Composition of ecowool and its main properties

High-quality ecowool contains only three components:

- 80% cellulose fiber.

- 12% boric acid, which inhibits the development of microorganisms, mold, and mildew.

- 8% borax, or potassium tetraborate. It repels insects and rodents and at the same time is a strong fire retardant.

Several types of raw materials are used to make ecowool:

- Waste from paper and cardboard production.

- Residues from the production of corrugated cardboard products.

- Printing defect.

- Waste paper unsuitable for processing into high-quality paper, including contaminated paper.

Not so long ago, ecowool appeared on the Russian market and is gradually gaining popularity for thermal insulation of buildings for a wide variety of purposes: from airports and concert halls to warehouses, industrial buildings and private homes.

What is ecowool made from?

Article on the topic - RockWool insulation.

The main characteristics of ecowool offered by the market are as follows:

- Thermal water coefficient at the level of mineral wool and expanded polystyrene is 0.036-0.043 W/mK. It must be borne in mind that due to seamless application, the overall thermal insulation ability is significantly higher than that of other materials.

- The density depends on the method of installation (or application) and can range from 25 to 90 kg/m3.

- Heat resistance group – G2, smoke generation – D2.

- The vapor permeability of laid ecowool is 0.3 mg/(mhPa).

- Air permeability(80-120)*10-6 m³/msPa.

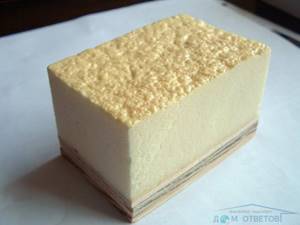

Fluffed ecowool is ready for application

The strength of the material is low compared to others. It is not suitable for insulating flat roofs, where the insulation has to withstand heavy loads during operation.

Advantages of the material

Undoubtedly, each material has a number of advantages over others. What are the advantages of ecowool?

Elastic and elastic cellulose fibers in ecowool (unlike mineral fibers used for the production of other insulation materials) do not shrink the material over time.

Ecowool Extra

The thermal insulation layer, made according to all the rules using ecowool, is more durable. Among other things, the thermal insulation properties do not deteriorate over time, which cannot be said about some other materials.

This coating is completely hygienic, hypoallergenic and non-toxic, and is also safe for humans and animals throughout the entire life of the building. Due to special processing, the components that make up ecowool remain non-toxic even with significant heating, without emitting harmful volatile gases.

Structure of mineral wool and ecowool

In the event of a fire, ecowool will not only not ignite, but will also actively localize the fire, preventing its further spread. Belonging to the category of substances that are difficult to ignite, the material does not melt or burn even at high temperatures. The decay of cellulose fibers is safe for humans and nature, and when the source of fire is eliminated, the process stops immediately.

Ecowool is fireproof

Ecowool is hygienically resistant and not susceptible to rotting, mold, various fungi and bacteria. The biostability of the insulation also extends to the materials in contact with it; their physical, chemical and consumer qualities are preserved.

It is known that concrete and brick without special treatment over time under the influence of microorganisms can be subject to destruction processes at the cellular level, which in turn can negatively affect the condition of walls, interpanel seams or window openings, causing freezing or icing of certain areas. The use of ecowool can significantly minimize this risk.

Insects and rodents do not grow in the heat-insulating layer of ecowool. Cellulose fiber and an admixture of boron are an unacceptable environment for their habitat, due to the property of boron to block the respiratory tract, causing swelling of the mucous membranes and, as a result, the death of the rodent. For certain regions, this is perhaps the only way to protect your home from rats and mice.

The fine-fiber structure is capable of filling all the voids and recesses of the room being treated, regardless of the building material, which makes it possible to build a soundproofing wall and allows you to at least double the sound insulation in comparison with mineral wool slabs, reducing to zero the transmission of sound waves through gaps and cracks in walls, floors or ceilings . No other material can provide this.

Ecowool for home

High moisture-resistant properties and low vapor permeability make it possible to accumulate and remove moisture from the hollow capillaries of the material fibers without the latter losing its qualities. Ecowool is hygroscopic, which means it does not accumulate micro-condensation, regardless of weather and climatic conditions, which prevents rotting of internal wooden floors.

The ability of the material to “breathe” makes it possible to install ecowool without using an additional vapor barrier layer, without worsening the microclimate of the building.

Ecowool allows you to obtain an even, seamless contour of thermal insulation, in which the insulation fills all hard-to-reach places and irregularities without the formation of temperature bridges.

Ecowool quality

Installation of the material is waste-free, which certainly reduces the cost of work.

Laying the insulation layer can be done at any time of the year, regardless of temperature conditions. The installation process itself is easy and technologically advantageous - there will be no waste of material. In addition, this heat-insulating composition is distinguished by high speed of installation work.

Thermal insulation ecowool

Ecowool allows for “additional insulation” during major repairs without dismantling the existing insulation layer.

In addition, ecowool can be reused without any processing.

The use of ecowool allows you to reduce heating costs in winter by 2-3 times. And keep your home cool by 30-40% in the summer.

This material is universal and can be used on any surface - vertical, horizontal or inclined.

Ecowool: main characteristics

Ecowool is a lush mass, the structure resembles construction wool. Has a gray color. Doesn't smell. When heated, it does not emit harmful substances. It is considered one of the most environmentally friendly and safe materials for humans and animals.

Thermal insulation made from ecowool has a number of advantages over other materials.

- In cold and humid climates, it lasts longer than synthetic products. The guaranteed service life of the insulation is up to 65 years.

- During operation, ecowool adapts to the ambient temperature. In winter, a house insulated with it is warm, in summer it is cool.

- Rodents and insects do not like it, and mold does not grow in it.

- Ecowool insulation perfectly absorbs noise and serves as an excellent means of sound insulation.

- The product is light in weight, easy to transport and install.

- The mass fits tightly into the place allocated to it, without forming voids.

- During operation, it does not cake for a long time.

- Minimum consumption of cellulose mass – 28-65 kg/m3

- Ecowool insulation is carried out in any weather, regardless of the time of year. There is no need to wait for the thermal insulation layer to dry. After applying the material, you can lay the finishing sheet.

These characteristics are determined by the component composition of the material. It is made from the following elements:

- cellulose extracted from waste paper processing;

- flammable agent (fire retardant);

- antiseptic (boric acid).

Cellulose is a hygroscopic material. Therefore, thermal insulation made from ecowool is not afraid of moisture. It can absorb up to 14% of liquid and release it through evaporation. Ecowool itself does not deform and does not lose its heat-retaining qualities. When renovating a floor, you can save on hydro- and vapor barrier materials.

They sell insulation in 2 forms: compressed briquettes of standard sizes and loose mass packaged in bags in a slightly compacted form. Before use, you need to beat it to give it fluffiness.

Ecowool insulation has disadvantages that you need to know about before purchasing and using it.

- The material undergoes complex technological processing in production. Most of it consists of natural ingredients. This determines its high cost compared to synthetic insulation.

- To install ecowool over large areas using a mechanized method, special expensive equipment is required.

- Ecowool insulation does not burn, but smolders. Floors around stoves and fireplaces should be additionally covered with fireproof sheets.

- The material is characterized by high flowability and low density, so the base for it must be solid, no floating structures.

Reviews from craftsmen and amateurs say that working with cellulose material is not difficult. A special video shows how to apply ecowool thermal insulation to a wooden deck or concrete base in different ways. Therefore, you can install it yourself with strict adherence to technology.

Ecowool or polyurethane foam: what to choose?

Hello, Daniil!

Insulation is undoubtedly one of the most important stages of construction, because the temperature inside the house directly depends on the quality of the insulation itself and the correctness of its installation; Also, high-quality insulation allows you to save a lot on heating costs. On the modern market, the most popular insulating materials are polyurethane and ecowool, but this does not mean that these products are similar to each other. Polyurethane foam and ecowool are fundamentally different insulation materials, therefore, in order to understand which one is better, you should consider each depending on the parameter.

Environmental Safety

The environmental friendliness of polyurethane foam is not just a fact - it is confirmed by many certificates of hygiene services. This insulator is highly resistant to various chemicals, which suggests a long service life of such insulation. These parameters are due to the fact that polyurethane, both simple and foamed, is completely inert to almost all chemicals, which means it does not decompose when interacting with them.

Such properties have made polyurethane foam a material used in the insulation of modern equipment (refrigerators, boilers, thermostats, medical devices that come into contact with drugs and the mucous membranes of human organs).

Ecowool is cellulose or paper, crushed into tiny fibers, with the addition of chemicals. Substances used to impregnate cellulose raw materials must have the following properties:

- Reduced flammability (fire retardants);

- Reduced ability to absorb moisture (hydrophobic);

- Repelling pests (poisons).

But despite the fact that cellulose insulation contains chemicals, it remains absolutely safe for humans.

Characteristics of polyurethane foam

Polyurethane foam is an insulator consisting of 5 - 10% binder, the rest of the insulation is gases and air. This insulator has the following characteristics:

- Density within 50 - 150 kg per m2;

- Thermal conductivity - 0.020 - 0.028;

- The pores of the material are closed;

- Temperature range - from -160 to +150 degrees;

- Service life - from 20 to 50 years.

The material is quite soft, easily deformed and does not lose its structure. It is worth noting that polyurethane foam can easily withstand bending, but quickly wears out when pressure is applied to it (the permissible reduction should be no more than 10%).

Polyurethane foam is valued for its low thermal conductivity, which means that only a 2 mm wide layer freezes or warms up. It follows from this that for high-quality thermal insulation you will need an insulator layer of 5 mm or more.

The polyurethane foam insulating layer will become stronger over time due to crystallization of the structure. This material does not mold, does not rot, is not digested by rodents and is not susceptible to fungus. But at the same time, polyurethane foam is a poor sound insulator and can be dangerous to humans; if absorbed, may cause volvulus.

Parameters of cellulose insulator

Ecowool is a product obtained by recycling paper with the addition of components that prevent combustion. The main properties of this material can be considered the following:

- Density: from 30 to 75 kg/m2;

- Thermal conductivity: 0.032 - 0.041;

- Low air permeability;

- Passivity to chemical influences;

- Good sound insulation parameters;

- Shrinkage susceptibility - 1.2%;

- Service life: from 5 to 10 years;

- Operating temperature: -40 to +120 degrees

In terms of density parameters, both insulators differ little, but the thermal conductivity of ecowool is higher, which means that the minimum insulator layer will be already 10 mm. It should be noted that at temperatures above -45 degrees the material begins to deteriorate.

This insulation cannot be used to insulate external surfaces.

There are a lot of manufacturers on the modern market who produce low-quality ecowool, violate technology, and produce products that do not comply with GOST standards, so you should be very careful when purchasing.

Application methods

Ecological cotton wool can be:

- apply by hand;

- blow out using a mechanized dry method;

- Spray onto the surface after moistening.

The manual method involves loosening with improvised tools in any suitable container. Laying in a uniform layer is carried out on insulated surfaces. If you need to insulate a cavity in the wall, then you will have to fill it with environmental wool. The minimum density for laying in the wall is 65 kg per 1 cubic meter. m, and inside the floors this figure is limited to 40 kg per 1 cubic meter. m.

If it is necessary to insulate large building structures, it is advisable to use complex equipment. The dry mechanized method involves the use of blowing machines, in the hoppers of which the insulation is loosened and then supplied in an air flow to the desired location. This technique has proven itself well in relation to:

- interfloor ceilings;

- attic floors;

- basement spaces.

It does not matter whether construction is being carried out from scratch or the building has been in use for some time. Blowing is carried out with a certain reserve, because even loosening gives only a time-limited effect. Gradually, the wool will become denser, its specific gravity will increase by 5 kg per 1 cubic meter. m. Then, if a preliminary reserve has not been made, the thickness of the thermal barrier will be reduced. There is hardly any need to explain how this will end for the residents of the house.

Dry blowing is equally well developed technologically for surfaces directed in a horizontal or vertical plane, as well as for inclined structures. A similar method can be applied along the pediment and along the pitched roof, for thermal protection of walls covered with a layer of gypsum plasterboard. Preparation for the introduction of environmental wool involves creating holes in film materials, and a flow of substance should be supplied into these holes.

In some cases, you can simplify your work and avoid contacting specialists if you use a garden vacuum cleaner. Preparation begins with beating the cotton wool with a construction mixer - any container of the required size is suitable for this. Filling is carried out somewhere up to half the height, and the mixer should be turned off when the material does not rise to its outer edge. Using a garden vacuum cleaner can save money, but you will need to hire a helper. In addition, the vacuum cleaner will have to be modified; in its standard guise it is not entirely suitable.

Important: this method allows only dry processing. If you need wet thermal insulation, you will still have to call professional installers with special machines

It is not advisable to take a garden vacuum cleaner with an internal shredder. To work, you will need a flexible corrugated hose, the length of the hose is from 7 to 10 m, and the suitable diameter is 6-7 cm.

In this case, there is no need for a waste collection bag. Instead, a corrugation is put on the pipe. To make removing the bag easier, breaking the teeth that hold it in place with pliers helps. To secure the corrugation, it is recommended to use adhesive tape or insulating tape. In both cases, you will have to check whether air will leak out through the joint.

Floor insulation begins with beating ecowool in a barrel with high walls. There is no need to increase the volume of material very much. The pipe nozzle is immersed in the insulation, and at this time someone holds the tip of the hose near the floor. This technique allows you to reduce the emission of dust outside. It is better to cover the floor with plank flooring and reserve a free board for each of the cells, then you will have to deal with dust less.

Walls insulated with ecowool are initially covered with oriented slabs. Holes corresponding in diameter to the corrugated pipe are prepared 0.1 m from the ceiling. The hose inserted there should not be brought to the floor by about 30 cm. When the walls are saturated with cotton, carefully monitor the sound of the vacuum cleaner. As soon as the suction tone changes, you immediately need to raise the hose the next 30 cm (several holes will increase the accuracy of the work).

Advantages

When considering the pros and cons of ecowool, it is difficult for an ordinary buyer to separate reality from the myths propagated by the marketing services of manufacturers.

Reality

Ecowool has the following advantages:

good level of thermal protection. Not excellent, as many publications claim, but sufficient for insulating various structures of a house or apartment - approximately at the level of mineral wool and polystyrene foam; durability. Insulation manufacturers claim a 50-year service life. The given figure cannot be verified on the territory of Russia due to the short period of application

In Finland and Canada, many houses built more than 70 years ago have such insulation; the absence of connecting seams is an important advantage over other types of thermal insulation materials. Even under conditions of the most complex surface geometry, cellulose fibers fill all cavities and cracks, eliminating the appearance of cold bridges; good sound insulation properties

Slightly lower than basalt wool, but higher than most types of insulation; fire safety - does not ignite when exposed to an open flame;

- ability to retain heat when wet. For example, glass wool, which has absorbed only 1% of water, increases the thermal conductivity coefficient by 8-9%, ecowool, when wet by 25%, increases thermal conductivity by 2-5%;

- vapor permeability - walls under such insulation “breathe”;

- good adhesion to all types of building materials, especially when working wet;

- environmentally friendly, despite the presence of borax and boric acid in the composition;

- high resistance against microorganisms and rodents.

Myths

The marketing services of manufacturers and sellers are actively promoting advantages that do not exist at all or cannot be explained logically:

- low moisture permeability - in fact, insulation based on cellulose fiber perfectly absorbs water. Another thing is that it dries well without losing its properties;

- good absorption. This plus is generally difficult to comment on, since the word “absorption” refers to the ability of a substance to absorb moisture. It turns out that with mineral wool getting wet is a significant disadvantage, while with ecowool it is a plus;

- the ability of insulation to soundproof an apartment from the noise of a construction site, a plane taking off, or passing cars. This is not entirely true. The insulation protects against airborne noise at a fairly good level, but cannot damp out sound waves of the structural and shock type (these noises are well distributed by the ground and the building structure);

- ease of insulation. It is difficult to agree with such a statement, since the vertical and inclined layer of ecowool does not adhere to the base of the insulated surface. It is necessary either to attach a film to the sheathing and add insulation between it and the wall (roof), or to resort to the wet application method, which is not feasible without special equipment;

- quick implementation of thermal insulation - when working manually, it takes several days to insulate, for example, a roof. Using special equipment for applying fibers using the wet method, you have to wait 2-3 days until the thermal insulation layer dries;

- low cost of material. The budget price of insulation is the main mantra of manufacturers. But there are nuances here that are ignored: expensive installation technology (hiring a team of specialists makes the total cost of insulation work equal to that of basalt wool insulation, and in some cases even slightly higher); insulating ecowool with your own hands, instead of saving, leads to excessive consumption of material and a thicker layer of insulation, which, ultimately, again equalizes the cost of work with insulation with basalt fiber wool;

- the possibility of applying it over old insulation is a myth that is difficult to explain. For example, as the experts who proposed this insulation option see, the technology of thermal insulation work on the outside of the building (along the facade) or in the attic space.

Minuses

Like any building material, cellulose wool has not only advantages, but also disadvantages:

- Complex installation technology that requires professional equipment and precise control of void filling. Only open horizontal surfaces - floors and attic floors - can be insulated using the manual method (dry pouring).

- Long drying time when installed wet. It will take 2-3 days, and sometimes more, to dry completely.

The first drawback is easily solved - just order an ecowool insulation service in, and you don’t have to worry about equipment and compliance with technology. As for drying, it is better to carry out insulation in the warm season or use additional heat sources so that the material dries faster.

How is it suitable for the production of ecowool?

Structurally, the activator washing machine consists of a body, insulated disks on which the blades are attached. The latter will be used to shred paper. To do this, instead of the activator, a system of knives is fixed. If the machine is equipped with a motor of insufficient power, it must be replaced with a more powerful one. In this case, you should be careful and select the engine according to the design dimensions of the mount and connection to the screw.

From the above it is clear that almost everyone can afford to make ecowool at home. But this method also has a downside: quality. Made by hand using a converted washing machine, ecowool is of very low quality, even relative to the cheapest, but industrially manufactured samples. Do not forget that the buyer now knows much more about the item of purchase, and therefore selling home-made ecowool is a disastrous business. No one will buy it if there are better quality samples at an affordable price. This means that such insulation can be used exclusively for personal purposes.

Advantages of ecowool

Ecowool has a huge number of advantages that make this material indispensable in specific situations. So, the main advantages of ecowool are:

- low level of thermal conductivity, which is at the level of 0.04 W/mK. In this indicator, ecowool can be compared with other types of insulation, such as mineral wool, but in a number of its other advantages it outperforms them. Thus, ecowool is installed in a seamless manner, easily blown even into the most inaccessible places, which allows you to more effectively fill all the voids, and therefore increase the level of thermal insulation of the room;

- fire safety, because when exposed to fire, the material does not ignite, but can only smolder slightly;

- high level of sound insulation: a 15 mm layer of insulation reduces the noise level by 9 dB. That is why the material is often used where not only thermal insulation is needed, but also reliable sound insulation;

- environmentally friendly, since the material does not contain toxic components, such as formaldehyde, which can negatively affect human health, cause allergies, diseases of the skin or respiratory system. But still, before buying insulation, it is better to inquire about the composition, namely, what kind of fire retardant was used. So, for example, if ammonium sulfate is present in the composition, then with a high degree of probability an unpleasant odor will be felt, and the durability of the insulation in this case will not be maximum;

- maintaining an optimal indoor microclimate and controlling humidity. Thus, even when the humidity level increases to 30%, the thermal insulation performance of ecowool does not decrease, unlike other types of insulation, which, at a humidity level of already 5%, lose a number of their positive properties. By the way, all this means that when using ecowool, vapor barrier will not be required;

- the ability to do without a vapor barrier film is a great way to save a little when installing ecowool, which is also an undeniable advantage;

- efficiency is also manifested in the fact that to insulate a room you will not need a very large amount of insulation, and the price of ecowool is quite affordable;

- ecowool will not become a place for the development of mold or bacteria, or a place of residence for rodents, unlike some other mineral insulation materials.

Comparative cost of attic insulation with different types of insulation

When insulating a house, many people ask the question: “Which insulation to choose? What is ultimately better, warmer, safer and most importantly more economical: ecowool, expanded clay, mineral wool, glass wool or polystyrene foam?

We did a little analysis

The calculation was carried out in accordance with the requirements of SNiP II-3-79 “Construction Heat Engineering”, taking into account the climatic conditions of Kazan.

Options for ensuring standard heat transfer resistance indicators for residential buildings (using the example of attic floors with an area of 100 m2, room temperature 20°C, Rreq = 4.338 m2*oC/W, thermal resistance of floors is not taken into account):

| Glass wool insulation (Izover Pitched Roof) | Basalt insulation (Rockwool light batts) | Expanded polystyrene (GOST 15538-86) | Expanded clay (expanded clay gravel GOST 9757) | Ecowool | |

| Thermal conductivity (under operating conditions B), W/m*C | 0,043 | 0,047 | 0,05 | 0,165 | 0,04 |

| Required layer thickness, mm | 180 | 200 | 210 | 680 | 170 |

| Density, kg/m3 | 15 | 37 | 25 | 500 | 35 |

| Load on the structure, kg/m2 | 2.7 | 7.4 | 5.25 | 340 | 6 |

| Cost of insulation, rub./m3 | 2080 | 1600 | 1300 | 1500 | 1120* |

| Cost of insulation RUR/m2 (insulation only) | 375 | 320 | 270 | 1020 | 190 |

| Cost of vapor barrier (Izospan V), rub./m2 | 15 | 15 | 15 | — | — |

| Cost of delivery of insulation (within a radius of 30 km) | 1500 or independently | 1500 or independently | 1500 or independently | 12000 or independently | 1500 or independently |

| Cost of installation, insulation (and film) | 2000 or independently | 2000 or independently | 2000 or independently | 10000 or yourself | 6500 or independently |

| Total costs for insulation of 100 m2 on a turnkey basis, rub. | 42500 | 37000 | 32000 | 124000 | 27000 |

| Total costs for insulation of 100 m2 with independent delivery and installation, rub. | 39000 | 33500 | 28500 | 102000 | 19000 |

*At the price of ecowool 32 rubles/kg

Ecowool: origin

At the beginning of the 20th century, a new material for insulating building surfaces appeared on the construction markets of Europe and the USA. It was called ecowool. For its production, cellulose was used, which was obtained from substandard wood.

The Germans organized serious production of this heat-insulating material in 1928. Ecowool insulation became the most popular in the middle of the last century, when mass construction of frame buildings began. In Canada, Finland, USA, Germany, Austria, Japan it is especially popular.

The Finns especially mass-produce and insulate their houses with eco-wool. Compared to other materials, this building product is optimally suited for residential premises and buildings with a certain microclimate, for example, museums. In Finland, cellulose wool is produced in large quantities and exported to nearby countries. Russia is one of these.

In the Russian Federation, cellulose insulation has been used not so long ago, but its popularity is growing. Especially often they insulate private houses. Positive consumer reviews about the quality and use of ecowool speak in favor of the widespread use of this material. Due to increased demand, we are establishing the production of cellulose insulation. In the markets you can see Russian analogues to foreign models.

Frame insulation technology

Thermal insulation of a frame house is carried out using a dry or wet method. For application to walls, it is better to choose a “wet” technology; for floor insulation, a “dry” method is suitable.

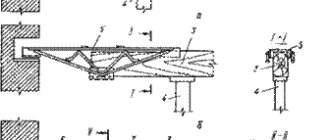

Equipment for blowing ecowool

High-quality insulation of vertical surfaces is impossible without the use of specialized blow molding installations for installing ecowool. There are many different models on the market, differing in power, completeness and scope of application. Equipment for ecowool can be designed for both dry and wet methods.

Some craftsmen make the unit with their own hands. To make a blowing installation with your own hands, you need to understand the principle of constructing the equipment. Required working nodes:

- Platform. A frame for fixing a loading funnel with a motor, a blower, a sluice and a gearbox.

- Engine. Use a two- or three-stage motor.

- Gateway. Provides cotton wool capture and air dosage. Inside the chamber, the material is turned over and fed into the hose under pressure.

- Gearbox. Increases power output by reducing the speed of the ripper and motor.

- Baking powder. A system of knives like in a blender for fluffing and preparing the mass.

- Loading funnel for laying insulation.

- Control Panel.

The described complete set corresponds to the dry spray unit. To implement the wet-glue method, you will need a block for moistening the cellulose briquette.

Thermal insulation of the house: wet method

The technology is great for application to open areas. The method allows you to control the uniformity of laying and ensures a high density of the thermal insulation layer. Cellulose wool is fed under pressure and adheres to the surface. High adhesion is ensured by lignin - it is released when water is added to ecowool.

Work progress:

- Lath the walls.

- Fill the hopper with the fluffy mass.

- Start spraying. At the exit, dry cotton wool from the nozzle is moistened and supplied under pressure.

- Distribute ecowool evenly over the surface of the walls.

- Wait until it dries completely and cut off the excess - the waste can be reused.

“Dry” filling of wall space

The waterless method can be implemented on horizontal and inclined surfaces. Spraying is used to insulate closed cavities, non-demountable structures, and interfloor ceilings.

The essence of the method:

- At the top of the wall, make a hole commensurate with the dimensions of the insulation supply hose.

- Insert the sleeve and turn on the equipment.

- Fill the voids, periodically tamping the dry mass.

- Close and seal the hole.

Blowing into the cavity is carried out regardless of weather conditions and avoids the dismantling of structures. However, the technique has several significant drawbacks - it is difficult to ensure uniform distribution and the required thermal insulation density.

Manual filling of floors

The easiest way is to insulate the ceiling or floor. The technology does not require specialized equipment, but takes more time. The method is only suitable for thermal insulation of horizontal surfaces.

Do-it-yourself backfilling sequence:

- Level the surface, install the logs - the height of the boards is 8 cm, the approximate size of the cells is 40*80 cm.

- Fluff the compressed briquette well. Place the mixture in a large container and mix vigorously with a drill and mixer attachment.

- Fill the space between the joists with insulation. There should be an abundance of ecowool - a small pile of dry material will subsequently cover the floorboards.

Experts advise letting the cellulose wadding “settle.” The lignin included in its composition will react with moist air vapor and a dense crust will form on the surface of the insulation. The layer will improve heat retention.

Insulation of ecowool at home

Ecowool can be insulated in two ways: dry and wet. These two methods are fundamentally different, since in the first case, the material is poured dry, and in the second, it must be moistened. Accordingly, the wet method can be used to insulate the walls of buildings, a variety of vertical surfaces, and the dry mixture can be used for thermal insulation of horizontal objects - roofs, floors, ceilings and the like.

Dry application of ecowool

In this case, dry material is simply poured into the prepared space. For example, logs can be used to lay the floor, or vice versa, the roof. The space is thoroughly cleaned of dirt and dust; it is advisable to do this with a vacuum cleaner. All surfaces must be clean and dry.

The next stage: working with insulation. Ecowool must be poured from the bag into a plastic container of suitable size - it should be larger than the volume of the material. Using a special attachment on an electric drill, you should carefully fluff the ecowool.

When carrying out such work, it is recommended to use personal protective equipment: goggles, a respirator, and protection from cellulose dust.

The fluffy material is poured into the designated compartments. This must also be done wearing goggles and a respirator. You should cover the ecowool in a dense layer, at least about ten centimeters.

And the last operation is to carefully compact the insulation until a uniform and homogeneous layer is formed.

The dry method also provides another method of insulation: making a special box around the perimeter of the entire building, into which slightly moistened insulation is poured. In this case, moisture is necessary so that the wool can be compacted. Of course, this option is quite troublesome in terms of making such a frame, so it will not always be practical. As a rule, it is chosen by those owners who want to insulate their home themselves, without resorting to the help of specialists.

Applying ecowool using a wet method

Requires preliminary preparation. In addition to the usual cleaning of wall surfaces, you will need to install lathing, which will become the basis of the thermal insulation layer. This design is simple to implement and can be made of metal profiles or wooden slats. Wooden lathing is more relevant, since wet ecowool will stick better to the loose structure of wood than to a slippery metal surface.

The insulation, as in the dry method, must first be fluffed and then soaked in water. Some manufacturers advise using a special adhesive solution instead of ordinary water - recommendations for the use of each specific type of ecowool should be read on its packaging. In addition, it is necessary to take into account the type of surface being treated: if we are talking about the ceiling, then it is better not to take risks and dilute the material with glue.

Next, wet ecowool is applied to the sheathing. This is done using a special installation that sprays the solution under pressure.

That part of the insulation that, when applied, falls behind the surfaces installed for insulation, must be carefully cut off using a sharp stationery knife.

It needs to be dried thoroughly and can be reused. That is, in fact, applying ecowool is a waste-free process.

There is also the option of applying it using a wet method without using a special installation for ecowool, as this is not always convenient. In this case, it is necessary to prepare a viscous ecowool adhesive solution and apply it using the “throwing” method onto the wooden sheathing. Next, the mass, before it dries, needs to be tightly leveled, using the frame elements as beacons. One cannot fail to mention the disadvantage of this method: the density of ecowool applied in this way is much greater than when sprayed, which means its thermal conductivity is greater.

This method is more artisanal and does not correspond to the technology originally conceived by ecowool manufacturers. However, it is widely used, since purchasing a special installation for application is an expensive process and simply not practical for a single use. Typically, using installations, insulation is applied only by specialists involved in professional construction work.

Advantages and disadvantages of ecowool

Ecowool is a unique material that has a lot of advantages, however, it also has disadvantages; we will describe these qualities in more detail, point by point.

The advantages of ecowool include:

1. Environmental safety. This material is undoubtedly the most environmentally friendly of the insulation materials on sale. All components of ecowool are non-chemical, non-toxic and not dangerous to human life and health. This material is also not hazardous to the environment. For a building material, which is essentially ecowool, this is a huge plus.

2. Durability. High-quality material, which is properly laid in compliance with all manufacturer’s recommendations, can easily last for fifty years.

3. Ecowool is suitable for processing large areas. Of all the insulation materials, this material is the easiest to work with on large objects. Naturally, we are talking about spraying it using a special installation.

5. Fire safety. Despite the fact that the basis of ecowool is cellulose, which is known to burn well, the insulation itself is not flammable. This effect is achieved due to the addition of borax, which is a crystalline hydrate - that is, when heated, its molecules release a large amount of water, which prevents the ecowool from igniting.

6. Versatility. Ecowool can be used to insulate absolutely any object, regardless of the construction material, climatic region, size and other circumstances. It is also convenient because it is suitable not only for walls, but also for ceilings, floors, partitions and the like.

7. Good sound insulator. Ecowool, unlike some other insulation materials, well delays the propagation of sound waves, therefore, it can be used not only for insulation, but also for soundproofing rooms.

8. Seamless installation. Thanks to its free-flowing texture, ecowool turns into a seamless insulation in any type of application - both dry and wet, which means that during operation no cracks or so-called “cold bridges” will appear in it, which can worsen the thermal insulation properties.

9. Thermal insulation of hard-to-reach places. Thanks to spray application, ecowool can be used to insulate the most inaccessible places, joints, corners - due to the absence of seams and uniform application, it will create a dense layer on any surface!

10. Not high cost. This point is also important, especially if large areas are insulated. Ecowool, for all its advantages, has an affordable price.

Disadvantages of ecowool:

With such a huge number of advantages, ecowool has only one - the only disadvantage, and even that, one might say, is conditional:

For high-quality installation of ecowool, a special installation is required that sprays the material under high pressure. In general, insulation with this material is best entrusted to professional builders who have experience working with it.

This disadvantage is quite controversial, since, even taking into account the involvement of specialists and the necessary equipment, the list of advantages of ecowool significantly exceeds its only disadvantage. If you make some simple mathematical calculations, it becomes obvious: once you have taken care of high-quality insulation of your home, you can forget for many years about saving energy, dampness, cold floors and similar troubles caused by atmospheric changes.

How to make ecowool with your own hands, equipment and blowing of ecowool

Ecowool is one of the types of thermal insulation materials. This is a cellulose insulation that consists of an antiseptic and recycled cellulose. Cellulose fibers make up almost 80% of the material itself. It creates an excellent homogeneous seamless layer of insulation. What is ecowool insulation, reviews about it - we will talk about this in our article.

Definition of ecowool. Its advantages

Ecowool consists of fibers that contain lignin, a substance that, when moistened, imparts stickiness. This material is completely harmless and absolutely non-toxic.

In addition, all its components are non-volatile, which means that they cannot harm the environment and people.

There are other advantages:

- good thermal insulation and sound insulation material;

- not susceptible to rotting and fungus;

- in the event of a fire, it is not susceptible to fire for a long time;

- trouble-free installation;

It should be noted that in ecowool, as in all thermal insulation materials, rodents appear that consider it as their food.

This material contains substances such as boric acid and borax. They reduce the fire hazard and provide good protection against fungi and rot. The low cost of wool is associated with simple installation and inexpensive raw materials from which it is made.

Do-it-yourself ecowool. Laying methods

Ecowool can be installed by both professionals and amateurs. There are the following installation methods:

Blowing ecowool with your own hands confronts a person with certain problems. This method is used to insulate floors and flows. Ecowool is easy to install with your own hands; no special equipment or special skills are required.

Manual installation includes several stages.

First you need to prepare the insulation by pouring it into a container such as a bucket or basin. The next stage, “fluffing,” is carried out using a drill.

Blowing ecowool with your own hands requires direct manual installation, which consists of filling it into the ceilings. But there are situations in which additional blow molding equipment is required. After filling the insulation, it must be closed. To do this, you can use sheet materials, for example, plywood.

With the mechanized laying method, equipment specially designed for this is used. And wet-glue processing is usually carried out by professionals.

It is the last method that is of the highest quality.

Having considered what ecowool is with your own hands, the equipment that is used in this process is also worth considering:

- blowing installation - necessary for uniform supply of insulation;

- corrugated hoses - supply ecowool to the place of insulation;

- pump set;

- special nozzles for blowing.

This equipment is necessary when it comes to mechanized insulation of a building.

Recommendations for do-it-yourself insulation

Using ecowool, you can insulate your walls yourself. floors, ceilings, attics and roofs. On construction sites you can find out more specifically what ecowool insulation is, reviews about this process and recommendations.

But we will give some basic recommendations in our article:

To determine the density, it is necessary to take into account the material consumption

It is important to know that when insulating with your own hands, the material consumption is much higher than with mechanized insulation. Density control can be calculated using a formula and thereby reduce material consumption. To insulate different floors, there are standards for the thickness of the floor. The thickness of the ceiling for the floor is 15-20 cm, for attic floors - up to 30 cm, the thickness of the ceilings between floors is 15-20 cm. If the ecowool insulation process is carried out manually, then it must be taken into account that the material consumption may be slightly higher than originally envisaged. When insulating materials such as concrete, brick or iron with ecowool, it is necessary to prevent the possibility of the ecowool absorbing condensed moisture. Likewise, when insulating a roof, it is imperative to protect the insulation from penetration of sub-roof condensate. This can affect not only the quality of the building's thermal insulation, but can lead to gradual destruction. This thermal insulation material is excellent for insulating residential buildings and utility rooms, as well as for insulating individual building elements.

This can affect not only the quality of the building's thermal insulation, but can lead to gradual destruction. This thermal insulation material is excellent for insulating residential buildings and utility rooms, as well as for insulating individual building elements.

Main characteristics of ecowool

Ecowool is a modern thermal insulation material that is used for insulation and sound insulation of residential buildings, educational institutions, music studios, industrial and commercial facilities of various levels. The basis of ecowool is cellulose fiber. The share of this component in the total volume of insulation reaches 81%. The remaining part comes from additional mineral materials, which are fire retardant and antiseptic additives. In particular, the antiseptic properties of ecowool are ensured by the composition of 7% borax, and fire resistance is a consequence of the use of 12% boric acid in the composition.

Boric acid is an antiseptic

The third element included in ecowool is Lewis acid 8*. There was such a scientist. He brought her out. Formula "H3BO3". Tenth grade, third quarter, chemistry. Externally, it is a crystal-like mass with a characteristic scaly structure, colorless and odorless. Used as an antiseptic - it resists the popularization of harmful microorganisms. Suppresses mold growth in the bud. Fights against fungal plaques of various origins. In classic ethyl alcohol it occupies ¾, that is, the majority (75%) of the main composition. For obvious reasons, it is dangerous for humans if it enters deep into the esophagus and stomach.

8* Gilbert Newton Lewis - chemist from the USA

Use in medicine

As you probably understood from the above paragraphs of the text, not a single medical procedure can be done without boric acid. Antiseptic agents based on it are used by doctors from all over the world everywhere and without any exception. Drops of it are placed in the ears to prevent otitis media and other diseases. In general, I can talk about it for a long time. The article is not enough to describe all the benefits of the acid, which was discovered by a famous scientist from the United States of America. Want to know more? Click on the link indicating the chemical properties of boric acid.

Other applications

- research and laboratory activities of scientists;

- production of construction and finishing materials;

- food industry in Western countries 9*;

- film industry and photography;

- jewelry making and foundry production;

- fire protection and fireproof environment;

- luminescence and non-thermal glow.

9* preservative “E-284”