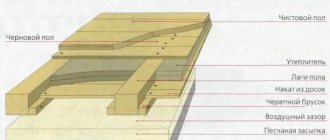

Attic spaces, the frame of which is presented in the form of wooden trusses, are correctly called “cold”. These objects are not particularly durable compared to reinforced concrete structures, but they have their advantages.

Basically they come down to the great possibilities of using thermal insulation materials. A classic attic floor on wooden beams is equipped with insulation using ordinary carpentry tools, unlike reinforced concrete, where special equipment is required.

Insulation of the attic floor, in addition to insulation, requires the installation of proper vapor barriers and exhaust hoods that prevent the formation of mold and mildew. And if you correctly follow the technology when installing insulating material, then air exchange will be guaranteed.

Options for insulating an attic floor using wooden beams

The design of the attic directly depends on the parameters of the building and the purposes intended for the use of this room. The under-roof space plays the role of a kind of air gap separating warm heated rooms from the cold roof.

In this case, the floor in the attic performs two tasks:

Isolating. In the attic of a house, the air temperature is almost no different from the street temperature. In this case, the floors have an insulating function, thereby preventing the penetration of cold air into the living spaces.

Carrier. In most cases, the ceiling on wooden beams between the attic space and the upper floor of the house, like the walls, has a load-bearing function. In this regard, it must be reliable and durable, since people move along it, utensils are stored or any equipment is placed.

Therefore, in order to know the permissible load on the attic floors, it is necessary to make a calculation. Then, based on their results, draw up a project that will show how to properly insulate the attic floor of a building.

Insulation of the attic floor on a reinforced concrete slab

If you need to insulate the attic floor using reinforced concrete slabs, then this can be done in two ways: with or without lathing.

The first method is universal, but is most often used for light types of insulation. The installation of the attic floor of a cold attic in this case will look like this:

- A vapor barrier is carried out on the attic floor of the cold attic, which should cover the entire insulation layer also from the sides. Since the vapor barrier simply needs to be laid on the floor, it is not necessary to use specialized materials for these purposes - ordinary cheap plastic film will do.

- A wooden block with a width equal to half the required thickness that the insulation for a cold attic should have on top of the film with its narrow side The distance between the bars is usually taken equal to the width of the roll or slab of the selected brand of insulation.

- Insulation for the attic floor is laid between the boards . If it is necessary to use several layers of heat-insulating material in thickness, it is laid with overlapping joints of the previous layer.

- Exactly the same ones are attached across the already laid bars , at a similar distance from each other. A second layer of attic insulation is laid between them.

- -permeable cold attic waterproofing is laid on top , which is secured either with a special adhesive tape or with a thin block nailed along the sheathing. This stage can be omitted if high-quality waterproofing of a cold roof made of corrugated sheets has already been performed.

- Floor boards are nailed across the bars or walkways are laid for movement.

Since properly insulating the ceiling under a cold roof is very important to save on heating the house, I recommend using exactly the given transverse diagram for laying thermal insulation. This arrangement of the attic floor minimizes the possibility of a cold bridge forming through the wooden beams, since most of them will be insulated with insulation.

The second method of insulating a cold attic using reinforced concrete slabs without using lathing is suitable in cases where moisture-resistant solid types of insulation that can withstand significant loads without loss of properties are used for thermal insulation.

Scheme of the attic floor installation on a reinforced concrete slab

In this case, the vapor barrier of the attic floor is also installed first. Next, the attic floor slabs are insulated with a layer of thermal insulation of the calculated thickness.

A leveling screed is poured over it. The finished floor is already laid on the screed. If the insulation of a concrete attic floor is carried out with aerated concrete and materials similar in density and properties, then you can do without hydro- and vapor barriers, as well as screeds.

Top ↑

Selection of material for insulation

The technique for insulating an attic is simple, since the material is laid directly on the floor, in the gap between the rafters and wooden floor beams. If you plan to use the attic space as an attic, then you also need to insulate the roof.

To insulate the floor between the beams in the attic, several types of insulation are used:

- Mineral wool.

- Styrofoam.

- Expanded polystyrene.

- Sawdust.

- Expanded clay.

- Foam.

Let's take a closer look at each insulating product.

Polyurethane foam

Its parameters are almost identical to polystyrene foam. It has higher mechanical strength and low toxicity. Available in yellow and orange slabs measuring 120/60 cm. Marked with the letters PPU. This information should be taken into account due to the fact that in trade organizations it is also often called expanded polystyrene, and when ordering by phone, it is worth clarifying what they are selling PPU or PSB-S.

Insulation using polyurethane foam

It’s just as easy to install with your own hands as polystyrene foam. The simplest operations of cutting to size and laying between beams or rafters do not create any difficulties. Laying a vapor barrier layer is not required.

Note

One significant disadvantage of these materials is their low fire resistance. Therefore, it is worth taking a responsible approach to the installation of electrical wiring when insulating the attic floor, so as not to start a future fire in the walls with your own hands.

Special corrugated non-flammable insulation of the electrical wire should be used. When using the attic as a non-residential space, it is enough to apply a fire-retardant coating to the insulation and enjoy the warmth in the house for at least 30 years, proud that it was created with your own hands.

Cost of materials

- Name

- Foam plastic PSB-S-25

- Polyurethane foam Polimer

- Mineral wool ISOVER

- Unit

- sheet

- balloon

- m2

- Price, rubles

- 100

- 400

- 33

https://opotolkax.com/wp-content/uploads/2016/05/utelitel-min.jpg 3072 4551

admin

https://opotolkax.com/wp-content/uploads/2016/04/image-min.png

2016-05-24 16:49:482019-03-06 19:06:51Insulating the attic floor with your own hands

What to do when the LED lamp blinks... How to connect an LED strip to 220

Mineral wool insulation

In order to save heat, the material must be placed between steam and waterproofing films. Vapor barrier protects against moist air masses that form in living spaces near the ceiling, especially at the junction with the walls. The second layer protects the wool from water entering from the roof through microcracks and holes in the roof.

The attic space of a house is insulated most often from the floor rather than from the ceiling of the lower floor. For this purpose, mineral wool is a reliable, inexpensive insulating material with high compression, allowing it to cover the surface of not only the floor, but also beams of various shapes. This insulation is sold in rolls or slabs of different thicknesses.

At the same time, it has the following advantages:

- Budget cost.

- Easy to install.

- Rodents do not grow in such insulation.

- High fire safety of the material.

- Ability to isolate any uneven surface.

At the same time, when working with mineral wool, it is necessary to take protective measures: wear thick clothing, work in goggles and protective gloves, and it is also advisable to use a respirator.

Insulating the attic with mineral wool

Bulk insulation materials

What is attractive about bulk insulation is its affordable cost and relatively easy installation instructions. Plus, all bulk materials are harmless.

But bulk options have 2 common disadvantages:

- Suitable for horizontal floors only . More precisely, there are technologies for filling the same expanded clay into inclined rafter systems, but doing this with your own hands is very problematic.

- The thickness of any backfill is at least 2 times greater compared to cotton slabs or polystyrene.

Bulk insulation has the richest history - people do not know how many thousands of years they have been used. However, it is difficult to say which insulation is better; it all depends on specific conditions.

Let's look at the 3 most popular options:

- clay is baked clay that looks like round granules of different sizes. The material is strong, durable and non-flammable. Quickly absorbs moisture, but also dries quickly.

This is interesting: Insulating the attic in a house with a flat and pitched roof

Among bulk insulation, expanded clay is considered the golden mean.

- Perlite is a porous volcanic rock; the price of perlite is slightly higher than that of expanded clay, but this material absorbs moisture less.

- Sawdust is the cheapest, practically free option, but sawdust must be prepared for a long time before use (dried and impregnated with different compounds), according to technology this takes at least six months, and most importantly, sawdust burns well.

When choosing insulation for backfill, you should not focus solely on price. The difference between the cost of sawdust and expanded clay is small, but the latter will last longer than the house itself.

Styrofoam

Insulating an attic space with polystyrene foam is a good option for converting it into an attic, suitable for year-round use. This material has low thermal conductivity, as it is produced in the form of foamed air granules pressed into slabs.

During installation, the foam must be cut so that the plates fit tightly between the attic floors. Any gaps and cracks become “bridges” for the penetration of cold, and thereby significantly worsen the quality of insulation.

In this case, it is necessary to maintain a distance between the foam board and the waterproofing film of at least 2-3 cm. It is recommended to use it as insulation with a thickness of 70 mm, and in regions with a harsh climate - 100 mm.

Attention! When installing a vapor barrier film, you need to pay attention to the fact that it faces the insulation with the required layer, according to the instructions. Otherwise, the opposite effect will be produced: all the steam will be directed towards the insulating material.

Roof insulation from the inside with foam plastic

Choice of insulation

Before purchasing thermal insulation material, it is necessary to take into account several quality characteristics, including:

- degree of vapor permeability;

- weight;

- strength;

- flammability;

- price.

There are two types of ceilings:

- Made from concrete slabs

. These products do not burn and have high load-bearing capacity. Concrete is considered to have partial vapor permeability. But for slabs this indicator is insignificant and therefore, when choosing which insulation is best for the ceiling, it is customary not to take it into account. - Wooden

. In private households, ceiling structures are often made of wood, which burns well and allows a little steam to pass through. If you block the air supply to the rafters, they will begin to rot over time. In addition, laying flammable insulation on a wooden surface is very dangerous.

One of the main parameters that influences which insulation to choose for the ceiling is where it is installed. This is explained by the fact that the ceiling can be thermally insulated both from the side of the unheated attic space and from the inside of the building.

For the home craftsman, the easiest way to do insulation is in the attic, because in this case there is no need to hem the ceiling from below. In addition, in the case of external installation, you will not have to decide what thickness of insulation is best to use, since there will be enough space in the attic. You can use both bulk material and in the form of slabs. You need to choose insulation for the attic based on your specific situation.

The situation is different with the installation of thermal insulation from inside the room. In private homes, you can’t always find really high ceilings, which means you will need to take every centimeter away from the living space.

As practice shows, property owners rarely decide to lower the ceiling surface by more than 15 centimeters. Accordingly, it is better to use insulation that is lightweight, but at the same time durable and with a low degree of thermal conductivity.

To find out which insulation is better for the ceiling under certain operating conditions, you should analyze information about the materials most often used in construction.

Extruded polystyrene foam

When insulating the ceiling of a living space over attic floors, this material is considered the best option for many builders. This insulation does not cause any difficulties during installation; it can be laid under any beam ceiling.

It also saves space, since you can get by with two to three times less thickness than using the same mineral wool. Extruded polystyrene foam comes in different types, as it is produced by different manufacturers. To insulate attic floors, the density of such material should be about 32-34 kg/m, and its thickness should be from 40 to 100 mm.

Manufacturers also produce shaped elements from expanded polystyrene, which are used to lay out complex fragments in the attic ceiling. It is convenient to install this insulation in two layers: the first layer is laid between the attic floors, and the second layer is applied end-to-end along the bottom row, covering the wooden beams as well.

The main disadvantage of such insulation is that it is flammable. To reduce the fire hazard, you can lay mineral wool with expanded polystyrene, or add antipyrine.

Insulation of the attic with polystyrene foam

Thermal insulation using foam plastic

In terms of popularity, this material occupies a leading position because it is lightweight, accessible and inexpensive. The strength of the foam will be sufficient for arranging insulation. Laying this material does not require special knowledge or high professionalism. But polystyrene foam also has disadvantages - low vapor permeability, and besides this, it burns well.

Is it possible to sew wooden floors with this material from the outside or inside? There is no clear answer to this question. It is undesirable to lay polystyrene foam in a continuous layer on top, because then warm and humid air will begin to accumulate in the wood, resulting in the appearance of fungus and mold.

If you install this insulation on wood from the inside, then air access will be provided from above to the ceiling, but there is no point in clogging the ceilings with waterproofing in a breathable and environmentally friendly house.

In some cases, some craftsmen lay foam plastic between the load-bearing ceiling beams, while others have a negative attitude towards this approach. The fact is that the beam has a minimum thickness of 15 centimeters and, if it is clamped on both sides with this material, it will not cope with the effects of moisture and will become damp.

Taking into account the above information, we can conclude that polystyrene foam is a good choice when you need to decide what kind of insulation to insulate the ceiling both outside and inside, if it is made of reinforced concrete slabs. When the floor is made of wood, the use of this material is undesirable.

Nowadays extruded polystyrene foam, a modern type of foam, is no less popular. It does not allow moisture to pass through and retains heat 30% better. Expanded polystyrene is a more effective analogue of polystyrene foam if it is necessary to insulate a concrete floor from the inside. In this case, you can use sheets of smaller thickness.

In the case of insulating a concrete floor with foam plastic from the inside, slabs with a thickness of 50 - 75 millimeters will be sufficient. If you plan to install external thermal insulation, the minimum thickness of the ceiling insulation in a private house should be 100 millimeters.

Expanded clay

Expanded clay for the attic of a house is a traditional method of thermal insulation of a technical floor. This material is poured between wooden floors with a layer thickness of at least 150 mm. This mass is a universal means that can insulate floor structures, and it can also be used as thermal insulation together with other bulk materials.

Attention! Expanded clay is a fairly light insulation material, but when a thick layer is applied, the load-bearing surface of the ceiling will bear a large load.

Thermal insulation is best carried out at the construction stage of the building, since it is easy to waterproof the ceilings of the rooms under the attic and provide for an exhaust hood.

To do this, cover the ceiling with a vapor barrier film to protect the expanded clay layer from getting wet. It is not recommended to pour it directly onto the floorboards for another reason: during operation and operation of the room, a lot of dust is released, which penetrates into the living rooms.

Expanded clay insulation layer

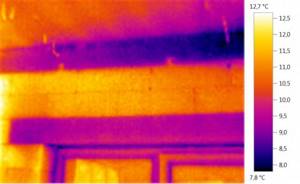

The need for insulation

To make your home comfortable and cozy, it is necessary to maintain a certain microclimate throughout the year. That is, heating in winter and air conditioning in summer.

Heat loss through non-insulated floors can be quite high (the surface is red on the top of the photo).

And in order to spend as little money as possible on this, the home needs to be built using energy-efficient technologies, insulating it with the help of thermal insulation materials. Especially when it comes to a cold attic and the floor separating the basement from the living floor.

There are several groups of materials for this:

- fiber (mineral wool);

- slabs (foam plastic and similar materials);

- bulk (sawdust, expanded clay, etc.).

They all have different technical characteristics, and the installation technology is different. Therefore, in each specific case something specific is used. Let's talk about this in more detail.

Sawdust

Sawdust is a product of lumber processing in the woodworking industry. This is the cheapest insulation for attic floors, since you can buy sawdust at any sawmill for free. Thus, sawdust is still an option as a reliable heat insulator in attic spaces.

On a note! Sawdust is of organic origin, therefore, it is completely harmless to human health. Since ancient times in Rus', sawdust mixed with clay has been used as insulation in attics.

Sawdust has the following advantages:

- Low cost of thermal insulation. Probably, the popularity of such insulation lies precisely because of this factor: its cost is almost equal to the cost of transportation.

- Safety for human health. Wood shavings and sawdust do not cause skin irritation, allergies, or poisoning, which cannot be said with complete confidence about modern insulation materials.

- Low thermal conductivity coefficient. Unlike wood, chips have a porous structure, so they have low heat conductivity.

- Easy installation. To form a heat-insulating layer in the attic floors, no special skills are required. You just need to mix sawdust with clay or lime, and then pour it into the space between the attic floors.

The only significant drawback is the fire hazard of the material, despite the mixture with other non-flammable substances.

Thermal insulation from sawdust

Insulation for attic floors: which one to choose?

Before insulating the attic floor, you need to select a heat-insulating material that is suitable specifically for your case. Unfortunately, there is no universal option for the best way to insulate an attic floor. This choice depends on many factors, the most significant of which are:

- heat-insulating properties of the material;

- fire safety;

- price;

- ease of installation;

- environmental friendliness;

- hygroscopicity;

- strength;

- weight;

- resistance to rotting, temperature, acid and alkali.

You must decide which of these factors are most important to you and which can be neglected.

Top ↑

Insulating the ceiling of a cold attic with mineral wool

Mineral wool is one of the most popular materials for floor insulation. The best characteristics for thermally insulating the attic floor of a house are its type based on basalt fibers, which is called stone (basalt) wool.

Insulation based on basalt fibers belongs to the class of non-combustible materials with a melting point above 1000 °C; and has excellent thermal insulation properties. However, it easily absorbs moisture, so when using it, the requirements for hydro- and vapor barrier are particularly high.

It is better to insulate the attic floor with mineral wool using rolls, since the joints between the slabs, although not much, do reduce the effectiveness of thermal insulation. It must be laid close to the beams or guides, but avoiding jamming.

Mineral wool laid in two layers when insulating the attic floor

Installation of mineral wool is very simple, so this thermal insulation material is most often chosen when they want to insulate an attic floor with their own hands without the involvement of specialists. While working, do not forget to use personal protective equipment: thick rubber gloves, goggles and clothing that covers the entire body. For people prone to allergies, this kit must be supplemented with a respirator.

Advantages:

- High thermal insulation properties;

- Fire safety;

- Environmental friendliness;

- Ease of use;

- Relatively low price.

Flaws:

- Tendency to form compactions, good crushability;

- Hygroscopicity.

Top ↑

Insulating the attic floor with foam plastic

Polystyrene foam is a very inexpensive material, which, in fact, is foamed polystyrene foam and, due to these “bubbles” with air, retains heat. It is cheap, has good heat-insulating properties, is moisture resistant and can withstand fairly large compressive loads.

Foam boards of different thicknesses

However, all its advantages are more than offset by one drawback - this material is fire hazardous. Already at a temperature of 80 °C; polystyrene foam melts, releasing a huge amount of harmful substances, and at a temperature of 210 °C; a fire occurs. Therefore, insulating the attic floor over wooden beams with polystyrene foam is not a good idea. However, it can be used between non-combustible materials, for example, when laid as insulation on a concrete slab with screed poured.

Advantages:

- High thermal insulation properties;

- Low price;

- Moisture resistant;

- Resistant to rot;

Flaws:

- Fragility;

- When heated above 80 °C; begins to release toxic substances;

- Very flammable;

- Deforms already at a temperature of 60 °C;

- It is an excellent refuge for mice.

Top ↑

Insulation of attic floors with extruded polystyrene foam

Extruded (extruded) polystyrene foam is made from the same material as polystyrene foam, but using a fundamentally different technology. In the CIS, the most common insulation materials of this type are from the Penoplex company. The performance properties of extruded polystyrene foam are much better than those of polystyrene foam, especially with regard to the ignition temperature of the material.

Extruded polystyrene foam in slabs of various thicknesses

However, insulating a wooden attic floor with penoplex is still not recommended. Despite the fact that open combustion of this heat-insulating material occurs at a fairly high temperature, it is still a fire hazard. Firstly, extruded polystyrene foam supports combustion, and secondly, it releases very caustic and toxic substances when heated to even very low temperatures, and they are the cause of death in a fire in most cases. Therefore, penoplex is far from a better option than insulating the attic floor of a house, even if it is reinforced concrete.

Advantages:

- High thermal insulation properties;

- Moisture resistant;

- Resistant to rot;

- High density;

- Withstands fairly heavy loads;

- Light weight.

Flaws:

- When heated above 80 °C; begins to release toxic substances;

- Fire hazardous;

- Deforms when heated.

Top ↑

Insulating the attic floor of a house using polyurethane foam

Polyurethane foam boards are one of the best existing insulation materials. This material has excellent thermal insulation properties, it is durable, resistant to chemical and bacteriological influences, non-hygroscopic and fireproof.

Polyurethane foam insulation in the form of a plate with foil coating

Polyurethane foam is the best way to insulate the attic floor in a private home. If you can afford it. The high cost is its main and probably only drawback. Because of this, it may even be difficult to purchase this material in small towns.

Advantages:

- The best thermal insulation properties among the materials considered;

- Fireproof;

- Not affected by moisture and chemicals;

- Does not rot;

- Eco-friendly;

- Convenient to use.

Flaws:

- Price.

Top ↑

Insulating the ceiling of a cold attic with sawdust

Previously, in the absence of other materials, insulating a cold roof with sawdust was a widespread phenomenon. Now this method of thermal insulation is used by those who like its environmental friendliness. At the same time, despite popular belief, the design of an attic floor using such insulation is by no means cheap. Sawdust is not laid “dry”, but in a special solution, the production of which requires money and a lot of time.

The composition of a sawdust solution for insulating a cold attic is as follows:

- 10 buckets of sawdust (you need wood sawdust, which is formed during sawing and processing of wood; furniture sawdust is too small for these purposes);

- 1 bucket of hydrated lime (fluff);

- 1 bucket of cement;

- 5-10 buckets of water with an antiseptic , for example, boric acid, soap or copper sulfate (pour gradually using a watering can, the final amount depends on the size of the sawdust).

The resulting mixture is placed on the base between the beams and compacted. The thickness of the layer of such insulation for the attic floor should be at least 300 mm, but it is better to do more, since the thermal insulation properties of sawdust mortar can vary greatly. Walkways for movement are laid on top of such insulation to cover the attic, for which sheets of chipboard or thick plywood can be used.

Advantages:

- Comparatively cheap;

- Environmental friendliness;

- Good thermal insulation properties.

Flaws:

- Labor-intensive self-production;

- The thickness of the attic floor is large;

- Difficult installation;

- Differences in thermal insulation properties depending on the composition.

Top ↑

Insulation of attic floors with expanded clay

Another relatively cheap material that can be used to insulate the attic floor of a private house is expanded clay. It is made by firing clay and is one of the most environmentally friendly building materials. In addition, expanded clay has good thermal insulation properties, is fireproof, durable and inert to acids and alkalis.

Using expanded clay, you can insulate both reinforced concrete and wooden attic floors. However, in the latter case, you need to carefully consider the calculation of the load-bearing capacity of the beams, since expanded clay insulation weighs much more than modern insulation materials. Concrete attic floor slabs can easily withstand very heavy loads, so expanded clay can be used for them without additional calculations.

A layer of expanded clay insulation placed between the beams of the attic floor sheathing

If the wooden attic floor of a house is being insulated, then the sheathing is first made over the beams and only after that the heat insulator is filled in. Expanded clay is poured in a layer of 250-300 mm and carefully leveled. It is then covered with a floor made of planks.

If you are insulating attic floors made of concrete, then waterproof the floor with self-leveling or coating materials, then expanded clay is mixed with cement and poured with a layer of 350-400 mm.

Advantages:

- Environmentally friendly material;

- Good thermal insulation properties;

- Fireproof;

- Resistant to acids and alkalis;

- Not subject to rotting;

- Durable;

- Low cost.

Flaws:

- Weight;

- Difficulty in installation.

Useful article? Save it on social networks so you don’t lose the link!

Top ↑

Team oprofnastile.ru

Read on topic:

Monolithic slab on corrugated sheets

What are the advantages of monolithic flooring on corrugated sheets? What is its structure and installation technology? How to calculate? Read about all this in the article.

Foam

Recently, two types of insulating materials have become popular for insulating attic floors: blown-in wool and ecowool. The latter material consists of 80% cellulose fibers made from waste paper, and 20% from additives, which are fire-fighting and antiseptic components.

This material has low thermal conductivity, it is very light, and looks like regular polyurethane foam. Both types of insulation are usually sprayed onto the boards between wooden beams, but sometimes ecowool is used in granules in a crumbly state. In this case, this mixture, as an option, is simply poured between the floor beams and compacted.

Foam - insulation for the attic

Installation process

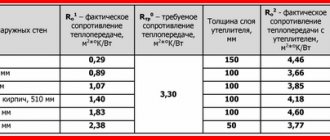

Having decided on the material for thermal insulation, the question arises: how to properly insulate the attic floor? If we talk about mineral wool, what density should it have and what layer of insulation will be best?

Selecting the layer and density of mineral wool

It is better to do insulation with mineral wool in two layers

In short, the larger the layer of mineral wool, the better. However, you need to remember that mineral wool has its own coefficient of thermal conductivity. The lower this coefficient, the higher the thermal insulation properties, and, therefore, it is possible to lay a smaller layer of wool or have greater insulation efficiency. Mineral wool with a thickness of 15-20 centimeters is often used, however, to ensure increased thermal insulation, a 30-centimeter layer of insulation can be used. It is also worth noting that with equal insulation thickness, two layers of mineral wool are always better than one.

You also need to pay attention to the density of mineral wool, because it varies: from 30 kg/m3 to 220 kg/m3. Thermal insulation properties practically do not depend on density. Denser insulation is used for facades and floors under screed. Mineral wool with a density of 35 kg/m3 is also suitable for attic flooring, since the insulation will be located on a horizontal, non-loaded surface.

Vapor barrier

Since mineral wool tends to absorb moisture, you need to start insulation by laying a vapor barrier material.

Vapor barrier - the first layer of insulation

Important! It is best to lay a layer of vapor barrier under the wooden beams, because otherwise they will be very susceptible to rotting. However, if it is impossible to install a vapor barrier film under the beams, they need to be impregnated with solutions that protect against rot and mold.

The best option is to lay a continuous layer of vapor barrier, but due to the size of the attic this is not always possible, so all joints must be taped with special tape to ensure tightness. The edges of the vapor barrier must be raised above the level of the future insulation and taped with the same tape.

Thermal insulation

When working with heat-insulating materials, you need to wear special clothing

Next comes the installation of insulation. It must be laid so as to completely fill the entire space between the wooden beams. If we are talking about mineral wool, then it does not need to be pressed or squeezed. It should completely cover the space between the beams, leaving no cracks or gaps. It would also be a good idea to cover the floor beams themselves with heat-insulating material, because they can serve as a kind of cold bridges.

When laying mineral wool, it is very important to protect yourself, and especially your respiratory tract, from insulation fibers. Therefore, you need to use a respirator, as well as gloves, goggles and long sleeves.

Waterproofing

We complete the insulation of the attic floor with waterproofing and subfloor installation

Due to the property of mineral wool to absorb moisture, waterproofing must be laid over the layer of mineral wool. This is also necessary if a concrete screed will be poured over the insulation.

If the attic is constantly used, a subfloor can be made on top of such a heat-insulating “pie”. Its role can be a concrete screed or OSB slabs. If the attic is practically not used, then you can simply lay boards on top of the existing beams. Then, if necessary, go up to the attic, moving around it will not create difficulties.

As you can see, insulating the attic floor is an accessible task, even for those who have never done it. You need to decide on the material for thermal insulation, although most often it is mineral wool. When installing a heat-insulating “pie”, it is important to remember the need for vapor barrier and waterproofing. This will allow you to achieve high results in insulating the attic floor.

Vapor barrier

The vapor barrier film protects wooden beam ceilings from moisture formed in the air of residential premises. In addition, it protects floors from the appearance of mold and mildew in the insulating material.

Regardless of how the attic floor is made, the vapor barrier for the floor should form a continuous carpet that does not allow condensation to penetrate. Particular attention should be paid at the joints with walls, where there is a high probability of condensation penetration. To do this, the covering film is overlapped and its edges are glued together with tape.

Vapor barrier under insulation

Option No. 1 – foam insulation

The work of laying this heat insulator is not difficult:

- Concrete slabs generally have a flat surface, so surface leveling problems rarely occur. All you have to do is putty the joints between the plates, or better yet fill the cracks with polyurethane foam.

- The next step is to apply a deep penetration primer to the ceiling twice. Since smooth concrete has low adhesion, without this treatment the required effect will not be achieved.

- Next, they take pre-prepared sheets of insulation, spread them with adhesive and apply them to the ceiling surface. Many craftsmen place them without gaps, as densely as possible. But there will still be gaps between the sheets, so they are initially glued with a gap of 5 - 7 millimeters. Then the gaps are filled with foam, the coating is continuous.

- But polystyrene foam should not be left in this state, since it is a flammable material and the ceiling looks ugly. Its surface needs to be plastered. To do this, apply a layer of Ceresit CT83 3–4 millimeters thick with a spatula and immediately embed a reinforcing fiberglass mesh in it.

- Next, to be on the safe side, the foam plastic is additionally secured with umbrella dowels, which requires a hammer drill. A hole is drilled in the concrete through the thickness of the ceiling insulation, a plastic dowel is placed in it and the central rod is driven in. For one square meter of such fasteners you will need 5 pieces.

When everything is dry, begin applying the decorative finish. If you don’t want to use Ceresit CT8, you can use any starting plaster, but before doing this, the foam should be primed.

If the ceiling is to be insulated with this material in a wooden building, then the insulation is laid between the load-bearing beams to their entire depth and the gaps are foamed. The ceiling is hemmed from below, and it is better to fill the subfloor on top, since you will have to move around the attic. In this case, installation of a vapor barrier is not required, since moisture is not dangerous to the foam.

Despite the fact that there is a large selection of adhesive compositions on the construction market, experts most often use the following three options:

- "Liquid Nails"

. High-quality glue, but the process of applying it is not easy and therefore when using it you need to follow the instructions. - Polyurethane foam

. A pattern of it is applied to a sheet of foam plastic. Then they apply insulation to the ceiling. Next, the sheet is pressed against the surface several times over the course of an hour, since the foam expands and until this process is completed, the material will move away a little. - Dry mix Ceresit CT83

. It is simply diluted according to the instructions, applied to the sheet using a notched spatula and glued. If such a tool is not at hand, it is necessary to lay “buns” at several points and attach the insulation.

Insulation technology

To apply the insulation correctly, follow the step-by-step instructions:

Step #1 . Carry out an inspection and, if defects are found, eliminate them. Treat boards and timber with antiseptics and fungicides.

Treatment of attic floors with antiseptics

Step No. 2. Lay out the vapor barrier material, seal all gaps with mounting tape.

Attic vapor barrier

Step No. 3. Lay (pour) insulation into the openings of the wooden floors on the floor.

Laying insulation in openings

Step No. 4. Pay special attention to the joints between the slabs of insulating material. If necessary, apply additional insulation.

Step No. 5. Lay the waterproofing film overlapping, and fasten the joints with mounting tape.

Attic waterproofing

Step No. 6. Separately install insulation on the ventilation duct, chimney pipes in the form of basalt wool, perlite, and it is advisable to install a special corrugation on top.

Insulating the air duct in the attic

Basic requirements for attic floors

The main quality that any attic floor must have is strength. If we are talking about an attic roof, then the entire structure should not sag or deform under the weight of furniture or equipment located in the attic. There is such a thing as deflection norm. For attic structures it is 1/200 of the entire span. The maximum load per square meter is 105 kilograms. Another equally important parameter of the ceiling is fire safety, which applies to a greater extent to wooden structures. So, fire resistance has the following limits:

- for concrete or reinforced concrete structures it is 1 hour;

- for wooden structures (in the absence of additional protection) – five minutes;

- for wooden flooring on beams, with backfill and plaster - about 45 minutes;

- for wooden floors with only one plastered surface - 15 minutes.

Installation of wooden attic beams

The attic ceilings are designed to separate the living rooms from the under-roof space. They do not allow cold air to pass through, so the main task is their thermal insulation. Various equipment is also often installed in the attic.

In this regard, another important task is to create a solid foundation that can withstand this load. Thus, the safety of people, their comfortable living, and also the durability of the structure depend on the high-quality arrangement of wooden floors.

Installation of floors under insulation

Slab insulation

Now I’ll tell you about another category of insulation for floors - slab. I also often encountered them in the process of work. They are especially popular among novice builders due to their ease of installation.

Slab insulation boards are excellent for thermal insulation of floors.

When you start talking to someone about slab insulation, you immediately hear mention of polystyrene foam. And everyone, using this term, imagines a porous and light material from which every boy built a boat in childhood.

However, in fact, foam plastics are a whole group of insulating materials made from polymer foam. Specifically, for insulation of floors in construction, two types of foam plastics are used - polystyrene foam and polyurethane foam. I will describe them in more detail below.

Expanded polystyrene

A fairly inexpensive insulation material that is sold in every hardware store and is used in almost every second construction project. Expanded polystyrene is made from a special polymer, but different technologies are used for this. As a result, there are several insulation materials on the market, the technical characteristics and performance properties of which are quite different.

Pressed polystyrene foam is a classic of the genre.

You can learn more about this from the table.

| Name | Reduction | Properties |

| Pressless suspension | PSB | A material with a uniform internal structure and varying densities, which determines its performance properties. There are grades of polystyrene foam from 15 to 50. The lower the density, the greater the heat-retaining properties, but the worse the strength. For insulation, it is better to buy material marked PSB-S, which extinguishes during a fire and does not contribute to the spread of the flame. |

| Pressed polystyrene foam | PS | It is characterized by increased hardness, strength and hydrophobic properties. Unlike the previous version, this insulation does not have a capillary system, and the granules are compressed. It is rarely used for insulating floors, as it has a high cost. More suitable for the manufacture of multi-layer insulating panels. |

| Extruded polystyrene foam | EPPS XPS | The most effective slab insulation I know. It is manufactured using complex technology, when the foamed raw material mass is pressed through special devices, forming heat insulator slabs. The material has a low thermal conductivity coefficient and high strength. It can be laid under a floor screed without supporting joists, that is, to insulate those floors that will serve as floors. |

Extruded polystyrene foam is a material with excellent technical characteristics.

Polyurethane foam

Typically, polyurethane foam is applied to surfaces using a spray gun, but I have also come across slabs made of this material on the market for thermal insulation materials. They are soft, elastic and hard. The density of the insulation is in the range from 20 to 200 kilograms per cubic meter, that is, the heat-retaining properties are different.

Sheet polyurethane foam is an alternative to spray foam.

Slab polyurethane foam has a closed cell structure, so it is not afraid of moisture. However, it does not withstand direct exposure to sunlight and disintegrates.

But other technical characteristics are excellent:

- the material has a zero emission level of chemical compounds, therefore it is safe for health;

- not subject to biocorrosion;

- tolerates mechanical stress well.

Advantages of slab insulation

The biggest advantage of this category of heat insulators, in my opinion, is the ease of installation and its speed. This reduces the cost of insulating floors and shortens construction time.

Slab insulation is easy to use in private construction.

On the other hand, they cannot be laid on the floor without seams, which often cause unproductive heat loss. However, if you strictly adhere to the technology (I have repeatedly described methods of insulation using polystyrene foam and EPS), this problem can be avoided.

But there is another category of insulation that is ideal for thermal insulation of horizontal floors (including the attic and basement). About them - in the next section.

Insulation materials

Various thermal insulation materials can be used as interfloor insulation for a wooden house:

- glass wool;

- basalt wool;

- slag;

- Styrofoam;

- penoplex;

- expanded clay;

- foamed polyurethane;

- shavings, sawdust.

The choice is based on the availability of the material, its cost, and characteristics. Thus, mineral wool and expanded clay are the most acceptable from the point of view of fire safety. At the same time, penoplex does not absorb moisture, does not cake, and has high thermal insulation properties. Sometimes materials are combined to increase thermal protection.

Various types of cotton wool

Most often, various types of construction thermal insulating mineral wool are used to insulate interfloor ceilings. They are made by melting and drawing fibers from raw materials. These fibers are then intertwined on special machines and formed into mats or rolls. In some cases, such mats or rolls are stitched with synthetic threads to increase the strength of the products.

For glass wool, the raw materials are waste and waste from glass production; for mineral wool and basalt wool, igneous rock melts are used. Slag is produced by melting blast furnace slag.

Different types of cotton wool have different properties. They have different densities and different thermal conductivities. These characteristics depend not only on the type of feedstock, but also on the specified production parameters.

Foam plastic and penoplex

These are two similar materials in properties and production method. The starting materials for their production are plastics of various compositions. During the production process, they foam and, when hardened, are formed into sheets of the correct geometric shape. The difference lies in the fact that during formation, penoplex is extruded through a special device - an extruder.

Both foam plastic and penoplex have closed pores filled with gas in their volume. Only in polystyrene foam it is ordinary air, and when foaming polystyrene foam, carbon dioxide is usually used. In terms of thermal conductivity, both materials are almost identical. But due to the fact that the pores in the penoplex mass are distributed more evenly and they themselves have almost the same size, its strength is much higher.

Very often, when forming sheets of penoplex, their ends are not made even, but in the form of two or more ledges. When insulating, two adjacent sheets, connecting to each other during installation, provide better insulation, since the joints are not blown through and retain heat well.

Expanded clay

Expanded clay is a building material that consists of many oval granules - pellets with an average diameter of 10 to 20 mm. The material of these granules is clay and shale sand. The pellets themselves are obtained by firing pre-prepared semi-finished products in special ovens. When heated, pores of different sizes appear in the volume of expanded clay, as a result of which it has a very low density. One cubic meter of bulk expanded clay can weigh only 300 kg. For comparison, it can be noted that one cubic meter of pine wood weighs 500-550 kg at natural humidity.

Note! Expanded clay is an environmentally friendly material. It is durable and will not rot or decompose.

Polyurethane

Foamed polyurethane is used, as a rule, for insulating basement and attic floors. It is simply applied using special equipment, and later it foams in air and takes on a three-dimensional shape. The advantage of using such material is that it fills all the leaks and cracks in the ceiling structure, allowing you to create a sealed water- and windproof thermal protection.

Sawdust

Wood shavings and sawdust have recently been used much less frequently, but more recently they have also been used to insulate interfloor ceilings, filling the cavity between the beams. To prevent such insulation from rotting inside the ceilings, it is treated with special compounds that kill putrefactive bacteria and woodworms. When laying, shavings or sawdust are mixed with lime.

Vapor barrier

To properly insulate interfloor ceilings, it is not enough to use only materials with thermal insulation properties. If you do not protect the insulation from the action of moisture located in the interior of the premises, various microorganisms will multiply in the material, which can subsequently lead to mold or mildew. To avoid this phenomenon, it is necessary to make the correct vapor barrier for the insulation.

Any of the many options produced by industry can be used as a vapor barrier. Ready-made protective membranes are very widely represented on the building materials market. When building and insulating a private house with your own hands, you can use available materials if you know their strength and vapor barrier properties and use them correctly.

As the main layer, the coefficient of vapor permeability of which should be minimal, you can use ordinary polyethylene film or foil. This layer is laid below the insulation, preventing moisture vapor from the basement or lower floor from penetrating into it.

As the second layer, which will be on top of the insulation, you can use wax paper or glassine. These materials have greater vapor permeability than foil or polyethylene. They will facilitate the free release of vapors from the thickness of the insulation upwards.