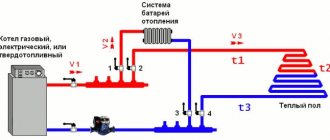

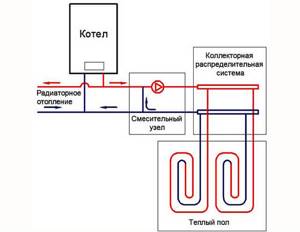

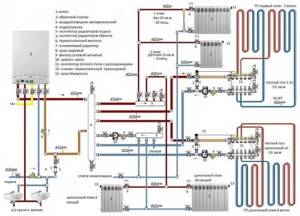

Now the moment has come when it’s time to connect your heated floor to a heating source. There are various ways to accomplish this task. Of course, the choice of method depends on many factors, such as the choice of boiler for the system, the area of the heated floor, the presence of radiators that work in conjunction with the heated floors.

Not to mention, if you decide to install a water heated floor in an apartment whose house has a common heating system. If you are interested in the last point, then you do not need this article, feel free to follow the link to the article “water heated floor in an apartment.” Here we will consider connecting a heated floor to a wall-mounted and floor-standing boiler. It doesn't matter whether it's gas or electric. If you are interested in connecting a solid fuel boiler, then read the article “how to connect a heated floor to a solid fuel boiler”

Types of collectors by number of branches

The cold water supply collector, like the hot one, can be divided according to the number of outlets. Their number can be equal to the limit from 2 to 6. The products have two fasteners that correspond to the diameter of the supply pipe and are intended for docking. With their help, several blocks are connected into one collector without the use of additional adapters.

Sometimes it happens that one block is enough, but as an alternative solution, special plugs are used for plugs. Collectors can be used to disconnect some consumers, while others are not affected. This is suitable in cases where plumbing needs to be repaired or replaced, a damaged area needs to be restored, or a drain or a specific area of a pipeline needs to be cleaned.

How to make a collector yourself

To create a comfortable temperature in the house, the entire heating system must be calculated. To do this, take into account such points as:

- Technical characteristics of the heating boiler (power, water heating temperature, efficiency, etc.).

- Number of circuits. For convenience, you need to draw a detailed diagram of the heating system circuit.

- Availability of additional equipment (pump, pressure gauge, storage tank, etc.).

Taking into account all the components that will be included in the system, the heating collector is calculated. In cases where it is not possible to select the necessary equipment in the retail chain, it is manufactured independently. If you know how to handle a welding machine and have plumbing skills, building such a device will not be difficult.

To make a heating distribution manifold with your own hands. While ensuring the correct operation of the heating, you need to think through and calculate every little detail.

Before work, draw the supply and return sections of the manifold on a sheet of paper. Then mark the connection points of the components (boiler, pipes from all circuits, additional equipment). In addition, they provide for the possibility of connecting new elements to the collector in the future. For convenience, the figure shows all the dimensions of the threaded connections with which the system elements will be connected. To make a collector with your own hands, you will need:

- Prepare pipes of the required length and diameter. For ease of manufacture, the part of the collector into which the outlet pipes will cut is made from a rectangular pipe.

- Cut from a pipe or select ready-made pipes.

- Mark and cut the required number of holes. It should be taken into account that to connect solid fuel boilers and indirect heating boilers, the pipe is cut into the end of the supply section. Electric or gas wall-mounted boilers are mounted on the switchgear from above. The gas manifold for the floor-standing boiler is also connected at the end.

- Clean all workpieces from rust.

- Make markings and cut holes for the pipes.

- Weld all the elements of the manifold, then carefully weld each connection.

- Weld elements for mounting to the wall to the device.

- Remove scale by cleaning all welding areas.

Such a device will help to evenly distribute heat in the heating system.

Before painting, the boiler distribution manifold is checked for functionality. To do this, it is filled with water, trying to create as much pressure as possible in the equipment. The device must be completely sealed. If moisture is released at the joints, you will have to boil the problem areas again.

If you decide to make a distribution manifold with your own hands, its quality and reliability must meet the tasks.

Do-it-yourself water supply pipe installation

All people who are building a house or have bought an old home are interested in the question of whether it is possible to install water supply pipes with their own hands. In order for YOU to find the answer specifically, let’s expand on the topic in more detail, and you will draw conclusions after reading.

So, what will you learn from the article:

- Brief description of wiring diagrams

- Advantages of each wiring system

- Plumbing elements

The layout of water supply pipes is done according to two schemes:

- tee or sequential, when two pipe lines are laid, hot and cold, and then pipes are supplied from them to each device.

- A manifold pipe is when a separate pipe runs from the manifold to each device.

Tee layout of water supply pipes.

The tee pipe routing scheme is cheaper and less labor-intensive than the manifold one. Its implementation requires fewer pipes. This is sometimes the main factor when choosing a plumbing scheme. And, despite the main drawback - the loss of pressure in each of the plumbing fixtures, when they are turned on at the same time, it is more popular than the manifold. A separate tap must be installed on each branch in order to repair a separate device without disconnecting the entire system from the water.

Manifold layout of water supply pipes.

The manifold water supply wiring diagram allows you to evenly distribute the pressure in the system using a special device - a manifold. Plus, all the connections are in one place, so you won't have to crawl under the sink to turn off the water to replace the faucet. Some manifold models may have control valves, which allows you to regulate the pressure on each device separately.

The installation of water supply pipes takes place in several stages. Let's look at them using the example of a collector wiring system:

- Installing a tap or valve on a cold and hot water riser. This must be done in order to be able to shut off the water for repairs to the water supply system.

- Installation of a coarse water filter. Such a filter purifies water from coarse impurities and does not make it completely suitable for drinking.

- Installation of water meters for hot and cold water.

- Installation of a fine filter - optional.

- Installing a pressure reducer is most likely not necessary in an apartment, but in a private house it will be useful. The reducer allows you to reduce the pressure if it is too high for your plumbing fixtures. Set to the maximum allowable pressure, it will discharge excess water into the sewer system at excess pressure.

- Installation of the collector. The collector can have from two to four outputs. You can twist several collectors to obtain the required number of outputs. You can choose a collector for any pipes, even plastic ones. Installing a collector will allow you to shut off each device individually when the water supply remains to the others, as well as regulate the pressure at each outlet.

As you can see, laying out water supply pipes with your own hands is quite possible without the involvement of specialists, unless, of course, you have time or the amount of work is small. Comments on the above can be left below.

If you don’t understand something, go to the page: ask a question about repairs

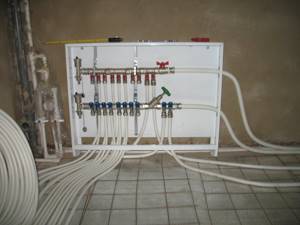

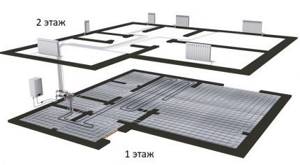

Space for the system

The best place to place the heating manifold device will be its selection during the design process. If you have a building with several floors, then on each floor there is space for a collector block. Usually a niche is made in the wall, which is located at a small height from the floor. The niche must be located in a room that is protected from excess moisture.

Manifold cabinet

The device can be installed directly on the wall, if it is a utility room, or special manifold cabinets for heating are perfect for it. Such cabinets are made of metal, they have a door and stamping, which is used for connecting pipes in the side walls. There may also be special mounts inside for the manifold block. The cabinet can be overhead or built-in.

Elevator heating unit

Types of collector units

Before considering the types of combs, we will indicate ways of their use in water heating systems of private houses and apartments:

- distribution and regulation of water temperature in underfloor heating circuits, abbreviated as TP;

- distribution of coolant to radiators using a radial (collector) circuit;

- general heat distribution in a large residential building with a complex heat supply system.

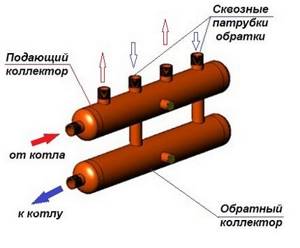

On the left in the photo is a coplanar manifold for distributing the coolant among the branches, on the right is a ready-made manifold module with a hydraulic arrow

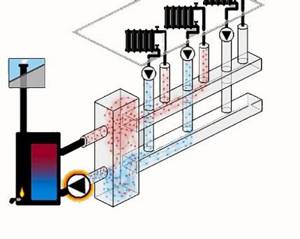

In country cottages with branched heating, the manifold group includes the so-called hydraulic arrow (otherwise known as a thermo-hydraulic separator). Essentially, this is a vertical manifold with 6 terminals: 2 from the boiler, two to the comb, one on the top to remove air, and water is discharged from the bottom.

Now about the types of distribution combs:

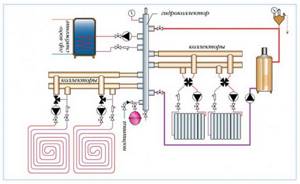

- To limit water temperature, regulate flow and balance heating floor circuits, special collector blocks made of brass, stainless steel or plastic are used. The size of the connecting hole of the main heating main (at the end of the pipe) is ¾ or 1 inch (DN 20–25), the branches are ½ or ¾, respectively (DN 15–20).

- In radiator beam circuits, the same combs of underfloor heating systems are used, but with reduced functionality. We will explain the difference below.

- For general house distribution of coolant, large steel collectors are used, the connection diameter is over 1” (DN 25).

Factory manifold groups are not cheap. To save money, homeowners often use hand-soldered polypropylene combs or buy cheap distributors for water supply systems. Next we will indicate the problems associated with the installation of homemade and plumbing manifolds.

Combs for radiator and floor systems – made of stainless steel, brass and plastic

Collector heating system - general principles for designing wiring diagrams

Correct design and calculations of the collector system can only be done by qualified specialists; when performing design work, they must be guided by the following rules:

- To determine the length of the circuits, parameters of heating radiators, coolant temperatures, it is necessary to calculate heat losses in the main line and circuits. This operation will allow you to determine the optimal dimensions of heating devices (the number of their sections) and the lengths of the contours of heated floors, otherwise the rooms will be too hot or cold during normal operation and additional adjustments will be required, reducing the efficiency and performance of the system.

- It is prohibited to connect heating radiators to collectors for heated floors - they have different hydraulic resistance and operating temperature conditions (coolant temperature 40 - 55º C for heated floors and 60 - 80º C for heating radiators).

- The permissible temperature difference between the water supply line and the return line is 5 – 15º C, the optimal difference is 10º C (55/45, 50/40, 45/35, 40/30 degrees).

- The temperature of the floor surface for living rooms and offices is 21 - 27º C, in living rooms, corridors, hallways - 29 - 30º C, in bathrooms and swimming pools - 33º C, in home workshops with active physical activity - about 17º C.

- The distance between adjacent turns of pipes in the living rooms of a private house lies in the range of 150 - 300 mm, it is excellent for different zones and changes in increments of 50 mm:

- For edge zones and near windows, the interpipe distance is 100 - 150 mm.

- In the central zone of medium and large rooms, the standard inter-turn distance is about 200 mm.

- In bathrooms, showers and bathrooms, a distance between hinges of 150 mm is used.

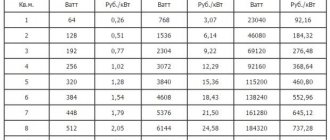

Rice. 8 Heat consumption of a cottage - calculation example

- The maximum loop length of large underfloor heating rings with a diameter of 3/4 inch (16 mm) should not exceed 70 - 90 meters, the value depends on the material of the pipes and increases with increasing diameter (for 20 mm pipes the permissible length is 120 meters.)

- The electric pump must have a rated power calculated mathematically; exceeding it leads to excessive noise, and a low value does not provide the optimal speed of coolant movement.

- According to building codes, the number of circuits connected to one comb should not exceed 8; the European standard allows the use of 12 branches.

- In underfloor heating manifolds, it is necessary to have mixing tees or bypass jumpers to ensure that the cooled coolant from the return line is mixed with the hot liquid entering the combs from the boiler. In the absence of such a device, the heated floor will overheat, causing discomfort among residents, increased wear or deformation of some types of pipelines.

Rice. 9 Design of a collector comb for heating radiators and its connection

What to consider when designing and installing

When carrying out planning and installation work, the following rules are followed:

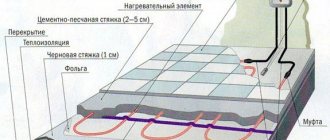

- When pouring screed under heated floors, it is necessary to install damper gaps around the perimeter of the premises - this prevents deformation of the floor during thermal expansion of the screed and helps avoid the appearance of cracks.

- Also, the screed must have a thickness that ensures its uniform heating and heat retention for a certain time; usually the layer thickness is in the range of 30 - 50 mm. It should be taken into account that a thick layer will heat up for a long time and cool down slowly, while a thin layer, when heated quickly, retains heat for a short time - this will cause more frequent switching on and off of the equipment, and accordingly its increased wear.

- Under underfloor heating pipes, it is necessary to lay thermal insulation to prevent heat from escaping into the concrete slab; usually for these purposes, foil penofol (foamed polyethylene) is used, laid with an aluminum layer up to reflect thermal radiation.

- Before pouring the screed, coolant is supplied into the pipes with double pressure, which is released after it hardens - thus, the channels formed in the screed will not further compress the pipeline when it expands after filling with coolant.

- Supply pipes should not have butt joints under the screed; areas not related to the contours of radiators and heated floors should be placed in corrugated insulation to reduce heat loss.

- The floor covering of heated floors must have high thermal conductivity; the use of wood, linoleum, and carpets that interfere with heat transfer is excluded.

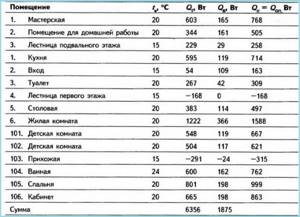

Rice. 10 Manifold wiring with hydraulic arrow - diagram

Principles of drawing up wiring diagrams

The optimal placement of the collector block is above the level of the heated floor; if it is heating a two-story dacha or cottage, it is more convenient to place it on the second floor in the center. In this case, all contours will have approximately the same length, in contrast to installing the block near external walls or in the corners of buildings.

Distribution manifold design and operating principle

The main function of the collector is to distribute one significant flow of water into several small ones. To do this, you can find devices on sale that have from 2 to 4 outputs. In order to organize a significant number of branches, you need to connect several similar combs together.

To connect the collector, you need to connect it directly to the riser of the house's water supply system. For this purpose, the devices have special threaded connections on both sides. They can have internal and external threads.

A plug is usually installed on the unoccupied end of the collector. You can also connect any plumbing fixture to this place. Most often this concerns a water hammer damper equipped with a membrane device.

Outputs can be organized in the following ways:

- using valves;

- using ball valves.

Valves not only allow you to control fluid flows. Their functions include adjusting the pressure in a specific section of the water supply system.

Heating collectors: types of devices

There is no standard heating manifold configuration. The device can be made in any modification, which allows it to be adapted to a variety of heating systems with different types of devices and the number of circuits. The comb has from 2 to 12 circuits; the price of the heating collector depends on this indicator. During operation, the number of involved branches may vary.

The device can be made in any modification, which allows it to be adapted to a variety of heating systems

According to technical characteristics, heating distribution units can be divided into the following types of collectors: solar, with a hydraulic arrow and radiator. Based on the number of system elements, simple and advanced models are distinguished. The first option is not equipped with additional devices to control and adjust the operation of the device. It is represented by a simple comb with several branches, each of which can be turned off. In such a system, control over the temperature and volume of the coolant is not assumed.

Improved products are equipped with pressure and temperature regulators, pressure sensors, water supply control units, thermostats for automatic pressure adjustment, electronic mixers and valves for regulating the supply of cold and hot water, air vents for releasing air bubbles from pipes.

Important! The configuration of the collector unit may vary depending on certain system requirements, which affects the functionality and cost of the installation.

Operating principle and types of solar collectors

The time has come to say a few words about the design and operating principle of the solar collector. The main element of its design is the adsorber, which is a copper plate with a pipe welded to it. Absorbing the heat of the sun's rays falling on it, the plate (and along with it the pipe) quickly heats up. This heat is transferred to the liquid coolant circulating through the pipe, which in turn transports it further through the system.

The ability of a physical body to absorb or reflect solar rays depends, first of all, on the nature of its surface. For example, a mirror surface perfectly reflects light and heat, but a black surface, on the contrary, absorbs it. That is why a black coating is applied to the copper plate of the adsorber (the simplest option is black paint).

The principle of operation of the solar collector

1. Solar collector.2. Buffer tank.3. Hot water.

4. Cold water.5. Controller.6. Heat exchanger.

7. Pump.8. Hot flow.9. Cold flow.

You can also increase the amount of heat received from the sun by correctly selecting the glass covering the adsorber. Regular glass is not transparent enough. In addition, it glares, reflecting part of the sunlight falling on it. In solar collectors, as a rule, they try to use special glass with a low iron content, which increases its transparency. To reduce the proportion of light reflected by the surface, an anti-reflective coating is applied to the glass. And to prevent dust and moisture from getting inside the collector, which also reduce the throughput of the glass, the housing is made sealed, and sometimes even filled with inert gas.

Despite all these tricks, the efficiency of solar collectors is still far from 100%, which is due to the imperfection of their design. The heated adsorber plate radiates part of the received heat into the environment, heating the air in contact with it. To minimize heat loss, the adsorber must be insulated. The search for an effective way to thermally insulate an adsorber led engineers to the creation of several types of solar collectors, the most common of which are flat and tubular vacuum.

Flat-plate solar collectors

Flat solar collectors.

The design of a flat solar collector is extremely simple: it is a metal box covered with glass on top. Mineral wool is usually used to insulate the bottom and walls of the housing. This option is far from ideal, since heat transfer from the adsorber to the glass through the air inside the box cannot be ruled out. With a large temperature difference between inside and outside the collector, heat loss can be quite significant. As a result, a flat solar collector, which functions perfectly in spring and summer, becomes extremely ineffective in winter.

Design of a flat solar collector

1. Inlet pipe.2. Protective glass.

3. Absorption layer.4. Aluminum frame.

5. Copper tubes.6. Heat insulator.7. Outlet pipe.

Tubular vacuum solar collectors

Tubular vacuum solar collectors.

A vacuum solar collector is a panel consisting of a large number of relatively thin glass tubes. An adsorber is located inside each of them. To prevent heat transfer by gas (air), the tubes are evacuated. It is precisely due to the absence of gas near the adsorbers that vacuum collectors are characterized by low heat loss even in frosty weather.

Vacuum manifold device

1. Thermal insulation.2. Heat exchanger housing.3. Heat exchanger (collector)

4. Sealed plug.5. Vacuum tube.6. Capacitor.

7. Absorbing plate.8. Heat pipe with working fluid.

Who are “black” and “gray” collectors?

This market segment, after the adoption of the law on regulation of collection activities, was finally forced out of the legal space and is now a type of fraud or extortion.

“Black collectors” are usually associated with various semi-legal purchases, pseudo-pawnshops and microloan offices. There, citizens who are obviously insolvent (but have valuable property - for example, real estate) are convinced to borrow money, charge crazy interest rates on them, and then “set” debt collectors on people who are in debt. The task of these “specialists” is, if possible, to deprive the debtor of valuable property. Through intimidation or even violence.

“Grey collectors” are not directly associated with crime, but they do not shy away from illegal methods when trying to collect bank or other “legal” debts. The press writes about them, telling terrible stories about children of debtors scared to death by threats, about apartment locks filled with foam, about entrances painted with obscene phrases about debt-ridden residents, about beaten fathers of families.

You can distinguish unscrupulous debt collectors by the following characteristics:

- They do not comply with the requirements of the law (in terms of the number of calls, the content of conversations, etc.);

- They refuse to show documents and identify themselves;

- Attribute other people's functions to themselves (try to describe property, use violence);

- They don’t try to come to an agreement, they immediately turn to threats.

Modifications of distributor combs

Today, there are many types of collectors for heating systems on the equipment market.

Manufacturers offer both connecting links of the simplest design, the design of which does not provide for the presence of auxiliary fittings for regulating the equipment, and manifold blocks with a full set of built-in elements.

The simple-to-use devices are brass models with one-inch branches, equipped with two connecting holes on the sides.

On the return collector, such devices have plugs, instead of which, in the case of “expanding” the system, additional devices can always be installed.

Intermediate assemblies that are more complex in design are equipped with ball valves. For each outlet they provide for the installation of shut-off control valves. Sophisticated, expensive models can be equipped with:

- flow meters, the main purpose of which is to regulate the flow of coolant in each loop;

- thermal sensors designed to monitor the temperature of each heating device;

- automatic air release valves for draining water;

- electronic valves and mixers aimed at maintaining the programmed temperature.

The number of circuits, depending on the connected consumers, can vary from 2 to 10 pieces.

If we take the manufacturing material as a basis, then intermediate prefabricated collectors are:

- Brass - characterized by high performance parameters at an affordable price.

- Stainless steel structures are extremely durable. They can withstand high pressure with ease.

- Polypropylene - models made of polymer materials, although they have a low price, are inferior in all characteristics to their metal “brothers”.

Models made of metal are treated with anti-corrosion compounds and covered with thermal insulation to extend their service life and improve performance parameters.

Parts of the device can be cast or equipped with collet clamps, allowing connection to metal-plastic pipes.

But experts do not advise choosing combs with collet clamps, since they often “sin” by leaking coolant at the valve connection points. This occurs due to rapid failure of the seal. And it is not always possible to replace it.

Unit #2 - collector

The collector is a device responsible for distributing hot water through heating circuits, as well as setting up and adjusting heated floors. The device must have a sufficient number of terminals to connect all circuits to them.

The simplest models are equipped only with shut-off valves. They are extremely cheap, but do not provide even a minimal opportunity to customize the system.

Devices with control valves allow you to adjust the water flow for each circuit, which allows you to adjust the heated floor for the most uniform heating of the premises.

The manifold of any model must be equipped with a drain outlet and a special air vent valve. The most convenient to use are devices with servo drives on valves, equipped with pre-mixers that mix the heated water supplied to the system with the cooled water returning and thereby regulate its temperature.

Such a device fully automates the functioning of a heated floor, but its cost is very high.

Manifold with servomotors on valves and pre-mixer. Necessary system adjustments are made automatically

How is it arranged?

Although the hydraulic arrow is very important in the heating system, its structure and design are quite simple. This is a fragment of a round or square pipe in which there are two holes on the boiler side and the same number of holes on the heating system side. To prevent the hydraulic separator from becoming clogged, it can be equipped with mesh filters that trap debris formed in the coolant. After a certain period of time, the screens may become clogged and will need to be cleaned.

Using this device, it is possible to separate the hydraulic systems of the heating unit and the heating system itself. Moreover, the hydraulic separator can be used with a manifold for four, three, two circuits and with one branch boiler. The heating system and boiler circuits receive their own hydraulic mode.

When choosing a hydraulic gun, you need to understand its operating principle and the advantages it has:

- provides good performance, minimal pressure loss and productivity;

- creates hydraulic balance and the necessary temperature conditions;

- serves as protection against heat stroke;

- saves energy;

- reduces hydraulic resistance.

The air vent valve removes oxygen bubbles from the device, thereby protecting the rest of the equipment from corrosion, extending its service life and ensuring stable operation. The same applies to filters that trap debris.

A device with perforated partitions is provided inside the hydraulic separator. They are necessary to divide the internal space in half so that unnecessary resistance is not created.

Boiler connection

The most effective source of heating is considered to be connecting a heated floor to a gas boiler and for this reason it is better not to consider other types of heating units. This statement is explained by the high cost of electricity and the ability to independently regulate the temperature regime in the system.

After the location of the collector has been determined and its installation has been completed, you need to install the heating device and begin connecting the heated floor to the boiler.

Advantages of a collector circuit for distributing water supply pipes in an apartment

In apartments, simple water pipe installation is most often performed. There is a pipe coming from the riser. Then, with the help of tees, there are branches from it to plumbing fixtures. At the same time, few people know about another type of pipe routing - manifold. And in vain, because such a system has a number of advantages that need to be discussed.

But first we need to talk about the types of wiring that exist in plumbing today. The first type is tee wiring. In such a system, all consumers are connected from one pipe using tees. It is possible to install shut-off valves in front of each consumer in case of an emergency.

Collector wiring. This system has clear advantages over the tee system. A shut-off valve is installed at the entrance of the water supply to the apartment. The difference is that each device has a separately supplied pipe. In this case, all valves are concentrated in one place.

Sometimes you can find a mixed system. This means that it contains elements of tee wiring and collector wiring. For example, water can be supplied to the washbasin and bathtub from the collector (that is, a separate pipe for each consumer), and the toilet and bidet are connected via tee wiring.

How to become a collector

After the activities of collectors received legislative registration, this profession became much more attractive. In 2021, in the Russian Federation, according to the Federal Tax Service, about half a million organizations indicated “collection services” as one of the types of activity when registering. About one and a half hundred professional collection agencies are officially registered in accordance with the new law, and this number is increasing every month. The demand for truly qualified employees is also growing.

What should a collector be able to do?

The main work of a collector is constant conversations with debtors. Not sincere, but rather tough, sometimes rude. At the same time, it is necessary to be able to competently talk about the existence and composition of the debt, offer possible repayment options, and explain the legal consequences of non-payment. You also need to not be afraid of conflict situations and be able to resolve them.

In addition, the duties of the collector include the following functions:

- Collection of information about the debtor within the framework of the law;

- A full range of work with overdue debts (calculation of amounts and terms, informing the debtor, preparing a package of documents for submission to the court);

- Preparation of financial reports for debtor clients

Who can become a collector

There are not many collectors with many years of experience in this profession, so most often candidates are selected from related fields. The requirements are something like this:

1 Education

Legal, economic, military, pedagogical, psychological. Preference is given to those who have graduated from universities in specialties related to work in law enforcement agencies. Also a plus will be completed courses for collectors - these are now organized at large collection agencies (for example, FASP) or in specialized training centers (for example, DA.Collection).

2 experience

The best option is an employee of the debt collection department in any bank. Other former employees of banks and law enforcement agencies are also in demand. They willingly hire stress-resistant callers from any field (with a legal or economic education).

3 Skills

Firstly, of course, communication skills are extremely important. If you are afraid to talk to people or don't like it, there is no point in going to debt collectors. At the same time, the candidate must have a low level of empathy. If you feel sorry for every debtor, you will quickly fall into this category yourself, left without income (read about collectors’ salaries below). The ideal option is to have the skills to communicate firmly with antisocial elements or with disloyal clients.

Skills in using various computer programs and Internet sites are important. In particular, reference and legal systems, databases, services of government bodies (Federal Tax Service, Federal Bailiff Service and others).

Knowledge of general accounting principles. It is clear that specialists will understand the intricacies of corporate intricacies (if the debtor owns large assets), but if we are talking about an ordinary debtor who was fired from work, the collector must be able to calculate his debt.

In the capitals, knowledge of foreign languages will be a big plus. Moreover, if a collector can speak the languages of the peoples of Central Asia or the North Caucasus, he simply won’t be worth it. But English at Intermediate level and above is also considered a good option.

Mobility is considered an important skill: the work of a debt collector involves traveling, and sometimes the debtor has to be caught in the most unexpected places.

Installation stages

All work to create the wiring of the water supply system in the apartment has the following sequence:

- First of all, emergency valves must be installed on the riser.

- Next, meters are installed, as well as water filters.

- The next step is to install the manifold, after which ball valves are installed at the outlets.

- Now all plumbing fixtures are connected.

- The last stage is to check the entire system for functionality.

If the water supply distribution is to be created in a new building or in an ordinary apartment where the entire system is being completely replaced, then it will not be difficult to do everything yourself.

Please note: if you are installing pipes in a fairly old building, first of all you need to check the condition of the main riser there, since it may be necessary to initially replace it due to wear.

How debts are “knocked out”

It is difficult to work with very tough debtors. They are involved in money matters, in the world of risks, so they think about how to protect their property. Conversations have no effect on them; they purposefully took money for the sake of deception. And they are not going to pay. Without power they don't understand. Even in court they can escape - they simply transfer the property to other people and that’s it.

In Russia, it is difficult to get rid of debts and repaying them is pointless. There are a thousand options to save property from bailiffs, various legislative tricks. The tax office and bailiffs are trying to start collecting debts from relatives (spouse, children), but so far they have not been very successful. It’s really funny, a man transfers up to 10 apartments and cars to his children, makes a deed of gift to his wife, bankrupts the company, leaving the workers “without their noses” and even the court can’t do anything to him. This is a 100% scammer.

Show-offs work against the majority of ordinary citizens who have taken out loans and “forgot” to repay them - the very sight of a healthy guy with a gloomy face instantly puts the “client” in the right mood.

The work begins “from the stove”:

1. The person is contacted and reminded of the existing debt. They ask when he will pay.

2. The calls continue regularly , it puts a lot of pressure on the psyche. The content of the conversation changes. Phrases about a black list, a trial, and threats to involve the debtor’s relatives are heard more often. If Vanya can't pay, maybe his brother Petya can help? It works. Most debtors do not want to involve relatives or friends in their problem.

3. Every day those boys sitting in the department call hundreds of clients. There is a certain period of time when a person matures and must react. If there is no reaction, the field department appears. That's where I got a job.

4. Moreover, the main task is not so much to intimidate a person, but to shame him , to disgrace him in public. The basic rule is to speak firmly, without allowing personal favor or using diminutive words.

Of course, you need to prepare before your visit. Find out all the ins and outs. Awareness has a depressing effect on a person. He understands there is nowhere to go. They will find it anyway.

Nowadays, people leave so much information about themselves on social networks that there is no need to search specifically for them.

Classification of oil and gas reservoir rocks

According to the types of void spaces, reservoirs are distinguished: porous, fractured, cavernous, porous-fractured, porous-cavernous, porous-fractured-cavernous. Under natural conditions, the most common oil and gas reservoirs are pore reservoirs - sands, sandstones, porous limestones, dolomites. Vuggy, porous-cavernous reservoirs are reef limestones (shell stones, coral massifs), weathered, leached cavernous limestones, gruss, gravelites, pebbles, conglomerates. Fractured, porous-fractured reservoirs include fractured rocks of all types, including granites, basalts, clays and mudstones. Oil deposits in fractured mudstones of the Bazhenov formation (Upper Jurassic) were discovered in the Salym region of Western Siberia.

The most popular and often used in the practice of geological work is the classification of reservoir rocks by porosity and permeability, carried out by A.A. Khanin (Table 7). Rocks that are practically impermeable to oil, gas and water are called seals (screens, fluid seals). These include clays, mudstones, dense limestones, marls, rock salt, gypsum, anhydrides and some other dense rocks. Tires of several classes differ in a number of indicators. The highest class tires include rock salt, gypsum, anhydrite and plastic montmorilonite clay. The quality of tires is influenced by the homogeneity of the rock, mineralogical composition, absence of impurities and cracks. The presence of sand and silt particles in clays significantly reduces the shielding properties of tires. Tires of regional, zonal and local ranks differ in size. The higher the uniformity and thickness of the cover layer, the better its shielding qualities.

| Classification of sand-silt reservoirs rocks by porosity and permeability (according to A.A. Khanin, 1973) | |||

| Collector class | Effective porosity, % | Permeability, µm2 | |

| I-very high | Sandstone medium-grained | >16.5 | ≥1 |

| Sandstone fine-grained | >20.0 | ||

| Coarse-grained siltstone | >23.5 | ||

| Fine-grained siltstone | >29.0 | ||

| II-high | Sandstone medium-grained | 15-16.5 | |

| Sandstone fine-grained | 18-19.0 | 0.5-1.0 | |

| Coarse-grained siltstone | 21.5-23.5 | ||

| Fine-grained siltstone | 26.5-29.0 | ||

| III-medium | Sandstone medium-grained | 11-15 | |

| Sandstone fine-grained | 14-18 | 0.1-0.5 | |

| Coarse-grained siltstone | 16.8-21.5 | ||

| Fine-grained siltstone | 20.5-26.5 | ||

| IV-medium | Sandstone medium-grained | 5.8-11 | |

| Sandstone fine-grained | 8-14 | 0.01-0.1 | |

| Coarse-grained siltstone | 10-16.8 | ||

| Fine-grained siltstone | 12-20.5 | ||

| V-low | Sandstone medium-grained | 0.5-5.8 | |

| Sandstone fine-grained | 2-8 | 0.001-0.01 | |

| Coarse-grained siltstone | 3.3-10 | ||

| Fine-grained siltstone | 3.6-12 | ||

| VI-very low, non-industrial. | Sandstone medium-grained | <0.5 | <0.001 |

| Sandstone fine-grained | <2 | ||

| Coarse-grained siltstone | <3.3 | ||

| Fine-grained siltstone | <3.6 |

Making a solar collector for alternative heating in your home

Recently, the interest of ordinary people in renewable energy sources has increased. Because of this, many homeowners are looking to buy a solar collector for home heating, which converts the sun's energy to heat water. But the decision to buy a solar collector for heating in a store is not always rational. The cost of the finished device is far from budget, so such a purchase can hit the family budget hard. To avoid expenses, you can make a solar vacuum collector for heating yourself. Various solar collectors for home heating, reviews of which are positive, have the following design details:

- container for storing heated water;

- heat exchanger;

- device for collecting solar energy;

- insulating layer.

The materials from which the collector can be made are very diverse.

There are known technologies for the independent production of solar collectors from polypropylene, ordinary garden hoses, window frames, plastic bottles, old refrigeration units and other available materials. The collector assembly diagram directly depends on the type of material chosen, so it is worth studying after the owner has decided on the concept of the collector. Self-made vacuum solar collectors for home heating, the price of which in the store is $200 or more, can be used as full-fledged heating sources.

Vacuum solar collectors have a number of advantages:

- energy efficiency;

- environmental friendliness;

- autonomy;

- availability.

It is not difficult to make traditional distribution or solar collectors for heating your home with your own hands. This does not require large material costs, complex technological equipment or solid experience. However, these hand-made devices will greatly optimize the home heating system and will help the owner create a reliable, efficient and uniform source of heating for his home.

How to choose the right comb

In addition to the brand, you need to take into account the material from which the water supply manifolds are made:

- Stainless steel. Characterized by strength, corrosion resistance, low cost.

- Polyethylene. It costs even less than steel, but has one limitation. It cannot be used for installation of heating systems.

- Polypropylene. The material is good for everyone, and the only difficulty arises is that the connection involves soldering using specialized equipment.

- Brass. Strong, durable, versatile material for assembling a high-quality, reliable plumbing system.

You also need to pay attention to the fastening system. Threaded connections require the use of standard tools, which are found in almost every home

The difficulty lies in the need to cut threads on the pipes. Plastic elements require soldering. It is not practical to buy equipment for one-time use. Combined fastening methods involve the use of both tools.

What happens if you don't pay your debt?

Many people are afraid to imagine this. But in vain! According to the law, collectors can do little against the debtor. Especially if the creditor only entered into an agreement and asked for “help”, and did not transfer the case completely.

It is enough to remember from whom the person took the money. At the bank? Go there.

Collectors can only remind a person about the debt, and for a limited time. Maximum 5 years. Then compile a report and submit it to the lender. It will indicate that the client is ignoring the requirements.

It is important to understand that debts must be repaid. Especially those taken from the bank. MFOs and other microcredit organizations work more cunningly. They have crazy interest rates. If you miss a day, you'll pay a fine . But the collectors themselves do not have the right to go to court to repay the debt or take away property. According to the law it is impossible. Unless the lender has officially sold them the borrower's debt obligations. Even then, the agency can only take the citizen to court. And figure it out there.

Letter from the Bank of the Russian Federation dated 08/21/2020

The right to choose between consent to the assignment of rights and its prohibition

The Central Bank explained that the borrower, within the terms of the lending agreement, should be given the right to choose between consent to the assignment of rights (claims) and its prohibition. At the same time, the choice in favor of prohibiting the assignment of rights (claims) should not prevent the conclusion of a consumer credit (loan) agreement. This choice is made by the borrower within 5 working days from the date of provision of the individual terms of the agreement to the borrower, unless a longer period is established by the lender. That is, the contract can be taken home for full review and for decision. It is not necessary to sign a loan agreement immediately without reading the terms. And each borrower should have the right to refuse to transfer his debt to third parties at the stage of signing the contract; this should not affect approval.

How to assemble a collector with your own hands

It is impossible to directly connect a heated floor to the boiler with your own hands. For this you need a manifold with valves. It is installed in a cabinet, and the piping begins from there. The collector is provided with access to only one person who will service the system.

The range of collectors in stores is quite large, but it is often difficult to choose the right one for your heating system. In addition, a switchgear is needed on each floor of a private house, which leads to a significant increase in costs. A homemade manifold for heated floors is the right solution, allowing you to save a significant amount of money.

Connection

Since the heating system has a supply and return branch, the collector must consist of two combs connected to them. At the joints, branches are installed to drain water and remove air from the pipes.

The collector is assembled according to the number of connected loops. At each outlet, located at the top or bottom of the comb, taps are installed to ensure that individual circuits are turned off while the rest of the heating is running. It is recommended to make the distance between them 10-20 cm.

Manifold manufacturing

Before assembling a manifold for a heated floor, you need to understand the purpose of each element. It is recommended to make combs with your own hands from a square pipe. Round threaded pipes are welded to them for connection to the boiler and to the circuits. To do this, markings are first made, then holes are drilled, and then the pipes are attached. All joints are thoroughly scalded. A plug is made at one of the ends.

The scale is knocked off, the collector is cleaned and painted with oil compounds. In Fig. Below is a simple 3 loop manifold. The comb and coolant supply pipes from the boiler are painted red, and the return pipes, through which cooled water is supplied to heating, are blue.

DIY distribution manifold

Air vents are connected to the top of the combs, and plugs are installed at the bottom to discharge sludge. Each circuit can be closed with valves, which also serve to regulate temperature and pressure.

The distribution manifold is designed to control a small system that serves as additional heating. It will be much more complex if used for the main heating system in a large house. Assembling a manifold from polypropylene pipes is much simpler, but the simplest models are made this way.

DIY collector made of polypropylene pipes

Assembly of the collector unit

The underfloor heating manifold contains devices that ensure efficient operation of the system. Each circuit must have control valves. For a complex system, it is advisable to install automatic control valves.

Usually they operate in constant mode, the coolant flow changes only at the main supply inlet. For house areas up to 200 m², two-way valves are used. Their advantage is smooth adjustment. Valves often become clogged. Therefore, they are installed on detachable couplings (“American”) so that they can be removed for cleaning.

A more complex device is the three-way valve. It ensures mixing of forward and reverse water flows, maintaining the specified temperature at the outlet. Inside it there is a movable partition that regulates the flow of water from two inlet pipes. The device is used in all complex systems with automatic control of a large number of circuits. Its advantage is its significant throughput.

With the slightest turn of the tap, the temperature regime of the system changes. The adjustment can be manual or automatic. A three-way valve is often combined with a servo drive operating from an outdoor air temperature sensor. When the weather changes, the temperature in the rooms is maintained constant. As soon as cooling occurs, a signal from the weather sensor enters the control unit and the coolant temperature rises.

The principle of operation of the collector

As for the principle of operation of the collector, everything is quite simple. The heat generator that heats the water releases the liquid to the supply comb. At this intermediate node, the speed of the coolant flow slows down significantly, which is facilitated by a larger radius. This allows water to be distributed over several outlets.

Once you know how much coolant is consumed when heating an apartment (house) along all circuits, all that remains is to select the required power of the heat generator (boiler) and the speed of the fluid flow, after which the cross-sectional area will be known. When making calculations, be sure to convert liters to mm3.

In order for the coolant to flow to devices that radiate heat into the premises, pipes of a slightly smaller cross-section are used on the collector block, through which the liquid reaches individual parts of the circuit, gradually falling into the radiator or onto the heated floor grid. Due to this design, each element of the heating system, to which the collector block is connected via a circuit, is heated to the same temperature.

When liquid enters a radiator or heated floor, it gradually gives up its heat, and then moves back along a different path, reaching the distribution unit of the collector block. Here the reverse comb is activated, directing the cooled coolant to the boiler or other generator for reheating.

Types of heating systems and their differences

Heating systems are based on the principle of circulating hot water. Based on this, they distinguish:

- heating system with circulation based on natural pressure;

- heating system with circulation through a pump;

There is no need to dwell too much on the description of the first system, since this installation has long been considered obsolete and is practically not used in the construction of new housing due to its low efficiency. Such heating is used in small private houses and some public institutions. Let us just point out that its operation is based on the principle of the physical difference in the density of warm and cold water, which leads to its circulation.

A forced circulation heating system requires special pumps to provide circulation. This method makes it possible to practically heat a larger number of rooms than the first. Accordingly, this system is considered the most effective. There is a huge selection of pumps for circulating coolant in the system, which makes it possible to vary their power and other quality characteristics based on the size of the premises and their number.

A heating system with circulation by means of a pump is divided into:

- two-pipe (connecting radiators and pipes in parallel, which affects the speed and uniformity of heating);

- single-pipe (series connection of radiators, which determines the simplicity and low cost of installing a heating system).

The collector heating system is highly energy efficient compared to the above, due to the fact that each radiator is personally connected to one supply and one return pipeline, through which water is supplied using collectors.

Features of the collector system and its differences are as follows:

The manifold wiring of the heating system ensures that each radiator is independently regulated and does not depend on the operation of others. In addition, the collector system often uses other heating devices that also operate independently of the collectors. Radiators are mounted parallel to the collectors, which, according to the principle of operation, makes the collector system similar to a two-pipe one.

The installation of collectors is carried out in a separate utility room, or in a specially designated cabinet-stand hidden in the wall. The location for the collectors must be planned in advance, as they can be quite impressive in size. The dimensions of the distribution manifolds depend on the power of the radiators, which depend on the size of the rooms.

The manifold wiring of the heating system significantly outperforms the other heating systems listed above in the ability to dismantle and replace the radiator without the need to stop the entire system. Also, manifold wiring requires more piping for its operation than a two-pipe system. Despite significant one-time costs during the construction phase, these measures have a positive effect on the further energy efficiency of the system. That is why the collector heating system has the greatest effect and quickly pays for itself when building housing with a large area.

Types of collectors in heating systems

Collector installations used in the design of closed circulation heating systems come in three varieties.

Depending on the purpose of the design, the following are available on the market: radiator and solar systems, as well as devices equipped with a hydraulic arrow.

Radiator collector heating

Whatever type of heating is designed in the house, radiators are always present in it. Therefore, collectors that distribute coolant flows directly to batteries installed in rooms are the most popular type.

The distribution unit consists of two interconnected combs: the first directs the coolant to the appliances installed in the rooms, the second takes it back to the boiler

Collectors used for radiator heating, depending on the architectural and interior features of the room, can be connected in various ways.

According to the connection method, the radiator heating system can be made in any of the following versions:

- top connection;

- bottom connection;

- side installation;

- leading diagonally.

The lower connection method is still the most widespread. With such a layout, the contours hidden under the surface of the baseboard or floor are not so striking.

And calculations confirm that with a lower connection, all the advantages of private heating are fully manifested.

Each floor of the house is equipped with a collector for radiators. Install it in the center, masking the device in a niche or in a cabinet specially built for it on the wall.

The installation location should be chosen so that, if possible, branches of equal length are supplied to all devices.

If it is impossible to achieve equality of the rings connected to the collector, then each outlet is equipped with its own circulation pump.

In fact, all branches connected to the distribution node represent an independent circuit with its own shut-off valves, and sometimes automation.

A striking example of a collector heating scheme is water heated floors.

The collector wiring diagram ensures a uniform supply of heat to all rings of the water-heated floor system.

Underfloor heating pipelines are assembled from copper pipes or their plastic analogues; permanent fittings are used for connections.

Valves are installed in the heating rings, with the help of which they regulate the supply of coolant, and, if necessary, disconnect the “warm floors” from the general heating network.

A “warm floor” manifold is a structure that includes a series of pipe rings, which is laid under the floor covering

Such systems are always equipped with a circulation pump. It is placed in an intermediate collector unit at the entrance to the return pipe.

The number of pipes on the distribution unit depends on the number of rooms connected to one comb.

The number of collector groups is determined based on the length of the circuits. The calculations are based on the ratio in which 120 meters of pipeline are allocated to one collector group.

Hydraulic boom

When installing powerful and extensive heating systems, which are designed in residential buildings with a large area, distribution manifolds equipped with a thermo-hydraulic distributor or hydraulic switch are used.

When installing a connecting link, a heating boiler circuit is connected to it on one side, and radiator heating or “warm floors” on the other.

The hydraulic arrow is a vertical hollow pipe equipped at the ends with elliptical plugs, the main purpose of which is to equalize the pressure exerted on the coolant

The presence of a hydraulic distributor allows you to solve several problems at once:

- avoid sudden changes in temperature in the pipes, which have a detrimental effect on the service life of the system;

- by mixing and secondary circulation of part of the coolant, maintain a constant volume of boiler water, as well as save fuel and electricity;

- if necessary, compensate for the flow deficit in the secondary circuit.

Maintaining temperature balance is achieved due to the fact that the device allows you to separate the hydraulic circuit of the boiler from the secondary circuit.

Option for manufacturing a homemade manifold distributor, equipped with a hydraulic arrow, which is made of a steel square pipe and equipped with fittings

Optimal operation of a system equipped with a hydraulic arrow can be ensured if each circuit is equipped with its own circulation pump.

Solar collector installations

Devices of this type are chosen when installing an autonomous water supply system in non-gasified areas where the level of solar radiation is quite high.

Solar-powered air combs operate through the greenhouse effect, converting sunlight into thermal energy

The design of solar installations is slightly different from traditional counterparts. In essence, they are a kind of greenhouses that accumulate solar energy.

The natural circulation of the coolant in them is carried out due to convection currents and under the action of fans attached to the absorbing plate.

The solar absorber is a small flat box covered with a black absorbent plate. This heat-receiving plate accumulates heat.

The accumulated heat is transferred to the coolant, which can be air or liquid circulating through the pipes.

The main purpose of the solar collector is to direct and redistribute the energy of the Sun to household needs and needs

On sale you can find moving collector systems powered by solar energy. Their design is designed in such a way that mirrors and heating elements “monitor” the movement of the sun, thanks to which its energy is absorbed to the maximum.

But due to the high cost of equipment, the use of solar installations as the main source of heating in the climate of even the southern regions of our country is unprofitable.

Therefore, they are more often used as an additional source of heat when installing heating systems using solid fuel and gas boilers.

Distribution manifold system for two-pipe heating system

There are many options for collectors for heating. There are devices with a lot of parts. The supply structure contains flow meters, which are responsible for the uniform distribution of the coolant.

The design of the distribution combs controls the heating of each battery. The comb is considered the main part of the distribution structure. It is installed after the boiler and before the safety mechanism. This part looks like a pipe with pipes placed. Installation is carried out on the return and inlet lines.

DIY hydraulic collector

The hydronic collector of the heating system provides the following benefits when heating your home:

- The movement of the coolant improves and the pressure stabilizes.

- The volume of hot water on each beam of the system is regulated. Energy costs are reduced.

- Battery repairs are performed without shutting down the entire structure.

To create a comb, the following sequence of actions is performed:

- Measurements are taken between individual pipes.

- The size of the device body should be 12-17 cm larger than measured.

- A pipe is cut out and pipes are mounted on it.

- The structure is checked for leaks.

Before carrying out installation work, it is worth checking the possibility of installing a comb for a particular system. Polypropylene fittings are made without reinforcement, which can affect depressurization. You can purchase a ready-made device.

To increase circulation, special pumps are installed. If the structure is mounted in a special room, then a protective box is not required. To control and dose the coolant, fittings are installed.

WATCH THE VIDEO

A safety group is installed on the distribution mechanism.

In addition, when calculating the comb element, the difference in the size of the contours should be taken into account. The collector heating system is very popular among owners of private houses.

Basic recommendations for choosing a heating collector

Before purchasing a heating manifold, you should study the technical characteristics of the devices, which include the throughput of the system, the maximum operating pressure of the product, the possibility of connecting additional circuits, the availability of control and automation equipment, and the amount of electricity consumed. These parameters are indicated in the device passport.

Important! The pressure in the distribution system will depend on the location of the manifold.

When choosing a collector for radiator heating or a heated floor system, it should be taken into account that a high-quality and durable device will have a high cost. This is due to the fact that durable, expensive materials are used for its manufacture, and the production technology is carried out using the latest, improved equipment. A guarantee of quality is the purchase of a manifold from a well-known manufacturer with a worldwide reputation.

A simple system can be installed independently, but it is better to entrust the installation of an advanced type heating collector to a specialist. This is especially true for a distribution unit with 3-4 circuits. The collector system will be able to fully function if there are taps, plugs and a circulation pump for each circuit, which will increase the cost of the system.

You can install a simple system yourself, but it is better to entrust the installation of an advanced type heating collector to a specialist

Pipe selection

Wiring from metal-plastic pipes In order to correctly install the water supply system in your apartment with your own hands, it is recommended to use either metal-plastic pipes or purely plastic ones.

As for the use of steel or copper options, it is better to avoid them, because working with them requires not only skill, but also additional traumatic tools for cutting, welding and bending.

However, they remain the best option for creating a water supply system. No deposits appear on their walls during use, and the fairly low thermal conductivity makes it possible to use such pipes to provide hot water supply.

Of the variety of plastic pipes, polypropylene pipes are considered the best in terms of price/quality ratio. To solder polypropylene pipes, a special “soldering iron” is used, which is very easy to learn how to use.

Related Posts

- Heating distribution manifold

- Heating collector: principle of operation, installation and connection rules

- Airborne solar collector

- Categories and groups of classification of water supply systems

- Why do you need a collector in a water supply system?

- Leningrad heating system for a private house

- Disadvantages of polypropylene pipes in home heating

- How to install a chimney correctly with your own hands: all the nuances when installing a chimney

- Choosing a manifold for heated floors: types, equipment

- Setting up solar heating or how to build a homemade collector

- Dismantling of heating systems

- A supply of hot water that is always at hand: how does an electric water heater for heating work?

- Do-it-yourself organization of an autonomous water supply system for a private home and cottage

- Which pipe to choose for heating

- Which rehau pipes are best for heating and water supply?

- How to make steam heating

- Laying pipes in the bathroom with your own hands

- Choosing between metal-plastic and polypropylene pipes

- Heating project

- Installation diagram of an apartment's water supply, collector wiring, copper pipes on compression fittings

- Do-it-yourself installation and replacement of sewer pipes in an apartment

- How is thermal energy for hot water calculated?

- Hydraulic accumulator selection and principle of operation

- Autonomous heating in an apartment in a multi-storey building

- Optimal heating distribution in a private house: comparison of all typical schemes

Read with this

- Heating distribution manifold

- Heating collector: principle of operation, installation and connection rules

- Airborne solar collector

- Categories and groups of classification of water supply systems

- Why do you need a collector in a water supply system?

- Leningrad heating system for a private house

- Disadvantages of polypropylene pipes in home heating

- How to install a chimney correctly with your own hands: all the nuances when installing a chimney

- Choosing a manifold for heated floors: types, equipment

- Setting up solar heating or how to build a homemade collector

Materials for the production of distribution manifold combs for heating

Different materials can be used to make a heating manifold, but they must be characterized by increased strength and high performance characteristics.

The main disadvantage of steel collector elements is their high cost.

Currently, steel, polymer and brass manifolds are very popular. Steel can be used for the production of both central and local elements. It does not deform under the influence of high temperatures and high pressure; special alloys are not subject to corrosion, which increases their service life. The main disadvantage of steel elements is the high price of heating collectors.

Brass devices are no less in demand. Due to the fact that the material can withstand high pressure and temperature, it is ideal for local and centralized units. In terms of its technical and operational characteristics, it is similar to stainless steel. Brass manifolds are characterized by a high cost, exceeding the price of steel analogues.

Polymer products have a more limited range of applications. Plastic collectors are not able to withstand high temperatures in the central unit, therefore they can only be used for local options, where the coolant temperature will be lower. The products are characterized by light weight, ease of installation and long service life. The main advantage of the products is their low cost.

Important! Polymer pipes should not be used to connect a heated floor system.

Currently, steel, polymer and brass manifolds are very popular

How to connect a heated floor to a boiler - step-by-step guide

Since water-heated floors are increasingly being installed in suburban households, it would not hurt their owners to know how to properly connect such a heating system to a gas boiler. If you don’t want to do this kind of work yourself, knowing the nuances will help you monitor the progress of installation and startup of heating equipment.

Without reliable and high-quality heating, it is impossible to ensure comfort and coziness in the house. After completing the installation of the heated floor covering and connecting it to the collector, the heated floor should be connected to the boiler. This heating option is most often used for rooms with high levels of moisture - it is installed in kitchens, hallways and bathrooms.

According to experts, the most optimal way to provide heating for private households is to install a heated floor from a double-circuit gas boiler in a suspended design with forced draft.

Laying schemes for water heated floors

The uniformity of surface heating depends on the correctly selected layout scheme. “Snake” is used when the same intensity of heating of the floor covering is not needed. For example, in a living room it is not necessary to heat the space under cabinet furniture or wardrobes.

The “snail” scheme allows you to arrange pipes with coolant for uniform heating.

The combined method makes it possible to warm up the corners of the outer walls of the room.

Snake

The second “snake” method implies that pipes with hot and cooled water are placed side by side. As a result, uniform heating of the entire surface occurs.

Schemes for connecting a water heated floor to a heating system - comparison and selection of the best one.

Let's look at four main schemes that are most often used in our realities. But before moving on to their detailed study, it is worth paying attention to the minimum requirements that generally apply to heated floors. They can influence the choice of scheme in one way or another.

Connection diagrams for water heated floors

From the boiler

Direct connection of the boiler to the underfloor heating manifold is prohibited due to safety precautions. Modern gas wall-mounted or floor-standing boilers must have an operating temperature above 55 0 C, otherwise condensation will form on the boiler heat exchanger or chimney. Direct connection is possible either to a condensing boiler or to boilers adapted to operate at temperatures below 55 0 C, provided that the heating circuit includes only a heated floor system.

From the radiator

The connection from the radiator is suitable for the snake or snail installation method. In order to connect to the radiator system, you will need two taps: a regular radiator valve installed on the supply, and an RTL valve with a thermostat that limits the return flow temperature. The thermostat reacts to exceeding the permissible temperature and closes automatically. When the liquid cools to a set value, the valve automatically opens.

The connection diagram from the radiator is as follows:

This scheme has a number of disadvantages, in particular, various pipes and connections stick out outside, taking up free space. It is much more convenient to use a unibox - a device consisting of a two-way valve with a thermostat, a Mayevsky valve for air removal and threads for connecting fittings. All elements are compactly placed in the installation box.

From the pumping and mixing unit

A prerequisite for uninterrupted operation is the following: between the supply and return movement, the temperature difference should not be higher than 10 0 C. To maintain the necessary parameters, a pumping and mixing unit comes to the rescue. It allows you to dose a mixture of cooled water into heated water.

The pumping and mixing unit is sold as a set, the principle of its operation is as follows:

ATTENTION! The pumping and mixing unit is sold complete with instructions for connection and installation. Please note the following: the thermostatic valve should be located on the side of the high-temperature circuit; it is important not to mix up the supply and return pipes. Then there should be a pump, then a bypass. The arrow on the balancing valve was directed towards the fluid supply, and not vice versa.

From three way valve

The heated water flows directly from the boiler into the distribution manifold, diverges through loops and returns to the boiler, set to the “warm floor” temperature. The situation becomes somewhat more complicated if the house has additional radiator heating. The water in the radiators has a temperature of 70 0 C, and in the loops it does not exceed 35-45 0 C. In this case, you will need a three-way thermostatic valve. It is installed on the circulation pump and regulates the supply temperature. The purpose of the three-way valve is to connect the high-temperature heating circuit and the underfloor heating manifold.

ATTENTION! Make sure the installation is correct! The thermostatic mixing valve is installed at the junction of the radiator module and the heated floor circuit, and a circulation pump is mounted behind it.

The regulator is a thermostatic head with an immersion sensor or a drive with a controlled controller. If the permissible water norm is exceeded, the automation blocks the supply from the boiler. When the liquid cools, the rod automatically rises, allowing hot liquid to flow into the loops.