In pursuit of comfort, most owners of private houses or apartments install heated floors.

However, it is worth noting that if there is air in the structure (if it is not vented), the quality of operation of the entire system is significantly reduced. In addition, this leads to equipment failure, the cost of which is quite high.

To avoid these problems and additional financial expenses, you should know how to bleed air from heated floors.

Causes of air

The main reason why water circuits become airy is violations during the preparation of the project; during installation work; due to the use of the floor.

The accumulation of air masses in the coil is caused by:

- Inaccurate calculation of thermal load;

- Errors made when calculating the size and number of loops, as well as the diameter of the pipes;

- Incorrect selection of pump, safety and control components;

- Laying a highway with a large number of differences in height;

- Not high quality material;

- Poor installation - lack of tightness of joints and threaded connections;

- Violations of the rules when the floor is first launched;

- Failure to comply with the temperature level during operation;

- Depressurization of the pipeline due to a breakdown or defect;

- Impaired fluid circulation in the circuit, which is caused by a decrease in pressure due to a pump malfunction;

- Breakdown of the automatic air vent, as well as the safety and shut-off valve;

- The release of gases when heating the coolant contained in it.

Important! Before starting the device for the first time, you should remove air from the heated floor circuits.

What are the dangers of air jams?

If there are voids in the pipes, heating the floor will be less effective. If you do not pump the pipeline, the voids will increase and lead to a decrease in pressure.

Depending on the design features of the device, airiness can lead to:

- to freezing of pipes in corner rooms - when installing floors from central heating;

- to a complete or partial cessation of heating - in the presence of heating hydrofloors and radiator heating operating from the central heating of the entire house located in the basement;

- to partial or complete cessation of heating, the occurrence of emergency shutdowns of the boiler and freezing of CO - with floors operating from an autonomous heating system;

- to a complete or partial stop of heating, as well as to frequent interruptions in the operation of the boiler - if the house has heated floors and radiator appliances that operate from an individual heating source.

How to bleed air from a heating radiator correctly: in an apartment or house, using a Mayevsky tap and other methods.

Taking into account all the design features: the number of loops in the room, the presence of separate wiring for each room, we can say with confidence that a complete cessation of circulation in the pipeline cannot occur.

Only if all loops of the circuit are clogged with plugs at the same time will the water stop moving along the main line through all rooms and floors of the house, as a result of which all heating will stop functioning.

Design features

It is necessary to take into account in advance the details that distinguish certain equipment. So, in some situations, a built-in boiler pump is used to circulate coolant throughout all circuits. For a large facility, its performance may not be enough, so you will need to install a separate power unit.

When using radiator heating, routes are created with a minimum number of turns, without sharp corners. By adding tilts towards the boiler, natural circulation can be ensured under the influence of gravity.

In heated floors, long pipelines with a large number of bends are installed

It is more difficult to pump water through such a system. Only coercive methods are used here. If there are errors in the calculations, the power of a separate pump will not be enough for distant circuits. In this case, their poor heating cannot be eliminated by removing air plugs. The system will need to be modernized.

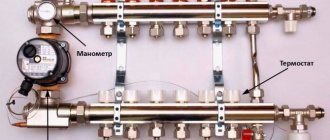

The comb regulators must first be correctly adjusted. In addition to mechanical flow meters, valves with electric drives are installed. Such devices change the coolant supply rate taking into account the readings of temperature sensors.

Types of air vents

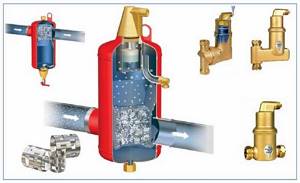

To bleed air from a heated floor, vents are often used, which can be manual or automatic.

Manual devices are mainly installed on heat exchangers, and automatic devices are installed on the upper section of the collector or pipeline.

Automatic models

These devices are produced by both domestic and foreign manufacturers, and each type has its own design features - it depends on the brand. Devices are:

- With a reflective plate inside the housing - it is installed at the entrance to the working chamber, and is designed to protect internal parts from water hammer.

- With a spring shut-off valve, which is equipped with an air vent, air can be released through it.

- With side threaded connections.

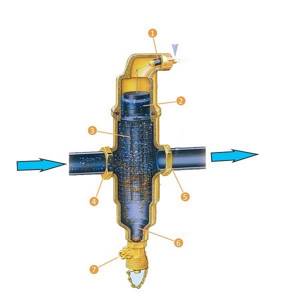

- Microbubble separators - installed in the pipeline on two inlet pipes. The liquid, passing through a tube with a copper mesh, forms a water vortex, it slows down the air and directs it upward. After which, air bubbles are released through an automatic valve.

- With a rocker mechanism - their chamber contains a plastic float connected to a shut-off drain needle. When it descends into the airy environment, with the help of a needle, the release hole is opened to allow the air flow to escape.

Manual

Manual devices are Mayevsky cranes. The design is simple, so they are most often installed in heating. During operation, the mechanical air vent seals the exit from the housing well.

If it is necessary to remove air, the valve is turned several turns, as a result of which the de-airing process begins.

Components of equipment

It is worth taking a closer look at the parts of the system that were mentioned above.

Disassembled crane

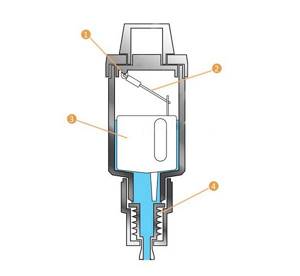

The operating principle is described in the air release instructions. The design of the Mayevsky crane is easier to study using this drawing. Such a miniature product is installed instead of a plug in the upper part of the collector comb. There is a carving in the central part. A screw is screwed in there, pressing the plastic seal.

To ensure the tightness of the connection, a rubber ring is used. All listed parts are included as standard with the product. No additional consumables are required for installation and operation.

The use of automated devices greatly simplifies the task. Without careful user control and additional settings, they are able to perform their functions over a long service life.

Automatic gas vent

Here is a schematic diagram of one of the devices in this category:

- The node (1) creates a rigid fastening of the rod (2) to the inside of the body with the desired angle. They regulate the opening level of the exhaust valve.

- During operation, air accumulates in the upper part. The float goes down. In a certain position, it will open the shut-off device, which will release the gas out.

- Next, the float rises to its original position, and the cycle repeats again.

- A soft seal (4) is installed in the lower part, ensuring the tightness of the connection.

Separator

Such a device performs similar functions more effectively:

- Here is an example of a flow separator. It is installed at the top point in the pipeline section using threaded connections (4, 5).

- A mesh (3) is fixed in the central part. When a stream of water passes through such a structure, air bubbles are released from it (2).

- They rush upward. The same unit is installed in this part as in the automatic gas vent. When the float drops below a certain level, the draft will open the valve (1) to release air to the outside.

- The cell sizes and other mesh parameters are selected so as not to create unnecessary obstacles to the movement of the coolant. However, this design traps rust particles (6). They accumulate at the bottom (7). There is a screw-on cap that can be opened to remove contaminants when performing routine maintenance.

Removing mechanical impurities reduces the load on different parts of the heating system. If you install a simple filter on the main water supply line, clogging of radiator ducts and boiler heat exchangers will be prevented. This will also extend the life of the valve jets of automatic air vents.

How to bleed air yourself

Pumping a water floor is not difficult; you can do this procedure yourself.

However, it is worth noting that depending on the design of the structure, the process of removing air flow from the pipes varies.

#bleed air from the heated floor, #air in the pump, #starting the heated floor, #water heated floor

How to bleed air from a circuit operating from a circulation pump

To remove air from a sex circuit equipped with a pump, you must perform the following steps:

- It is necessary to close the flow meters on the manifold leading to all loops.

- Vent the circulation pump.

- Open the ball valve or Mayevsky valve on the comb, and one floor loop.

The process of opening the Mayevsky tap is to hold the white part of the valve with one hand so that it does not dangle. The second is to unscrew the valve located in the middle.

- Then you need to turn on the circulation pump at low speeds. The pressure should be 20% higher than normal.

- Turn off the pump and close the valve after water appears from the air vent.

- This procedure must be repeated several times, at intervals of several minutes, until all the air is drained.

- This action must be carried out with each loop. Repeat the process for 2 - 3 days until the air is completely bled out.

- Then the pump must be turned on to maximum and the entire pipeline must be purged.

Only after complete bleeding of the air masses should the heating floor be started. During operation, the circuit may become airy again, so it is recommended to periodically press out the air.

Bleed from gravity system

If you have a gravity-flow structure in which there are no release valves, the question arises - how to remove air from the underfloor heating system? You will have to wait until the air masses come out through the expansion tank.

In this case, the device should not be running and the water in it should be cooled. The process may take several days.

In a word, in order to bleed air bubbles from such a line, you need to turn off the boiler and motor and allow the hydrofloor to cool.

How to bleed air using automatic vents

Currently, there are special diverters or separators that automatically expel air masses from the circuit.

With their help, it is easy to bleed plugs, and they do not require special maintenance and care work.

Automatic diverters should be installed at the highest point of the heating pipeline, because this is where air accumulates.

There is no need to include them in the safety group, since there is no concentration of air masses there.

We expel the air using strong water pressure

It is theoretically possible to bleed off the air with high water pressure, but it is quite difficult to do. You will need a powerful pump with a pressure of more than 2 atmospheres to blow through the pipes.

But removing traffic jams using this method can only be done from an open system, with a small number of branches. In addition, this method leads to overfilling of the expansion barrel. Therefore, it is recommended to use it only if you have experience in carrying out similar work.

Pressing out plugs by draining water

This method is recommended to be used if a gravity-flow structure will be aired. A large amount of water is drained from below, and at the same time poured from above.

In this way you can bleed the plugs. They shift, break and are squeezed out of the pipeline.

Formation of air masses in a heated floor system

A pump is needed to bleed the system.

How to bleed air accumulated in the system will depend on the incident that led to such a result.

Some circumstances require immediate intervention, while others are not capable of causing significant damage to the system.

If the heated floor was installed with noticeable differences, it is worth acquiring an additional pump for pumping the coolant.

It is recommended to install several automatic air vents that will help bleed air masses from the system. One is installed on the return lines, while the second should be on the supply.

Running the circulation pump will also help expel excess air. The more air that has accumulated, the louder the circulation pump will operate. It is worth paying attention that the system must be pumped at maximum speeds. This will significantly save time and allow you to completely remove air from the system. If it was recently pumped, but the air has already collected again, the problem may be in the pump itself.

With the comb installed, each circuit is closed in turn, and the air vent must be open on each of them. It is necessary to bleed air gradually, so after cleaning the first circuit, the next one opens. The descent is carried out in stages and at the moment of bleeding only one circuit should be open.

If this procedure does not give the expected result, the next air release should be carried out no earlier than in a few days.

To properly clean the system, a person must understand the structure of the comb and understand the principle of its operation. If you do not have the necessary knowledge, you should seek help from specialists. For more information on releasing air, watch this video:

Recently, separators have become increasingly popular, whose function is to automatically remove air bubbles from the system, which significantly simplifies the further operation of the entire system.

How to prevent air locks from occurring?

The main disadvantage of water floors is the formation of air pockets, otherwise they have excellent performance characteristics and are easy to use.

Even despite the correct installation work, the water system can become airborne during operation. To prevent this, you must adhere to the following rules:

- Conduct regular preventive inspections of the structure for defects and leaks;

- monitor the level of temperature and pressure of the coolant, since sudden jumps lead to blockage of pipes;

- periodically pump air in the pump housing and manifold;

- if you cannot service the device or replace faulty equipment yourself, you should invite specialists;

- install the circulation pump only for water supply, this will prevent air from entering the pipeline due to the fault of the pump;

- install a separator on the return hose in front of the manifold, with its help it will be possible to expel air;

- the coolant should not be drained from the hydrofloor pipeline, since small air blockages can be easily removed using a separator or manifold valves;

- To set up the collector, it is better to invite a specialist.

For your information! If a circulation pump is used, it is recommended to connect it to an uninterruptible power supply, in which case the water flow in the floor loops will remain unchanged.

Formation of air masses in a heated floor system

A pump is needed to bleed the system.

How to bleed air accumulated in the system will depend on the incident that led to such a result.

Some circumstances require immediate intervention, while others are not capable of causing significant damage to the system.

If the heated floor was installed with noticeable differences, it is worth acquiring an additional pump for pumping the coolant.

It is recommended to install several automatic air vents that will help bleed air masses from the system. One is installed on the return lines, while the second should be on the supply.

Running the circulation pump will also help expel excess air. The more air that has accumulated, the louder the circulation pump will operate. It is worth paying attention that the system must be pumped at maximum speeds. This will significantly save time and allow you to completely remove air from the system. If it was recently pumped, but the air has already collected again, the problem may be in the pump itself.

With the comb installed, each circuit is closed in turn, and the air vent must be open on each of them. It is necessary to bleed air gradually, so after cleaning the first circuit, the next one opens. The descent is carried out in stages and at the moment of bleeding only one circuit should be open.

If this procedure does not give the expected result, the next air release should be carried out no earlier than in a few days.

To properly clean the system, a person must understand the structure of the comb and understand the principle of its operation. If you do not have the necessary knowledge, you should seek help from specialists. For more information on releasing air, watch this video:

Recently, separators have become increasingly popular, whose function is to automatically remove air bubbles from the system, which significantly simplifies the further operation of the entire system.

Tips and tricks

As you know, the more complex the equipment, the higher its cost, while such a device is less reliable. Therefore, in order for the hydrofloor to work properly, you need to buy and install high-quality components.

Today there is a huge range of kits for installing water floors on the market. When choosing, you should carefully read their characteristics and features.

You can use a mechanically driven device, which is reasonably priced. In addition, the operation has been proven by many years of practice, so it rarely breaks down. Devices with a sulfur drive are more expensive, and there are more elements that can fail in this design.

When choosing a device for bleeding air, experts recommend paying attention to Mayevsky taps - they are reliable, durable and do not need adjustment.

Automatic devices have a more complex design and are more expensive. In addition, they become unusable when dirty.

As you can see, air locks lead to malfunctions, but this problem is easy to solve. The main thing is to bleed the air from the pipeline in time, and this must be done correctly and regularly.