Here you will learn:

- Features of pyrolysis boilers

- Operating principle

- Advantages and disadvantages

- Fuel used

- Popular models

Heating houses with solid fuel boilers is quite common in small settlements where there is still no gas. In most cases, the most common firewood or fuel briquettes are used as fuel.

The disadvantage of such boilers is that they force many approaches to add new portions of fuel. Long-burning pyrolysis boilers are devoid of not only this drawback, but also some others - we’ll talk about this as part of our review.

Pyrolysis: what is it?

Even in ancient times, people realized that burning wood was not the best way to release energy. The most effective was the use of charcoal .

At that time it was not yet known that the process of burning coal was called pyrolysis. Essentially, this is the breakdown of organic substances, possible under the influence of high temperature. To prevent such decomposition from becoming simple combustion, it is necessary to limit the access of oxygen. Coal pits were previously used for this, but an important disadvantage of this method was the loss of energy that is released during the burning of coal. To avoid this, special pyrolysis boilers were created.

Operating principle and equipment design

Pyrolysis boilers are like a home laboratory that releases gas from wood that is necessary for heating. In general, pyrolysis is widely used in industry .

We are talking about the breakdown of organic compounds into simple substances. This is possible with limited oxygen and high temperature. The pyrolysis boiler is a two-chamber equipment, in the upper part of which wood pyrolysis occurs at a temperature of 200–800˚C. As a result, it decomposes into gas and charcoal. The mixture of released gas and air enters the lower chamber, where it burns at a temperature of about 1000–1200˚C. This generates a lot of heat. In fact, in modern pyrolysis boilers, gas is burned, not wood, so the efficiency is about 95%.

Using the equipment, according to reviews from owners, is not difficult, because gas combustion is easier to control, which means the control process can be automated .

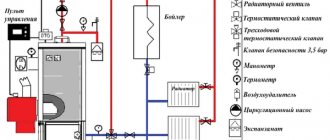

As mentioned earlier, the boiler firebox is divided into 2 chambers, between which there is a grate. In the upper part, smoldering and pyrolysis of the fuel occurs. The gas flows with air into the second chamber, where there is a fireclay nozzle. Such fireboxes are characterized by high aerodynamic resistance, because forced draft is used here.

Pyrolysis boilers are divided into several types based on the location of the combustion chamber:

- upper loading compartment - in this case, the gas after combustion of the fuel moves through the pipe and enters the lower part of the firebox, and the ash falls into the afterburning chamber, due to which it is frequently cleaned;

- lower chamber - this option is considered more preferable, because processed products immediately enter the chimney, which means that the unit will need cleaning less often, but additional costs will be required to equip the chimney.

It is worth noting that 2 types of ventilation can be used for the operation of the equipment:

- natural - needs a high chimney, which provides powerful draft;

- forced - in this case it is necessary to connect to the electrical network and have a pump system.

The duration of the boiler operation depends on the temperature, type of fuel, and the quality of the home’s thermal insulation. In any case, such pyrolysis boilers are considered more efficient in contrast to traditional solid fuel models.

Features of operation

Before starting the boiler, you need to familiarize yourself with the features of its operation. Unlike traditional solid fuel analogues, the loading hopper of this model requires pre-heating. When the temperature in this reaches 500–800˚C , solid fuel can be loaded. After this, all that remains is to start the pyrolysis mode and activate the smoke exhauster.

The mentioned sequence of actions will make it possible to burn the fuel slowly. As a result, the effective release of pyrolysis gas occurs, which means that the optimal temperature regime will be maintained in the home.

Operating efficiency factors of pyrolysis boilers

The performance of heating equipment, the efficiency and speed of heating the premises, in addition to fuel resources and their humidity, are influenced by the following factors:

Choose a boiler depending on the characteristics of the room

- room temperature;

- temperature level to be achieved;

- presence (absence) and quality of building insulation;

- specifics of the current heating system.

Suitable fuel

Owners of such equipment mention in their reviews that various solid fuels are suitable for heating. This can be coal, peat and wood . Naturally, the chosen option affects the combustion duration:

- 5 hours – soft wood;

- 6 hours – hardwood;

- 8 hours – brown coal;

- 10 hours – black coal.

Experts recommend giving preference to dry firewood with a humidity of up to 20% and a length of 45–60 cm. Thanks to them, a lot of heat is generated and the life of the boiler is extended. If such high-quality firewood is not available, you can use other organic fuel :

- pellets;

- wood waste;

- some types of peat;

- coal;

- food industry waste containing cellulose.

It must be remembered that pyrolysis boilers will have a white flame and will not begin to emit by-products if they use fuel whose humidity does not exceed 20%. If this parameter is higher, the release of water vapor is inevitable, which will lead to the formation of soot and deterioration of the calorific value.

Owner reviews

Anna Limeiko, 32 years old, Zaporozhye

I am the mother of a little son, who is now 5 years old. When we were 3 years old, we were diagnosed with an allergy, and it was never possible to identify a specific irritant. Therefore, the doctor advised us to move out of town. So my husband and I decided to convert our dacha into a country house. There were no special issues with this, except for heating. Our friends gave us a solid fuel boiler and my husband connected it to the system. On his first day of work, his son developed a terrible cough. As it turns out, such a unit produces a large amount of harmful impurities, which provoked an attack in the child. Having decided to change the boiler, we settled on a pyrolysis unit, and did not regret it at all. Firstly, we only fill it up in the evenings, and secondly, we’ve had it for over a month now and our son has never had any health problems. And this is not to mention the fact that this boiler produces a minimum of ash and soot, which is why it is quite easy for me to care for.

Anatoly Reznichenko, 45 years old, Volgograd

I got the house from my parents. Heating there was always only from a wood stove, like in fairy tales. Having moved there, I decided to modernize the house. Since I understand these systems, I immediately settled on the option of a long-burning pyrolysis boiler. True, I had problems with the choice of fuel. But through experimentation, I came to the conclusion that the best and most effective material is dry wood (humidity no higher than 20%). At the same time, I recommend preparing firewood 0.5 m long. And if you take wood, it should be pure wood, that is, legs from old chairs or tables are not suitable. The fact is that they are treated not only with paint and varnishes, but also with all kinds of impregnations. That is, during their combustion, toxins that are very dangerous to health can be released. Pyrolysis boilers can also be fueled with briquettes and pellets for heating, wood waste, and some types of peat. When selecting a fuel or its alternative, you need to take into account the following point: when the flow of primary and secondary air is selected correctly, and the air humidity is normal, then there will be no release of combustion by-products. Otherwise, high humidity can lead to the appearance of not only unwanted water vapor, but also tar and soot. And this will lead to a deterioration in the thermal conductivity characteristics of the gas, which can cause the boiler to fade.

Alexander Nesterenko, 45 years old, Pskov

I have been interested in the topic of pyrolysis boilers for a long time. When I started finding out the prices for such a device, I was amazed. The minimum cost of this heating unit starts at $1,000, if we take a domestic manufacturer. And imported models are even more expensive. Therefore, I became interested in the question of self-assembly of pyrolysis boilers. As it turned out, a custom-made boiler costs 1/3 less than buying a ready-made unit.

Oleg Belozerov, 31 years old, Kazan

I want to leave my opinion about this boiler. This device has an order of magnitude larger volume of the loading chamber, due to which I only fill it in the evenings. This model is perfectly adapted to our latitudes, so no failures were observed during 2 years of operation. I would also like to say that such a boiler has the function of heating the supplied air into the combustion chamber. This boiler is very similar to the Polish model from Irleh. But since there is heating here, the quality of ignition of pyrolysis gases is much better. I would also like to say about safety, since my wife and I are waiting for a new addition. Despite the fact that the boiler is in the furnace room, children always know how to find passages to any room. So, the loading compartment has a door combined with a kindling valve, and is also equipped with an additional hinged door. This allows not only me to use the boiler carefully, but if a child appears nearby, he will not immediately open all the doors. Blago is an excellent option for houses with an area of 100-200 sq.m.

Nikolay Kulikovsky, 29 years old, Uzhgorod

And we have a “Teplolov” type boiler installed at our house. It has a fairly simple design that even my girlfriend can handle. At first I used clean firewood, but as it turned out, this boiler works great with waste wood (pieces), pressed briquettes and wooden logs. But it’s worth saying right away that the volume of the loading chamber is designed for elements from 40 to 90 cm. But in order for the effect to be achieved, the diameter of one log must be at least 10 cm, but not more than 25 cm. I also add sawdust there, but not that much. Another advantage I would like to note is the possibility of adjustment, and this in turn makes it possible to save money. One load is enough for us for 11-12 hours, while the area of our house is 94 square meters. m. We were completely satisfied with this purchase.

Advantages

Modern pyrolysis boilers are in great demand . Here the fuel burns completely, which means there is no need to regularly clean soot from the equipment. Separately, it is worth mentioning the absence of acrid smoke. Since the fuel burns almost completely, waste generation is minimal. Accordingly, such gas generators are considered more economical. This also makes it possible to use sewing waste for pyrolysis. The use of high-quality fuel ensures that the boiler operates for 12 hours on one charge.

Traditional solid fuel boilers have always been difficult to control due to the characteristics of the fuel, but the use of pyrolysis helps solve the problem. Since the main combustion takes place in the afterburner, the operation of such equipment is possible in automatic mode.

Advantages and disadvantages

The advantages of solid fuel pyrolysis boilers include the following:

- The raw materials used for the furnace burn almost completely. This is an indicator of a high degree of environmental friendliness, a minimum amount of harmful emissions, it is almost 2 times less than that of a standard boiler that runs on solid fuel.

- Easy to maintain and maintain, as very little ash is produced during combustion.

- Easy availability of raw materials, and there is no need for heavy chopping of firewood.

- Quite easy to maintain, if it is not possible to heat the house from the central gas main, it is a good alternative in terms of cost.

- There is no need to load firewood frequently; you only need to do this 2 times a day. The burning time of one load is about 9-14 hours.

- It is able to warm up the heating circuit of the house quickly enough.

The disadvantages include the following:

- High market value.

- The need to load fuel.

Flaws

If you want to purchase a pyrolysis boiler, be sure to pay attention to its disadvantages .

- First of all, it is worth noting the high price. Naturally, the costs will pay off as you use the equipment, but before that you will need to make a large investment.

- To use the unit, you will need fuel of a certain moisture content. If this figure is 30% or more, the material must be dried independently. Otherwise the boiler will go out.

- Extinguishing of the pyrolysis chamber can occur due to insufficiently high coolant temperature. To avoid this, in some cases it is advisable to install a bypass pipe. Such a solution will complicate the design and make the system less efficient.

- Many models use air pumps to create forced draft. Accordingly, the boiler will have to be connected to the electrical network.

Criterias of choice

There is no need to skimp on the quality of the boiler, since both the efficiency of the device and the safety of its operation directly depend on this.

Main selection criteria:

- Equipment power.

- Efficiency This figure for high-quality models is 87-90%. There is not much difference between them, but all other things being equal, it is better to choose a higher coefficient.

- Weight and dimensions. They influence where the device will be installed.

- The material from which the body is made. In many models, the latter is made of boiler steel - thick enough to withstand high temperatures. It is inferior in strength to cast iron, which increases the weight of the device. In addition, the steel case is better able to withstand mechanical deformation and is easier to repair. Cast iron, despite its strength, is considered a brittle metal, so simply repairing cracks will not work.

Many home owners purchase single-circuit models. They are used in conjunction with a boiler. In double-circuit systems it is difficult to provide both heating and hot water at the same time. In terms of their effectiveness, they are inferior to the first.

Recommendations for choosing equipment

If you are sure that you can constantly buy dry firewood or dry it yourself at home, then you can safely buy a pyrolysis boiler. Otherwise, preference should be given to modern equipment, the furnace of which is designed for pyrolysis and traditional combustion of fuel. Such a device can operate on wood, the humidity of which reaches 35–45% .

If there are no problems with fuel, pay attention to the loading chamber. Firewood measuring 55–65 cm in size should be placed here. Both chambers should have a coating of expanded clay concrete. Thanks to it, an optimal temperature regime is maintained inside the device, which ensures high-quality combustion of the selected fuel and protects the walls of the product from burnout.

Popular models

Naturally, when buying such a device, it is worth studying in detail the market and the models presented on it; it would also not be superfluous to study the reviews of the owners of pyrolysis boilers. This will help you make the right choice of pyrolysis boiler. The most popular models include Bourgeois, Geyser, Motor Sich, and Hearth. Next, let's look at these models in more detail.

Bourgeois K

The Bourgeois K boiler is made of 3 mm thick steel, which minimizes heat loss. Can heat an area of up to 200 m2, depending on the chosen model. If the boiler is fully loaded, its operating time is 8-9 hours. This type of device is not dependent on electricity. Low market value of about $300. It has proven itself to be a reliable device and can operate on a variety of fuels.

Pyrolysis boiler Burzhuy K

Trojan

The Troyan pyrolysis boiler has a high efficiency of about 92% and is characterized by uniform heating of the heating system. Trayan boilers series TR are equipped with a reliable mechanical automation system. The line is represented by models of varying power from 10 to 30 kW, this will allow you to choose a unit according to your room area.

Pyrolysis boiler Trayan

For example, 10 kW is designed for 80 m2, 15 kW up to 160 m2, 30 kW up to 330 m2. An average of 3 fuel loads per day is required. The advantages include the presence of a safety system against overheating of the heating system. It is possible to install a heating element, which is very convenient if there is a shortage of firewood; you can also combine these heating methods. Market value is about $700.

Hearth

Let's look at the model Ochag KP-100, which can heat a room of up to 1000 m2 and is equipped with an automatic system, with which it is possible to set the desired temperature. It is possible to load large firewood up to 70 cm long, the burning time of a fully loaded chamber is approximately 9 hours, it all depends on the room and how high-quality insulation it has. Relatively low efficiency of about 80%. The control panel displays the temperature of the heat output and the fan operating power.

Pyrolysis boiler Ochag KP-100

Atmos

The Atmos DC 24 RC device is equipped with an exhaust fan, the fuel for the firebox is briquettes with a diameter of up to 100 mm and for wood, as an exception, sometimes you can use coal in briquettes. The combustion chamber is equipped with a rotating grate, which ensures good combustion. The device can heat up in a few minutes. Efficiency 91%. Quite a high market value of about $1400.

Pyrolysis boiler Atmos

Motor Sich

The Motor Sich 16 kW device is designed for long-term combustion, equipped with a large loading chamber, one load is enough for about 12 hours of operation, of course, this is an average figure, it all depends on the quality of the insulation of the room, on windows and doors. High efficiency of about 93%.

Pyrolysis boilers Motor Sich

The heat exchangers are manufactured in a seamless manner, which minimizes the loss of transferred heat. The case is made of high quality steel 8 mm thick. Can work on firewood, wood waste, peat. Capable of heating an area of up to 190 m2, two loads are required per day. Market value $1300.

Geyser

The Geyser PC 20 model is designed to heat a room with an area of up to 200 m2, with ceilings no higher than 3 meters. Equipped with an automatic control system. Two loads per day are required, efficiency is 87%, it has established itself as a fairly reliable boiler, unpretentious in maintenance, its cost is $900.

Pyrolysis boilers Geyser