What is a steam boiler?

Steam home boiler

From the name itself it is clear that this is a device that generates juicy steam, which is subsequently used in the heating system of an apartment or house. In this case, the operation of the steam system is based on the fact that the steam has a pressure above atmospheric. In essence, this is a simple heating boiler that will work on any type of fuel. If you decide to install this type of heat generator in an apartment in the city, then the suitable fuel option is gas.

It must be said frankly that the design of a steam boiler is quite complex, so it is necessary to consider it briefly. The boiler itself consists of two parts, the upper of which is a drum saturated with water. The water supply system can be varied. For example, from a water meter unit or from any tank using a pump. From the drum downwards there are pipes through which the water will move. They are called descenders. Remember - these pipes do not heat up.

The lowering pipes are connected to the collectors, and lifting lines from the pipes go up from them. In other words, a system emerges that resembles connecting vessels. This is the working principle of a steam boiler. The riser pipes themselves form heating surfaces that pass through the area where fuel is burned. A steam-water mixture is formed in them, but this is not yet pure steam for a steam heating system. Zoning needs to be done.

This process takes place in, in other words, separators. The mixture enters there through pipes and is divided into water and steam. Water flows into the drum, and steam is supplied to the steam line connecting the separator and superheater. Here the steam is brought to the desired temperature and pressure. After this, it goes to a steam turbine, which drives it into the heating system.

How the system works

Do not confuse water and steam heating at home. They have many functional differences, despite their external similarities.

Both of these types have components:

- boiler;

- radiators;

- pipes.

Steam heating is considered effective; you can get by with a small number of batteries.

Steam is a coolant for steam heating of a private house. You can make such a system with your own hands, following the instructions for assembling and installing the components. For a water system, water plays the role of carrier. The boiler evaporates water rather than heating it. The coolant vapor moves through the pipes and becomes a source of comfortable temperature in the house. The steam cools inside, after which it condenses. In this case, 1 kg of steam is converted into 2000 kilojoules of heat. For comparison, water cooling at 50°C provides only 120 kJ.

The heat transfer of steam is several times higher, which explains the high efficiency of this type of heating. The condensate formed inside the radiator passes to the lower part and independently moves to the boiler. There are several types of heating systems. In this case, the specification is carried out according to the method of returning the coolant, which has been transformed into condensate.

- Closed. There are no contours in this case. Accordingly, condensate moves through pipes that lie at a certain angle. It goes straight into the boiler for further heating.

- Open. There is a storage tank here. Condensate enters it from the radiators, and the pump is involved in pumping it back into the boiler.

Steam boiler production technology

What is needed to make such a system?

- Stainless steel sheet metal 1 mm thick.

- Stainless steel pipes of various diameters - 100–120 mm, 10–30 mm.

- Valve for protection.

- Asbestos in the form of sheets.

The first step is to purchase the drawings of the steam boiler. This is not a problem today, because they are freely available on the World Wide Web. Task number 2 is to determine how much power the device needs. Everything depends on the steam heating system, the size of the private house, the number of heating devices in it, and so on. Other publications on this site can help you understand this issue. Third, it is necessary to select the shape of the unit. It can be round, rectangular or square.

High pressure steam boiler

For ease of manufacture, you can take a pipe 100–110 cm long. This will be the body of the unit. Please note that the wall thickness must be at least 2.5 mm. The fundamental point is the design of the combustion chamber and the supply of flame and smoke tubes to it.

It is best to make the firebox from stainless steel sheets, in which holes are drilled for the described tubes. Their ends are first rolled to create a tight fit to the surfaces. For better sealing and increased strength of the connection, the tubes should be welded using argon welding. If you do not have these abilities, you can attach them with regular electrodes.

Then you need to attach the pipe manifold by welding and install a safety valve. The unit is insulated using asbestos sheets. At this point we can consider the work done. Afterwards, the steam heating system and the boiler are connected.

What do steam units work on?

We have already said that there are no difficulties with choosing fuel for steam boilers. However, if we are talking about the effective and convenient operation of a steam heating system, then gas is a suitable option. There is less fuss with it, and you can make an automatic system. She herself will control all processes that are associated with temperature conditions, gas supply, fuel efficiency and fuel economy.

Steam boilers that run on wood or diesel fuel, and also electric analogues, operate on a similar principle, although there are quite serious differences in the design design. This is especially true for the combustion chamber and spray devices. The latter, for example, are completely absent in boilers running on wood or electricity. But in many cases, craftsmen who assemble boilers with their own hands try to fit them either to atmospheric burners or to diesel spray devices.

Consumers always have a substitution of choices. You can purchase a ready-made device, or you can create it yourself. But let's accept the true state of affairs. The circuit of a steam boiler is quite difficult, and it will not be possible to understand it without knowing the simple principles by which the device does not stop working. In addition, you will need to purchase special materials required by the standards and requirements to create this radiator. Here you will need reliable fireproof metal products. In addition, you will need to make very correct calculations.

It must be added that steam boilers operating in the heating system of an apartment or house, especially gas boilers, must be equipped with a safety unit. This is not just a stove or fireplace, and everything is connected with high-temperature steam, which is supplied to the system under pressure. Thanks to this, the automatic control system is an important and mandatory component.

Of course, it is impossible to say that every person can make a steam apparatus with his own hands. But everyone is simply obliged to know the working principle of the device, its design features, subtleties of operation and other points. This can be attributed to those who have decided to install this model in their home.

Boiler selection

In order to choose the right heating device, the first thing you need to do is calculate the area that will be heated. To do this, you need to calculate the area of each individual room by multiplying the width by the length. After this, all the results must be added, the final figure will be the desired value. It is important to remember that this is true for ceiling heights up to 3 m; if it is higher, then it is necessary to make an additional power reserve.

- For a total area of up to 200–300 m2, a capacity of 25–30 kW is sufficient.

- For 400‒600 m2 - 35‒60 kW;

- 600‒1200 m2 - 60‒100 kW.

The next step will be the choice of fuel. Steam boilers can easily operate from the following sources:

- Liquid. This could be, for example, diesel fuel or used oil. When using this option, it will be necessary to place the unit in a separate room. This will help avoid inhaling harmful fumes and their negative effects on health.

- Solids - firewood, coal, peat and anything that can burn and release a large amount of heat.

- Gaseous. This is usually natural or liquefied gas.

- Electrical.

In some cases, solid fuel solutions are significantly cheaper, but it is worth considering not only the cost of fuel, but also the time that will be spent on kindling. In this case, it can reach several hours, and it is necessary to constantly replenish the firebox to maintain the temperature at the proper level.

Some manufacturers combine different types of fuel. For example, they combine a firebox for loading solid fuel and provide the presence of a heating element. At the same time, efficiency does not decrease, but it turns out to save on consumption, and therefore on payment.

Making a homemade steam boiler

Many owners of comfortable apartments in the city dream of replacing them with a personal home. After all, modern housing outside the city limits is in no way inferior in terms of comfort to apartments in megacities. And many begin to make their dream come true by purchasing new country houses.

Naturally, a newly built house must have not only water supply and sewerage, but also a heating system. The cheapest and fastest option for good home heating is steam heating. This can be explained quite simply. First of all, due to the fact that it is not very difficult to assemble a steam boiler with your own hands.

This can be done by anyone who has a desire, even those who do not have certain knowledge. Secondly, this type of heat supply is good, it has been tested in operation. And, finally, a homemade steam boiler will cost the owner significantly less than purchasing very expensive foreign equipment. In addition, there are also certain advantages of this type of home heating, which will be discussed below.

Demand for steam heating

This type of creating comfort and warmth in the house with the help of steam was and remains very common in our country. Steam heating for a private home is distinguished not only by its availability and commonality, but also by its efficiency. The main feature of this design is the use of superheated steam as a coolant. In this case, the heat source is either a steam apparatus purchased through a retail network or a homemade steam apparatus.

This device is used to produce superheated hot steam under pressure greater than atmospheric. It is formed using heat energy, which is released when fuel is burned in a specialized chamber.

To create this design yourself, no fundamental knowledge is required. But, still, have an idea about certain subtleties first of all.

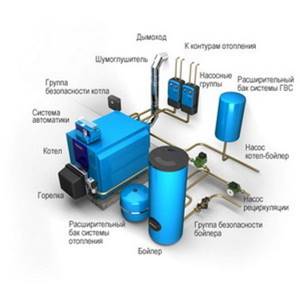

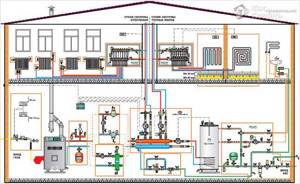

In most cases, the steam heat supply of a residential home consists of the following devices and components:

- Steam unit

- Stoyakov

- Pipe-wires

- Heating devices

This set of components is typical for a personal heating system. The heat is generated in it by a steam boiler, assembled and installed with your own hands, which can operate on almost any fuel.

Such heating can be created single-circuit or double-circuit. With the first option, only heating of the premises will occur; the second method also involves the preparation of hot water.

The piping system consists of vertical and horizontal components. The wiring can be lower or upper - it depends on the properties of the structure.

Of course, before creating such a heating system in your own home, you need to carefully analyze all its pros and cons.

The important advantages are:

- Affordable installation process and small size

- Fast warm-up

- Possibility of heating large areas and volumes

- Economy

- High heat transfer without heat loss

- Inability to freeze the system

The disadvantages usually include:

- Inability to change the ambient temperature in the house

- Aggressive effect on pipes

As you can see, such heating has more advantages than disadvantages. And the installation of the system done on our own further complements the list of good qualities.

Essence of the question

Water heating

Some people get confused and believe that in fact the correct name for such a system is water heating, and the prefix “steam” remains from past times, when heating was carried out by industrial boiler houses that produced large volumes of steam. In fact, today there are boilers that provide space heating by converting liquid into two physical states. The strengths of this solution are:

- double heat transfer - by convection and infrared radiation;

- minimal losses in the heat exchanger when transferring energy from the source;

- high reliability;

- there is no danger of the system defrosting during the cold season;

- Possibility of use at any time of the year;

- long service life without failures.

We make an accurate calculation

The key structural element of the system is the heating apparatus. In order for all equipment to work with the greatest efficiency, it is necessary to make a good choice of steam boiler in terms of power. In this case, the area of the heated premises is taken into account.

There is the following relationship that must be adhered to when calculating a steam boiler:

- a power of 25 kW is enough to heat an area of up to 200 m2

- 25-30 kW corresponds to 300 m 2

- power 35-60 kW will heat up to 600 m 2

- 60-100 kW – up to 1200 m2.

DIY steam heating

The installation of steam heating consists of two stages - design and installation itself.

Stage 1. System design

System design

We remind you once again about the peculiarities of using steam as a coolant - the high temperature of the pipeline and radiators, as well as an increased accident rate. When all the pros and cons are weighed, you can begin work. First, a draft of the future system is created.

Boiler

Wood boiler

First, the required power of the heat generator is determined. In this case, the area of the house is taken into account - if it does not exceed 200 m², then a device with a power of 25 kW is sufficient, but if it fluctuates between 200 m² and 300 m², then a minimum of 30 kW will be required. Based on this information, a boiler is selected. The following factors should be considered when purchasing:

- the type of fuel that will be used;

- possibility of heating water for domestic needs.

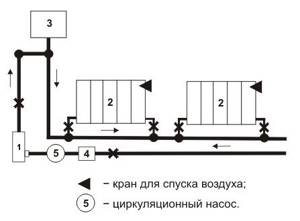

Heating scheme

Two-wire system with top wiring

Single-wire system with bottom wiring

Diagram of an open heating system

The scheme also needs to be decided in advance. The choice of one option or another depends on:

- boiler location;

- area of the heated room;

- conditions for installation of heating devices;

- the required number of these devices.

In short, this is a rather difficult choice, in which the video below will help.

Pipes

For steam heating, the use of conventional plumbing pipes is unacceptable due to the high temperature of the entire system

For this reason, great attention should be paid to the choice of pipes, even if it is small.

- Copper pipes are characterized by excellent thermal conductivity and high cost. Installation is carried out by soldering.

- The advantage of steel pipes is their resistance to aggressive environments and mechanical stress, the disadvantage is their susceptibility to corrosion. A welding machine is required to install them.

- Galvanized products combine the positive qualities of the previous ones - they do not rust and are relatively inexpensive. The pipes are joined using a threaded connection.

In order to facilitate installation work, at the design stage it is necessary to determine:

- location of radiators;

- pipeline length;

- installation locations for distributors, main line branches, adapters, etc.

Price issue

After drawing up the project, future costs are determined. It is difficult to say how much the equipment of such a system will cost, without reference to heating devices, scope of work and specific conditions. Let us only note that, according to experts, steam heating will in any case be cheaper than conventional water heating.

Stage 2. Installation work

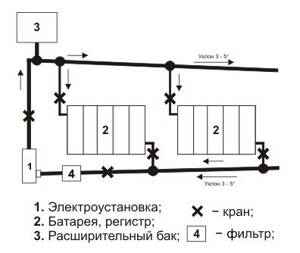

Step 1. First, based on the sketch, an exact wiring diagram is drawn.

Heating wiring diagram

Step 2. Next, radiators are installed. It is recommended to place them under the windows - this will not only heat the glass, but also prevent fogging and, as a result, a shift in the “dew point”.

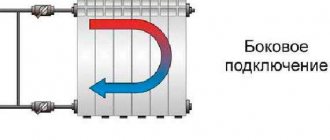

Connecting a multi-section radiator

Installing a heating radiator

Installing a heating radiator

Radiators are installed next

Step 3. The expansion tank is attached. It must be connected to the pipeline leading from the heat generator to the radiators. Another important point: the tank must be installed at the highest point of the heating system.

Fastening the expansion tank

Fastening the expansion tank

It can be closed or open, with or without overflow.

Step 4. Pipelines are installed. This happens as follows: the pipe is brought to the radiator, cut if necessary, after which the leads and inputs are connected. Then the pipe is connected in the same way from the first radiator to the second, then from the second to the third, etc.

Step 5. The circuit is closed, that is, it is brought to the beginning - the heat generator

It is important that the boiler is equipped with a filter and (if necessary) a circulation pump

Vortex heat generator

Step 6. Next you need to install the boiler itself. Quite often, country houses are adjacent to car garages. The heating device can be installed in one of these garages.

Heating boiler installation

In this case, installing a heat generator is no different from a similar procedure in a residential area. In this case, the fill/drain unit can be installed on any section of the highway. This unit is necessary to drain the coolant at the end of the heating season or before repairing the system.

Step 7. All heating devices are tested. If they are new, then it is advisable to invite a specialist for a test run.

Design principle and production technology

The heating apparatus must include:

A steam boiler, the design of which is incredibly simple, is not very difficult to assemble with your own hands. The main component in this design is the drum.

The pipeline system is installed specifically to it, as well as safety devices and instrumentation, which make up the steam boiler automation circuit.

The design of the apparatus can be represented in detail by different elements. Liquid is supplied to the container located in its upper part by a pump. The lower pipes are directed to the bottom - they do not heat up. Through them, water from the tank is supplied to the collectors and then follows into the lifting wire of the pipes.

It forms heating surfaces located in the fuel combustion zone. The circulation system of such a device is based on the working principle of vessels that communicate with each other.

To create a working device with your own hands you will need:

- Pipes

- Sheet steel (stainless steel)

- Safety valve

- Asbestos

- Set of tools

- Welding machine

- Devices for measuring work

When starting work, you should first find and learn detailed drawings of such devices. Material must be prepared according to specific requirements. So stainless steel pipes should have a diameter of 100 to 120 mm, steel should be 1 mm thick, and the diameter of other pipes is 10 and 30 mm.

A piece of pipe, the length of which is at least 110 mm and the thickness of 2.5 mm, can be taken as the base of the boiler. They also make 12 smoke tubes (100 mm), and a fire tube, which is much larger in size.

Their length depends on the size of the device. The external and internal partitions of the boiler are made of stainless steel sheets. Holes are made in them for absolutely all existing tubes, which are fixed to the base using argon welding.

At another assembly step, the safety valve and manifold are welded to the body of the device. The thermal insulation of the unit is made from asbestos sheets.

A practical automation scheme for a steam boiler is designed to regulate its operation, remote control, thermal control, alarm and blocking.

Preparatory work

Diagram of the heating system in the house

The first step will be to draw up a drawing. A plan of the building in which the installation will be carried out is drawn on a sheet of paper. The location of the boiler is determined. It is advisable to allocate a separate room for it. This is done in order to ensure maximum safety. If it is a closed system with natural circulation, then it should be at the lowest point. This is necessary so that water can flow to it freely.

The wiring of the entire system is plotted, as well as the location of all the elements that were listed in the previous subsection. When performing this step, it is better to be in a specific room, then you will be able to plan everything in the best possible way, taking into account the need to bend the pipeline around obstacles or ledges. All corners and transitions must be marked on the diagram. After the drawing is completed, you can most accurately calculate the material that will be needed for the successful completion of the entire project.

Some craftsmen make a steam boiler themselves. It is either cooked from sheet material, or a special circuit is made from pipes, which is laid inside a brick stove. In the second case, it will be necessary to monitor the condition of the heat exchanger, which is best made of stainless steel, which will extend its service life. It is also very important to clean smoke ducts more frequently.

Water treatment of steam boilers

Key disruptions to the good functioning of this type of heating equipment are caused by the formation of scale on the walls of the water supply system. To ensure trouble-free operation of the device, the water that enters the steam units must be purified in advance.

An important task facing the preparation of liquid for its subsequent use in the apparatus is to reduce its scale and corrosive activity. Destruction of heated surfaces and pipes occurs under the influence of carbon dioxide and oxygen entering the system with the liquid.

Water treatment for steam boilers can consist of both cleaning using chemicals and using an electromagnetic pulse. In the first option, substances are taken that prevent the appearance of scale and reduce the effect of rust on the internal surfaces. In the other, a field is formed that generates high-frequency vibrations that can prevent the appearance of scale.

What to take into account when designing

The high price of other types of equipment is the main reason for attempts to build this device on our own. As we understand, this is not difficult to accomplish.

However, you need to understand that making such a unit with your own hands requires a preliminary correct calculation. Also, to do this you need the availability of refractory alloys, tools and equipment.

Steam units, especially those running on natural gas, must fully comply with safety standards. For this purpose, they are equipped with automated control systems.

DIY steam boiler

A steam boiler is one of the most popular and widely used types of heating units. The main structural part of the unit in question is the combustion chamber. It burns the loaded fuel with intense release of thermal energy. The resulting heat is used to heat the water with the future release of steam. Steam is used for various industrial and domestic needs, especially home heating. At the same time, you can easily manage the manufacture of the simplest boiler with your own hands.

DIY steam boiler

Contents of step-by-step instructions:

Design Features

The design of the boiler in question is based on a kind of drum. Pre-prepared water is supplied to such a piece of equipment using a system of pumps and pipes. The compartment at the bottom of the boiler contains downcomers. Such elements have different diameters and do not heat up during boiler operation. Through a pipe system, liquid from the drum passes into the collectors. The latter are very often located at the bottom of the boiler.

The collector is connected to the drum using a lifting pipeline. Due to the pipeline, heating surfaces are created at the place of combustion of the loaded fuel.

A system of pipes and wires is connected to the steam generator, operating according to the mechanism of communicating vessels. A mixture of liquid water and superheated steam moves in hot pipes. This mixture has a fairly low density, which allows it to easily flow into the separator compartment, where zoning of steam and water occurs. The liquid component is sent to the steam boiler drum.

The steam passes into the steam line, and then into specialized heaters, where the pressure and also the temperature of the steam increase to the required values. Once completed, the steam is directed to the required steam turbine.

Making a steam boiler

Installation

The installation of a steam heating system depends on the selected scheme. You should also read all the recommendations from the manufacturers of the equipment you use.

Attention: It is necessary to take into account the distance from the boiler to the ceiling and walls of the garage. The latter must be fire resistant. The room in which steam heating will be installed must have a good ventilation system.

Heating installation includes the following steps:

- Preparing the installation site.

- Installation of boiler and radiators.

- Piping the boiler and radiators.

- Test run and control of correct operation.

* By installing a steam heating system in the garage, you will be able to feel comfortable in it while doing, for example, repairing your car. It will be warm even in the most severe frosts. The main thing is that it is designed and installed correctly.

Before you start heating your garage using this system, you should test it. This is necessary to check the tightness of the circuit, because you should know in advance whether it can withstand the operating pressure. Also, during the tests, it is possible to find out whether steam is supplied evenly and whether it does not enter the condensate-conducting pipe (if the wiring is two-pipe).

We recommend that you read the link to the basic article on implementing heating in a garage on your own.

Types of steam boilers

There are several variations of steam boilers. They are divided accordingly with the following characteristics:

- a method of moving a mixture of steam and water. Accordingly, with this parameter, the equipment is divided into boilers with forced and real movement;

- method of condensate return: open and closed devices;

- the nature of the movement of the coolant: gas-pipe and water-pipe units.

Gas-pipe and water-pipe heating equipment have different designs and performance. The category of gas-pipe equipment includes boilers in which gas movement is carried out in flame and smoke tubes. As they move, the gases heat the water in the system. The tubes rest on edges on the sides of the combustion chamber.

In water-tube equipment, water flows through tubes. In this case, gases wash the pipes from the outside.

The boilers in question can use solid fuel, as well as fuel oil and gas.

An example of organizing steam heat supply

Additional nodes

Cast iron batteries

In addition to the boiler and pipes for the main line, you will need mandatory elements that you cannot do without:

- Radiators. These can be cast iron batteries, steel products or pipes with fins. It is better to install them under windows. This creates a heat plug that cuts off cold air. This will also prevent the formation of condensation on the glass.

- Fitting. Various connecting elements: couplings, angles, bends, adapters that will be required when installing the pipeline.

- Reduction-cooling unit. Converts steam into liquid state.

- Gearbox. Designed to regulate pressure in the system.

- Expansion tank. It is better to use an open type element. If you want to install a sealed tank, then it must be equipped with a pressure gauge and a pressure relief valve. If this is not done, this may lead to its failure.

- Container for collecting condensate.

- Circulation pump. For systems with forced fluid movement.

- Hydraulic seal. It will be necessary when you need to drain the system to repair it or replace any components.

- Filter. It will be necessary to remove solids before water enters the boiler. This is necessary to ensure that nothing reduces performance.

- Mayevsky cranes.

It is possible to install an indirect heating boiler in a steam heating system. In this case, you will need a valve with three inlets. It connects to the thermostat and redirects the movement of the coolant.

How does a stereotypical steam heating boiler keep working?

Heat is generated in the combustion chamber. Subsequently it arrives at the heating surfaces. There are 2 types of heating surfaces: convective and radiation.

Working principle of steam boiler

The composition of convective surfaces includes the following elements:

- air heaters;

- economizers;

- heat exchange devices.

The listed additional equipment is necessary to increase the efficiency of the boiler, rationalize fuel consumption and reduce the level of heat loss.

The main thing is that the water used to operate the boiler is exceptionally clean - impurities are not allowed. Due to this, before being fed into the boiler, the liquid is first cleaned of gases and various types of impurities, ultimately becoming nutritious.

The purified liquid is sent to the economizer. A specialized pump helps her do this. In the economizer, a liquid heat carrier is heated under the influence of gases. Then the liquid passes into the upper compartment of the drum compartment. Here the boiler water is mixed with the nutrient liquid.

Some water volume passes from the upper compartment of the drum compartment to its lower compartment. The movement of water is carried out through boiling tubes.

At the top of the steam boiler, the gases have a lower temperature, which gradually becomes higher as they approach the lower compartment of the unit.

The water is heated and everything, together with a mixture of steam and water, is sent to the upper chamber of the drum.

The second part of the liquid from the upper drum compartment goes for redistribution. The water in the boiler is heated. The resulting steam bubbles go to the upper compartment of the drum compartment.

In the upper chamber of the drum, due to the separator, almost complete zoning of the mixture of liquid and steam occurs. As a result, juicy steam is formed, which helps to further increase the beneficial effect of the boiler. It is this juicy steam that is used by the end consumer.

In order to increase the efficiency of boilers, their operation is organized in such a way that in the upper chamber of the drum compartment the level of “low” and “high” water fluctuates. Between the mentioned liquid levels there is a reserve water reserve, which is designed to maintain the operation of the heating unit in the event of a stoppage of liquid flow into the system.

The possible “highest” liquid level in the drum compartment is determined based on the fact that water does not enter the superheater.

The maximum possible “low” level of liquid in the drum must be calculated in such a way as to prevent overheating of the upper compartment of the drum, as well as the boiler bundle. The main thing is that water enters the lowering tubes in a stable volume.

To further increase efficiency, the design is equipped with an air heater.

The liquid in the system can circulate forcibly and naturally. Natural movement is based on the difference in density between the liquid and the vapor being created. The mixture of water and steam in the rising tubes has a lower density than the similar composition in the descending tubes. However, the pressure reading and temperature reading remain similar throughout the tube. Eventually the steam, which is a gas by nature, rushes upward.

Forced circulation is provided by specialized pumping equipment.

Scheme for transferring a steam boiler to water heating mode

Assembling a conventional steam heating boiler

If you wish, a simple boiler can be assembled with your own hands. A home-made device will have a somewhat simplified design when compared with factory-assembled equipment, but this will in no way affect its efficiency and efficiency.

Boiler assembly kit

Before you begin, prepare the following items:

- pipes of various diameters;

- stainless steel sheets;

- sheet asbestos;

- safety valve;

- hacksaw;

- ruler;

- roulette;

- chisel;

- hammer;

- welding machine;

- file.

Assembly of the unit

The work of making a boiler yourself is done in a couple of simple steps. Do each step of the instructions gradually, while looking at the drawings and diagrams.

Step one. Set good dimensions for the upcoming steam boiler. The size of the equipment determines its performance. Please clarify this point individually, taking into account the specifics of your own situation.

At the same step, prepare all the necessary drawings. If you wish, you can choose to have them compiled by a specialist or use ready-made drawings from open sources.

Second step. Prepare related materials. Previously, a list of required components was provided. First of all, purchase pipes with a diameter of 32 mm and 12 mm. Stainless steel sheets must have a thickness of about 2-3 mm.

3rd step. Prepare the boiler body. A good option is to weld the body without outside help from sheet metal. Choose the dimensions of the case personally, according to your own needs.

Fourth step. Make the base of the boiler. It used to be said that the design of steam boilers is based on a system of interconnecting pipes. First of all, prepare a piece of pipe about 11 cm long with a wall thickness of approximately 3 mm.

Cut a pipe 11 cm in diameter into 12 components - they will perform the functions of flame tubes. Cut the larger pipe into flame tubes.

Choose the length of the pipes according to your diagrams.

Fifth step. Make the required number of bulkheads and walls of the steam boiler. To do this, use stainless steel sheet type.

Sixth step. Prepare holes in the walls of the unit to locate the flame and flame tubes. Connect the mentioned parts in flared form to the boiler base. A welding machine will help you with this. At this step, you also need to focus on the inherent drawings and diagrams.

Seventh step. Attach the safety valve and steam manifold to the unit body. You will subsequently release the last steam through the valve.

Eighth step. Make thermal insulation of the boiler using asbestos sheet.

Steam generator connection diagram

Similarly, having understood the key provisions of the instructions, you will be able to assemble a simple steam generator with your own hands and include it in the heating system of your home. At each step of the work, you need to focus on your own drawings, because It is unrealistic to understand the order of assembling the unit using textual advice alone.

Types of steam heating systems

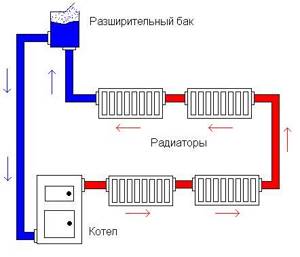

According to the method of installation, steam heating is distinguished into two types: with a closed and open system. In a closed system, condensate flows into a special receiving pipe, which is connected to the corresponding inlet of the cat. It is laid with a slight slope, so that the condensate moves through the system by gravity.

Schemes of open and closed steam heating systems

In an open system, condensate is collected in a special container. When it is filled, it is fed into the boiler using a pump. In addition to different system designs, different steam boilers are also used - not all of them can operate in closed systems.

In general, there are steam heating systems with pressure close to atmospheric or even lower. Such systems are called vacuum-steam systems. What is so attractive about this setup? Because at low pressure the boiling point of water decreases and the system has a more acceptable temperature. But the difficulty in ensuring tightness - air is constantly sucked in through the connections - has led to the fact that these schemes are practically never encountered.

Steam heating with low pressure is more common. Existing steam boilers for domestic use can create a pressure of no higher than 6 atm (at a pressure of more than 7 atm, use of the equipment requires permission).

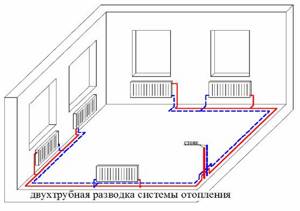

Wiring types

According to the type of wiring, steam heating is:

- With top wiring (the steam line is located under the ceiling, pipes go down from it to the radiators, and a condensate line is laid below). This scheme is the easiest to implement, since hot steam moves through one pipe, cooled condensate through another, the system is stable.

- With bottom wiring. The steam line is located at floor level. This scheme is not the best choice, since hot steam moves up through one pipe and condensate moves down, which often leads to water hammer and depressurization of the system.

- With intermediate wiring. The steam line is laid just above the radiators - approximately at the level of the window sills. The system has all the advantages of overhead wiring, except that hot pipes are within reach and there is a high risk of burns.

When laying, the steam pipeline is made with a slight slope (1-2%) in the direction of steam movement, and the condensate pipeline - in the direction of condensate movement.

Boiler selection

Steam boilers can operate on all types of fuel - gas, liquid and solid fuel. In addition to choosing fuel, it is necessary to correctly select the power of the steam boiler. It is determined depending on the area that needs to be heated:

- up to 200 m2 - 25 kW;

- from 200 m2 to 300 m2 - 30 kW;

- from 300 m2 to 600 m2 - 35-60 kW.

In general, the calculation method is standard - 1 kW of power is taken per 10 square meters. This rule is valid for houses with a ceiling height of 2.5-2.7 m. Next comes the choice of a specific model. When purchasing, check for a quality certificate - the equipment is dangerous and must be tested.

Which pipes to use

Only metals can normally withstand temperatures during steam heating. The cheapest option is steel. But welding is required to connect them. It is also possible to use threaded connections. This option is budget-friendly, but short-lived: steel quickly corrodes in a humid environment.

At least copper pipes don't corrode

Galvanized and stainless steel pipes are more durable, but their price is not at all modest. But the connection is threaded. Another option is copper pipes. They can only be soldered, they are expensive, but do not rust. Due to their higher thermal conductivity, they transfer heat even more efficiently. So this heating system will be super efficient, but also very hot.

Conditions for safe operation of the boiler

The boiler must be not only practical, but also non-hazardous. The key to good and good functioning of a steam heating boiler is maintaining a given level of heating of metal elements.

In view of this, the coolant must constantly circulate from inside the heated tubes with simultaneous cooling of the heating surfaces. The main thing is that the coolant stably removes heat from the pipe material, which is heated under the influence of flue gases. If heat removal is insufficient, the metal will simply overheat, become less strong, and the efficiency and safety of the equipment will decrease. In the worst case, the pipes will simply burst.

Constantly monitor the operation of the boiler. Correct all damage immediately after finding it. Even a very small flaw can quickly lead to a significant decrease in the efficiency of the unit and a deterioration in the safety performance of the system. Water will come out of the drum, steam will make its way into the lowering tubes, the drum and tubes will heat up very much, and an accident will occur.

Also, you, as the owner, must ensure that all structural elements and equipment used are of exceptionally good quality.

Advantages and disadvantages

Steam heating is not the most popular, but it has both positive and negative aspects. Moreover, the advantages are quite significant:

- High heating efficiency. The fact is that the steam in the system does not just heat radiators and pipes to a certain temperature. Due to the large temperature difference, it condenses. And during condensation, 1 liter of steam releases 2300 kJ of heat. Whereas when the same amount of water cools by 50°C, only 100 kJ is released. Therefore, a very small number of radiators are required to heat the room. In some cases, a certain number of pipes is sufficient.

- Since steam heating is a small system, it has low inertia. The room begins to heat up literally a few minutes after the boiler is started.

The disadvantages of steam heating systems are even more impressive:

- The high temperature of the steam leads to heating of all elements of the system to 100°C and above. This leads to the following consequences: very active air circulation in the room, which is uncomfortable and, at times, harmful (if you are allergic to dust);

- the air in the room dries out;

- hot elements of the system are dangerous and must be closed, and the pipes too;

- not all building materials can easily withstand prolonged heating to such temperatures, therefore the choice of finishing materials is very limited (in fact, it is only cement plaster followed by painting with heat-resistant paints).

As you can see, steam heating is not the best choice, although it is quite inexpensive to install.