and only then it will be established accurately. Therefore, you should not turn the thermostat back and forth, otherwise this may lead to breakdown of the entire system.

Nikita Karpenko, 37 years old, Arkhangelsk

When we built a house outside the city, we planned to live there all year round. The time came when it came to heating, and I settled on a closed-type system with natural circulation. Firstly, it was quite easy for me to create it with my own hands, and secondly, we were already a little limited in money. I didn’t have any particular problems with the installation, but when the first cold weather arrived, I realized that there was clearly not enough heat for the house. So at school, I was quite good at physics, and I realized that heat is “lost” in areas where the pipes were left open. Taking a roll of mineral wool, I wrapped all the pipes that run in open areas. Literally by the end of the first day, our family felt a significant warming in the rooms. Therefore, you need to remember such moments.

How a homemade long-burning boiler works

Principle of operation

The operation scheme of such boilers is based on the ability of solid fuel to smolder for several hours, while producing a large amount of thermal energy. It is typical that in this case the fuel is burned more completely, and the amount of waste, as a result, is noticeably reduced.

Boiler drawing

The main element of the boiler is the firebox, where combustion is limited and the intensity of the air supply is controlled using special devices. The fuel is loaded twice a day in large portions, after which it slowly smolders (the limited amount of oxygen does not allow it to burn fully).

The pipe through which the smoke is removed is passed through heat exchangers and heats the liquid in the heating system. It turns out that all you need to do is load fuel every 12 hours for uninterrupted heating of the house.

Boiler diagram

Main advantages

Long-burning boilers stand out from other types of heating systems. Of course, the main advantage is the duration of the work, but there are other important points:

- low fuel cost;

- autonomy;

- the ability to heat large areas at minimal costs;

- ease of installation and operation;

- safety;

- Possibility of making it at home.

Device structure

To make a boiler, it is more convenient to use a metal pipe ø30 cm or larger with a wall thickness of at least 5 mm (otherwise the latter will soon burn out due to the high temperature inside the device). The height of the structure can vary between 80 cm and 100 cm, it all depends on the area of the room.

Housing pipe

Regardless of the modification, the boiler consists of three main zones:

- loading area;

- zones of smoldering and heat generation;

- final combustion zones where ash burns and smoke gases are removed.

This element is made in the form of a metal circle 5-6 mm thick with a hole in the middle, through which oxygen is supplied to the firebox using a telescopic pipe. The diameter of the product should be slightly smaller than the diameter of the body. The height is adjusted using a special impeller.

Long-burning wood-burning boilerLong-burning wood-burning boiler

Long burning boiler

Air can be supplied in one of two ways:

- straight from the atmosphere;

- from a special heating chamber (it is located in the upper part of the structure), which ensures more efficient operation of the boiler.

A special air damper is used for adjustment.

The chimney pipe is welded on top. It must be perpendicular to the body for at least 0.5 m, otherwise excessive draft will be formed.

A door is equipped at the bottom to remove combustion products. Cleaning should be done infrequently, because the fuel will burn more completely.

There are two ways to heat the coolant, each has its own strengths and weaknesses.

Long burning boilerLong burning boiler

Method No. 1. A coil is connected to the heat exchanger pipe passing through the combustion zone, through which the water in the tank is heated.

Method No. 2. A separate metal tank is formed, through which the chimney pipe is passed. The hot smoke heats the liquid.

The first method is more effective, but at the same time more difficult to implement. The second one is easier to do, but it is only practical in small houses.

Design and principle of operation

The principle of long combustion is based on reducing the rate of fuel combustion by reducing the air supply. Oxygen is supplied to the primary combustion chamber in an amount sufficient for smoldering, but not providing intense combustion.

During the slow oxidation of wood, gaseous hydrocarbons are released, called pyrolysis gases. The process of organic decomposition of wood fibers under the influence of high temperature is called prirolysis.

Afterburning of oxidation products in the secondary chamber does not have a significant effect on the duration of combustion of the fuel fill, but significantly increases the overall efficiency of the wood-burning boiler. This is due to the fact that during the combustion of secondary gases, much more thermal energy is released than during intensive burning of wood.

Energy-dependent long-burning installations

The layout of long-burning wood-burning boilers involves the location of the main combustion chamber directly above the combustion zone of secondary gases, and communication between them is carried out through special ceramic nozzles capable of operating at temperatures from 800 to 1000 C. The bottom of the main fuel compartment is equipped with a special heat-resistant bed, most often made of fireclay bricks or ceramic concrete blocks.

Directed air movement (draft) is provided by a blower fan, the rotation speed of which determines the amount of oxygen in the work area. Based on the data received from the temperature sensor, the automatic control system (ACS) can increase or decrease the angular speed of the impeller. The advantages of this scheme include high accuracy of adjustment. In addition, the air passing through the upper combustion bunker is heated, which simplifies the process of ignition of pyrolysis hydrocarbons.

The intensity of coolant circulation in the heating circuit is regulated by a pump, which is also connected to the automatic control system. If the coolant temperature decreases, the air supply automatically increases.

The accuracy of adjustment and efficiency of energy-dependent long-burning wood heating boilers provide significant savings in firewood, which amounts to a significant amount over the entire heating season. However, one should not discount the fact that in the absence of power supply, such a boiler becomes a useless pile of scrap metal, since natural draft is, as a rule, not provided for in such designs.

Non-volatile long burning wood boilers

Despite the fact that the efficiency and productivity of such installations are noticeably lower than those equipped with automated control systems, they are completely independent of the availability of electricity, which is their significant advantage. The disadvantages of such systems include, first of all, the complexity of configuration.

In such a wood-burning boiler, the oxygen supply is adjusted by opening a special damper, which has a kinematic connection with a bimetallic thermostat located on the top cover of the product.

After igniting the wood load and obtaining stable combustion, the damper is brought into the operating position, thereby reducing the amount of air in the primary combustion chamber and providing optimal conditions for the chemical-thermal oxidation of wood fuel. Hot pyrolysis gases, under the influence of natural draft, enter the upper combustion chamber, where they mix with heated secondary air, as a result of which they ignite.

The coolant circulating in the water jacket quickly heats up due to contact with the hot walls of the combustion chamber. The high performance of such structures is ensured by a large heat exchanger area.

Reverse combustion wood fired boilers

The main feature of such devices is that the primary combustion process occurs in the direction from the upper layers to the lower ones.

The design is a vertically located cylinder with a rod and a pressure disk, ensuring uniform distribution of air over the entire combustion surface.

The gases formed as a result of pyrolysis enter the upper part of the housing, where they are mixed with preheated secondary air and ignite. The hot side surface is in direct contact with the coolant entering the heating circuit through the outlet pipe. For greater efficiency, the device can be installed in a protective casing, and the resulting cavity is filled with polyurethane foam or other non-flammable heat insulator.

Design features of a hot water boiler

A traditional unit of this type is a metal welded structure, which necessarily has a supporting frame, a frame, equipped with thermal insulation and protective materials. The main element of the design, as mentioned earlier, is the system of water heating pipes - a heat exchanger, through which boiler water circulates. The outside of the boilers is sheathed with sheet iron.

The very design of the device and the principle of operation indicate that these units are quite large in size. Models of different types have combustion chambers designed for different methods of loading and supplying fuel.

A ready-made, factory-assembled hot-water solid fuel boiler is a single block in which all structural elements can be divided into two parts: a screen surface and a convective surface. The surfaces are made of solid rolled steel pipes with a diameter of 76 mm. Installation of fins is provided between the pipes. This design feature of the heat exchanger allows one to minimize heat losses and reduce the leakage of hot gases through the body of the unit. All elements are connected into a single structure using a welding joint capable of withstanding pressure up to 10 atm.

*

Important! All internal connections of the water heating circuit must be welded only. High temperatures and pressure in the system place special demands on welding operations.

Loading of coal or firewood is carried out through a combustion unit, which is equipped with conventional or rotary grates (for boilers with manual fuel supply). Under the combustion part, when installing the boiler in the support frame, an air duct is installed at the very bottom, through which air masses will be pumped into the combustion chamber.

Cleaning heating equipment looks especially interesting. In manually fed units, ash and soot are removed through a special hatch. In mechanical feed devices, all similar processes are carried out by special mechanisms - conveyors.

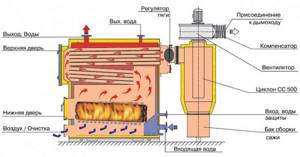

Pyrolysis boilers

The operating principle of these heat generators is based on separate combustion in two chambers communicating with each other through a nozzle made of refractory bricks. In the primary chamber, located on top, firewood smolders with limited air supply from the fan. As a result, a process of pyrolysis occurs, otherwise known as gasification, during which a mixture of flammable gases is released. It moves to the second chamber, where it is burned when secondary air enters. The working diagram of a pyrolysis boiler operating on solid fuel is as follows:

Flue gases from the secondary furnace enter the fire tube heat exchanger in the form of vertical flues surrounded by a water jacket. There they cool, transferring heat to the water, and leave the boiler through the chimney pipe. The performance of the fan is controlled by an electronic unit - controller, based on the readings of pressure and temperature sensors.

In general, the heat generator has good efficiency indicators - about 80%, but the unit is significantly more expensive than a classic one. In addition, the boiler shows high efficiency only when operating on dry wood, although this statement is also true for other solid fuel units.

Types of heating boilers

The type of boiler we are interested in is produced only in a floor-standing version - its mass is too large. And if you do not take into account the positions already described, then these are ordinary solid fuel boilers. Logic dictates that the power of such models depends on the intended purpose of the fuel unit. There are devices with minimum parameters - 7 kilowatts, and there are also with maximum parameters - up to 95 kilowatts. Such colas are mainly used for heating small houses. But there are also more powerful installations, for example, with 200 kilowatt power. They are used to heat houses with an area of more than 2000 square meters.

In the production of boilers, steel or cast iron is used, but even the steel differs from one manufacturer to another, which will affect the cost of the device. For example, heat-resistant metal is many times more expensive than low-grade metal, and, accordingly, such a boiler will cost more. Some models use fireclay bricks to line the firebox. This increases not only the cost of the unit, but also its strength and durability. By the way, such models can be single-circuit or double-circuit.

Heating boilers installation

This is not gas equipment, so you can install it yourself. True, there are several important warnings from experts:

- The boiler must be installed at a distance of at least half a meter from the nearest walls. The fact is that this heating device, even if it has a water jacket in its design, gets very hot. And if the walls of the house are built from flammable materials, they must be additionally sheathed with protection. For example, an asbestos sheet, brick or galvanized steel sheet, under which asbestos will still have to be laid.

- Any, even the most low-power boiler in this category, has a significant mass. Therefore, you need to take care of the frame on which it will be placed. The frame must be strong, non-flammable and reliable. Keep in mind that the weight of the boiler will increase due to the weight of the filling. Therefore, the best option is a free-standing foundation, built according to all construction canons with the laying of a crushed stone cushion and a reinforcing frame made of metal reinforcement. By the way, experts advise pouring a foundation at least half a meter high.