The primary task before starting interior work, after erecting the roof, is the attic floor using wooden beams. It must contain an internal layer of insulation, waterproofing and external layers of ceiling or floor covering. We will consider the types and characteristics of materials for flooring, as well as the technological features and nuances of this process in this article. And we'll start with some important preparatory points. To get started, we suggest you watch the video:

Attic flooring on wooden beams: design, installation and tips for do-it-yourself work

The primary task before starting interior work, after erecting the roof, is the attic floor using wooden beams. It must contain an internal layer of insulation, waterproofing and external layers of ceiling or floor covering. We will consider the types and characteristics of materials for flooring, as well as the technological features and nuances of this process in this article. And we'll start with some important preparatory points. To get started, we suggest you watch the video:

Wood floor tinting

To make a wooden floor look impressive and expressive, experts recommend tinting. The preparatory work for tinting the floor is no different from what needs to be done before applying a new layer of varnish. It must be remembered that the shade of the floor after tinting will change and largely depends on the porosity of the wood and the type of wood from which it is made.

Important! To ensure the final result, experts recommend tinting a separate board first. Apply the tinting composition with a flotex spatula. If the end result is not expressive enough, you can apply another layer of tint.

And finally, cover the floor surface with a colorless varnish, which will give it shine, strength and additional protection.

If the end result is not expressive enough, then you can apply another layer of tint. And finally, cover the floor surface with a colorless varnish, which will give it shine, strength and additional protection.

Apply the tinting composition with a flotex spatula. If the end result is not expressive enough, then you can apply another layer of tint. And finally, cover the floor surface with a colorless varnish, which will give it shine, strength and additional protection.

conclusions

Now you already know how to repair wooden floors, remove creaking floorboards and seal cracks

The work process does not require special knowledge, but it is important to adhere to consistency in the work, which will prevent roughness of the coating, the formation of bubbles and streaks

Materials and tools

Work on the attic floor should begin only when everything you need is at hand. It is worth purchasing materials in advance for load-bearing elements, insulation, and finishing (see also the article “How and how to properly insulate walls in a wooden house inside and out”).

For thermal insulation it is best to use mineral wool

An approximate breakdown of the necessary components by operation is given in the table:

Note! The price of materials and the volume of purchases can be very different, so you will have to make the final estimate yourself, based on the dimensions of your house and the approved floor insulation project.

As for the set of tools, for work we will need the following:

Without such a design, working under the ceiling will be very inconvenient

- Stepladder and scaffolding for performing operations at height.

- Wood saws (preferably reciprocating or circular saws, since you will have to work with a hacksaw for a very long time).

- Jigsaw for cutting plywood or OSB.

- Screwdriver.

- Knife for cutting insulation and membranes.

- Hand tools – hammers, pliers, chisels.

- Measuring tools – tape measures and levels.

It is also worth remembering about special clothing and personal protective equipment: gloves, respirators, construction glasses and mounting belts for securing when performing work on floor beams.

Attics - life under a roof

Hello, my name is Valentin Viktorovich, and I have the following question: how to make a floor in the attic with your own hands. Now, this is a classic cold attic, with an ordinary clay mound across the beams, but I would like to cultivate and adapt the attic for storing various household items. How and from what would you recommend making the floor?

Hello, Valentin Viktorovich. Arranging the floor in the attic is not much different from identical work on other floors, so if you are familiar with basic construction work, then you can easily cope with the task.

It is worth making the same floors as in the rooms in the attic even if you do not plan to use it as a living space . In addition, it is very important to remember about thermal insulation so that some of the thermal energy from the rooms located under the attic does not escape through the floor.

Considering that the floor in your attic is in the form of a clay mound, it should be quite dense, since straw mixed with clay is often used to create this type of covering. By the way, kraft paper coated with a layer of clay . So we can say you are lucky and almost half of your work is done thanks to the existing clay mound.

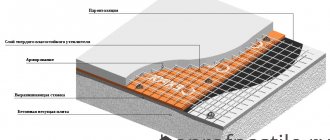

Scheme of laying and insulating the floor in the attic

Wooden beams with a cross-section of 50x150 mm are laid directly on the clay embankment, which can be further compacted if necessary. Laying should be done across the ceiling beams, taking into account the distance between the beams of 900 mm. Insulation must be laid between the beams , evenly distributed over the entire area.

Insulation is necessary not only for heat preservation, but also for sound insulation. As insulation, you can choose any material that suits your cost, having familiarized yourself with its pros and cons in advance in order to choose the best option for a material that perfectly performs its functions.

This is followed by a layer of film necessary for waterproofing and protecting the insulation from foreign moisture. This entire structure is covered with a board on top, on which you can lay any covering at your discretion.

We also recommend reading our article on the topic of construction and insulation of the floor in the attic!

Attic floor on wooden beams

When installing an attic floor, it is necessary to solve the following main tasks:

- Ensure the strength and rigidity of the floor. The ceiling must withstand the design load with an allowable deflection and not be unstable (not oscillate when moving along the ceiling).

- The heat transfer resistance of the ceiling must be no less than necessary to meet the energy saving requirements in the house. You can learn about energy saving conditions from the article “Heating costs and heat transfer resistance.”

- Sound insulation of the ceiling from airborne noise must meet the established standard. Read what airborne noise is in the article “Floating floors - soundproofing floors.”

- Vapor permeability and air permeability of the ceiling must comply with established standards.

In economy-class houses, the most popular are wooden prefabricated attic floors on wooden beams. Such floors are easy to install, light and inexpensive, and the disadvantages of floors when used as attics are less pronounced.

We list the disadvantages of wooden floors compared to metal and concrete floors:

- Limited load-bearing capacity and length of span to be covered.

- Tendency to unsteadiness - fluctuations when people move or move furniture.

- Flammability, susceptibility to rotting and biodegradation.

- Poor sound insulation of airborne and impact noise. The ceiling structure itself can become a source of noise in the form of creaking.

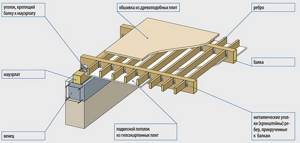

| Fig.1. Attic floor on wooden beams. 1 - upper skin with windproof backing; 2 - floor beam; 3 — heat and sound insulation; 4 - vapor barrier; 5 - ceiling lining |

A diagram of the construction of a modern wooden floor is shown in Fig. 1.

As wooden beams, timber with a section of 150-250 x 100-200 mm is used. or boards 100-250 x 40-80 mm.

The use of boards makes it possible to reduce the volume of lumber required for the construction of the floor, with a slight decrease in the durability, fire resistance, and sound insulation of the floor.

In the attic floor this decrease is quite tolerable.

When using boards, measures must be taken to prevent the beam from twisting under load.

To do this, the beams are sheathed on both sides - top and bottom - with a layer of rigid sheet or slab materials - plywood, chipboard, DSP or OSB with a thickness of at least 12 mm. (with beam spacing up to 600 mm).

The slabs must be mounted so that the short side of the slabs is perpendicular to the floor beams, and connections parallel to these beams are spaced apart; The sheathing, firmly connected to the beams, forms a load-bearing frame, which prevents the beam from twisting and increases the load-bearing capacity of the floor.

Sheathing sheets are often more convenient to attach to sheathing (bottom) or joists (top).

Sheathing slats with a cross-section of at least 19x89 mm. installed from below perpendicular to the beams with a pitch of no more than 600 mm, convenient for fastening sheathing sheets.

For hemming along the sheathing, you can use less rigid sheets - gypsum plasterboard, gypsum plasterboard with a thickness of at least 12 mm. All edges of sheets or slabs of sheathing must be located above the supports (frame or sheathing elements). Sheathing sheets are fastened with self-tapping screws 40 mm long. greater sheet thickness, in increments of 200 mm.

| Fig.2. Spacer between plank beams |

If logs are attached on top across the beams, then sheathing is not done over the beams. In the absence of upper cladding and joists, with a board height of more than 150 mm. install vertical struts

with a cross section of at least 100x38 mm., Fig. 2.

Vertical braces should be located in the span of beams at a distance of no more than 2100 mm from each beam support and from adjacent vertical braces. It is convenient to make spacers at the joints of sheathing sheets, if the sheathing is attached directly to the beams. The spacers are attached to the beams with nails or special metal brackets.

DIY repairs: step by step

R

restoration, strengthening or restoration are carried out in different ways:

- Repair using wooden auxiliary materials. Suitable for situations where it is not possible or meaningful to change the entire beam, but it is necessary to strengthen part of it with the help of an additional element. Overlays are always installed on both sides of the beam. They are mounted tightly and securely fixed with bolts. The length of these should be equal to the width of the beam and both overlays. In order to protect and extend the service life of the pads, before use they should be treated with a special antifungal substance and allowed to dry completely. If the beam is leaky at the junction with the wall, then the use of overlays is impractical. In such situations, a steel prosthesis is used.

- Beam prosthetics - the use of a steel rod or sheet. This material has fewer pads, is more durable and flexible in operation. But dentures are also treated before use with an anti-corrosion substance.

Repairs at junction points are carried out as follows:

- remove the damaged area;

- using onlays or a prosthesis, lengthen or connect the remaining sections of the beam;

- bolt the elements.

If more than ⅔ of the entire beam is damaged, the entire beam must be replaced, otherwise repairing such an element will lead to the collapse of the entire structure.

It is better to replace a beam eaten by a beetle or rotten in whole or in part, because both of these defects tend to spread quite quickly and, therefore, render the material completely unusable.

It is worth noting that any work using wooden material is carried out only after the elements have been treated with a special substance and it has completely dried. Protective solutions significantly extend the life of ceiling beams.

If you doubt your abilities, seek help from qualified specialists, although this will cost a pretty penny.

Installation of wooden attic beams

The installation of an attic floor is carried out in several stages, each of which determines the quality and reliability of the structure. The work algorithm looks like this:

1. Preparation. The required length is cut, the wood is treated with a special compound that protects it from rotting, swelling and other troubles, the edges of the beam are wrapped with roofing felt, then the finished element is lifted up.

2. Laying in two ways:

- without protrusion beyond the external walls;

- with outlet beyond the outer walls.

It is necessary to lay it along the length at the required distance in relation to other structural elements; for any installation method, the following is taken into account:

- the maximum span width should not exceed 4.5 meters;

- the timber is laid on the ends of the walls; in some cases, a mauerlat is used - this is a thick beam secured with thick nails or steel studs into the walls around the perimeter;

- roofing material is laid under each beam layer to ensure waterproofing;

- the pitch of wooden beams is selected based on the size of the thermal insulation material.

Waterproofing, vapor barrier, and insulation are laid between the upper and lower eaves. The lower flooring is made on supports to which boards are attached, but it is better to use slabs or sheets of plywood 15-20mm thick. Fastenings are carried out with self-tapping screws in increments of 10-15mm so that the heat-insulating materials are securely held. In order to mount the most durable structure, you need to fill the bottom of each beam with 50x50mm wooden blocks; they form a ledge on which boards or sheets are placed. You also need to secure the roll to the bars with self-tapping screws. The advantages of this design are exceptional reliability; the disadvantages will appear in the finishing of the ceilings, on which these bars will have to be sealed and hidden. Such a structure should be installed if you plan to actively use the attic.

Video on the topic:

4. The final stage of installing an attic floor on wooden beams is the installation of the floor, for which boards are sewn on top to act as a subfloor. For the finished floor, a tightly laid tongue and groove board is used.

The subfloor is mounted on the same bars, on top. But before proceeding to the last step, you should do:

- laying membrane-type vapor barrier;

- thermal insulation;

- another layer of membrane fabric.

The finished structure is an important element of the roof covering and the entire structure.

Functions

The design of the attic floor depends on the size of the house and the nature of the use of the under-roof space. The attic is a kind of air gap that separates the heated space of the first floor and the roof and thermally insulates it. Its floor performs the following functions:

- Carrier. The floors between the upper floor and the attic perform a load-bearing function, so they must be strong enough and reliable, because people move around it, equipment and storage areas are installed.

- Isolating. The room in an unheated attic has a temperature not much higher than the outside temperature. Therefore, the ceilings perform a thermal insulating function, preventing the heated residential floor from cooling down. To retain heat, they include a layer of insulation.

Remember that the temperature, comfort, and safety of living in the house depend on the correctness and quality of the work on arranging the attic. Therefore, it is better to entrust the design, installation or repair of floors to professional craftsmen.

Attic floor diagram

Construction requirements

Installation, repair and reconstruction of attic floors require a thoughtful approach, because the safety of using the house depends on them. To determine the maximum possible load to which a structure can be subjected, an engineering calculation is performed, and then, based on the calculations, a design is drawn up. There are a number of requirements for attic floors:

- Load bearing capacity. This indicator depends on the material from which the beams are made, as well as on the distance between them.

- Distance between beams. The maximum distance between wooden beams allowed by building codes is 4 meters.

- Resistant to temperature changes. The beams must be able to withstand temperature fluctuations well, since the difference between the air temperature in the attic and the living space exceeds 4 degrees.

- Impenetrability. The ceiling must protect against the penetration of cold air and moisture from the attic.

When designing, it is important to take into account all the requirements for attic floor beams so that the structure is strong enough, reliable and durable. The distance between the load-bearing elements of the floor must be calculated in accordance with the loads placed on it.

What is an attic

The attic space is limited by the roof slopes and the ceiling of the residential floor. This place is often used to create additional living space.

There are two types of attics in private households:

- Residential . It is called an attic. It can be equipped with a living room, study, bedroom, library, etc. The height of the room in this case should be at least 220 centimeters. In addition, it is necessary to provide ventilation, natural lighting, and insulate the slopes.

- Non-residential . Such attic space is usually used to house technical equipment and store old or unnecessary things. In this case, a 2-meter height will be sufficient, and there is no need to provide natural lighting. Instead of insulating the slopes, they insulate the attic floor.

When making a decision to repair or rebuild a house, you need to decide in advance for what purpose the attic will be used in order to make calculations and a design for the floor. The list of necessary materials and the gap between the beams depend on this. They must provide the required strength and load-bearing capacity.

Attic floor on beams: installation technology step by step

According to the calculation results, the section of the beam is selected. Typically its height is 150-250 mm and its width is 100-250 mm. Sometimes timber is replaced with boards with linear dimensions of 100-250 mm and 40-80 mm. At the same time, savings in lumber are achieved, and the performance characteristics of the future structure are somewhat reduced - however, for the attic floor this is not critical. It is desirable that the height of the beam is equal to the thickness of the calculated layer of thermal and sound insulation.

Features of installing wooden beams

The spacing of beam elements depends on the design load, the selected section and the span length. Typically, the interval between adjacent beams is maintained from 300 to 600 mm, coordinating it with the width of the sheets of the filing.

Wooden floors are made in the following sequence.

1. The ends of parts that will come into contact with concrete or brick are impregnated with an antiseptic and wrapped with roofing felt (waterproofing, plastic film) for a length of up to 300 mm. The end of the beam, previously cut at an angle of 60°, is not insulated, but a distance of about 30 mm is left from it to the wall.

2. To support beams or boards in the walls, make holes 120-200 mm deep. The ends are fixed using anchor ties. On the one hand, these metal parts are attached to the beams, and on the other, they are embedded in the wall.

3. From below, a sheathing of slats with a minimum cross-section of 20 x 90 mm is nailed to the beams, placing them in a perpendicular direction in increments of 0.6 m.

4. Logs are stuffed on top or vertical spacers (38 x 100 mm) are installed between the beams. The second method is preferable: it helps to increase the rigidity of the floor. Wooden spacers are nailed or secured with metal brackets.

Minor floor repairs in old private sector houses, “Stalinist type”

Updating the covering in a private old house, in a country house or in a Stalin building can be done with your own hands and without any problems. In this case, the cost will be much lower than when calling professionals. If only because it is impossible to draw up a preliminary estimate and indicate the price without inspecting the scene. In addition, specialists may, after starting work, find new defects and you simply will not have enough finances. But if the result is still important, and not the cost of the work, focus on a price of $15-25 per m².

Restoring parquet floorboards in an old house is almost impossible, since they no longer make such a product. It’s easier to replace the dies with something new; The damaged concrete base will have to be cut down and filled. You can’t do this without a team; find out the cost of the work in advance, indicating that the service is required in a Stalin building; Rotting of the interfloor ceiling requires contacting the Housing Office - no professionals will take on the work if it does not happen at the dacha. In multi-storey buildings, restoration work is carried out only with the approval of the management company; Small cracks and crevices in the floorboards are sanded, puttied and rubbed

It is important to choose putty and grout with water-repellent properties; Large seams (more than 6 mm) are removed by knocking down the boards. It is necessary to dismantle the covering, check the integrity of the logs, boards and “cushions” made of expanded clay and insulation. After this, start laying the boards

Each subsequent die is attached with a self-tapping screw to the previous one. Leaky boards can and should be replaced.

After this, start laying the boards. Each subsequent die is attached with a self-tapping screw to the previous one. Leaky boards can and should be replaced.

These simple procedures will help to re-lay floors and get rid of defects not only in country houses, but also in Stalinist buildings. Doing simple, easy work with your own hands is a matter of time; for all other problems, the help of specialists is needed.

List of sources

- pol-exp.com

- mrpol.su

- centro-pol.ru

- nalivnye-3d-poly.com

- prorab.guru

- remontsami.ru

- ru-remont.com

- polaremont.ru

- pol-pro.com

- mr-build.ru

Requirements for insulation of attic floors using wooden beams

To ensure that the insulation process does not compromise the integrity of the structure immediately or over time, the materials must meet a number of requirements:

1. Low thermal conductivity. This will allow you to reliably insulate the living area and significantly save on heating.

2. Light weight. Excessive load on the floors can compromise the integrity of the structure or reduce its service life.

3. Do not allow moisture to pass through. This will help not only to preserve the floors, but also to counteract the appearance of pathological flora.

4. Resistance to mold and rot.

Flooring device on wooden beams

Installing wooden floor beams allows you to solve the following problems:

- achieve the required strength and rigidity of the floor;

- ensure that sound insulation and heat transfer resistance correspond to the level necessary for energy saving;

- maintain compliance with established standards for vapor and air permeability indicators.

Selecting beams for interfloor ceilings:

- Floor beams made of timber

. Most often, rectangular beams are chosen for the manufacture of beams. The height of the beam should be in the range of 140-240 mm, and the thickness 50-160 mm. In this case, the rule is followed: the thickness of the beam is at least 1/24 of its length. Professionals note that greater strength is inherent in a wooden beam with an aspect ratio of 7:5.

- Log beams

. Economically more profitable solution. The log has high resistance to loads, but also low resistance to bending. The log is only suitable for use if it has been kept in dry conditions for at least one year.

- Floor beams made of planks

. The use of boards leads to a reduction in the amount of lumber consumed for the flooring device. But it is worth noting that in this case the fire resistance of the ceiling, durability and sound insulation are reduced. Typically, the board is used in the construction of attic floors. To strengthen the boards, you can use the technique of splicing two boards together along their length. Then the total cross-section will correspond to the load level. This design can withstand a load 2 times greater than timber or two boards laid close to each other. In this case, fastening is carried out with self-tapping screws or nails, fixed in a checkerboard pattern in 20 cm increments.

We recommend! Detailed description of wooden floor beams - types, types, calculation of beams for bending, strength and load.

Section of wooden floor beams

Directly depends on the magnitude of the expected load on the beams. The load is divided into constant, created by the floor, furniture, and variable, depending on the number of people and objects on the floor at the same time.

Method of installation of wooden floor beams

Installation of solid wooden beams Installation of solid wooden beams.

In this case, the beams are laid without splicing. To minimize deflection, you need to lay them along a shorter wall. Thus, the number of beams will increase, but the length of each individual beam will decrease.

Installation of reinforced (spliced) beams

Laying reinforced (spliced) beams.

This installation method involves installing a joint on the internal wall of the building.

Laying beams in short runs

Laying beams in short runs.

In builders' jargon, they are called changers. Essentially, these are beams laid perpendicular to the longitudinal beams. Serve to strengthen the overlap.

Scheme for laying beams in short runs

Material prepared for the website www.moydomik.net

It should be noted that the installation of floors using wooden beams will be reliable provided that the correct type of wood is selected. So, hardwoods are not suitable for this type of work. The reason for this is poor bending resistance, but coniferous wood is ideal. The main thing is that it is cleared of bark and treated with an antiseptic solution.

Advantages of wooden floor beams:

- light weight. This allows you to reduce the load on the walls and foundation of the house, simplify transportation and facilitate the installation process;

- the ability to do the work together, with your own hands, without the use of special equipment;

- accessibility and relatively low cost;

- the ability to install insulation;

- high speed of work.

Disadvantages of wooden floor beams:

- restrictions on the length of the covered span. The length of wooden beams does not exceed 6,000 mm, and they can cover a maximum of 4,500 mm. without installing additional vertical support;

- the need for additional protection of wood from rotting, biological destruction and splitting;

- instability. A wooden beam can “play” when people move along it and create additional noise. Additional sound insulation device is required.

Specifications

The main technical indicators that attention is paid to when choosing a suitable equipment model are:

- graph of the dependence of liquid pressure on the amount of liquid supplied to the system;

- power consumed by the unit’s engine from the network;

- coolant performance;

- permissible temperature of the pumped medium;

- dimensions and weight of the device.

The first of the characteristics allows you to understand what volumes of water are pumped by the pump depending on the pressure developed in the system. The higher this indicator, the less water resource must be passed through the unit to obtain the required pressure. To correctly select a sample of equipment, the operating point must be located under the graph curve. When choosing this indicator, it is advisable to ensure a supply margin of at least 20%. Another parameter is directly related to it - pump performance.

The dimensions of the purchased sample and its weight are also taken into account when choosing a suitable model. This also applies to the operating conditions of the pump – the minimum and maximum permissible temperature of the pumped medium. The reliability and durability of the purchased sample depends on the correct selection of this indicator.