Knauf has been working on the creation of thermal insulation materials from fiberglass for 70 years, and today its range continues to expand. Mineral wool of new and improved series enters the market, less effective and “morally obsolete” ones are discontinued. Currently, the Knauf company offers builders glass wool, which is superior in its insulating characteristics to basalt. At the same time, it is absolutely environmentally friendly, characterized by minimal water absorption and dust formation. Let's look at the new products in this review.

For private developers

TeploKnauf is a series designed for use in private low-rise construction. Available in the form of soft rolls and slabs, compressed in packaging 2-8 times. This simplifies and reduces the cost of transportation, but requires patience from buyers: after removing the film, the cotton wool needs to be given several days for the elastic fibers to straighten and restore their original volume.

To increase the hydrophobicity, Knauf mineral wool is impregnated with water-repellent compounds in production. The slabs have a size of 61x123 cm, which allows them to be tightly installed between the rafters with a standard pitch of 0.6 m without the use of additional fasteners. Builders in their reviews especially note the tenacity of the fibers that hold the slab in the wooden frame.

- HeatKnauf for the cottage. Universal insulation is available in the form of mats with a thickness of 50 or 100 mm. For small facilities where accurate calculations of the building’s energy efficiency are not made, such a limited selection of wool can be called quite sufficient. It is used for inclined and vertical structures - its rigidity is enough to fit between the rafters or into the sheathing of the wall.

- TeploKnauf for roofing is a rolled material with a thickness of 50 and 150 mm with a sheet size of 5.5x1.2 m. It has increased water-repellent properties thanks to the special impregnation Aquastatic. Absorbs about 45 dB of airborne noise.

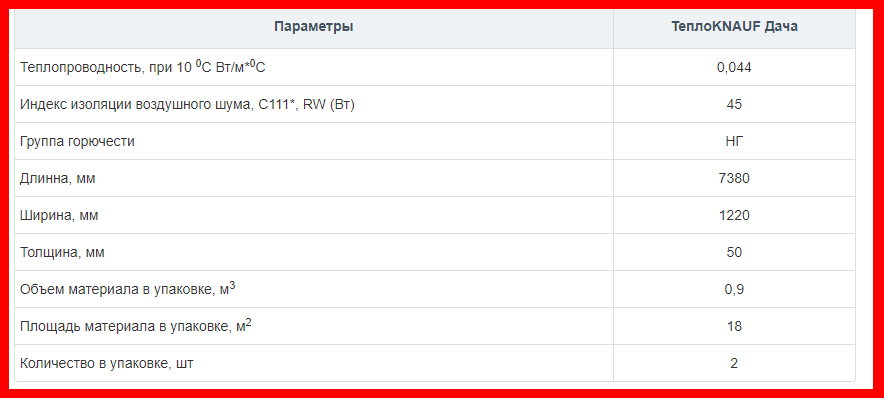

- HeatKnauf for floors. A separate series of 50 mm thick mineral wool rolls allows for economical use of insulation in accordance with the specific operating conditions of the interior. Here the canvas size is already larger - 7.38 x 1.22 m, and 2 mats are pressed into the package.

Most of the materials in this Knauf line are positioned by the manufacturer itself as “3 in 1” insulation, which retains heat, absorbs noise and protects against dampness. This is probably why they are so expensive.

| Knauf Cottage (new series) | For roofing | For floors | |

| Thermal conductivity, W/m K | 0,037 | 0,037 | 0,040 |

| Density, kg/m3 | 15 | 11 | 11 |

| Package volume, m3 | 0,6 | 1 | 0,9 |

| Cost, rub/pack. | 1005 | 1540 | 950 |

Fibrous materials

- Basalt wool is distinguished by a fairly low coefficient of thermal conductivity of up to 0.05 W/m2 K. It shows the amount of energy that passes through a layer of insulation with an area of 1 square meter with a temperature difference of 1 Kelvin (equal to 1 degree Celsius). A reliable thermal barrier is provided by still air located between the randomly located fibers of the slab or roll.

- Knauf mineral wools are non-flammable materials, do not spread combustion over their surface, and do not emit substances harmful to breathing when heated. 3. Stone wool has high biological and chemical resistance. Does not react with active chemicals, is not used as food by rodents and insects, and does not spread fungus and mold in its volume. Does not deteriorate when exposed to sunlight.

- Knauf mineral wool is a material with a high degree of vapor permeability, which allows it to be used with so-called “breathable” materials. These include wood, foam and aerated concrete, and slag blocks. Due to their internal structure, they absorb moisture when there is an excess of it in the air and release it when there is a deficiency. On the one hand, this is a good quality that allows you to maintain indoor humidity at a constant level. On the other hand, the negative side is that there is a danger of the development of microorganisms on the surface under the insulation.

- Knauf mineral wool confirms its environmental safety with appropriate certificates. It contains no substances harmful to human health. During operation, Knauf mineral wool does not emit harmful substances and fibers into the atmosphere.

- Dense slabs are an excellent sound insulator, reducing noise levels by 45 dB.

- A distinctive characteristic of Knauf insulation is its long service life. If the manufacturer sets this period at 50 years, then the fact is much longer.

Minvata TechnoNIKOL

TechnoNIKOL is a domestic manufacturer of insulation materials, one of the five best European companies producing these products. TechnoNIKOL mineral wool is made of basalt fibers, which are characterized by high environmental friendliness and thermal insulation properties. This material is used for insulation of both multi-storey buildings on an industrial scale and in private housing construction. The most common types of mineral wool produced by TechnoNIKOL are presented below:

- Rocklight

is a basalt slab with a low content of phenol in resins, due to which this material has increased safety and environmental friendliness. The main area of application is insulation of private houses. It can be used to isolate horizontal, vertical and angled surfaces. The load on the structures is small, so they may not have high strength, which expands the scope of their application. - Heatroll

is a material consisting of long rolls of cotton wool that have improved sound insulation properties. They are most widely used in the insulation of roof slopes, floors between floors and attic spaces. - Technoacoustic

- designed primarily for sound insulation, in addition it has good heat-saving properties. It is presented in the form of cotton wool, made from specially arranged basalt fibers, due to which one layer of this material can prevent the penetration of sound up to 60 dB. This type of insulation is mainly used in the interior decoration of a building - partitions between walls, ceilings, attics. - Technoblock

- produced in the form of low phenolic flat slabs that are resistant to combustion, noise and heat insulation, and are also not susceptible to moisture. They are used in most cases for insulating layered warehouses and frame buildings.

The main characteristics of TechnoNIKOL mineral wool: thermal conductivity 0.035-0.039 W/mS, vapor permeability 0.3 mg/mhPa, water absorption 1.5-2%, Density 25-50%, compressibility 8-55%. Prices for TechnoNIKOL mineral wool are quite low and easily compete with foreign analogues. Thus, Rocklight slabs can be purchased for only $38 per cubic meter.

Having examined the main types of mineral wool offered for sale, you can make a choice in favor of one manufacturer or another. Depending on the scope of use, the conditions, price and other nuances, you should buy a certain brand of mineral wool. Not only the comfort and warmth of your home, but also the safety of the whole family will depend on how responsibly you take this matter.

The topic of modern thermal insulation materials, both imported and domestically produced, continues to interest readers, because thanks to these materials it is possible not only to reduce home heating costs, but also to significantly reduce the cost of building construction. A leading specialist advises.

For the dacha

TeploKnauf Dacha is one of the early developments in the field of insulation of attic and interfloor ceilings. It is recommended for use in seasonal summer cottages and outbuildings. Characteristics of Knauf dacha:

- thickness -100 mm;

- roll length – 7.4 m;

- width – 1 m 22 cm.

The density of the heat insulator is measured in kg/m3 15 Dacha. A roll of Knauf dacha insulation contains 18 m2 of material.

Installation features

Preparing the frame for external wall insulation

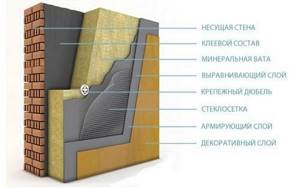

When installing Knauf Cottage brand mineral wool, you must follow the manufacturer’s recommendations and basic rules so that the result is as ideal as possible. The installation process consists of several stages and includes installation of the frame, the insulation itself, and the application of a vapor barrier film. You can handle this process yourself if you have skills in the field of construction and finishing work, or you can entrust the installation to professionals.

Frame

A primary wooden frame is necessary for direct installation of insulation on the walls. Without it, the material will not hold up. Before installation, the walls are cleaned of unnecessary elements and wooden blocks are prepared, which are treated with a fire-resistant compound. They are fixed horizontally and vertically to the walls from one corner to the other; in the presence of unevenness, special substrates are made from various materials.

The beams are secured using 75 mm self-tapping screws, each fastening is installed at a distance of at least 40 cm from each other. After installing the first beam, you need to measure 58 cm from it, since the width of the slab is 61 cm, then fix the second and subsequent beams while maintaining this distance. The windows are framed with bars horizontally and vertically, taking into account the plane of the wall.

If necessary, you can use additional substrates to level the surface of the walls and secure all the beams with the slabs as securely as possible.

Installation of insulation

Installation of insulation

Plates are installed starting from the corner, they are slightly compressed and placed between the beams, then fixed to the wall using special mushrooms. For one slab you will need at least 3-5 mushrooms, taking into account the material in one package, each of them is mounted in a through hole with a diameter of at least 6 mm, made with a hammer drill or drill. The insulation can be cut to fit the spacers using a paint knife. After filling all the cells between the bars, they proceed to installing the film.

Installation of vapor barrier film

Vapor barrier for attic roof

The film is necessary to prevent the formation of condensation inside the insulation; if it is present, the vapor particles simply come out to meet the cold air. It must be installed with the smooth side up, taking into account the instructions, each strip is placed from bottom to top, taking into account an overlap of 10 cm or vertically from the corner. For the most reliable fastening, the film is sewn to the wood blocks using a construction stapler. The seams must also be taped with double-sided tape to prevent them from coming apart. After the walls are covered, you can begin installing the siding.

Siding

For siding, bars measuring 25x50 or 25x100 mm, special screws with a length of 35 to 55 mm and a screwdriver are used. The frame boards are impregnated with a bioprotective solution and cut to the required length, which must correspond to the length of the boards for the first frame. Next, you will need to form the corners and screw them to the horizontal bars on the first frame vertically, the next boards are attached at a distance of at least 25 cm from each other. Following these rules helps make the structure more durable in addition to the standard insulation procedure.

It is important to always follow the manufacturer's recommendations and not combine materials that are incompatible with each other. In this case, the insulation copes well with its direct and additional functions.

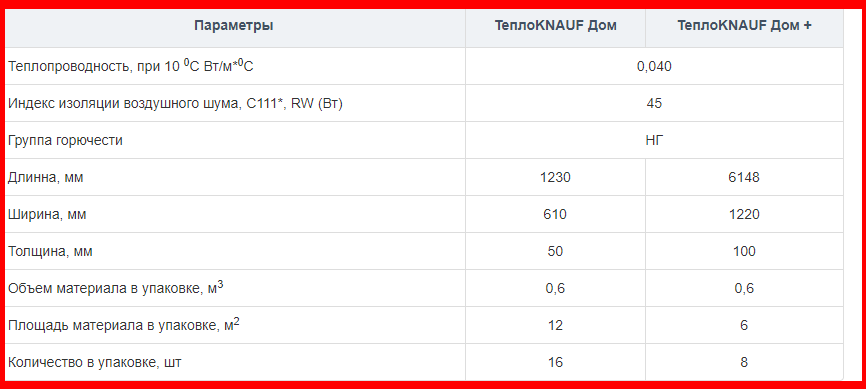

For a simple home

TeploKnauf Cottage is an advanced development for insulating detached houses for permanent residence. The use of Knauf Cottage ensures effective insulation and rational spending of funds. HeatKnauf Cottage is an extremely elastic heat insulator that combines protection from cold, noise and water.

Knauf Cottage insulation is available in rolls and slabs. Roll material is intended for thermal insulation of pitched roofs. Mineral wool slab thermal insulator is excellent for external walls and soundproofing of internal partitions.

Knauf Cottage has a thickness of 100 mm, which allows:

- reduce installation time;

- reduce the amount of waste, thereby saving money;

- avoid additional fastening of the material due to increased elasticity.

Basalt wool

It is often called stone wool, hinting at the origin of this material. It is obtained as a result of melts and extrusion of mountain dumps, slags and slag mixtures.

- Knauf basalt insulation is available in the form of rolls, slabs, pipes and even lamellas glued to metal foil.

- The density of the proposed types of insulation is different. Thus, the Knauf Insulation LMF AluR product, which is designed for insulation and insulation of air ducts, external walls and facades, has a density of 35 to 90 kg/mK. Roll insulation has density parameters from 80 to 100 kg per cubic meter. And the materials intended for insulation of roofs and facades of buildings, Knauf Insulation DDP slabs, have a density of 150 to 200 kg per cubic meter. In terms of density, only some types of rigid polyurethane foam approach basalt insulation with an indicator of 100 kg/mK.

- The thermal conductivity coefficient of this type of insulation ranges from 0.04 to 0.045. This indicator is not the minimum; for example, it is somewhat less for fiberglass, and even more so for liquid insulation. Approximately in the same group with basalt wool is polyurethane foam with an index of 0.04 to 0.05. However, this low degree of thermal conductivity makes stone wool one of the most effective thermal insulation materials.

- Knauf basalt insulation has such valuable qualities as excellent sound insulation, fire resistance, and a wide range of uses.

- In the manufacture of Knauf basalt insulation, artificial resins are used as a binder, which reduces the environmental friendliness of the final product. But this material is produced using hydrophobization technology, which increases its water resistance.

- Basalt wool, like fiberglass insulation, has biological and chemical neutrality, which increases the safety of its use for insulating residential premises.

Application:

- Knauf stone wool slabs are used for insulation of flat roofs, facades, and external walls. Knauf Insulation HTB boards, reinforced with canvas or foil, are successfully used for pipelines.

- Rolled basalt-based insulation is used for insulating pipes and other engineering structures and equipment.

- Mineral wool cylinders are used for thermal insulation of pipes. Additional reinforcement with foil enhances the waterproofing of structures.

- Another type of roll material - LMF AluR - consists of lamellas glued to a foil base. This product does an excellent job of insulating air conditioning and heating systems. It is great for baths, saunas, and any wooden structures.

Price:

Layer insulation

TeploKnauf Premium is the first material developed for use in private households. Does not contain fiberglass. During operation, it does not change its dimensions and does not shrink, which avoids ruptures in the insulation layer.

It has increased heat-retaining capacity and good sound insulation. Resistant to getting wet. It is used for insulation of enclosing structures, including layered masonry walls. The mini-slab has dimensions of 1230x610 mm.

For professional use

The use of Knauf Insulation insulation gives excellent thermal insulation results regardless of who installs it: a professional builder or the owner of the house.

The line of manufactured products allows you to select the material needed for a specific case.

Due to its environmental friendliness, Knauf Insulation insulation is recommended for use in residential buildings, preschools, schools, medical and medical institutions.

Characteristics

Mineral wool from the commercial manufacturer Knauf operates on a three-in-one principle. Now I’ll tell you what it is. Everything is very simple: this mineral wool protects from sounds, moisture and perfectly retains heat in the house (your home turns into a thermos).

It is sold in almost every normal store. There are two types. The first is in the form of a roll, its size is 61.4 centimeters by 122 centimeters. The second is in the form of a slab, its dimensions are 123 centimeters by 61 centimeters and a height of 5 centimeters. But if you want very good noise insulation (you live near the railway) or thermal insulation, then use Knauf Cottage Plus mineral wool. It is much denser and the duty of the slab (it does not come in rolls) is as much as ten centimeters. This is much better than putting two layers of five centimeters each.

Personally, I used it not only for the facade. But both for the roof and for the partition (place of plasterboard), and I’ll say it’s pretty good.

Monolithic insulation

- The thermal plate is made from polystyrene foam. Thanks to the extrusion process, it acquires the property of thermal insulation. The numerical indicator of specific thermal conductivity is one of the lowest among insulation materials and is at the level of 0.04 W/m2 K.

- Knauf Therm expanded polystyrene can operate for more than 50 years, subject to operating conditions.

- The thermal plate is destroyed when exposed to direct sunlight. It has extremely low chemical resistance to acids, solvents, and petroleum products. Therefore, the insulating outer layer on the walls must be protected with plaster or siding.

- She has complete biological passivity. Does not spread fungus, mold, bacteria on its surface. Not used as food by rodents and insects. Therefore, it is better to insulate the roof from the inside using polystyrene foam materials.

- Thermal board has a high density, which makes it an indispensable sound insulator for building envelopes.

- Its fire danger is quite high. When exposed to open fire, the hot plate ignites, maintains combustion, and releases substances harmful to breathing into the atmosphere.

- When used under the required conditions, the thermal stove is absolutely environmentally safe. It does not smell, does not emit harmful substances, and does not break down.

Description of mineral wool brand "Knauf"

Mineral wool "Knauf" is also called stone wool and is made, no matter how funny it may sound, from stones. This material is also called basalt wool, the production of which uses stones of lava origin. They are melted down, and then binders are added to them. The fibers are formed into rolls or solid slabs.

Mineral wool can be produced using different technologies using different materials. The production process affects the technical characteristics of basalt and mineral wool. Traditional mineral wool is good, but can be susceptible to moisture, dust and be harmful. All these troubles were overcome within the framework of modern production. As a result, it is possible to obtain an almost ideal insulation.

Knauf mineral wool is produced without the use of formaldehyde and phenolic resins. Almost all the negative reviews about the dangers of mineral wool used to be aimed precisely at the fact that when exposed to high temperatures, the material begins to emit phenol fumes, which are quite toxic.

The material described does not contain harmful resins, and therefore no harmful fumes. The same can be said about the ability to emit dust. It negatively affects a person's lungs and irritates the skin. However, most often mineral wool does not generate dust. This characteristic is characteristic of glass wool. However, if the mineral wool fibers are poorly formed, they can break, which causes the release of dust.

New development

Monolithic materials are used for thermal protection of houses, cottages, walls, facades, roofs, floors, foundations.

The newly developed Knauf Therm Floor is a durable material for insulating plinths, foundations, and blind areas with a load of up to 12 tons per m2. Flor foam has moisture absorption of up to 0.8% of the volume of insulation. Used in the installation of “warm floor” systems.

If you need an effective, convenient, innovative material to protect your home from heat loss and noise penetration, choose Knauf products. It meets all the stated characteristics and will help you forget about the cold and noise in the house for a long time.

KNAUF INSULATION thermal plate 037

KNAUF INSULATION Thermal plate 037 is a material made from natural mineral wool, created in the form of slabs. These insulation materials are used both in construction and renovation. Its main feature is that it has high sound-absorbing properties.

KNAUF INSULATION THERMAL PLATE 037 in use

Main properties of KNAUF INSULATION THERMOPLATE 037:

- vapor tightness;

- convenient standard size;

- elasticity;

- elasticity.

The thermal plate combines low weight and high thermal insulation, so choosing the desired thickness of the material is not difficult. A suitable thickness will reduce the load on the main frame. Another important plus of this thermal insulation is that even after decades, the material will not lose its original appearance and will continue to keep the house warm.

Application:

- interfloor ceilings;

- base in the form of insulation for siding;

- partitions;

- attic coverings;

- insulation of floors.

Insulation “TEPLOKNAUF COTTAGE” & “TEPLOKNAUF COTTAGE+”

Insulation “TEPLOKNAUF COTTAGE” & “TEPLOKNAUF COTTAGE+” are also insulation materials based on natural mineral wool and modern high technologies. This type of insulation is suitable for that category of people who want to bring warmth and comfort into their home without extra costs. Like other thermal insulations, the material “TEPLOKNAUF COTTAGE” & “TEPLOKNAUF COTTAGE +” is non-flammable, but at the same time it contains 3in1 technology. 3in1 implies that this insulation will retain heat, prevent the penetration of sounds, and it also has water-repellent properties .

Application of insulation materials “TEPLOKNAUF COTTAGE” & “TEPLOKNAUF COTTAGE+”:

- roof;

- walls.

Types of insulation materials “TEPLOKNAUF COTTAGE” & “TEPLOKNAUF COTTAGE+”:

- rolls;

- slabs

TEPLOKNAUF COTTAGE+ is a unique, completely new type of thermal insulation. Its thickness is 10 cm. What contributes to:

- Savings (it is better to use this insulation, 10 cm thick, than another and lay it in 2 layers of 5 cm each).

- The smallest amount of waste generated.

- Less labor costs.

- Reliable fastening in the structure.

- Other building materials are of a similar thickness.