The heating system in a private house, as a rule, comes in two types - with natural and forced circulation. If in the first case water moves due to thermal expansion, then during forced circulation the coolant is pushed into the pipeline by the impellers of electric pumps, and for efficient operation, the correct selection of a circulation pump for the heating system is important.

The task of selecting a suitable model includes choosing its operating principle and calculating the main parameters - the volume of pumped coolant and pressure (supply height). You can carry out the necessary calculations yourself using formulas, tables or online calculators - for this you need to know what initial data to enter and how to make the calculations correctly.

Fig. 1 Circulation pumps for a private house in operation

What speed should I set on the heating pump at low boiler power?

Adjusting the power of the circulation pump is usually carried out in order to increase or, conversely, reduce its performance . The higher its speed, the faster the hot water passes through the pipes and the more heat it gives off. In turn, the lower it is, the slower the liquid passes through the system, the faster it cools and, accordingly, the heat transfer will be less.

The minimum power of heating equipment is set mainly in the spring . At this time, it is already quite warm outside, but the house itself does not warm up enough and there is a need for a little heating of the room.

Pump speed modes may vary depending on the model and configuration. On average, the minimum is 30-35 l/min , the maximum is 80-90 l/min .

Why do you need to check the settings?

To ensure maximum performance of the device, before using it . This is done, as a rule, according to two parameters.

Noise insulation. There are several reasons why a heater may make a lot of noise:

- incorrect installation;

- air in pipes;

- voltage fluctuations;

- device malfunction.

To avoid these problems, it is better to entrust the installation to a specialist who will carry out comprehensive diagnostics and ensure the correct installation and functionality of the device.

Uniform heating. The main reason for uneven heating of radiators is insufficient power. Low speed contributes to the rapid cooling of the water, as a result of which the heat simply does not reach the end of the system.

Airiness or an incorrectly selected thermostat mode also leads to a similar problem . May affect the performance of the device and improper installation .

This is especially true for aluminum and bimetallic batteries, which must be installed as level as possible.

Manufacturers and prices

Heating is the main system of a private home; unlike water supply and sewerage, its stop can cause significant financial damage if it breaks down in winter and defrosts. Even if the owners are present in the house and the circular device is out of order, you will have to urgently buy a new device, and this is not always possible in remote rural areas. Also, high-quality pumping equipment for heating increases living comfort and saves energy resources - so it is better to choose models from well-known manufacturers, avoiding the Chinese counterfeits described above.

Wilo is a well-known German manufacturer that supplies the market with a wide range of household circular saws of the RS, Stratos, Smart, Top series, all modifications have the following features:

- Manufactured in accordance with the European energy saving directive EnEV for heating circuits with a thermal power of more than 25 kW, according to which only automatic control of the operation of pumping equipment and the presence of at least 3 stages of regulation of electricity consumption are allowed.

- Designed for European AC voltage of 230/400 V with a tolerance of 10%.

- The housings are mainly made of cast iron.

- The power of the units, depending on the pressure and volumetric characteristics, ranges from 40 to 200 watts; the previously selected electric pump for a one-inch pipe Wilo - Star RS 25\6 has a power of 99 watts.

- The cost of Wilo circular electric pumps ranges from 50 to 100 USD.

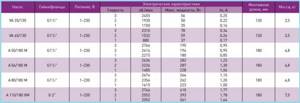

Rice. 14. Selection of a circulation pump for a heating system from popular brands Grundfos, Wilo, DAB

Grundfos is a world-famous Danish manufacturer of pumping equipment; the market offers models UP, UPS, UPSD, Solar and their more modern analogues Alpha2, which have the following features:

- The cases are made of cast iron, brass and stainless steel (marked with the letter N).

- UPS models are equipped with 3 shaft rotation speeds; in Alpha2 the frequency is automatically adjusted.

- There is a wide range of powerful models with a supply volume of up to 15 m3/cu.m. and pressure up to 15 m.

- The cost of Grundfos electric pumps is 70 - 100 USD, the price of powerful devices can reach up to 500 USD.

If we compare the power of Wilo and Grundfos units, then the Grundfos UPS 25-60 180, similar to the previously reviewed Star RS 25\6 device from Wilo, consumes one and a half times less electricity - its power is 60 W. In addition, Grundfos has a maximum supply volume of 4.35 m3/h. versus 3.5 m.cub./h. at Wilo.

DAB is a well-known Italian manufacturer that supplies the market with household circular pumps of the A and VA series, their distinctive features:

- Single-phase models have 3 rotation speeds and built-in overload protection.

- The operating temperature of the coolant is from -10 to +110 C.

- For domestic use, the VA line is most suitable, the maximum productivity of which is 3.5 cubic meters per hour and the maximum pressure is 6.5 m (for the A series, the corresponding maximum values are 16 cubic meters per hour and 11 m.) .

The choice of DAB models is the best option in terms of price and quality ratio, the DAB VA 35/180 circular machine with a maximum productivity of 3 m3/h. and a head of 4.3 m costs about 60 USD. - this is for 40 USD cheaper than Grundfos and Wilo.

Rice. 15 DAB options

How electronically controlled circulation pumps should work

Models with electronic heating type have two types of speed control: manual and automatic. Manual regulation involves setting the power of the device at the desired level. In this case, pressure drops are not corrected.

Photo 1. Control circuit for the DAB EVOSTA circulation pump with electronic control. Selecting the operating mode is done with one button.

In the case of automatic control, the reduction or increase in speed is carried out by the system itself and directly depends on the temperature in the pipeline. The autopilot itself determines the optimal level of performance and, if necessary, reduces energy consumption without reducing productivity.

Important! Automatic reduction of pump speed is only possible after hydraulic balancing of the system.

Other pump calculation options

The above calculation method is one of the options for calculating the necessary parameters. A number of manufacturers use a different technique. You can also entrust the calculation of the circulation pump to a qualified specialist. Knowing the details of the design of a particular system and its operating conditions, he will professionally make all the calculations.

Usually the maximum load for the operation of the heating system is determined. In reality, it will be lower, so it would be wise to purchase a device whose parameters are slightly lower than the calculated data. Calculating the power of the heating circulation pump reflects the optimal result. Purchasing a more powerful device is not advisable and the system’s performance will not improve, and costs will increase.

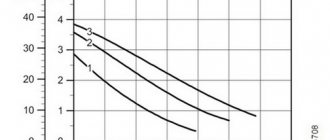

After receiving the calculation results, it is necessary to pay attention to the pressure and flow data on pump models, taking into account its operating speeds. The characteristics can be reflected on a graph with two coordinates - pressure and productivity, and then the point of intersection of these values can be determined. Based on the graphic image, the desired heating pump model is selected for a particular home.

Point A in the figure corresponds to the required parameters based on the calculation results, and point B indicates the actual characteristics of a certain device model specified by the manufacturer. The circulation pump is more suitable for the operating conditions in a particular heating system, the smaller the distance between these two points.

A change in temperature outside is a reason to turn on a different speed

The presence of several modes in the heating pump will allow you to adjust the heating level in a particular room . This function is important when there is a sharp change in temperature outside. In this case, the device can be manually switched to the required power or the autopilot can be turned on, and the system itself will adjust to the desired temperature.

All modern heating systems are equipped with a circulation pump. With the help of which, a continuous circulation of hot water occurs in the pipes , as a result of which the room is heated.

They are available in different configurations and can have 3 speeds : minimum, medium and high.

What speed should I set on the heating pump at low boiler power?

Adjusting the power of the circulation pump is usually carried out in order to increase or, conversely, reduce its performance . The higher its speed, the faster the hot water passes through the pipes and the more heat it gives off. In turn, the lower it is, the slower the liquid passes through the system, the faster it cools and, accordingly, the heat transfer will be less.

The minimum power of heating equipment is set mainly in the spring . At this time, it is already quite warm outside, but the house itself does not warm up enough and there is a need for a little heating of the room.

Procedure for calculating pump parameters

The circulation pump must solve two main problems:

- create in the heating system such a coolant pressure that will be able to overcome the hydraulic resistance that arises in individual structural elements;

- provide the required performance and thereby facilitate the movement of heat through the system, sufficient to heat the house.

Based on the assigned tasks, calculation of the circulation pump for heating is required to determine the thermal energy needs of the house and the hydraulic resistance of the entire system. Without knowing these parameters, it is impossible to select a device for forced movement of coolant.

How electronically controlled circulation pumps should work

Models with electronic heating type have two types of speed control: manual and automatic. Manual regulation involves setting the power of the device at the desired level. In this case, pressure drops are not corrected.

Photo 1. Control circuit for the DAB EVOSTA circulation pump with electronic control. Selecting the operating mode is done with one button.

In the case of automatic control, the reduction or increase in speed is carried out by the system itself and directly depends on the temperature in the pipeline. The autopilot itself determines the optimal level of performance and, if necessary, reduces energy consumption without reducing productivity.

Important! Automatic reduction of pump speed is only possible after hydraulic balancing of the system.

Heating circulation pump repair

Circulation pumps very rarely break down. But if there are any malfunctions, you should seek help from a specialist. But in order to prevent equipment malfunctions, it is necessary to periodically check its operation and monitor the serviceability of all pump elements.

Rules for operating the circulation pump

When using a circulation pump for heating, you should follow some rules:

- The pump must not operate at zero flow. Therefore, its operation should be constantly monitored.

- It is advisable to use the boiler frequently. With rare switching on, some elements may oxidize and the device will fail to work. It is recommended to turn it on for a short time at least once a month.

- If there is no water in the heating system, the pump cannot be turned on.

- Periodically check the heating of the motor. Do not allow the device to overheat excessively.

- Hard salts often precipitate in pumps. To avoid this, it is necessary to control the temperature of the coolant. It should be less than 65°C. Then the circulation pump can work normally.

- It is necessary to check the connection of the electrical wires located in the terminal block.

- It is imperative to control the water supply pressure to the heating system. With slow or strong flow, the pump may deteriorate its performance or completely cease to perform its function.

- You need to check the pump housing and find out if there is grounding.

- Periodically check the operation of the pump. This should be done based on the technical characteristics of the equipment.

- During operation, the pump should not make noise or vibrate. The circulation pump should operate without any noise.

- It is necessary to frequently check the connections between the pipes and the pump. Sometimes a coolant leak occurs. If you have such a problem, you need to replace the gaskets or tighten the connecting components. Leakage must not be allowed when the circulation pump is operating.

Preparing the pump for the heating season

To ensure that your heating system does not fail during the winter, it is necessary to check the operation of the entire system, and in particular the circulation pump, before the start of the heating season.

It is necessary to check the serviceability of the device:

- There should always be lubricant on the gasket and pipes. If it has dried out, then it is necessary to lubricate the elements again; It is necessary to check the mesh filter. It often becomes dirty and interferes with the normal operation of the pump. If you notice blockages, you need to clear them;

- The circulation pump must be connected to the pipelines correctly. The best installation option would be in front of the heating boiler. With this arrangement, the formation of air pockets is minimized;

- The correct connection of heating equipment to the network can be checked with a special tester;

- Before the start of the heating season, it is necessary to check the operation of the pump. You can perform a test run.

Pump problems and how to fix them

Any repair work can be carried out if the equipment is disconnected from the network. It is also necessary to pre-drain the area.

Let's look at what problems the circulation pump can have:

- If you turn on the pump, but the shaft does not start to rotate, you hear a noise. Why is there noise and the shaft does not rotate? If you have not turned on the pump for a long time, the shaft may have oxidized. It is necessary to check its serviceability. If the pump is blocked, it must be disconnected from the network. Next, you need to drain the water and unscrew all the screws that connect the housing and the electric motor. The impeller can then be turned by hand and the motor removed. Pumps with low power have special notches. With their help you can unlock the shaft. Simply turn the notch with a screwdriver.

- Electricity problems. Often the pump is connected in a way that does not correspond to the voltage indicated in the technical data sheet of the equipment. It is necessary to check whether the voltage in your home matches the recommended one. It would also be a good idea to check the terminal box and all connections in it. You should also check the phases.

- The wheel is blocked due to a foreign object. In this case, it is necessary to remove the engine as indicated in the first paragraph. To prevent various objects from falling into the wheels, you can install a special mesh filter in front of the circulation pump.

- If the pump turned on as usual, and then it turned off. In this case, deposits may be the cause. They are formed between the stator and rotor. To fix the problem, it is necessary to remove the engine and clean the stator jacket from scale.

- The pump does not turn on and does not hum. There may still be no tension. There can be two reasons: the motor winding burned out or the fuse was damaged. First of all, you need to replace the fuse, but if after replacing it the pump does not start working, then the problem lies in the winding.

- The circulation pump vibrates during operation. This is often due to bearing wear. In this case, the pump operation is accompanied by noise. To fix the problem, you need to replace the bearing.

- When the pump is turned on, a sharp noise appears. In case of such a problem, you need to bleed out the air, and then install an air vent at the highest point of the piping.

- If the motor protection is triggered after starting the circulation pump? In this case, it is necessary to look for the cause in the electrical part of the engine.

- Often there is a problem such as improper water supply, as well as its pressure. The technical data sheet of the equipment indicates the same values, but during operation the pressure and flow differ significantly. This problem occurs in three-phase pumps due to incorrect connection.

- You need to check the terminal box. And also check the fuse contacts for contamination. It would be a good idea to check the phase resistance for grounding.

Connection methods

Electrical connection using a plug and socket. This method involves installing an electrical outlet in close proximity to the place where the circulation pump is mounted. Sometimes they can be supplied with a connected cable and plug included, as in the photo:

In this case, you can simply plug the device into the mains using an outlet located within reach of the cable. You just need to make sure there is a third, grounding contact in the outlet.

If there is no cord with a plug, they need to be purchased or removed from an unused electrical appliance.

You should pay attention to the cross-section of the cord conductors. It should be in the range from 1.5 mm 2 to 2.5 mm 2. The wires must be stranded copper, ensuring resistance to repeated bending

The cord with a plug for connecting electrical appliances to the network is shown in the photo below:

The wires must be stranded copper, ensuring resistance to repeated bending. The cord with a plug for connecting electrical appliances to the network is shown in the photo below:

Before connecting the circulation pump, you need to find out which of the three wires of the cord is connected to the ground pin of the plug. This can be done using an ohmmeter, while at the same time checking the integrity of the remaining wires.

Open the terminal box cover. Inside the box there are three terminals designed to connect the device to the network, marked as in the picture:

We unscrew the clamp of the cable coupling (in the first photo it is a plastic nut into which the cable is inserted), put it on our cord, and insert the cord into the coupling. If there is a cable tie inside the box, thread the cord through it. We connect the ends of the cord wires, previously stripped of insulation, to the terminals.

The wires connected to the plugs of the plug should be connected to the L and N terminals (don’t be afraid to mix them up, this is not critical), the wire of the grounding contact of the plug should be connected to the PE terminal (but you can’t make a mistake here). The instructions supplied with the product prohibit its operation without protective grounding. Next, tighten the clamp (if any), tighten the cable sleeve clamp tightly, and close the terminal box cover. The pump is ready to be plugged into the mains.

Fixed connection. The connection diagram for the circulation pump to the electrical network with grounding is provided below:

The requirements for the wire cross-section here are the same as in the previous version. For this installation, the cable can be used either flexible or inflexible, copper, VVG brand. or aluminum, AVVG. If the cable is inflexible, the installation should ensure that it does not move. To do this, the cable along the entire route is secured with clamps.

In this embodiment, a residual current device (differential circuit breaker) is used. Instead, you can use a regular single-pole circuit breaker, passing only the phase wire through it. If the machine is installed in a panel where there is a PE bus, then the cable from the pump to the machine must be three-core. If there is no such bus, the PE terminal should be connected to a grounding device. This connection can be made with a separate wire.

Separately, I would like to consider such an installation option as connecting the pump to the UPS. It is the most preferable and ensures the independence of the heating system from power outages. The connection diagram of the circulation pump to the uninterruptible power supply is provided below:

The power of the UPS should be selected based on the power of the pump motor. The capacity of the battery is determined by the estimated time of autonomous power supply of the circulation pump, that is, the time when the power supply is turned off. We talked about how to choose a UPS for a boiler in a separate article. Requirements for cable cross-section, as well as the presence of protective grounding, apply to all connection options.

Finally, we recommend watching video instructions for connecting various pump models to the electrical network:

Connection diagram of the circulation pump to the thermostat

So we looked at how to properly connect the circulation pump to the electrical network. The diagram and video examples helped to consolidate the material and clearly see the nuances of installation!

It will be useful to read:

Connection diagram of the circulation pump to the thermostat

What is a circulation pump and why is it needed?

A circulation pump is a device that changes the speed of movement of a liquid medium without changing pressure. In heating systems it is installed for more efficient heating. In systems with forced circulation it is a mandatory element, in gravity systems it can be installed if it is necessary to increase the thermal power. Installing a circulation pump with several speeds makes it possible to change the amount of heat transferred depending on the outside temperature, thus maintaining a stable temperature in the room.

Cross-section of a circulation pump with a wet rotor

There are two types of such units - with a dry and wet rotor. Devices with a dry rotor have a high efficiency (about 80%), but are very noisy and require regular maintenance. Units with a wet rotor operate almost silently; with normal coolant quality, they can pump water without failure for more than 10 years. They have a lower efficiency (about 50%), but their characteristics are more than sufficient for heating any private home.

Technical specifications

When deciding how to choose a circulation pump for a heating system, consider its physical and technical characteristics, the main of which are:

- Bandwidth. Measured in cubic meters per hour or liters per minute, it shows the volume of liquid that the electric pump pumps per unit time; the higher the flow rate, the greater the flow rate. The indicator depends on the diameter of the pipeline used and can reach values of up to 15 cubic meters per hour.

- Pressure The value is measured in meters of water column and indicates the height to which the electric pump can push liquid through a vertically installed pipeline. The maximum pressure of a circulating electric pump for varieties with a wet rotor is about 17 meters, although units with higher pressure characteristics may be found, but they are ineffective in operation (they have large overall dimensions and are too expensive).

- Temperature Range. It is clear that in a heating system, pumping equipment must withstand the maximum heating temperature of the coolant with a margin; commonly used modifications are designed for a maximum temperature of up to 110º C; some types can work with liquids with temperatures up to +130º C.

- Noise level. Basically, for use in individual homes, devices with a low noise level are chosen; such features have pumping equipment with a wet rotor, the noise characteristics of which do not exceed 35 - 40 dB.

- Compound. In residential individual houses, a heating main with a small cross-section of up to 1.5 inches is used - in this case, all pumping equipment is installed in the main using threaded connections (designed for pipelines with a diameter of up to 2 inches). The outlet fittings of most household electric pumps are equipped with external threads and are easily integrated into the line using American couplings.

- Dimensional parameters. The installation length is the main indicator of the device when built into a pipeline (for circular types, standard sizes are 130 and 180 mm), the diameter of the inlet and outlet pipes is also taken into account (standard 1 and 1.25 inches).

- Protection class. According to the international classification, the standard protection class for pumping equipment of heating systems is IP44 - this means that the unit is protected from the entry of solid mechanical particles with a diameter of more than 1 millimeter (the first digit in the marking) into the housing, and its electrical part is completely closed from drops and splashes, flying at any angle.

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but on the supply or return pipeline it doesn’t matter. Modern units are made from materials that can withstand temperatures up to 100-115°C. There are few heating systems that work with a hotter coolant, so considerations of a more “comfortable” temperature are untenable, but if you feel safer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system; it makes absolutely no difference whether there is a pump in the supply or return branch. What matters is the correct installation, in the sense of strapping, and the correct orientation of the rotor in space. Nothing else matters.

There is one important point regarding the installation location. If the heating system has two separate branches - on the right and left wings of the house or on the first and second floor - it makes sense to install a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule remains on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal conditions in each part of the house independently of the other, and also in two-story houses to save on heating. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of movement of the coolant is set much lower, and this allows you to burn less fuel, without compromising the comfort of living.

Grundfos pump - is it capable of passing coolant without electricity?

The house has both an electric boiler and a solid fuel boiler. The electric one will work to maintain the desired temperature in the absence of the owners in the house, and the solid fuel one will work as the main one during their presence. The system has a built-in pump connected to both boilers.

The question is this. If for some reason there is no electricity in the house, but the solid fuel boiler is working, will the coolant be able to pass through the pump freely?

Igor Iofchu wrote: will the coolant be able to pass through the pump without hindrance?

Yes. Any hydraulic centrifugal pump with a locked rotor creates insignificant hydraulic resistance.

Vladimir_Vas wrote: Yes. Any hydraulic centrifugal pump with a locked rotor creates insignificant hydraulic resistance.

That is, there is no need to make a special arc to bypass the pump? I'm afraid that the solid fuel boiler might boil if something happens.

Igor Iofchu wrote: I’m afraid that the solid fuel boiler might boil if something happens.

Maybe. But not because of the resistance of the de-energized pump. You take any circulation pump from the shelf and just blow into the pipe - the questions will disappear on their own.

Vladimir_Vas wrote: Maybe. But not because of the resistance of the de-energized pump. You take any circulation pump from the shelf and just blow into the pipe - the questions will disappear on their own.

OK. Thanks a lot. They calmed me down.

Igor Iofchu wrote: If for some reason there is no electricity in the house, but the solid fuel boiler is working, will the coolant be able to pass through the pump unhindered?

With a normal EC, it will be able to pass, but not entirely unhindered.

Igor Iofchu wrote: So there is no need to make a special arc to bypass the pump?

With EC, the pump is switched to bypass and the return valve, with a ball of positive buoyancy, the valve or, especially, the shut-off valve on the main line should not be installed at all, since the check valve may stick, the shut-off valve may not be switched at the right time and the hydraulic resistance will be greater than just pump located on the main line.

With an EC with a pump, so that without electricity there is the minimum possible hydraulic resistance, the bypass with the pump must be connected to the main line at the minimum possible angle, without a check valve and, even more so, without a shut-off valve on the main line between the pump connection points.

Igor Iofchu wrote: I’m afraid that the solid fuel boiler might boil if something happens.

To do this, you need an EC and RB on the boiler return, but in any case, measures must be taken to forcibly reduce the critical temperature of the coolant.

Harness

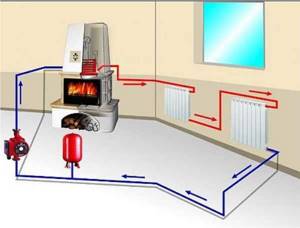

There are two types of heating systems - forced and natural circulation. Systems with forced circulation cannot work without a pump; systems with natural circulation work, but in this mode they have lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is installed into it. This gives high heating efficiency and reliability. It is clear that the installation of a circulation pump in these systems is different.

All heating systems with heated floors are forced - without a pump, the coolant will not pass through such large circuits

Forced circulation

Since a forced circulation heating system without a pump is inoperative, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They can jam the impeller and stop the motor. Therefore, a mesh dirt filter must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also advisable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps and remove the unit. Only that part of the water that was directly in this piece of the system is drained.

Natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not working. One ball shut-off valve is installed on the bypass, which is closed the entire time the pumping is running. In this mode, the system operates as forced.

Installation diagram of a circulation pump in a system with natural circulation

When the electricity goes out or the unit fails, the valve on the jumper is opened, the valve leading to the pump is closed, and the system operates as a gravity system.

Installation features

There is one important point, without which the installation of the circulation pump will require rework: it is necessary to rotate the rotor so that it is directed horizontally. The second point is the direction of flow. There is an arrow on the body indicating which direction the coolant should flow. This is how you turn the unit so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, just when selecting a model, make sure that it can work in both positions. And one more thing: with a vertical arrangement, the power (pressure created) drops by about 30%. This must be taken into account when choosing a model.

What to consider when choosing a specific model?

Depending on the purpose for which a surface pump is purchased, the characteristics that you should focus on differ.

Pump for watering a personal plot

In this case, the main equipment parameters are:

- Performance. To water a garden, one cubic meter per hour is sufficient;

- The suction depth at which the equipment will be operated. The surface pump lifts water from a maximum depth of nine meters. In this case, you should remember the vertical-horizontal ratio, which is one to four. When working at a depth of two meters, the pump must be eight meters away from the well. If the suction depth exceeds four meters (or the total length of the supply line is more than twelve meters), the pipe clearance should be increased by ¼ inch;

- Pressure You should focus on the most distant point of consumption.

Using a surface pump, you can easily organize watering of your garden plot. The equipment is easy to install and does not require special installation skills

To connect a surface pump, the following components are needed: hoses (for water intake and for irrigation); fitting for connecting the hose and pump; a check valve and a mesh filter, which is installed on the check valve and traps sand and solid particles.

Pump for home water supply system

When choosing a surface pump intended for water supply to a country house, you need to focus on the volume of water consumed, the number of consumption points and the required pressure in the system.

Designing a home water supply system based on a surface pump requires taking into account the volume of water consumed and the number of flow points

To simplify calculations, you can take the following values:

- A house for a family of four consumes 3 m 3 per hour;

- House for two families - 5 m 3 / hour;

- House for four families - 6 m 3 per hour;

- Personal plot - about one cubic meter per hour.

In dry times, water consumption can increase significantly; on hot days, 40-55% more than usual will be spent on watering alone.

In addition to these parameters, you need to pay attention to: If the value is set to 3.5 atmospheres, then the maximum pressure in the system must be greater than the total horizontal and vertical pressure of the supply line (distance to water plus 45-50 meters). A distance of 10 meters vertically or 100 meters horizontally equates to a pressure of one atmosphere

A distance of 10 meters vertically or 100 meters horizontally equates to a pressure of one atmosphere.

To organize water supply at home, in addition to the pump itself, you will need the following components:

- Connection fitting;

- Inlet and outlet hose;

- Check valve with strainer;

- A hydraulic accumulator, the role of which is played by a tank with a capacity of 30-60 liters. It must maintain pressure in the system;

- Flexible line for connecting the pump and tank;

- Five-pin adapter for the second output;

- Pressure gauge;

- . It connects to a five-pin adapter. It sets the pressure values at which the pump will turn on or off.