Service price

The cost is calculated individually based on the length of the pipe and the type of material used to make the inner liner.

By consulting with our specialists, you can find out how much cladding will cost for your home. You can be sure that it will cost much less than installing a new pipe. The ideal condition of the smoke exhaust channels is not only a mandatory requirement that must be met for the legal operation of heating equipment. This is a matter of safety for people in the premises. According to statistics, carbon monoxide poisoning occurs quite often during the heating season. This substance has no odor, so people do not notice the problem and quite often end up in the hospital in serious condition. If there are children in the house, then poor draft in the chimney can be fatal.

Specialists from Ventgazservice LLC will restore the patency of smoke channels using special inserts. This will provide good traction and prevent the rapid accumulation of soot. Our priorities are compliance with industry standards and safety.

General description: what is Furanflex?

To understand what Furanflex is, let's start from the very beginning. A chimney is a duct (pipe) that runs from a stove, fireplace or boiler through all of these to the top and out through the roof. Very often the chimney duct is made of brick.

A sleeve (sleeving) is an insertion of a pipe made of a different material into a brick chimney. At the exit we have a pipe in a pipe, and in this case the smoke will not come into contact with the brickwork, but with an additional pipe placed (a sleeve, which is usually made of ceramics, steel and a polymer sleeve).

Pipe lining with Furanflex

A correctly installed sleeve protects the chimney channel from fouling with soot, and also protects from condensation and exposure to high temperatures. As a result, the service life of the channel is significantly extended, and the likelihood of its breakdowns and blockages is reduced.

During installation, it is unwound, lowered into the chimney channel, straightened along the entire length and secured at the top (at the pipe outlet) and at the bottom (at the place of attachment to the stove). Next, a plug is placed on the hose from below (it is blocked), and a special installation is connected from above, through which hot steam is supplied to the hose.

Under steam pressure, the hose expands along its entire length, pressing against the walls of the air duct. Under the influence of temperatures, the sleeve becomes elastic and is then glued to the brickwork, at which point the installation process ends. At the same time, both fireplace and stove chimneys can be lined in this way.

Where and what is it used for?

Furanflex is used for lining, that is, to protect the main chimney channel. Moreover, even if the protective liner fails, replacing it is both cheaper and easier than replacing the main chimney duct.

The use of Furanflex is justified in the following cases:

- To protect the smoke channel during its construction.

- To protect an existing smoke channel.

- To restore a smoke duct that has become unusable (and it usually doesn’t matter what exact reason led to the failure of the smoke duct).

Typically, lining in this way is used for lining chimneys located in low-rise private buildings. Somewhat less often - for channels located in baths or saunas. But there is no prohibition on the use of this technique for chimneys in industrial systems.

Material and characteristics

The Furanflex protective sleeve consists of several structural elements (layers or segments), so it makes sense to consider them all.

Sleeve segments:

- internal segment - made of thermoplastic polyethylene, used exclusively at the installation stage and used to hold the middle layer (segment) - after installation it is immediately removed from the channel;

- middle segment - made of thermosetting polymer resin using fiberglass (330 g per square meter), and there are usually several layers of fiberglass (about four);

- outer segment - made of polyester fabric (if we are talking about Furanflex Black or Ventiflex), or from fiberglass with Kevlar reinforcement (if we are talking about Furanflex RVW).

General information about Furanflex material

Product Specifications:

- Basic length: up to 30 meters.

- Basic sleeve diameter: from 60 to 1000 millimeters.

- Wall thickness: from 2 to 3 millimeters.

- Tensile strength: exceeds 400 N/mm.

- Maximum smoke temperature (with prolonged exposure): up to +250 degrees (if we are talking about Furanflex Black), or up to +700 degrees (if we are talking about Furanflex RVW). One-time short-term temperature rises up to +500 for the Black model and up to +1000 for the RVW model are allowed.

- Maximum channel bend angle: 45 degrees.

- Minimum ambient temperature: no more than -50 degrees.

- Service life: from 10 to 30 years with proper installation and subsequent operation.

Briefly about the manufacturer

The Furanflex company is based in the Russian Federation, and its products are aimed specifically at the CIS market. The company has a representative office in Ukraine.

Considering that the described products are rare in the construction market of the CIS countries and the choice of them is small, the Furanflex company can be called a fairly large manufacturing company of such devices. This is the largest manufacturer of chimney hoses and the most popular in Ukraine, Russia and Belarus.

When to line a chimney

There are several factors that indicate the need to perform a casing procedure:

- Initially, the combustion product exhaust system was designed incorrectly;

- the constant use of a fireplace or stove, which is connected to a brick chimney, is assumed;

- the channel is very long;

- depressurization of the smoke channel;

- if the design suggested lining the mine, but this was not done;

- the chimney is made of brick inside the outer wall of the building;

- Soot accumulates very quickly in the shaft and must be cleaned frequently.

Correct order of work

This type of work such as lining a brick chimney does not fall into the category of complex activities. It is used to restore high-quality smoke removal when the owner of the house does not have the opportunity to completely redo the chimney duct.

Sleeving is performed in one of two ways:

- a steel liner for the chimney is installed;

- The FuranFlex system is used, but it can only be used for gas heating appliances with low combustion product outlet temperatures.

Before lining a brick chimney, a number of preparatory measures should be carried out:

- it is necessary to identify existing damage, including on the brickwork, and check the entire structure for strength;

- Next, you need to examine the tightness and integrity of the chimney system, and also find out the degree of clogging;

- in addition, you need to check the cross-section of the pipe and make sure there are no obstacles throughout the entire channel;

- after this, it is necessary to determine what cross-section the pipe has and its compatibility with the intended sleeve in order to prevent narrowing of the chimney;

- before installation work, you need to understand the design of the future sleeve;

- At the end of the preparatory stage, free access to the work sites is ensured.

The rules for performing pipe and stove work, dated 2006, state that it is advisable to install chimney pipes near partition structures and near internal walls that are built from fireproof materials. When there are no walls or partitions, mounted pipes are used.

The pipes are laid in the following order:

- the channel wall made of bricks is dismantled in the place where the heat generator is planned to be installed (the size of the disassembled surface is equal to the length of the elements that ensure condensate collection), a hatch is installed for cleaning the smoke exhaust pipe;

- the specified elements are fastened in the channel;

- ropes of the required length and sufficient strength are mounted to a straight section of pipe with hooks;

- the inserted pipe is placed in a brick smoke exhaust duct at a height that makes it possible to insert the next nozzle (read: “Do-it-yourself brick chimney”);

- gradually lowering the rope, the remaining pipes are attached until the channel is completely passed;

- the voids between the pipes and the walls of the brick channel are filled with non-flammable material that provides thermal insulation;

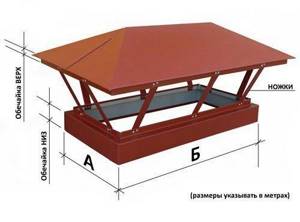

- a pipe is mounted on the head of the channel, onto which an umbrella is attached to the chimney pipe to protect it from precipitation;

- the disassembled chimney opening is filled with bricks.

Nuances and requirements for lining the chimney of a gas boiler

A chimney lining is a necessary solution if the pipe is made of brick. The presence of the insert does not protect against the appearance of condensation drops, but with the help of the lining it is possible to ensure organized moisture removal.

Before lining a brick pipe, you need to prepare:

- inspection of the chimney outlet;

- checking the section shape;

- identifying the degree of contamination;

- pipe cleaning;

- checking for tightness and functionality.

The cross-section is most often represented by a rectangle with dimensions of 14 x 27 cm; before installation, the dimensions of the sleeve, its length and shape are determined

Attention is paid to the cross-sectional area, because insert in the channel narrows the outlet

Types of chimney liners

Depending on the material from which the sleeve is made, there are:

- lining the chimney with liners made of refractory polymers;

- lining using steel pipes;

- using a corrugated stainless steel pipe as a sleeve.

We recommend that you read: How to make a spark arrestor for a chimney with your own hands?

Each of these methods varies in cost and has its own characteristics of use and installation.

Sleeve made of polymer liners

Polymers reinforced with glass fiber become flexible when heated and, after hardening, take the shape of chimney ducts of any configuration. But this property also imposes restrictions on the use of the sleeve at certain temperatures.

For gas boilers, which are characterized by increased condensation formation, a special sleeve made of fiberglass-reinforced polymers, FuranFlex, is used as a sleeve. A steam generator is required for installation.

Steel pipe for sleeve

Steel modules have a lower cost compared to other types of sleeves, but at the same time they are durable and easy to install. The pipe is simply inserted into the chimney.

At the same time, steel pipes are used in chimneys for boilers of any type of fuel. The only drawback of such sleeves is their inability to be used in mines that have a tortuous structure.

Corrugation for sleeves

Corrugated pipe is the most vulnerable to thermal effects, because has too thin walls that can quickly burn out.

In addition, the ribbed surface of such pipes is favorable for the deposition of soot and soot, therefore, use in chimneys for boilers operating on solid fuel is impractical.

Other ways to protect pipes

Ceramic liners can also be used for the reconstruction of chimneys: they can withstand high temperatures, have a smooth surface, but reconstruction requires partial destruction of the chimney to secure the ceramics, which, firstly, increases labor costs and entails financial losses, so lining with ceramics is not used popular among craftsmen.

Key mistakes when lining

The main mistakes include:

- Partial liner (not along the full length of the shaft).

- Using a knee instead of a special support element.

- Crumpling of the edges of pipes (if we are talking about stainless steel) during transportation, connection (of segments to each other) or lowering into the shaft.

- Jerks of the cable when lowering the sleeve.

- Narrowing of diameter.

- Too sharp turns (if we are talking about a polymer liner).

- Use of bulk thermal insulation (between the sleeve and the brick shaft).

- The absence of a U-shaped water seal - if the condensate is discharged directly through the hose into the sewer.

Please note: every mistake is quite serious. If you allow them, you can complicate your task in the future (if you need to replace the liner), or worsen the operation of the boiler.

Review of ceramic chimneys: pros and cons, installation rules

How effective is a Chimney Sweep log for cleaning a chimney?

Related Posts

System calculation rules

The purpose of their implementation is to select the optimal height and cross-section of the gas exhaust channel to ensure effective traction. The last characteristic is very important. If possible, it is best to have professional calculations done. If not, you can use averages. There are three main sizes that are widely used:

- Six. This is a square-shaped pipe having a row of six blocks. The dimensions of the internal channel are 250x250 mm. Used for Russian stoves and fireplaces, where minimal resistance to the flow of heated gases is required.

- Five. The chimney with a rectangular cross-section is formed by five elements. Section 125x250 mm. It is used for heating and cooking-heating devices.

- Four. A structure made of four bricks in a row. Size - 125x125 mm. Installed for low-power solid fuel boilers and kitchen stoves.

When choosing the height of a future structure, the following standards should be taken into account:

- If the roof covering is fire hazardous, the structure is placed at least 150 cm above it. For non-flammable materials, this value is 50 cm.

- The minimum distance between the grate head and the grate is 500 cm.

- When constructing a chimney on a ridge or at a distance of no more than 150 cm from it, the height of the part is 50 cm above the roof level.

- When installing a structure at a distance of 150 to 300 cm from the ridge part, its length is equal to the height of the ridge.

- If the structure is further than 300 cm from the ridge, it is allowed to be built below it. But the line drawn conditionally through the ridge and deflector should have a slope of 10°.

Carrying out work

Before starting work, you must carefully inspect the chimney. If there are large cracks or other defects in it, they must be eliminated using a composition that is resistant to high temperatures

In addition, it is important to ensure that the chimney has the required strength. If the chimney is not securely fixed, it may be destroyed during the installation of the liner

Before lining, the chimney is cleaned, so soot will not penetrate into the room during the process, and this will also make the work easier. Once again, the size of the chimney and the cross-section of the pipe planned for installation are verified. For the latter, it should be smaller so that there are no difficulties during installation. Additionally, you can make a small drawing, which will help you think through the process of joining individual components in advance.

Steel pipe

Installation of a chimney liner made of a steel pipe begins from the heating device. The first step is to disassemble the part of the chimney in the place where it is connected to the boiler or other appliance. The first pipe is mounted on the boiler or other device. There must be a hole in it through which the chimney will be cleaned. A corner or other additional unit is prepared into which the remaining parts of the steel sleeve will be secured. Now you will need to climb onto the roof to carry out the further lining process. The first part of the metal sleeve is attached to the rope or cable. Its descent into the chimney shaft begins.

The process must be continued until a small part of the sleeve remains on the surface, to which the second part of the sleeve can be attached. The second section of pipe is fixed and the descent continues. Thus, it is necessary to gain the full height of the chimney liner. When the sleeve reaches the place where the connection with the boiler should occur, it is fixed into the coupling. The space between the chimney and the sleeve is filled with insulation. To prevent rainwater from entering the pipe, it is covered with an umbrella or deflector. Part of the dismantled chimney is reassembled. The installation of the steel sleeve is shown in the video below.

Polymer sleeve

Installing a polymer sleeve into a chimney is a rather interesting process. FuranFlex products are often used for these purposes. A sleeve is selected whose length will correspond to the size of the chimney. A cable is lowered into the pipe and received from the inside of the room. A flexible pipe is attached to the second end of the cable. Gradually it stretches through the entire chimney. The upper part of the sleeve fits into a flange connection, at the end of which there is a locking mechanism. A steam generator is connected to the bottom. The sleeve is kept under pressure for a certain time. After this, the pressure is released, the sleeve is trimmed and joined. The process of sleeving in this way can be seen in the video.

Sleeving methods and materials

There are several ways to line a brick chimney using various materials and technologies.

Stainless steel pipe

The solution is relevant for smoke mains of any shape and length. Stainless steel sleeves provide excellent resistance to high temperatures and condensation. The structure is easy to install; no special equipment is required. Most often, owners of private houses line the chimney with a pipe with their own hands.

Stainless steel inserts of various designs are available on the market:

- round pipes. Perhaps the most popular liner option. Models are made with a cross section of up to 100 cm. The wall thickness varies between 0.5-1.5 mm, this design parameter depends on the characteristics of the base material;

- rectangular pipes. A stainless steel insert of this category is used less frequently than an analogue with a round cross-section. Models with dimensions of 14x27 cm are relatively common;

- oval pipes. The thickness of the material is 0.5-0.6 mm, common sizes are 20x10 and 24x12 cm. The cross-section of a stainless steel liner with an oval configuration of the required sizes corresponds to a round pipe with d15 and d29 cm;

- corrugated stainless steel sleeves. The corrugated pipe is presented in the form of a two-layer model made of different grades of stainless steel with a cross-section of up to 35 cm.

As practice shows, the potential of a corrugated stainless steel liner provides a service life of no more than 4 years, since the ribbed walls become clogged and the liner burns out under the influence of temperature loads.

Polymer sleeve

The liner is made on the basis of fiberglass mesh with polymer impregnation. Models are made up to 60 m long. Thickness parameters vary within 50 cm. The polymer solution provides a long service life - up to 30 years. The material is resistant to condensation.

The chimney can be lined with a polymer sleeve

The convenience of installing a flexible tab lies in the fact that a one-piece hose is inserted into the smoke channel, which can bend at an angle of 30°, which is important when there are bends in the brick main. At the same time, shaped elements are introduced into the design if necessary.

They note that without special equipment and certain skills, it is impossible to install a polymer hose into a smoke shaft yourself. It is noteworthy that models of polymer sleeves for high-temperature and low-temperature heat generators are manufactured using various technologies.

Ceramics

Ceramic liners come in round and oval shapes, the diameter varies from 12 to 45 cm, the length of straight elements is 33, 66 and 133 cm, and the wall thickness is 4-20 mm. Reliable ceramic sleeves are often used in the reconstruction of mines with significant deformations. The material does not react to soot combustion and is valued for its durability. When lining with a ceramic insert, it is necessary to disassemble the smoke shaft. The high cost and impressive weight of the product are the main disadvantages of ceramic sleeves.

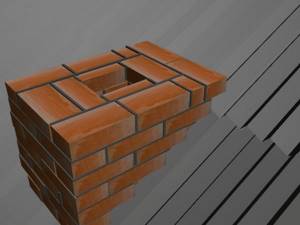

What is a sleeve

Almost all chimney pipes have a rectangular channel cross-section. For masonry, ordinary red or decorative brick is used. During operation, a lot of soot accumulates inside the channels, which negatively affects the performance of furnace equipment and also leads to the disappearance of draft. The whole problem lies precisely in the shape of the section, as well as the rough surface of the brick.

Round and oval channels have smooth inner walls, so no soot remains on them.

In order to avoid having to build an old chimney, a sleeve was created. Its essence is as follows: a pipe is placed inside the channel, while the brickwork remains intact and is not destroyed. The best option is a stainless steel sleeve, but ceramics, polymer, and asbestos are also often used.

Chimney lining with stainless steel

Chimney lining process

You can update the chimney using the lining method

The procedure involves selecting a liner based on material, section type and cross-sectional area. An insert is placed in the chimney along the entire vertical section of the outlet channel.

The problem with the destruction of internal surfaces is solved by two methods:

- dismantling the old pipe and laying a new one;

- lining of a brick chimney.

The first option is labor-intensive and requires certain costs. Requires disassembly, purchase of materials, payment for the work of a mason. They refuse to replace the furnace structure and make inserts into the existing pipe.

The essence of the process and the need

Over time, soot accumulates on the inner walls of a brick chimney, as a result the passage narrows and draft deteriorates. The rough surface is affected by temperature changes, condensation and aggressive smoke components. Insufficient removal of combustion products disrupts the operation of the heating system, causing the draft to stall.

Lining means installing a pipe into an existing chimney. Stove makers advise performing the operation during the construction phase of a fireplace or stove. The home is constantly heated, the inner surface of the masonry is destroyed and over time, installing a liner becomes necessary.

How is it useful?

Ceramic pipes have smooth walls on which soot does not settle

Smoke from the boiler firebox passes inside the liner and does not come into contact with the rough plane of the brick. The insert can be installed without waiting for damage and destruction of the smoke exhaust channel. Gas condensate in the pipe is an aggressive composition of moisture and chemical oxides.

When wood and coal burn in the firebox, vapors and carbon dioxide are formed, moisture is released from the firewood and exits with the air through the chimney. The difference between the external and internal temperatures in the pipe leads to the formation of drops and their settling on the walls. Soot is oxides of sulfur and nitrogen that interact with moisture and destroy the surface.

In what cases is this necessary?

Lining is an alternative to reconstructing a chimney to restore efficiency. The procedure is relevant if there is no possibility of rebuilding the pipe or installing a new one. Lining is only possible in chimneys with low temperatures of exhaust gases and in high heating systems.

A chimney is an engineering structure; the safety of a home in terms of fires depends on its quality. Sometimes the pipe is made of hollow stones or there is dried mortar and fittings left inside on the walls.

Causes of destruction of brick chimneys

There are natural and artificial factors that contribute to the destruction of smoke exhaust channels. Natural factors include:

- temperature changes;

- aggressive chemicals that are part of the smoke;

- condensation arising due to the difference in temperature inside and outside the channel.

Natural factors have a detrimental effect on brick structures, since brick does not have an anti-corrosion effect and quickly wears out with temperature fluctuations. Metal pipes cope with these factors much better, however, they also have their vulnerabilities.

In turn, artificial factors are no less, and sometimes even more destructive for brick channels. Let's look at them:

- incorrect technology for making brickwork, which refers to installation errors, can cause weak draft in the chimney structure;

- low quality of materials from which the smoke exhaust channel is assembled;

- operational errors;

- other errors during system installation.

Errors in the installation of this communication are perhaps one of the most common problems. During operation, improper design of the system affects its operation; the amount of condensate in the channel increases, which in the cold season leads to icing of the internal walls. Freezing of condensate destroys the mortar and thus spoils the masonry. In addition, improper design affects the traction performance in the system.

During the installation of a chimney, the use of low-quality bricks that have not undergone the hardening procedure properly leads to rapid wear. Using poor quality materials may cause a fire in the future. Destruction of the chimney structure can also occur due to mechanical stress. In any case (regardless of the cause of the destruction), experts recommend immediately responding and carrying out the necessary repair work.

Types of lining

Sandwich pipe lining

The principle of behavior of lined liners and their placement in the channel is the same, but the liners differ in material, so there are certain nuances for each type.

Specialized stores offer inserts:

- made of polymers;

- of steel;

- from corrugated pipe;

- polymer sleeve;

- made of stainless steel.

Polymer sleeves

A plastic pipe is installed inside the operated chimney. PVC products are reinforced with fiberglass fabric and, when heated, acquire plasticity. As a result of this property, irregularities and spaces on the clinker surface are filled. After hardening, the internal area becomes smooth, and the wall has a thickness of 2 cm.

The downside of the application is the temperature limitation. Lining a chimney made of brick with plastic is done with exhaust flows up to +250°C, so they are installed to work with low-power units.

Application of steel elements

Corrugated pipe lining

A structure made of a rolled pipe is placed in the straight section of the chimney, or rectangular, square, oval and round shapes are made with your own hands. Sheets are taken with a thickness of 0.5 to 1.5 mm. In channels made of steel materials, it is possible to provide the required modules for cleaning, inspection, and containers for accumulating condensate in accordance with the standards.

Steel products are used for fireplaces using various types of fuel. The material resists acids and is not subject to plaque deposits. The disadvantage is that only straight sections can be lined with this method; winding pipelines cannot be equipped.

Using corrugated pipe

Manufactured using various types of stainless steel, the pipe shells are made of two layers. The positive thing is that flexible liners are used for complex channels with turns. The products do not require connecting elements. Double-layer inserts significantly reduce the diameter of the air duct; this must be remembered when choosing.

Polymer sleeve

Polymer sleeve for chimney lining

The sleeve is made of copolymer resin and reinforced with fiberglass. The insert is used to combat condensate drops; it is used to treat low-temperature chimneys and those coming from powerful boilers.

Types of polymer products:

- Fitfire is a liner containing two layers, the maximum element has a length of 60 m. After installation, the chimney duct has a diameter of 80 - 500 mm. The manufacturer specifies a service life of 50 years; the hose is used to remove low-heat gases.

- Fitfire HT 1000 is used in pipelines of sauna and fireplace hearths with high smoke heating. The sleeve consists of three layers, the middle one is a reinforcing mesh.

When lining the chimney with a polymer sleeve, the internal protection is obtained without seams, with a smooth surface.

Stainless steel pipe

The material is one of the most popular types. The products work for many years and do not deform due to high temperatures or corrosion. Lining a brick chimney with a stainless pipe is often used because... There is a large assortment of ready-made inserts for sale, sometimes products are made by hand, taking into account the dimensions.

The inserts are made from stainless steel sheets with a thickness of 0.8 - 1.5 mm. To connect and turn the channel, standard tees and pipes are used, but to install them you need to know the exact layout of the chimneys. Sleeves with a rectangular cross-section are installed only on straight sections of chimneys.

Using steel corrugation

The smoke channel is not always directed straight; if there are bends, it is difficult to mount a sleeve made of stainless pipes. In this case, the sleeve is performed with flexible corrugation. It is easily located in the chimney, repeating its turns. The disadvantage of the design is the short service life - irregularities on the walls accumulate a large amount of soot, and the small thickness of the walls of the flexible sleeve contributes to rapid burnout. A corrugated sleeve will last 2–3 years.

For gas boilers that cause an increased amount of condensate, a FuranFlex polymer hose is used. This pipe is made of synthetic resins and reinforced with fiberglass. Polymer lining is used to remove gases having a temperature not exceeding 250°C. A flexible hose of the required length can be installed in a chimney of any design, because it goes along all the bends and ensures complete tightness of the system.

Work begins from the top, lowering the hose towards the heating device. The edge of the sleeve is connected to a steam generator pipe, through which steam under pressure passes along the entire length of the polymer sleeve, straightening the walls and causing them to harden. The diameter of the polymer pipe ranges from 80 mm to 1 meter; you can choose an option for a boiler of any power.

After the material has hardened, a tee is connected to the bottom to connect the pipe and the boiler. Manufacturers guarantee the service life of polymer pipes up to 30 years, but with cleaning once a year and proper care, it can be significantly extended.

Three common sleeving methods and materials used

The main essence of the sleeve is the insertion of the liner inside the brick shaft. Sleeves differ in material, size, and shape. The basic principle of installation is the same, but there are nuances.

Stainless steel

The sleeves are characterized by a long service life, resistance to high temperatures and condensation. Stainless steel pipes are suitable for shafts of any length and shape.

Stainless steel liners differ in design:

- Round pipes are produced with a cross-section from 6 to 100 cm. The wall thickness depends on the metal used and ranges from 0.5–1.5 mm.

- Rectangular pipes are used less frequently. When required, inserts with a wall size of 14×27 cm are used.

- Oval pipes are made of stainless steel with a thickness of 0.5–0.6 mm. Running sizes are 20×10 and 24×12 cm. The cross-section approximately corresponds to a round pipe with a diameter of 15 and 20 cm.

- Corrugated hoses are made in two layers from different grades of stainless steel. The cross-section varies from 8 to 35 cm. When installing a flexible stainless steel chimney, do not bend the corrugation with a radius less than two pipe diameters.

Of all the options, the corrugated sleeve is considered the most unreliable. Two-layer stainless steel burns out in four years from exposure to high temperatures, and soot lingers on the ribbed walls.

Polymer sleeve

The sleeve is made of fiberglass mesh impregnated with polymer resin. A one-piece hose is inserted into the shaft without the use of connecting segments. If necessary, use shaped parts. Maximum sleeve length – 60 m. Thickness – from 8 to 50 cm. Service life – up to 30 years. For high-temperature and low-temperature boilers, hoses with different compositions are used.

FuranFlex polymer systems for gas boilers, fireplaces and stoves are popular in Russia.

Sleeve sleeve allows you to get a solid channel without dismantling the brickwork of the shaft. The liner is resistant to condensation and is capable of bending at turns at an angle of 30 0 . Disadvantages include high cost, as well as the impossibility of independently installing a smoke exhaust duct without the skills and availability of special equipment.

Ceramics

Ceramic liners are considered reliable and durable. For lining, they are more often used when restoring destroyed mines. Elements are available in round and rectangular shapes. The connection takes place using a socket or tongue-and-groove lock. The diameter of the sleeves is from 12 to 45 cm. Straight pieces of pipe are produced in lengths of 33, 66 and 133 cm. Wall thickness varies from 4 to 20 mm.

Ceramics are not afraid of soot fire. The downside is the high cost and weight. Installation is not complete without dismantling the chimney shaft.

Features of installation of liners made of different materials

In modern construction, stainless steel, ceramics or a polymer sleeve are used to reconstruct the chimney. Ceramic liner and polymer are difficult to install. Most often, when lining chimneys with your own hands, stainless steel is used.

Preparatory work

Regardless of the type of liner chosen, a number of preparatory measures are performed before starting liner:

- Using a powerful flashlight, they inspect the smoke shaft from the inside. The degree of destruction, soot contamination, the presence of fallen pieces of mortar, bricks, and bird nests are determined.

- Use metal scrapers, brushes and other devices to clean the chimney. Bricks protruding from the masonry will prevent insertion of the liner. They try to knock down all the protrusions with a hammer or pry bar.

- Measure the length as well as the diameter of the chimney. The dimensions are transferred to the diagram, indicating all rotations and degrees of angles.

- The part of the chimney adjacent to the boiler or stove is dismantled. The installation of the shaped element will begin from this place.

- The bottom of the smoke shaft is cleared of debris and leveled if necessary.

After the preparatory measures have been carried out, the inserts necessary for the sleeve are purchased.

Installation of a stainless steel liner of round, rectangular or oval cross-section

Sleeving a small shaft with stainless steel without turning is carried out according to the following principle:

- All elements of the sleeve are assembled into one structure. The joints are treated with heat-resistant sealant, and the top is wrapped with aluminum-based adhesive tape.

- Two belts, cables or strong rope are secured to the bottom of the pipe with a clamp.

- The sleeve is carefully lowered down the shaft until it touches the bottom. If the length of the chimney is short, a lightweight stainless steel pipe is immersed by hand without using cables.

- The liner from below is connected to the inlet of the boiler or furnace and a condensate collector is installed. The sleeve is removed from the street above the brickwork of the chimney, and a protective cap is put on top.

Stainless steel lining of a long chimney with turns is carried out differently:

- The smoke duct is dismantled at the entrance to the boiler, as well as all areas where shaped connectors will be installed.

- First, the lower part of the sleeve is assembled from flat sections of the pipe up to the first shaped connector. The liner is lowered to the bottom of the shaft, connected to the inlet of the boiler or furnace, and a condensate collector is installed below.

- A shaped connector is installed on the second free end of the steel sleeve. A flat section of stainless steel is connected to it until the next turn of the shaft. The procedure is repeated until the sleeve is removed from the shaft.

The area where the pipes join is similarly reinforced with heat-resistant sealant and wrapped with aluminum tape. A head is installed on top.

Installation of corrugated stainless steel hose

The lining of a flue with a corrugated stainless steel is carried out in a similar way. The difference is the arrangement of the lower and upper exits from the mine. After installing the flexible hose inside the smoke channel, a rigid transition made of stainless pipe is attached from below. This section is used to connect the hose to the inlet of the boiler or furnace. A condensate collector is installed below.

At the upper exit from the smoke channel, the corrugation is placed above the masonry about 30 cm. To securely fasten the head, the exit can be made by extending a rigid section of stainless pipe. Upon completion of the lining, the brickwork of the chimney duct is restored.

Installation of ceramic liner

Lining with ceramic liners is more difficult. The process consists of the following steps:

- A roller mechanism is fixed to the holes of the condensate collector. The element in the sleeve is a load-bearing structure, and the first one descends into the chimney to a depth of 30 cm. Ceramics are heavy. For a safe descent, it is best to use a winch.

- The upper end of the condensate collector is treated with sealant. Using a socket or tongue-and-groove lock, a flat section of the pipe is secured.

- To connect the boiler, a hole is cut out on a flat ceramic sleeve using a universal fitting. A winch is used to lower part of the liner into the shaft. The next element is fixed to the end of the first pipe in a similar way. During descent, make sure that the sleeve with the hole for the fitting does not turn in the other direction relative to the boiler inlet.

When the condensate collector reaches the bottom of the shaft, it is connected to the boiler inlet. From above, a ceramic pipe is installed above the brickwork. The protrusion is made equal to the height of the cover plate.

Installation of a polymer sleeve

To line chimneys with a polymer sleeve, special equipment will be required. Initially, the liner resembles a coiled hose. The hose is lifted to the roof of the building, inserted through a channel to the bottom of the shaft, connected to a compressor and air is supplied. Under pressure, the soft walls of the stocking will straighten out.

When the hose takes on the internal shape of a channel, steam is supplied instead of compressed air. The polymer first softens and then hardens. A condensate collector is installed from below. At the exit from the shaft, the excess piece of the sleeve is cut off, and a head is installed on top.

Head device

To install the head, a rigid sleeve is built onto the surface of the chimney, and a cover plate is mounted around it. A cuff is attached near the pipe to prevent condensation from entering the brick shaft. The part of the sleeve protruding above the roof of the house is insulated with insulation. The height of the pipe should extend beyond the level of the ridge.

Common mistakes

When lining with any type of liner, you must not allow the sections to narrow, use a shaped turn for support, or pour loose insulation into the gaps between the liner and the walls of the shaft.

It is not allowed to drain condensate into the sewer through a hose without installing a U-shaped water seal.

Labor will be useless if the shaft is partially lined, as well as if there are steep angles.

Benefits of rehabilitation

The chimney duct rehabilitation process has undeniable advantages:

- the smooth inner surface of the chimney weakly retains soot;

- the thermal conductivity of the shaft decreases, due to which the pressure difference is maintained;

- the walls of the sleeve made of any material do not absorb condensate;

- a compensator is added to assemble and drain condensate from the channel.

It is always easier to replace a failed liner than to rebuild a brick shaft.

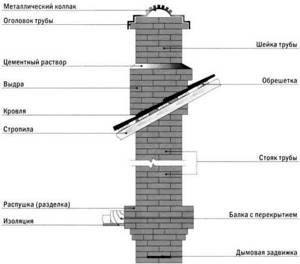

Classic chimney

Let's look at the structural elements of a classic chimney.

Construction of a classic chimney

Bottom part

From the top of the stove to the smoke valve (damper). Accepts very hot gases; fireclay bricks can be used for the channel. It’s better to buy a gate valve ready-made in a store; if it’s not possible, do it yourself. Store structures are more reliable; they are made of malleable cast iron and do not deform during heating. Steel gates can become deformed as a result of steel tempering. The deformed gate jams in the grooves, making opening/closing difficult. For laying the lower part of the chimney, it is recommended to use a clay solution without adding cement.

Steel gate in a brick kiln

Fluff

Performs two tasks: it increases the resistance of the chimney to wind loads - it rests on the floor beams. In addition, the increased size of the fluff serves as fire protection for wooden structures.

Pipe fluffing

Riser

Part of the chimney from the fluff to the otter. The longest section, during laying it is necessary to maintain the vertical position of all rows.

Laying the chimney riser

Otter

Special thickening over the roof covering. Traditional chimneys are made without the use of modern methods of sealing the exit above the roof; the increased dimensions of the otter prevent natural precipitation from entering the attic of the bathhouse. To improve insulation, sheets of galvanized steel can be nailed around the perimeter of the otter.

Otter

Neck and head

The length of the neck depends on the angle of inclination and type of roof; specific dimensions take into account all the features of the structure. The height of the neck affects the stability of traction, regardless of wind strength.

After the neck is formed, you can lay out the head

The cap is a decorative element of the chimney.

Chimney head options

Protective cap

Prevents rain and snow from entering the smoke channel. The cap has one more function. If no one uses the sauna stove for a long time, then birds can build a nest in the channel - the chimney will have to be cleaned. To prevent such situations, it is recommended to cover the exit with a metal mesh.

Installation of a canopy on the chimney

We can only give approximate dimensions of each chimney element; more precise parameters must be calculated taking into account the architectural features of the stove and bathhouse.

The main advantages of sleeves

- The draft improves and the operation of the heating device becomes more productive.

- This design is sealed, reducing the risk of fire hazards.

- There is no need for frequent cleaning of the chimney. Compared to brick walls, which can often be uneven, have cracks and ledges in which condensation and soot accumulate, contributing to the formation of congestion, the walls of the liner are smooth and even.

- The chimney pipe will last longer. Due to the acid resistance of liner materials to condensate (especially in gas ovens) compared to brick, which is much more susceptible to mechanical and chemical destruction.

- The design includes elements for condensate removal and cleaning.

- The sleeve reduces heat loss from the system

Advantages and disadvantages

The use of such a technique has both a number of undoubted advantages and a number of disadvantages. However, the advantages of Furanflex more than cover the possible disadvantages, of which, by the way, there are relatively few.

Advantages of the technique:

- it is possible to install the system without dismantling the entire shaft;

- after installation, although the diameter of the smoke channel decreases, it is not significant, which means that no problems with draft can arise (but a stainless steel sleeve, for example, significantly reduces the cross-section);

- the device can be placed either directly into an already operating chimney or into a newly made shaft;

- fairly quick and relatively simple installation (installation usually takes about four hours in total, and often most of the time is spent not on the installation itself, but on polymerization);

- high resistance of the material to corrosion phenomena (even higher than that of a stainless steel sleeve);

- smooth and even surface of the material from the inside, which helps reduce the likelihood of blockages and simplify cleaning of the device;

- there are no seams or joints, which leads to a significant reduction in the risk of system depressurization.

Disadvantages of the technique:

- DIY installation, although possible, requires the use of special expensive equipment and good knowledge of the installation process;

- it is often very difficult to find installation specialists in the provinces, since they may simply not be available;

- the cost of professional installation is quite high, as is the cost of the material itself.

How to liner

Progress:

- First, the lower section of the chimney, which is connected to the boiler, is dismantled to install a tee with compartments for condensate outlet and monitoring the operation of the system.

- A rope is attached to the mouth of the pipe to lift and lower the sleeve; the work will go faster if the rope is secured on both sides.

- The complete structure of individual elements is assembled on the ground, then tied with strong ropes and lifted to the roof and lowered into the chimney.

- The sleeve is laid to the height of the shaft so that the top rises above its mouth.

- The empty space between the outer side of the sleeve and the chimney is filled with non-combustible material, basalt wool is suitable.

- After installation, the edge of the pipe is covered with a cap or a horizontal pipe is installed, this will prevent precipitation from getting inside.

- All elongated bricks are inserted into place.

In principle, installation is not difficult, but if you do not have confidence in your abilities, so as not to create an emergency situation, it is better to invite a specialist. Any homeowner who is responsible for their home should check the condition of the chimney on the eve of the heating season. Timely lining will ensure the safety of the house and the health of its inhabitants. Ideally, the installation of modules is carried out during the construction stage, so that there are no problems with the chimney in the near future.

vote

Article Rating

Chimney dimensions

It is equally important to choose the correct chimney diameter for a solid-state boiler, as well as its height. Let's start with the latter - the height of the chimney must be at least 5 meters, and this is necessary just to create the correct draft

The diameter is selected based on the size of the pipe of your heating boiler, but it may be slightly larger.

- Heat accumulator for heating - description of the system and features of its use in a private home (120 photos)

- Pumps that increase pressure - review of 2021 models, recommendations for choosing parameters for the heating system (105 photos)

- Heating pressure testing pumps - manual and automatic models for modern heating systems (90 photos and videos)

Moreover, we are now talking about the chimney duct itself, and not about the entire structure, because there are often additional elements around it that depend on the project itself.

Where is it sold and how much does it cost?

It is easier to find specialists in the sale and installation of polymer stockings in large cities of the CIS countries. They cannot be found in provincial areas. Therefore, people living in the outback have to overpay. The estimate usually includes payment for the purchase, delivery and installation of Furanflex - the price can ultimately rise significantly.

If we talk about the cost of a polymer hose separately, it depends on the diameter of the product. The price is usually indicated in rubles per 1 linear meter. Approximate prices are given in the table.

| Product diameter (mm) | Product cost (rub./linear meter) |

| 100 | 6550 |

| 150 | 7750 |

| 200 | 9200 |

| 300 | 12300 |

| 400 | 16600 |

| 600 | 31000 |

Based on the data in the table, you can make an approximate calculation of the cost of lining a pipe with Furanflex. So, if the length of the chimney is 10 m and its diameter is 200 mm, then a hose will be required that costs at least 92,000 rubles. This amount does not include additional services such as rental of special equipment and professional installation.