Electric boiler for heated floors

An electric boiler is a device that heats the coolant using electricity. The operation of such units is characterized by productivity and efficiency. Efficiency can reach 99%.

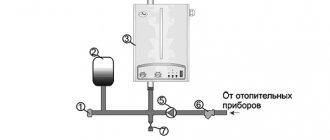

Electric boiler operation diagram

But despite the high efficiency and productivity of electric boilers, their use involves high costs, since electricity is an expensive fuel.

An electric heating boiler is constructed of a tank containing coolant and heating elements. In addition, the unit is equipped with a safety group consisting of a pressure sensor and a safety valve. The boiler has a pump that circulates the coolant, an air vent and an expansion tank.

The principle of heating water for heated water floors is based on the following: water enters the boiler and begins to warm up. When the desired temperature is reached, the coolant moves towards the warm water floor.

The operating principle of floor-mounted and wall-mounted electric boilers is identical.

Electric boilers are induction, electrode and heating elements.

Advantages and disadvantages

Let us note the main advantages and disadvantages of using electric boilers for heated floors:

- high efficiency;

- reliability;

- absence of combustion products;

- work autonomy, human presence is not expected;

- There are usually no difficulties with installation and further use.

A number of difficulties may arise when connecting the boiler to the network, since it will require separate electrical wiring.

Flaws:

- energy dependence;

- high price of electricity.

An electric unit for a warm water floor is more suitable for rooms that are not very large in size and with good thermal insulation, then their operation will be as economical as possible.

Installation and selection

Warm floors and an electric boiler are simply connected. The operating temperature for many models starts from 25°, so piping does not involve high costs. You will just need to acquire a collector, and then only in a situation where several circuits will be connected to one boiler. As already noted, there are no combustion products in the operation of such units, so you can install an electric boiler anywhere in your home.

When choosing an electric boiler for a warm water floor, you need to be guided by the following criteria:

- power: the performance of the heating device (calculated according to the size of the heated room);

- protection from air humidity;

- degree of automation of boiler operation;

- connection to a 220 V or 380 V network;

- design;

- manufacturer.

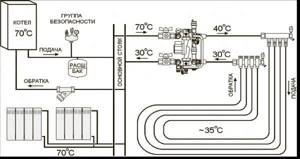

Connection diagram for boiler and warm water floor

Here are some manufacturers of electric boilers.

ManufacturerCountry

| FigNIT | Russia |

| Ferroli | Italy |

| Dakon | Czech |

| Eleko | Slovakia |

| PROTHERM | Slovakia |

| VIESSMANN | Germany |

Boiler selection criteria

Unfortunately, there are no specially designed boilers to which a heated floor system can be connected. There are, of course, models whose technical data sheets indicate that they can operate in this mode, but in general this is only one of the functions of the equipment.

Choosing an electric boiler

The choice of floor heating equipment should be made according to several criteria:

- the ability to adjust the heating of the coolant and floors;

- unit power;

- Type of fuel;

- compatible with floor heating system;

- high efficiency;

- ease of use, repair, maintenance;

- safety system;

- manufacturer;

- ease of installation.

How to choose an electric boiler

Everyone should choose the fuel that will be most profitable. In some regions it is cheaper to heat with electricity, in others - with gas.

Recommendations for selecting a boiler

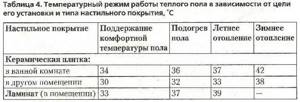

One of the most important parameters when choosing a heating boiler is the possibility of connecting it to a floor heating system. This is necessary in order to be able to set the temperature of the coolant that will circulate without damage to the equipment and budget. On the supply side, the heating system should produce only +35-45 degrees, and on the return side – about +25.

If you plan to connect an electric boiler in close proximity to the living room, it is advisable to pay attention to imported devices

On a note! If the house is heated by radiators connected to a boiler, from which the heated floor heating system also extends, then choosing a unit will be easier. If the heating of the premises will not be carried out by the boiler, then it is important to choose a model that will allow you to set a low floor heating temperature.

It is also important to evaluate the area of the room in which the heated floor system will be installed, the materials from which its finishing is made, as well as the parameters of the screed.

Installation of water heated floor

Description of the electric boiler

A water heating boiler, powered by electricity, is an insulated container of a certain volume. Polyurethane foam is used as a thermal insulation material. The container is protected from the outside by a stainless steel casing.

The inner surface is covered with glass enamel or made of steel, onto which enamel with the addition of titanium is applied. The coating can withstand high temperatures, does not react with water salts, and does not corrode.

The boiler has outlets for cold and hot water. Water heaters to which a heating system can be connected are equipped with outlet pipes for the coolant, which flows through a pipe system to the radiators or to the floor line, and returns through the cold circuit back to the boiler. The coolant is discharged through the hot water intake pipe.

To automatically regulate the operation of the electric boiler, a control unit is provided. It consists of a temperature sensor, a thermostat and a thermostat. The equipment is located under a protective steel casing. Only the thermostat panel is exposed to the external surface. It sets the thermal mode for water.

There is a heating element inside the container. This could be a heating element, an electrode or an induction coil. These devices are connected to a 220 V network. Depending on the heating source, there are some modifications of boilers.

- heating elements; This is the most common equipment for heating water. The coolant is brought to a certain temperature using a heating element. It is installed on the bottom surface of the firebox. To prevent scale from forming on the heating element, it is placed in a metal tube. Additional protection is a magnesium anode.

- Electrode boilers; a metal rod acts as an electrode. It is the cathode. Current is supplied to it. The boiler body acts as an anode. When the system is turned on, the ions begin to change their polarity and are attracted either to the rod or to the walls of the boiler. The chaotic movement of charged particles releases energy, which contributes to an increase in water temperature.

- The coolant can be heated using an induction coil, in the center of which there is a metal rod; Electric current is supplied to the coil. An electromagnetic field is formed around it and around the rod; vortex flows are created that heat the coolant.

If an electric boiler is used only for heating water, which is intended for household needs, then choose a low-power horizontal unit. It is easy to install on the wall. Vertical, high-power equipment is designed for a water heating system. They are installed on the floor or on the wall.

It is recommended to place water heaters in a separate room. If the unit is mounted on a wooden wall, then it is necessary to cover its surface with an asbestos sheet or basalt cardboard. The equipment is installed at a height of 1.5 m from the floor and 80 cm from the ceiling.

A distance of 50 cm is maintained from household heating appliances and gas stoves. Electrical cables are routed from above to prevent water from getting on them in an emergency.

The main manufacturers of heating equipment are Buderus, Logamax, Kospel EKCO, Aton Electro, Galan, Barsky Machine-Building Plant. The equipment is selected depending on the capacity, operating power, and the number of water circuits. For underfloor heating, units with 2 circuits are purchased.

You can assemble an electric boiler for underfloor heating yourself. A stainless steel barrel is chosen as a container. From the outside it is insulated with mineral wool.

Electric boiler in a floor system with heating and hot water supply

Only electric boilers with heating elements for the floor are allowed to be connected to heating water elements. They are equipped with two circular rings that have an individual heating system.

This structural device allows you to adjust the temperature of the water floor and water supply. Units with an electrode element are not connected to the DHW. If there is such a boiler model, it is necessary to modify the heater.

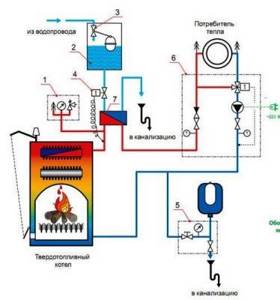

To arrange such communications you will need:

- Storage water heater. It provides heating of water for domestic needs. To do this, the liquid must be heated to a temperature that is 15 degrees higher than for a heated floor. Heating systems with a gas unit function similarly.

- Comb equipped with a collector. Do not connect the electric boiler directly to a heated floor, since there is a high probability of overheating. To prevent this, it is necessary to lower the high temperature due to the mixing unit, which is placed on the comb.

- Temperature sensors. Typically, temperature sensors that monitor the degree of heating of the liquid in the boiler are already installed in the system. But you will need another device that records the temperature in the room. This sensor is mounted at a distance of 20–25 centimeters from the floor.

- System for filtering the working environment and feeding the heating circuit.

- Grounding for an electric boiler.

How to connect a heated floor to a boiler?

In order to lay the water circuit on the subfloor and connect it to the boiler, you need to make a project. It indicates 2 parts: connecting the main line to the collector and connecting the collector to the boiler.

- The pipe is laid on the prepared rough base using a snake or snail. One end of the pipe is connected to a manifold with a hot circuit, the other to a pipe that carries the cooled coolant to the boiler.

- A three-way valve with a temperature control device and a temperature sensor is installed on the manifold: the control unit is designed to control the flow and temperature of the liquid into the floor line.

- Hot and cold circuits are diverted from the collector. They are connected to the outputs on the boiler.

- A membrane expansion tank, a circulation pump, a filter and a tube that removes air from the circuit are installed on the return pipe.

- Shut-off valves are provided for the pump. They are necessary in order to be able to turn off the pump and carry out repair or maintenance work. It is recommended to make a separate pipe structure for the pump and strengthen it on the return circuit using bypasses.

- Separate control units are installed for the electric boiler and the heating system. Automation in the boiler is provided by the manufacturer.

The supply pipe of the hot circuit is brought out at a slight angle. It is necessary for the coolant to pass to the collector under the influence of gravity. Cooled water is pumped under pressure to the boiler using a circulation pump. The pipe is installed at an angle towards the boiler: 3 mm per 1 linear line. m.

If the hot water outlet of the water heater is located on the side or top, then an expansion tank can be provided in the system. It is installed on the upper section of the house. Coolant is supplied to it from the boiler. From it the hot circuit is routed to the underfloor heating manifold. The cold pipe is tilting towards it.

Installation and Installation

Before connecting an electric boiler to a warm water floor, you must read the instructions supplied by the manufacturer and carry out all work in strict accordance with the instructions received. For more information about connecting a heated floor to a boiler, watch this video:

Collector unit

Required devices include:

- underfloor heating manifold unit;

- expansion tank;

- circulation pump installed on the return line.

As the installation diagram shows, the floor heating boiler is connected to the expansion tank, then you need to install a pressure gauge that controls the pressure in the system, then connect the manifold assembly. It is required to clearly distribute the coolant throughout all installed pipe circuits and regulate the temperature of the liquid in the system.

Now you can connect the heated floor directly, and on the return line you need to install a circular pump, which will ensure rapid and continuous movement of the liquid heat carrier through all pipes.

A prerequisite for efficient and safe operation of the equipment is the presence of its own electrical system output to the switchboard, separate from other devices. Electric boilers are installed to heat country cottages and small private houses, garages and private workshops. They are simple and easy to use, reliable and economical. Such equipment does not require the construction of chimneys and does not pose a fire risk. For details on installing heated floors in an apartment, see this video:

You can connect such a device yourself by choosing the most convenient model. Wall-mounted units take up minimal space and do not attract attention. Modern devices provide a smooth start of the system, are designed with the ability to connect a programmer and are equipped with an LCD display that displays the current state of the system. Electric boilers connected to a warm water floor help create an atmosphere of coziness and comfort in your home, avoiding unnecessary material costs.

How to choose an electric boiler for a water floor

Connecting a water floor to an electric boiler is often used when installing autonomous heating in apartment buildings. When choosing, determine:

- The main functions of the boiler - the consumer is offered household electric heating boilers with the possible connection of heated floors, and models in which this function is not provided. The latter will need to be re-equipped by installing additional equipment.

- Power – the boiler’s performance is calculated based on the heated area.

- Manufacturer - electric boilers are manufactured by German, Czech, Italian and Russian manufacturers.

The last two selection criteria are complex and require qualified assistance. Recently, experienced consultants were asked to share recommendations on the proper selection of an electric boiler, by power and manufacturer.

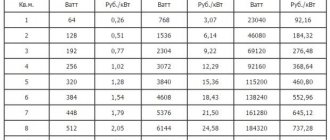

How to calculate boiler power for heated floors

The boiler is calculated using a special formula. It is believed that the thermal power when using an electric boiler only for a liquid floor should correspond to 1 kW for every 10 m² of heated area. If you plan to install a double-circuit electric boiler, about 30% of the required unit performance is added to the result obtained.

At the same time, the peculiarity of a double-circuit boiler is taken into account. When the DHW is turned on, heating of the coolant does not stop. Accordingly, the wiring experiences peak load. The technical documentation for the electric boiler specifies the cable parameters for connection. The wiring must be exactly as specified.

Choosing the boiler power is associated with another difficulty. After calculations, it may turn out that the required power of the heat generator will be 5.5 or 8.2 kW. The result obtained is simply rounded up.

Which electric boilers are recommended for water floors?

As has been noted several times in this article, not all electric boilers are suitable for heated floors. Some manufacturers' models can be modified, others cannot. Judging by operating experience and technical characteristics, it is better to connect electric boilers of the following brands to heated floors:

- Heating element boilers:

- Buderus Logamax, E series

- Kospel EKCO (series specially designed for connection to heated floors)

- Ferroli LEB and Ferroli ZEWS (with the possibility of connecting an indirect heating boiler)

- ACV E-tech W (for heating only) and ACV E-tech S (with the possibility of connecting an additional plate heat exchanger for domestic hot water)

- Vaillant eloBLOCK series

- Baxi AMPTEC (series, separately for radiators and heated floors)

- Rilano EVPM (with the possibility of using antifreeze)

- Barsky Machine Plant Zh7-KEP

- Electrode boilers:

- GALAN, HARNESS, GEYSER and VOLCANO series

- ATON Electro

All models have been tested under domestic operating conditions and have shown themselves to work well with low-temperature heating systems.

Heating costs with an electric boiler with a water floor

Electricity costs are one of the most significant disadvantages of electric boilers. But even simple calculations help to obtain results indicating that energy consumption will lead to costs much less than what you need to pay for central heating. Modern electric boilers are economical and have high thermal efficiency.

There are ways to reduce energy costs:

- The use of automation - costs, after connecting room thermostats, are reduced by 15-20%. Remote control helps to quickly change settings if necessary, without visiting the boiler room.

- Refusal from hot water supply - for comparison, an electric boiler for heating water uses up to 40% less electricity than a hot water supply circuit installed in an electric boiler.

Electricity consumption for each electric boiler is indicated in the technical documentation.

Features of underfloor heating without radiators, boilers for underfloor heating

People often think about underfloor heating specifically in the winter, when you really want to move around the premises barefoot, but the flooring is so cold that this is not possible. An option to make it more pleasant and tactilely comfortable is to install a heated floor system.

Pipes for water heated floors

There are different floor heating systems - water, electric, infrared. And often owners of apartments and houses make a choice in favor of the first option. The system will consist of main pipes through which the coolant - hot water - circulates, as well as a boiler that heats this water.

Water heated floor

On a note! In new buildings, floor heating can often be connected to the central heating system - it will have special outlets for connecting the heating system pipes. But in private houses, as well as older apartments, connecting to heating is impossible, so there are two options - using other heating systems or installing a water heating boiler.

Connecting underfloor heating to central heating

The boiler is often used to heat premises for various purposes - apartments and garages, houses and offices. This reliable device has acceptable dimensions and is not dangerous for use in a residential area. It also has a very convenient temperature control system, which will allow you to control the microclimate in the room. This will make it possible to leave the unit turned on unattended for a long period of time.

Electric boiler

On a note! The boiler belongs to an autonomous heating system; it will save a lot of money that would be spent on regular additional heating of the room.

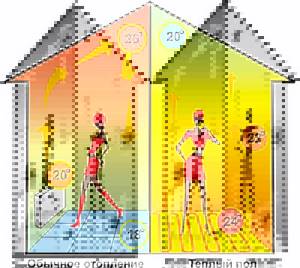

The temperature of the heated floor is much lower than that of heating radiators

Expert opinion

Afanasyev E.V.

Chief editor of the pol-exp.com project Engineer.

It is not recommended to use only a heated floor system without heating radiators to heat a room. The fact is that in order to warm the house to a comfortable temperature, you will have to heat the floors to at least +30 degrees, and this can negatively affect the floor covering, and it will also be unpleasant for a person to move on such hot floors. Also, thanks to radiators, the air in the room can be warmed up much faster than with a heated floor system. The latter even take longer to warm up due to the fact that they are covered with a screed, which also needs to be warmed up.

Conventional heating and underfloor heating

On a note! Only electric boilers can operate efficiently and economically at low power. Everyone else will burn too much fuel to keep the temperature low, which is not profitable.

An electric boiler brings comfort to your home

That is why the underfloor heating system should heat only the surface of the floor, the rest of the room should be heated by radiators. And, nevertheless, for the correct and economical operation of the equipment, it is worth purchasing a heating boiler.

Rating of popular manufacturers

PhotoNameRatingPrice

| #1 |

| Buderus Logamax, E series | ⭐ 97 / 100 | Find out more |

| #2 |

| Kospel EKCO | ⭐ 96 / 100 | Find out more |

| #3 |

| “Galan”, series “Hearth”, “Geyser” and “Vulcan” | ⭐ 91 / 100 | Find out more |

| #4 |

| Ferroli | ⭐ 96 / 100 | Find out more |

| #5 |

| RusNIT | ⭐ 97 / 100 | Find out more |

Buderus Logamax, E series

Country of origin: Germany. These are new heating element wall-mounted boilers of various capacities. Eco-friendly heat sources that are used to heat premises for various purposes, including residential ones.

Buderus Logamax, E series

pros

- it is possible to connect to any heating system;

- mounted in closed systems;

- high efficiency;

- The models are easy to install and require a minimum number of additional elements.

Minuses

- high price.

Electric and solid fuel

There are several types of boiler equipment, differing primarily in the type of fuel used. The most popular are:

- Electric.

- Solid fuel (pellet) boiler.

- Gas equipment.

Pellet

Despite the fact that in recent years there has been almost universal gasification, gas-powered equipment is still rarely installed in rural areas. Its main area of application is city apartments and country cottages, which are close in terms of living comfort to the conditions of a metropolis. In villages, solid fuel equipment is more often installed - a wood, pellet or coal boiler.

The most important advantage that distinguishes a solid fuel (pellet or wood) heating boiler is its low cost and ease of operation. In rural areas, firewood remains the cheapest fuel to this day, and the likelihood of supplying gas to remote corners of the country is still almost a fantasy.

Electric

An electric heating boiler has a lot of advantages, but all of them are covered by one significant disadvantage - high operating cost. In some ways, the following can also be considered disadvantages of the equipment:

- Volatility of the system. A power outage will have negative consequences for the entire heating network, and not just for the device itself. To minimize the risk of the system defrosting in the event of a power outage, an additional emergency generator will be required.

- The electrical network must be able to withstand significantly increased load. An additional line may be required. You will definitely need to install a separate machine.

- The device must be connected by a qualified electrician. Unprofessional installation is life-threatening.

According to the principle of operation, electrode and heating element electric boilers are distinguished. We will not dwell on the former, since it is extremely difficult to design and install such a device. Let's take a closer look at heating elements devices.

Safety requirements

Required :

- the presence of insulated supply cables having the required cross-section;

- The cable is laid in the appropriate cable channel;

- Protective grounding is required.

Important! Installation and connection of the device must be carried out carefully, without any exposed cable sections or exposed wires. It is necessary to monitor the condition of the heat exchanger body to prevent phase breakdown to the coolant (usually such protection is provided for by the boiler design, but safety is paramount).

Main structural elements of boilers

Which wall-mounted gas boiler is best to choose for home heating?

Before making an electric boiler on your own, you should carefully familiarize yourself with its main components:

- heating element;

- The boiler itself;

- Additional equipment for inserting regulators and sensors.

Among them, the greatest importance is given to such a device as a heating element. It is designed to convert standard electrical energy into high-quality thermal energy. In fact, this is a special tubular electric heater. As for the boiler, it can be made from a special pipe made of high-quality metal or some other container

No less important are a variety of additional structural elements, through which the process of using the boiler can be significantly simplified.

Modern models of such equipment are usually sold fully equipped. Among the main elements are:

- Expansion tank.

- High quality filter.

- Circulation pump.

- Safety valve.

Boilers that have all the required structural elements can be made independently; you just need to know and follow a few basic important points.

Characteristics

Typically the following characteristics are indicated :

- heater type;

- heater power;

- power consumption;

- electricity consumption;

- heat exchanger volume;

- volume of heated space.

In practice, power and volume are of decisive importance; other qualities are essentially derivatives of these quantities.

Alternative systems

Competition in the market for heating systems for electric boilers comes from installations running on diesel and solid fuels (including pellets), as well as gas and combined units.

In practice, when comparing the technical and economic indicators of the presented boilers, we can conclude that electric installations for heating a residential building are one of the best options for operation. Their main advantages are operational reliability, relative low cost of the device, silent operation, ease of installation and full automation.

Not all units are equipped with a full automation system, and some (solid fuel) do not have it at all.

Date: September 25, 2021

Connection diagram

Connecting the boiler to a water heated floor system is quite simple - you need to connect the corresponding direct and reverse flow pipes from the system to the flow and outlet of the electric boiler. For this purpose, the corresponding fittings of the boiler and the mixing unit of the heated floor are used.

If any malfunctions are found, repairs may be required.

Choosing a place and rules

Installing an electric boiler is only possible on a wall lined with non-flammable material and preferably in a non-residential area, although a kitchen would also work well. It is also necessary to provide for the possibility of water leakage: if such a place is located next to the boiler, this creates a danger of short circuit and fire.

Know for safety

According to established standards, there must be a distance of at least 5 cm from the electric boiler to the walls, the free space in front of it is provided at 70 cm, at the top - at least 80 cm, at the bottom - at least 50 cm.

If the boiler consumes no more than 3.5 kW, it can be connected to a regular electrical outlet. Boilers with a power of 3.5-7 kW are connected directly to the panel with a dedicated cable. They can be powered by 220 V.

A separate cable is not a whim of the manufacturer: safety instructions limit the maximum current at the socket to 16 A. But boilers with an electrical power of 7 kW or more are powered only by 380 V.

Device

The design of electric boilers largely depends on the type of construction, so you should consider them in order:

- Boilers with heating elements as a heater . The heat exchanger, inside of which there is a heating element, when turned on, it begins to heat the water. In essence, the principle of a conventional boiler is used. The system is simple and most vulnerable from the point of view of many processes that destroy and weaken the functionality. With a high efficiency of the heating element, equal to almost 100%, over time, scale will inevitably form on it, which significantly reduces heat transfer. The service life of the heating element, declared by the manufacturers, is 10 thousand hours, which in itself is not very long, but in practice, not every heater reaches this value - the coil burns out. Heating elements cannot be repaired.

- An electrode boiler works on the principle of heating water between two electrodes under voltage. There is a container - a heat exchanger, inside which an electric current is passed through the water column from one contact to another. There is a saving of about 40% of energy, since there is no need to heat anything - the temperature of the water changes depending on the course of the physical process. The inconvenience is that only special compounds can be used as a coolant, which eliminates the possibility of heating household water.

- The induction type of heater is the most advanced and economical of all currently used types of electric boilers. There is an inductor. It plays the role of the primary winding. Secondary (like a short-circuited turn) - heat exchanger housing. When current is passed through the primary winding, the secondary winding is inducted, causing it to heat up and give off heat to the water inside. Since the heating area is maximum, the boiler’s operating efficiency is very high.

Difficulties in operation

During use, the consumer may encounter some problems characteristic of electrode heaters:

- The quality of the coolant plays an important role. The service life of the product and reliability of operation depend on this. The use of tap fluid can lead to increased corrosion of metal pipes and radiators and a decrease in efficiency. Manufacturers recommend that owners of electrode boilers use ready-made compositions that have the necessary physical and chemical characteristics. The liquid changes its properties over time, so after 3-4 years the system needs to be filled with fresh coolant.

- It is necessary to pay attention to ensuring the electrical safety of the unit. The body of the device is connected to the neutral cable, the phase is connected to the electrodes. During installation, grounding must be provided. Electric boilers create a large load on the network, so before installing the heating device you should make sure that the wiring is reliable throughout the room.

- Under the constant influence of current, the processes of electrocorrosion of steel and cast iron are accelerated, which reduces the service life of the system several times. Aluminum or bimetallic communications and radiators should be used with electrode units. To provide heat to a cottage or home, you need to make sure that the elements of the heating system are made of recommended materials.

Electricity consumption

The amount of expected consumption is a very pressing question, since it determines the amount of money that will have to be paid regularly for electricity.

Therefore, before purchasing a boiler, it is useful to calculate its power and determine the consumption parameters.

Attention! The use of more modern designs of electric boilers makes it possible to stabilize and reduce electricity consumption and, accordingly, the cost of paying for it.

Advantages and scope of electric boilers

Most often, electric boilers are used in dachas and private homes. This is due to the fact that this equipment has a low cost and at the same time you can install it yourself, without calling a specialist.

Among the main advantages of electric boilers are:

- the equipment is safe (the design does not include open flames or the presence of flammable fuel sources);

- water heaters can be switched off for up to six months, without harm to their performance (relevant for dachas and country houses that are rarely visited);

- the dimensions are relatively small, so it can be placed in any room;

- Today there is a huge variety of electric boilers, varying in power, installation method and principle of operation;

- When water is heated, soot does not appear, which is dangerous for both humans and the environment.

Heater Specifications

Let's focus on storage type boilers. When choosing a model, you should pay attention to its technical characteristics.

Device power . It is this parameter that determines the intensity and speed of heating of tap water. The power of the water heater is directly related to the amount of electricity consumed. As a rule, household boilers have a power of 1.5-3 kW.

Note: There are electric boilers on sale, the power of which is much higher than the proposed parameters (6-10 kW). Such devices are specifically designed to work in conjunction with heating systems. The only disadvantage of such models is high power consumption

The power of a water heating electrical appliance is determined in accordance with traditional parameters: 1 kW – 10 m2 of heated area. Therefore, household storage boilers are of little use for heating residential premises. They can be used to install heated floors in confined spaces (bathrooms).

Storage tank volume . The more hot water you get, the less often the device will periodically turn on to heat the water circulating in the water circuit. For household appliances, the tank volume is usually 50-100 liters. Industrial water heaters used for the heating system have a storage tank volume of 250-300 liters.

Boilers specially designed to work with heating systems have some differences from household appliances. The main differences are as follows:

- such devices have a different arrangement of inlet and outlet pipes;

- cross-section of exit/input holes;

- large size storage tank.

Location of water inlet and outlet pipes . The cold water inlet is located at the bottom, while the hot water outlet is located at the top of the tank. Thanks to this arrangement of pipes, the maximum possible circulation of water in the hot water system is achieved.

Emergency strapping options

Whichever heating system option you choose, dual-circuit heating systems must have an emergency circuit that will act as protection in the event of various unusual situations, for example, if the electricity is suddenly cut off. There are several ways to cope with this problem.

Boiler emergency piping diagram

The supply of water from the water supply system to the system is used quite rarely, as it is ineffective. The whole point is that the plumbing system stops working when the power goes out. A certain amount of water is stored in hydraulic accumulators, however, this amount will simply not be enough to prevent overheating of the equipment. If antifreeze is used as a coolant, then approximately 150 liters of this expensive substance will simply be drained into the sewer system.

If you connect the circulation pump to an uninterrupted power source, you can be safe from a power outage in the network. However, this solution also has its drawbacks. This power supply may not work due to some unexpected situations. In addition, boilers with a double-circuit system require constant maintenance and preventive maintenance. It is constantly necessary to monitor the health of the batteries and check for serviceability by charging and testing their performance.

The circuit protects the heating system from overheating

The concept of gravitational circulation refers to a special circuit, which is characterized by small dimensions and serves to remove excess thermal energy in the heating system. This circuit must be turned on only after the pump is turned off, which will lead to the fact that not the entire building, but some part of it, will be heated.

One of the most effective methods is to create an emergency circuit. It is an indispensable component of any good heating system. Thanks to this circuit, the gravity and forced circuits can function in different parts of the system as usual. However, when the pump is turned off, only the gravity circuit will work.

So, we have discussed the main functions and technical characteristics of existing electrical boiler piping schemes. You only need to make your choice, relying on your technical knowledge, family budget and the general design of the heating system in your home. Having weighed all the nuances and settled on the scheme that is ideal for your home, you should proceed directly to installation.

Let's start installation

At the initial stage, you should determine the floor area,

where the heating circuit will be located.

It is absolutely not necessary to install underfloor heating in every room if you simply want to increase the comfort of your home.

You also need to decide what size floor requires heating. Specialists use the entire area, but this approach is not necessary.

The areas where furniture is planned to be placed can be left without heating.

Of course, this only applies when using underfloor heating as an additional heating system.

When planning, it is necessary to take into account that the effective size of one circuit is 50-60 meters.

The maximum length is

up to 100 meters.

The laying step is from 30 to 50 cm. If the floor is used as the only heat source, the step will be

15−20 cm.

The area heated by one circuit usually does not exceed 40 square meters.

The surface is cleared of debris; it should be flat, without significant slopes.

If necessary, perform alignment.

A damper tape 12-18 cm wide is glued around the perimeter; it smoothes out the thermal expansion of concrete.

It also insulates the concrete screed from the walls to prevent heat loss. After all work is completed, the excess tape is cut off.

Next, the materials that make up the bottom layer

warm floor.

In the basement floors it is necessary to use a waterproofing film. For these purposes, ordinary polyethylene film

with a thickness of 0.5-1 mm is quite suitable.

Next, insulation is laid, the main purpose of which is to facilitate the transfer of heat upward into the heated room.

This may be one of the following materials:

- Foamed polyethylene

with a reflective layer. There must be a marking on it stating that it can be combined with heated floors. Suitable when a thin floor thickness is required. - Expanded polystyrene boards

. There are special offers with projections for laying the heating pipe. Can also be used in damp areas. - Mineral wool

. It is not advisable to use it in damp rooms, since with increasing humidity, its heat conductivity increases. - Izover

.

Laying pipes for water heated floors

The next stage of installation will be laying the water circuit pipes. Mostly polypropylene, polyethylene or metal-plastic pipes are used. Pipe diameter 20 mm. The distances from the walls are at least 70 mm.

They try to lay each pipe in one piece, thereby

reducing the risk of water leakage

at the joint.

To make it easier to fasten the pipe, you can put a reinforcing mesh under it with a mesh size of 10x10 cm. The pipe is attached to it using wire, the distance between the fasteners is 1 meter. Leave a small gap

to compensate for the difference in thermal expansion.

Before pouring the screed, it is necessary to perform a pressure test of the system.

The water supply is opened, the pressure is set to 1.5 times higher than the working one, but not less than 0.6 MPa.

After half an hour of system operation, the pressure should decrease

by no more than 0.06 MPa;

after two hours - no more than 0.08 MPa from the initial value. The water temperature should not drop.

If the system is installed correctly, begin pouring concrete.

The thickness of the screed is determined by various reasons and should be within 3-7 cm. It is necessary to use special plasticizers that will increase the plasticity of the mixture and the heat transfer of the screed as a whole.

For large premises , expansion joints are provided;

in residential buildings they are usually made in door openings.

To create a seam, damper tape is used. be under pressure

during filling The complete drying time for the screed is 28 days.

When the heating circuit is running, the drying time is reduced. The temperature of the water carrier is maintained at 30 °C.

In the case of arranging a wooden option, the procedure is as follows. First, the edged board

25 mm thick.

These will be guides for the pipe and at the same time subfloor joists. We lay the heat-insulating material

directly on the subfloor or on the joists.

Metal heat-distributing plates with grooves for the heating pipe are placed on one of these bases. There is also an option for heated floors laid in polystyrene boards. Next, we install the pipes using one of the above methods, a snake or a snail, depending on the guides. also check

the finished heating system, and only after that we lay the finished floor.

For it, you can use boards no more than 45 mm thick, chipboard or plywood, followed by laying laminate, linoleum without a heat-insulating backing, or

thin parquet.