Power connection

The circulation pumps operate from a 220 V network. The connection is standard; a separate power supply line with a circuit breaker is desirable. The connection requires three wires - phase, neutral and ground.

Circulation pump electrical connection diagram

The connection to the network itself can be organized using a three-pin socket and plug. This connection method is used if the pump comes with a connected power wire. It can also be connected via a terminal block or directly with a cable to the terminals.

The terminals are located under a plastic cover. We remove it by unscrewing several bolts and find three connectors. They are usually labeled (the pictograms are N - neutral wire, L - phase, and “ground” has an international designation), so it’s hard to make a mistake.

Where to connect the power cable

Since the entire system depends on the performance of the circulation pump, it makes sense to make a backup power supply - install a stabilizer with connected batteries. With such a power supply system, everything will work for several days, since the pump itself and the boiler automation “pulls” electricity to a maximum of 250-300 W. But when organizing, you need to calculate everything and select the battery capacity. The disadvantage of such a system is the need to ensure that the batteries do not discharge.

How to connect a circulator to electricity through a stabilizer

How does the circulation mechanism work?

When the pump is turned on, water in the heating system (in a closed circuit) is drawn into the inlet under the influence of the rotation of a wheel with blades

When the pump is turned on, the water in the heating system (in a closed circuit) is drawn into the inlet under the influence of the rotation of the wheel with blades. The water that gets into the chamber, due to the action of centrifugal force, is pressed against the walls of the working chamber and pushed out (into the outlet). Following this, the pressure in the chamber drops, which promotes a new injection of water into the pump reservoir.

Thus, during a continuous cycle of pump operation, the heating system can be in a state of a constant set temperature, which significantly reduces the cost of fuel or electrical energy consumption for heating water.

Main varieties

There are different types of circulation pumps. Design features largely determine how a structure performs. There are two main types of equipment under consideration:

- With dry rotor.

- With wet rotor.

Dry rotor circulation pump

Circular pumps for heating systems are produced by various companies. The quality of the materials used determines how long the structure can last. In addition, there is a recirculation pump for heating.

Classification can also be carried out according to the following indicators:

- The type of material used in the manufacture of the case.

- Size and power.

- Installation type.

Glandless circulation pump

Most models have similar performance characteristics, taking into account which allows you to choose a more suitable version. Let's take a closer look at the design features of the dry and wet rotor versions.

Calculating pressure in two ways

- design. At this stage, a decision is made about which rooms will be heated and which will not, diagrams are drawn and the volume of the system in liters is calculated;

- boiler selection. Based on the volume of the system and the area of the heated premises, a heater is selected. For 15 liters of coolant, one kilowatt of heater power is required;

- determining the required volume of the expansion tank.

Now let's look at several different methods for calculating the pressure in the expansion tank of a sealed heating system.

Option #1.

For this we need the following quantities:

- system volume (OS);

- tank volume (VT);

- the maximum permissible value of the pressure gauge scale for a given system (DM);

- water expansion – 5%.

By the time you have to make calculations, you already know how many liters the system holds. The required volume of the tank is calculated by dividing the capacity of the circuit in liters by ten. Although this is an approximate calculation, it is very working.

The volume of the tank in a closed system may be more than necessary, but it cannot be less. An error will lead to replacement or installation of an additional one.

Air vent

Option #2.

It's good that we live in a world of fierce competition. To ensure that the client is satisfied with the purchase and does not have any problems with operation, boiler manufacturers indicate the required pressure of the heating expansion tank in the product data sheet. If for some reason this cannot be found out, then you can calculate this value, knowing what the pressure gauge readings should be in the operating mode of the system.

The latter can be found with one hundred percent probability in the technical documentation or on the boiler. Then 0.2-0.3 atmospheres should be subtracted from the working pressure. What is it for? If the pressure in the tank is greater than the working pressure in the system, the coolant will not be squeezed into the tank. He simply cannot do this, as an even greater force acts on him from the side of the tank. And if there is not enough air in the tank, then there will be difficulties with returning the coolant to the system.

Why does the circulation pump heat up: the main reasons and methods for eliminating them

There are several possible situations that indicate problems with such a device.

Incorrect installation

If the location of the rotor is incorrectly determined and its axis is displaced from the horizontal, there is a possibility of an airing effect. As a rule, it will be possible to find out about such an erroneous installation of the device immediately after the start of operation of the heating system.

To solve this problem, you will need to correct the rotor position.

Photo 1. Installation diagram of the circulation pump in the heating system. To install it you will need many components.

The device heats up due to a clogged system

The process of circulating coolant through pipes is fraught with the formation of rust and the accumulation of deposits. As a result, the pipes narrow, and the pumping equipment has to increase its own load to push the liquid. This is how it overheats. Cleaning the heating structure will resolve this situation.

Reference. A solution of caustic soda helps, filling the heating system for 1 hour.

Foreign body

Corrosive particles from old pipes or batteries break off over time and enter the circulator's motor, blocking its operation or causing the windings to burn out.

Unscheduled maintenance of the heating system will help, allowing you to get rid of foreign elements, and repair (or replacement) of the pump.

Lack of bearing lubrication

When it is deficient, bearings wear out at an accelerated rate. Due to their unsuitability for further operation of the device, its main element, the engine, jams.

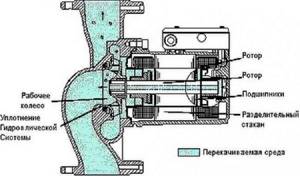

Photo 2. Diagram of a circulation pump with a wet rotor. The arrows indicate the location of all parts, including bearings.

The heating system device will have to be dismantled and taken for professional diagnostics.

Low voltage in the network

An indicator of this parameter below 220V provokes rapid airing of the pumping equipment and its failure. Determining the voltage in the network by using a voltmeter will help prevent the problem.

Insufficient pressure

Overheating causes incorrect phase connection when a three-phase wheel with blades is included in the heating circuit. In this case, the direction of its rotation will be disrupted. Insufficient pressure also occurs when the viscosity of the circulating fluid is increased. In this situation, the impeller encounters quite a lot of resistance.

To solve the problem, at the first sign of its manifestation, it is necessary to check the cross-section of the incoming pipe, set the required pump adjustment data and eliminate possible deposits on the inlet pipe filter.

Stopping after start

This problem occurs when the phase wires in the terminal box are incorrectly connected. And the fuse of the device is equipped with a loose contact.

To fix the problem, you need to remove it and thoroughly clean the clamps.

What to do if the pump gets hot and whistles

Such sounds often occur after air enters the heating line; when the circuit is filled with liquid, such excesses are difficult to avoid.

Therefore, after checking the integrity of connections and pipes, specialists bleed air from each radiator in a closed system in order not only to ensure the most uniform heating of the premises in the building, but also to protect the circulation unit from breakdowns and pump whistling due to air locks.

To carry out the manipulations, it is necessary to provide for the installation of Mayevsky taps, thanks to which you can quickly get rid of the airiness of the system. Automatic devices are widely used to remove excess air from the pipeline; this happens autonomously, without human intervention, which allows you to be confident in the productivity of the device.

Actions for prevention

In operating condition, monitor the engine heating level. If it seems too high to you, then it is better to remove the pump and contact the point of sale with a request to replace the unit. The same can be done in case of pressure mismatch

Also, to protect pumping equipment from sudden failure, it is recommended to carry out preventive maintenance of the unit, which will include the following actions:

- Regular external inspection of the pump housing and careful listening during operation. This way you can check the functionality of the pump and the tightness of the housing.

- Make sure that all external pump fasteners are properly lubricated. This will make it easier to disassemble the pump if repairs are necessary.

- It is also worth following some rules when installing a pumping unit for the first time. This will help avoid repair work in the future:

- So, when you first connect the pump to the heating network, you should turn on the unit only if there is water in the system. Moreover, its actual volume must correspond to that indicated in the technical passport.

- It is also worth checking the coolant pressure in the closed circuit here. It must also correspond to what is stated in the technical specifications of the unit.

- In operating condition, monitor the engine heating level. If it seems too high to you, then it is better to remove the pump and contact the point of sale with a request to replace the unit. The same can be done in case of pressure mismatch.

- Also, make sure that there is a ground connection between the pump and the terminals when connecting the pump. Here in the terminal box, check that there is no moisture and that all wiring is securely fixed.

- A working pump should not produce even minimal leaks. The connection points between the inlet and outlet pipes of the heating system and the pump housing deserve special attention.

Possible breakdowns and ways to eliminate them

troubleshoot the problem as necessary. By the way, it is recommended to protect the pump from surges in the network by installing a reliable stabilizer. This move will also protect the pump from the burning of a fuse, which fails as a result of constant pressure drops in the network

So, if something goes wrong with your circulation pump and it refuses to work, then we’ll try to repair the unit ourselves.

Important: but if you are not confident in your abilities or do not have the appropriate tool at hand, then it is better to contact a specialized center

If the pump makes a hum, but the impeller does not rotate

The reasons may be the following:

- Presence of a foreign object in the impeller area;

- The rotor shaft has oxidized due to long-term downtime of the unit;

- Loss of power supply to the mechanism terminals.

In the first case, you need to carefully remove the pump from the heating system and unscrew the housing in the area of the impeller. If a foreign object is found, remove it and rotate the shaft by hand. When assembling the pump in the reverse order, it is necessary to install a reliable filter on the pipe.

If there is oxidation, then clean it well, lubricate all movable elements of the working unit and reassemble the pump in the reverse order.

If there is a problem with the quality of the power supply, then you will have to check the voltage using a tester. First, completely replace the cable in all sections of the cable and if a break or fault is detected. Then, if the cable is OK, check the voltage at the terminals. If the tester shows infinity, a short circuit has occurred. If it shows less voltage, it means that the winding has broken. In both cases, the terminals are replaced.

If the unit shows no signs of life at all

This can happen if there is no voltage in the network. Using a tester, check the voltage and, if necessary, correct the problem.

By the way, it is recommended to protect the pump from surges in the network by installing a reliable stabilizer. This move will also protect the pump from the combustion of a fuse, which fails as a result of constant pressure drops in the network.

If the pump starts but then stops

The reasons may be:

- Presence of scale between the moving elements of the unit;

- Incorrect pump connection at the terminals.

In the first case, you will have to disassemble the pump and check it for scale. If detected, limescale deposits are removed and all joints between the rotor and stator are lubricated.

If there is no scale, then check the tightness of the fuse on the unit. You should remove it and thoroughly clean all the clamps. Here it is also worth checking that all wires in the terminal box are connected correctly in phases.

If the pump makes a loud noise when turned on

The reason for this is the presence of air in a closed circuit. It is necessary to release all air masses from the pipes, and install a special unit in the upper part of the pipeline to prevent the formation of air locks.

Another reason could be wear on the impeller bearing. In this case, you need to disassemble the unit housing, check the bearing and, if necessary, replace it.

If the pump is noisy and vibrates

Most likely, the issue is insufficient pressure in the system. It is necessary to add water to the pipes or increase the pressure in the area of the pump inlet.

If the pressure is still low

Here it is worth checking the direction of rotation of the working unit in the pump body. If the wheel does not spin correctly, then an error was probably made when connecting the device to the terminals in phases when using a three-phase network.

Another reason for a decrease in pressure may be too high a viscosity of the coolant. Here the impeller experiences a lot of resistance and does not cope with the assigned tasks. You will have to check the condition of the mesh filter and clean it if necessary. It would also be useful to check the cross-section of the inlet and outlet pipes and, if necessary, set the correct operating parameters of the pump.

Harness

There are two types of heating systems - forced and natural circulation. Systems with forced circulation cannot work without a pump; systems with natural circulation work, but in this mode they have lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is installed into it. This gives high heating efficiency and reliability. It is clear that the installation of a circulation pump in these systems is different.

All heating systems with heated floors are forced - without a pump, the coolant will not pass through such large circuits

Forced circulation

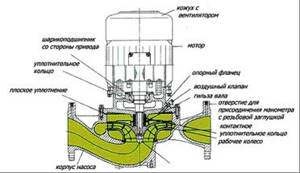

Since a forced circulation heating system without a pump is inoperative, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They can jam the impeller and stop the motor. Therefore, a mesh dirt filter must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also advisable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps and remove the unit. Only that part of the water that was directly in this piece of the system is drained.

Natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not working. One ball shut-off valve is installed on the bypass, which is closed the entire time the pumping is running. In this mode, the system operates as forced.

Installation diagram of a circulation pump in a system with natural circulation

When the electricity goes out or the unit fails, the valve on the jumper is opened, the valve leading to the pump is closed, and the system operates as a gravity system.

Installation features

There is one important point, without which the installation of the circulation pump will require rework: it is necessary to rotate the rotor so that it is directed horizontally. The second point is the direction of flow. There is an arrow on the body indicating which direction the coolant should flow. This is how you turn the unit so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, just when selecting a model, make sure that it can work in both positions. And one more thing: with a vertical arrangement, the power (pressure created) drops by about 30%. This must be taken into account when choosing a model.

Why is such a device installed in systems?

In a gravity heating system, water heated in the heat exchanger of a boiler or furnace moves through the pipes by convection and gives off heat to the batteries there. But at the point furthest from the heater, the radiators will receive the least amount of heat. After all, the coolant reaches there already cooled down. To solve this problem it is necessary to supplement the system with forced circulation.

A pump pumping water can significantly improve the quality of heating. Plus it makes it possible to reduce fuel costs for the boiler.

After all, the coolant, under the influence of the pressure created by the pump, passes through the working circuit much faster and returns to the heat exchanger less cooled. As a result, less heat energy is needed to heat it.

Structurally, this unit consists of an electric motor and a rotor immersed in water. The rotating rotor blades force water to move through the pipes at a given speed, thereby creating operating pressure in them.

Therefore, in order for the selection of a circulation pump for heating to be correct, it is necessary to accurately calculate several parameters that will correspond to the heating characteristics.

The device is so hot that you don't even need a boiler! Why does the pump in the home heating system get hot?

Improper operation of the circulation pump leads to various problems, including overheating.

Due to overheating, pumping equipment may fail, which will lead to the stoppage of the entire heating system. This is especially dangerous in winter.

ontakte

Odnoklassniki

The purpose of installing such a device is to pump fluids in the heating system and create pressure. These processes help heat the heating device, but not critically.

The temperature of the circulation unit and pipes should be approximately the same. If the deviation is large, then this is already overheating of the device.

Incorrect installation

If the location of the rotor is incorrectly determined and its axis is displaced from the horizontal, there is a possibility of an airing effect. As a rule, it will be possible to find out about such an erroneous installation of the device immediately after the start of operation of the heating system.

To solve this problem, you will need to correct the rotor position.

Photo 1. Installation diagram of the circulation pump in the heating system. To install it you will need many components.

The device heats up due to a clogged system

The process of circulating coolant through pipes is fraught with the formation of rust and the accumulation of deposits. As a result, the pipes narrow, and the pumping equipment has to increase its own load to push the liquid. This is how it overheats. Cleaning the heating structure will resolve this situation.

Reference. A solution of caustic soda helps, filling the heating system for 1 hour.

What to do if pumping equipment gets hot

When such a situation arises, the first thing you should pay attention to is the openness of the shut-off valves. Next, check the correct installation of the pump, its rotation and check valve

Air masses need to be vented from the heating device.

Attention! The rotation of the circulation pump must be in the same direction as the arrow marked on the housing. Compare the temperature of the unit itself and the check valve

The indicator should not differ much

Compare the temperature of the unit itself and the check valve. The indicator should not differ much.

The problem may also be in the load consumed by the device. To do this, each of its phases is checked.

Alternatively, the pump is disassembled and washed to eliminate the possibility of clogging.

It is necessary to resort to such a measure if performing simple actions does not help solve the problem and you need professional advice on how to get out of the current situation.

Rate this article:

Average rating: 4 out of 5. Rated by: 8 readers.

ontakte

Odnoklassniki

Centrifugal pumps: design features in heating systems

When it is turned on together with the operation of the boiler, the temperature in the living rooms rises almost instantly. In addition, convective heat transfer from heating devices is improved, since with forced circulation there are practically no stagnant zones in the network, and the coolant evenly washes all heating surfaces. The pressure created by the centrifugal device is sufficient for the liquid medium to successfully overcome all existing hydraulic resistance in the network: valves, mud traps, vents, batteries, bends and branches and rise to its highest point. For two-story households and above, the installation of a circulation pump in the heating system is mandatory. Proper installation of the unit reduces the cost of generating thermal energy by up to 20% due to the organization of effective heat exchange.

The electric pump for circulating heating water is produced in a housing in which working units and electrical elements are mounted. The main working element of the structure, which rotates the impeller, is the rotor located inside the stator winding.

The housing for such units is made from durable, corrosion-resistant materials:

- Aluminum alloys;

- cast iron body, with pulley;

- stainless steel;

- double or multi-component brass alloy.

Installation procedure for the circulation pump

It is important to remember that the device requires periodic maintenance, and therefore there must be enough free space near it. The most optimal area for placing the device is in front of the boiler unit. This scheme will prevent the formation of air jams. Additional advantages of this option are that the unit will operate with a low-temperature coolant, which will significantly increase its service life. An equally significant point in installing a centrifugal unit is the location of the working shaft. It must be remembered that the shaft must be placed exactly in a horizontal position. Otherwise, it will not be able to be completely immersed in a liquid medium, which will cause a significant loss of productivity and will contribute to the rapid decommissioning of its working units.

With dry rotor

A similar pump for heating a house got its name due to its design features. The features of the proposal are the following:

- Only the impeller is immersed in the coolant. It can be made using various materials. Most attention is paid to those that can withstand high temperatures.

- The rotor is located in a sealed housing. Several O-rings are used to protect the device.

- The efficiency indicator is 80%. Such productivity can be called very high.

- The service life is approximately 3 years.

- The structure requires regular maintenance. This is due to the fact that solids from the coolant can get onto the O-rings.

- There is a lot of noise during operation.

Dry rotor pump design

The only attractive quality is high efficiency. Therefore, such models are rarely installed in the house.

How circulation pumps are designed and work

The operating principle of circulation pumps is not much different from the design of drainage models. The device body is made of durable materials that are resistant to corrosion. Typically this is stainless steel, aluminum, brass, cast iron. When started, the engine begins to rotate a rotor equipped with an impeller. As a result, the pressure at the inlet pipe decreases and water is sucked into the hydraulic chamber. The rotation of the impeller creates centrifugal force. Water is pressed against the walls of the chamber and forcefully thrown into the pipeline through the outlet. This ensures forced circulation of the coolant in a closed heating circuit.

Design differences between different types of devices

There are two main types of pumps - with “wet” and “dry” rotors. The “wet” rotor is separated from the water by special sealing rings, between which there is a thin film of water. When worn, the rings wear out and are pressed closer to each other, which guarantees the tightness of the structure for several years. Cooling and lubrication are provided by the working fluid. Pumping equipment of this type is installed in systems with small coolant volumes, because It is difficult to ensure tight connections in large-diameter structures

When installing devices, it is important to ensure that the shaft is positioned strictly horizontally, otherwise the device may malfunction

The main advantage of “dry” models is their high efficiency. It is 80%, which distinguishes it favorably from the 50% efficiency of “wet” type devices. The rotors of “dry” heating circulation pumps do not come into contact with the liquid. Depending on the location of the engine, structures are divided into horizontal (cantilever), vertical and block. All “dry” models are noisy during operation and are sensitive to the quality of the coolant and air purity. It is advisable to install them in separate rooms of boiler rooms, controlling the purity of the water in the system and the air in the room.

Structural differences in the structure of the rotors of a centrifugal pump for heating

For in-house heating systems, two types of devices are used - with a “wet” or “dry” rotor. In the first, it is separated from the pumped liquid by special sealing seals in the form of rings, between which there is a thin film of coolant. As wear occurs, the sealing parts wear down and compress even more tightly, which ensures that the block is additionally sealed and can withstand loads for a number of years.

In order for this to happen, such devices require constant maintenance. During the process of pumping liquid, suspended solids that are present in the coolant get between the seal rings, thereby breaking the tightness of the entire structure.

The disadvantage of these centrifugal-type devices is their increased noise. Therefore they are not suitable for indoor residential premises. Due to the fact that they have the highest efficiency and consume less electricity for their own needs, units with a “dry” rotor are often installed at high thermal heating loads, in a separate building of a boiler room or heating point.

For devices operating with a “wet” modification, the impeller and rotor are placed in a liquid medium, they are washed by a hot coolant. Electrical components with a starter are placed in a sealed steel cup. When such a device operates, the coolant serves as a cooling and lubricating medium for the rubbing parts of the unit, so it operates almost silently and, therefore, they are preferable for installation in individual houses next to the boiler. Such devices are not fastidious in maintenance. And despite the fact that they have low productivity and low efficiency of no more than 50%, these units are more popular among owners of small cottages. The service life of the device depends on the equipment manufacturer and usually ranges from 5 to 10 years.

How circulation pumps are designed and work

The operating principle of circulation pumps is not much different from the design of drainage models. The device body is made of durable materials that are resistant to corrosion. Typically this is stainless steel, aluminum, brass, cast iron. When started, the engine begins to rotate a rotor equipped with an impeller. As a result, the pressure at the inlet pipe decreases and water is sucked into the hydraulic chamber. The rotation of the impeller creates centrifugal force. Water is pressed against the walls of the chamber and forcefully thrown into the pipeline through the outlet. This ensures forced circulation of the coolant in a closed heating circuit.

Design differences between different types of devices

There are two main types of pumps - with “wet” and “dry” rotors. The “wet” rotor is separated from the water by special sealing rings, between which there is a thin film of water. When worn, the rings wear out and are pressed closer to each other, which guarantees the tightness of the structure for several years. Cooling and lubrication are provided by the working fluid. Pumping equipment of this type is installed in systems with small coolant volumes, because It is difficult to ensure tight connections in large-diameter structures

When installing devices, it is important to ensure that the shaft is positioned strictly horizontally, otherwise the device may malfunction

The main advantage of “dry” models is their high efficiency. It is 80%, which distinguishes it favorably from the 50% efficiency of “wet” type devices. The rotors of “dry” heating circulation pumps do not come into contact with the liquid. Depending on the location of the engine, structures are divided into horizontal (cantilever), vertical and block. All “dry” models are noisy during operation and are sensitive to the quality of the coolant and air purity. It is advisable to install them in separate rooms of boiler rooms, controlling the purity of the water in the system and the air in the room.

Why does the circulation pump heat up - the main reasons

Ideally, the pump temperature should be the same as the coolant pipes. If it is higher, it means that either errors were made in the installation, or there are problems with operation. Typically, the circulation pump of the heating system gets hot for the following reasons:

– Incorrect installation. The easiest way to determine the presence of installation errors is: the device begins to overheat at the initial stage of operation of the heating system.

– Clogged system. Over time, various deposits and rust accumulate in the pipes. This leads to a narrowing of the water passage diameter. The pump has to work at increased load to push the coolant into the narrowed pipes, and the electric motor overheats. Preventive measures will help “cure” it - unscheduled maintenance of the heating system.

-Foreign body. If communications are slagged, pieces of rust or limescale may come off the internal surfaces of pipes and radiators. When they get into the pump, they jam the electric motor. The result is usually predictable: if you do not disassemble and clean the device in time, the motor coils will fail.

– Lack of bearing lubrication. If it is not enough, the bearings wear out much faster, which shortens the service life of the entire device as a whole. The engine jams. It is advisable to dismantle the pump and take it to a workshop.

–Low voltage in the network. If the voltage is below standard 220 V, the engine overheats and quickly fails. At the first signs of overheating, it makes sense to determine the voltage in the network using a voltmeter. Perhaps the problem is not in the pump itself.

If the circulation pump gets hot, the reasons can be very different. Do not rush to dismantle the device. First, measure the voltage in the network. If it is normal, flush the system with caustic soda, filling it for at least an hour, and then draining the solution. If this does not help, contact a specialist, otherwise the device will burn out and you will have to buy a new one, because rewinding the motor windings can be more expensive.

The main reasons for pump overheating

Under ideal conditions, the temperature of the coolant in the hot water supply system should be exactly the same as in the pump. Overheating of pumping equipment can occur for the following reasons:

- Incorrect installation of the device. In this case, the pump overheats at the beginning of operation.

- Presence of blockages in the circuit. Here the unit works in intensive mode to push the coolant through narrow holes, which leads to an increase in pressure and heating of the rotor. The way out of this situation is to flush the heating system under pressure.

- The entry of a foreign body under the impeller can be diagnosed by extraneous unpleasant noises or jamming, or engine overheating. In this case, it is necessary to disassemble the pump and remove a piece of scale or rust.

- Another cause of overheating is voltage fluctuations in the network. The device must be taken for diagnostics.

The reasons for overheating of the unit can be very diverse, but do not rush to remove the device from the pipeline or replace it. First, flush the heating with caustic soda solution. If this does not help, leave a request on the website to call a specialist or call

Examples of completed work

Installation of water heated floors (Novorizhskoe highway, Yakunino village)

Turnkey installation of water heated floors (Volokolamskoe highway, Dedovsk, SNT Prodmontazh)

Moscow region, Krasnogorsk district, village. Timoshkino. September 2015 Turnkey work was completed to install utilities for the cottage

In heating systems, circulation pumps are used to ensure uniform circulation of the coolant. Pumps pump working fluid from the boiler to heating devices, and when the liquid cools, back to the boiler. All modern boilers are equipped with circulation pumps, which ensure uninterrupted operation of the heating system. This equipment is quite reliable, designed for a long service life and, if used correctly, will work normally, without failures. If used incorrectly, various problems can arise, the most common of which is that the circulation pump gets hot.

Design features of the circulation pump

The pump housing is made of materials that are durable and resistant to corrosion, usually:

After the engine is started, the rotor in the pump, which is equipped with an impeller, begins to rotate. After this, the pressure at the inlet pipe decreases, as a result of which the liquid is sucked into the hydraulic chamber. Due to the rotation of the impeller, centrifugal force is generated.

The liquid medium is pressed against the walls of the chamber and thrown out through the outlet into the pipeline. This ensures forced circulation of the coolant in a closed heating circuit.

Should it be warmed up?

The main reason for installing this type of pump is the forced acceleration or deceleration of fluid flow through pipelines under pressure. Due to the conversion of electrical energy into kinetic energy, and due to the friction of the pump components among themselves during operation, its heating should be observed. However, temperatures increase slightly. The pump accelerates hot water, which also contributes to heating. Therefore, the heat generated by the pipe should be approximately the same.

It is much worse if the pump is much hotter than the pipeline. This indicates a malfunction.

Why does it smoke?

If the stove in the bathhouse smokes during initial use, the problem may directly be due to improper installation of the structure. We strongly recommend that you contact a specialist for help, since it will be quite difficult to find and fix the problem yourself.

In addition, there are other reasons why the stove in the bathhouse smokes. These include:

- First of all, strong winds can interfere with the exit of smoke from the chimney. In most cases, this is due to the fact that the pipe is located slightly below the ridge. The problem can be solved by making the pipe longer, or by installing a protective cap;

- Damage to the roof may also be the answer to the question - why does an iron stove smoke in a bathhouse? This is explained by the fact that if there is an attic flue, moisture enters it and seeps through damaged roof areas. This problem can be eliminated only by repairing these areas;

- An iron stove in a bathhouse smokes most often due to an excessively dirty chimney or foreign objects in it. Detecting this problem is as easy as shelling pears, since a clear sign is poor draft in the sauna stove. For example, very often birds build nests in chimney pipes, and debris and branches from nearby trees can get into an unprotected pipe. This problem can be solved quite simply; you just need to clean the chimney of soot, soot and foreign objects. As a tool, it is best to use a special flexible brush with nylon bristles;

- Among other things, smoke can be caused by too large a vent. This is explained by a large amount of cold air entering the hole, which subsequently heats up and pushes the smoke out.

The stove in the bathhouse is smoking - what to do? This is a rather serious problem that is easier and cheaper to prevent than to solve.

Attention! It is very important to properly design the stove and chimney to avoid smoke problems in the future.

chimney pipe

Problems arise due to the fact that strong air currents form above the roof, preventing the smoke from fully escaping from the chimney.

That is why the following factors should be taken into account at the design stage:

- If the pipe is located at a distance of 1.5 meters from the ridge, then its height should exceed the level of the top of the roof by 50 cm;

- If the pipe is located at a distance of 1.5 to 3 meters, then it is permissible to install a pipe whose height is equal to the level of the ridge;

- If the chimney is located at a fairly significant distance, which exceeds 3 meters, then the pipe should be no lower than an angle of ten degrees from the ridge.

Maintenance of circulation pumps

Pump malfunctions and ways to eliminate them

The design of a circulation pump with a “wet” type rotor is based on a modular principle. Modules can be configured in different configurations. It all depends on the power and size of the pump.

Any repair work can only be carried out if the power is completely turned off and the area has been drained.

Malfunctions of the heating circulation pump:

- The pump turns on, sounds are heard, but the shaft does not rotate. Why is the heating pump noisy and why do other “symptoms” appear? The reason may be oxidation of the shaft after a long period of inactivity of the device. If the pump is blocked, the device must not be left on. It is necessary to drain the water and all the screws that connect the pump housing with the electric motor must be unscrewed. Next, we remove the engine itself, and its impeller is turned manually. If the pump is of low power, the shaft can be unlocked by turning it with a screwdriver. For this purpose, there is a special notch at the end of the shaft.

- A foreign object has blocked the wheel. How to disassemble a heating circulation pump? We dismantle the pump motor using the above method. To prevent blocking from happening again, a mesh type filter must be installed in front of the pump.

- There are problems with the power supply. It is necessary to check the voltage in accordance with that indicated in the technical data sheet of the device. You should also check if all phases are present and if everything is connected correctly in the terminal box.

- The circulation pump does not make sounds (the heating circulation pump does not hum) and does not turn on. There is also no supply voltage. The fuse may be damaged. In this case, the fuse will need to be replaced. If nothing has changed after replacement, then the reason may be in the motor winding. Most likely it burned out.

- The pump turns on, but after a while it turns off. The cause may be deposits that have formed between the rotor and the stator jacket. It will be necessary to dismantle the electric motor and clean the stator jacket from scale.

- When the pump is turned on, a sharp noise occurs. Why is the heating pump humming and how to de-air the heating circulation pump? It is necessary to release the air and install an automatic air vent at the top point of the pump piping unit.

- The pump vibrates. The cause may be bearing wear. Typically this problem is accompanied by a characteristic noise. To eliminate the problem, the bearing will need to be replaced.

- The water pressure and its supply are lower than those indicated in the circulation pump passport. This malfunction is typical for three-phase type pumps if they were connected incorrectly.

- After the pump has been started, the external protection of the electric motor is activated. Most likely, the problems occur in the electrical part of the engine.

- It is necessary to check if there are phases in the terminal box. You also need to check if the fuse contacts are dirty. You can also check what the phase resistance to grounding is.

The circular pump creates conditions for the circulation of coolant throughout the entire heating system. Using this device allows you to improve heating performance and increase system performance. When installing pumping equipment, you can choose pipes with a smaller diameter, which allows you to save money.

Reasons why the circulation pump is noisy

The main condition for long-term and trouble-free operation of the device is proper installation, carried out in strict compliance with the manufacturer’s recommendations. If the circulation pump is humming, you should make sure that all installation operations were carried out without violations. To prevent this problem from occurring, experts recommend installing a pressure membrane tank (hydraulic compensator). With its help you can control the static pressure in the system. A membrane tank will eliminate cavitation loads, which not only contribute to the creation of hum, but also negatively affect the service life of the device. In order to create comfortable conditions for living in the house, you should choose the right location for installing the pump. It should be determined by the design features of the equipment

Particular attention should be paid to purifying the water used in the system. Many people are wondering why the circulation pump is humming at the beginning of the heating season? As a rule, this happens due to the fact that when the communications are filled with system liquid, air enters the heat-conducting pipes and the body of the pumping device. Air pockets can be removed through special holes equipped with screw plugs

Valves for removing air from the system should be located at the highest points of the heating system elements. Before each start of the system, make sure that there is no air in the system. Modern models of circulation pumps, due to their design features, do not require maintenance. Dirt accumulated during the summer period of inactivity can be removed by turning on the booster motor at maximum power.

Circulation pumps with automatic adjustment during operation do not create noise in the thermostatic pipeline valves. They quickly respond to the slightest changes in the heating system. For example, when a thermostatic valve opens or closes, the device automatically changes its technical characteristics without consuming excess electricity. Electronically controlled devices do not require manual deflation.

The circulation pump can also hum as a result of mechanical failure. It can be eliminated only after installing and disassembling the device. As a result of long-term operation of equipment, technological gaps increase. The problem can be solved by replacing the adjusting washers. This measure will prevent axial runout of the motor shaft. Also, the cause of loud operation of the pump can be wear of the working surfaces and shaft bushings. In this case, it will be necessary to replace parts that have become faulty, while simultaneously grooving the shaft. This will help prevent radial runout of the units. The causes of cyclic noise in the circulation pump are burning of the motor windings or interturn breaks. Such breakdowns can be repaired by specialists who repair electric motors and have professional skills and the right set of tools.

Typical circulation pump malfunctions

Compliance with all operating rules of the device does not guarantee uninterrupted operation of the unit. Breakdowns may occur that do not depend on human actions: the filter is clogged, voltage surges, etc.

If the engine does not turn on, but the pump does not make humming or other strange sounds, it is worth checking the fuse. It reacts sharply to surges in the electrical network and if the engine is threatened, it melts, thereby breaking the electrical circuit. In this case, the fuse will have to be replaced, after which the device will return to normal operation.

If the failure was not in the fuse, you should check the power cord, the circuit breaker in the distribution box and the electrical wiring. There may be a section of wire or switch that needs replacing.

After checking the wiring, you should move on to the electric motor winding. Its serviceability is checked by measuring the resistance. The multimeter should read 10-15 ohms. Some units are equipped with a starting winding, the resistance of which is 35-40 Ohms.

If the multimeter displays “infinity,” it means the winding has failed. And when the readings are closer to zero, an interturn short circuit has occurred. In this case, turning on the device is accompanied by the operation of fuses in the panel.

Modern devices have a low noise level, so often the owner of such a unit cannot understand whether it works or not? To diagnose the device, use a circulation pump shaft rotation tester indicator, which will show whether the device is working without an electrical outlet. To do this, you need to bring your indicator to the motor shaft and the scale will show whether the shaft is rotating or not working at all.

When the circulation pump hums, but the shaft with the impeller does not rotate, you should immediately turn off the unit, because the motor winding may burn out. There are several reasons for this malfunction:

- The shaft does not work due to downtime in the summer. For the same reason, the impeller sticks to the housing. In this case, you need to disassemble the device and manually rotate the shaft. Manufacturers took this point into account, so the shaft has a notch for a screwdriver.

- The impeller does not rotate due to a foreign object in the chamber. After removing it, system operation will resume.

If the device makes unusual noise during operation, this may be air accumulated in the system. To remove it, it is recommended to install an automatic air vent on the heating circuit. But if it is not there, then the air is bled off manually

Why does the circulation unit heat up?

The temperature of the device must match the temperature of the coolant pipes. If it rises higher, it means that errors were made during installation, or improper operation was taking place. The circulation unit may overheat for the following reasons:

- initially incorrect installation. It is not difficult to determine the problem: the pump heats up at the initial stage immediately after installation.

- blockage in the system. During long-term operation, deposits and rust accumulate in the pipes, which leads to a decrease in water passage. The device is overloaded to ensure normal coolant circulation. In this case, the engine overheats, but unscheduled maintenance can cope with the breakdown.

- foreign body. When communications are slagged, pieces of rust or plaque break off from pipes and radiators, which, when they get into the device, jam the electric motor. If the device is not disassembled and cleaned in time, the electric motor coils may fail and the device will simply stop turning on.

- Lack of lubrication for bearings. If there is insufficient amount of lubricant, the bearings are poorly lubricated and quickly wear out, which leads to a reduction in the service life of the unit as a whole. If the engine jams as a result, the pump is dismantled and handed over to a service center.

- low voltage in the network. At voltages below 220 V, the electric motor overheats and quickly fails. In the first minutes of overheating, it is worth checking the voltage in the network with a voltmeter, because the problem may not be in the pump.

The device works, but does not pump coolant

One of the problems that happens with heating units is the operation of the pump without pumping water. There are four reasons for this condition:

- air ingress or water leakage, which can be eliminated by repairing holes and cracks in the pipes;

- incorrect adjustment of the heating system. The malfunction can be solved by checking the correct position of the taps (primarily before the pump);

- no water. To repair such a malfunction is to supply water to the device.

- Valve blocked or stuck. To resolve, repair or replace the valve.

Date: September 25, 2021

Video about heating pump repair

If the circulation pump of the heating system heats up, you should not immediately disassemble it, for the reason that breakdowns can occur in different ways. First you need to measure the voltage in the electrical network and, if the parameters are normal, then you need to flush the internal circuit of the network. To do this, introduce a caustic soda solution into the circuit for 1 hour. After this, you need to rinse the pipelines with clean water. If the reason for the stop was scale, it will go away and the pump should start working. If this action does not bring results, and the boiler is under warranty, then it is better to contact a service center.