Application

The scope of expanded clay is very wide. Products of this type are used for the following purposes:

Production of expanded clay blocks;

Sound insulation and insulation of such elements of buildings and structures as roofs, walls, foundations, floors;

Production of “warm” solutions for masonry work;

Arrangement of drainage elements when growing plants;

Pipeline insulation;

Purification of water from various impurities (filtration).

Depending on the type of work and the nature of the problems that need to be solved by using expanded clay, the material of the most suitable fraction is selected. Thus, expanded clay sand, the diameter of the granules of which does not exceed 3 millimeters, is widely used for the preparation of “warm” masonry mortars. This is explained by the fact that the seams are considered the weakest link in terms of thermal resistance. And if a “cold” solution of cement and sand has a high level of thermal conductivity, then replacing it with expanded clay reduces the heat transfer coefficient by almost 3.5 times.

Material fraction 0-5 millimeters is mainly used when making screeds. The use of expanded clay for these purposes makes it possible to create a floor that retains heat much more effectively. The material of this fraction is also used as a filler in the process of manufacturing concrete products for various purposes, when arranging hydroponic and drainage systems in crop production.

Expanded clay gravel, the granule diameter of which is 5-10 millimeters, is one of the most popular. It is used as backfill for gypsum fiber sheets in the process of installing “warm” floors made using German technology, as well as for insulating building facades. In the latter case, expanded clay gravel is mixed with the required amount of cement, after which the resulting composition is poured into the space between the cladding layer and the surface of the load-bearing wall. This thermal insulation is called “capsimet”. Expanded clay of a fraction of 5-10 millimeters is widely used for the manufacture of various concrete products, for example, the resulting material is in the form of building blocks, which have all the advantages of this natural material.

Gravel of a fraction of 10-20 millimeters is an excellent insulation for walls in well masonry, for wooden floors, and roofs. It is also used in the construction of sewer systems, water pipelines and other communications.

A distinctive feature of expanded clay with a granule diameter of 20 to 40 millimeters is its low bulk density compared to gravel of other fractions. In this regard, it is often used as insulation for filling attics, cellars, and foundations, since in such cases there is a need to obtain a large heat-insulating layer. Expanded clay of this fraction is also considered the optimal choice for arranging drainage systems when planting fairly large shrubs and trees.

Scope of use

The parameters listed above allow it to be used in the manufacture of blocks. Used for backfilling walls and floors. Drainage and thermal insulation properties have led to the fact that expanded clay is successfully used in agriculture and households, in the construction of hydroponic systems, decorative coatings, and drainage.

Road construction cannot do without it. It has the qualities necessary for constructing earthen embankments. Especially when it comes to sections of the road with water-saturated soil. Backfills made on its basis are excellent for strengthening construction dams, piers, and bridges.

Widespread in private construction. Used for insulating attics, floors, attics. Suitable for foundations and cellars. Now you know what expanded clay is, what it is used for, and how it is made.

Answers from experts

Leka+:

In addition to expanded clay and brick chips, you can use small pebbles (aquarium grade), shells (if you suddenly have a bunch of unnecessary ones from the holidays), you can simply break old clay pots or unnecessary cups and plates. For very small plants and small pots, you can use coconut fiber or pieces of natural loofah or sisal sponges and pieces of natural sponge. And as a temporary measure (while the cuttings are rooting, while the seedlings are growing) - even pieces of polystyrene foam

A.T.:

Broken brick!

In large pots, when the root of the plants is small, then half of it, sometimes even more, is filled with cones

Galina Zelinskaya:

Crushed RED brick, expanded clay

Irina:

If the pot is large, but expanded clay or bricks are not at hand, then you can use used tea bags. which should be placed on the bottom of the pot in one layer.

Marina Chepurnaya:

expanded clay, foam plastic

Nina Tuzova (Kvashnina):

pistachio shells. advised. but I haven't tried to do that myself

Elena Protopopova:

Bricks, pebbles, old shards, etc. WASH ONLY!!!

Anna Glivatskaya:

You can use walnut shells, just pre-treat them in a manganese solution

Ms. Flora:

And also pine bark, it is useful not only for orchids, as an antiseptic, but it is good to put it on the bottom or in the soil. It both disinfects and drains.

Maximka:

Why shells? Not all plants need this lime. Shards, expanded clay and even pieces of foam.

avmir:

Broken brick, crushed stone, expanded clay, but not shells. And generally avoid limestone, chalk, and gypsum.

Tane4ka:

I don't think shells are a good idea. Sea salted ones need to be washed, washed, washed. Again, the edges are sharp and the roots may get cut. And they will alkalize. Expanded clay or small stones are better.

Clementine Lady:

I like expanded clay as drainage. Lightweight, washes well when replanting, does not injure the roots, there are large ones and small ones, for any holes in the pot. I didn’t notice any disadvantages when using it.

Irina K:

You can use coals from a fire

Irina Smirnova:

I like to use pebbles and gravel. Easily found on the street, in any size. Then just wash it thoroughly and put it in the bottom of the pot. Excellent drainage is obtained. Sometimes I use expanded clay, but not all plants like it. For example, I have adeniums. They do not tolerate expanded clay. As soon as the roots in the pot grow to the expanded clay drainage layer, the leaves immediately begin to turn yellow and drop. For a long time I struggled with the problem of yellowing leaves, until someone here on “ANSWERS” told me that I need to give up expanded clay for adeniums. I replaced the expanded clay drainage with fine crushed stone - everything was fine. Well, Adena doesn’t like expanded clay...

Photo Lady:

I always place one large flap of flat shell in the center of the drain hole. So that the roots don't get out there. In general, all my pots have many holes, so the bottom layer is pebbles, very large bark (I have mostly orchids, but there are others), large pieces of charcoal, and then the necessary soil or substrate. Pebbles are also needed to weigh down small pots. In large plants I put a pebble in each hole. at the bottom of a huge pot. The water drains, but the earth does not wake up.

tsuatsua tsautsautsa:

It is better to do drainage s polyfacture /catalog/livnevaya-kanalizatsiya/ correctly and efficiently, so that the flowers are watered constantly, then there will be no problems, this is called storm drainage.

Application of expanded clay in agriculture

According to most farmers, the material is the best drainage and substrate for crops grown hydroponically.

Expanded clay absorbs moisture when watering and releases it when the soil dries. Quite often, crushed stone and sand are added to optimize air exchange between the plant and the air environment in heavy clay soils.

Drainage, which is based on expanded clay, does not allow the soil to become acidic or silt. At the same time, the material does not weigh down the soil and prevents the formation of mold, moss and fungi.

The material showed itself remarkably well when constructing beds. A layer of 2 - 3 cm poured into its base provides excellent drainage. Gravel scattered between plants retains moisture, performing a mulching role.

Expanded clay has a hard outer shell and a porous core, which makes it a unique organic substrate for hydroponics, a complete soil substitute.

Tips and tricks

Before using the material, you need to familiarize yourself with the basic recommendations:

- It is recommended to choose insulation in a situation where, for example, there is a need to fill the voids between the cladding and the load-bearing wall in a garage adjacent to the house.

- By filling with expanded clay, it is possible to almost halve the depth of the base and prevent freezing of the soil that is in contact with the base. It must be remembered that direct freezing often provokes misalignment of windows and doors.

- The material is effective during the construction of a bathhouse. The use of such wall insulation will help retain heat inside the room much longer.

- Expanded clay is effective in arranging heating networks. The heat from the pipeline will go into the home, and not into the ground. In the event of an accident, you will not need to dig for a long time to find the damaged part of the highway.

- Expanded clay concrete will be an excellent solution for summer cottages. In country houses, the material can be used as a construction material, as well as to arrange paths inside the yard.

Expanded clay is a material with a wide range of uses. It effectively retains heat inside any room. At the same time, such material does not have a negative impact on the well-being of residents and on the environment.

Role in the construction of wooden houses

Can be used at every stage of construction. Thanks to its high thermal insulation and sound insulation parameters, it is excellent for protecting the foundation from freezing during the cold season. And this, in turn, avoids skewing of the building.

To insulate a wooden house from the inside, the material is poured under the ceiling of the lower floor. Helps improve the microclimate not only inside the basement, but also inside the entire house. Reliably protects the lower part of the building from the negative effects of condensation and groundwater.

The formwork deserves special attention. To build it, you need to dig a ditch 2.5 meters deep and 30-40 cm wide. The outer side of the ditch is covered with formwork made of boards or slate. The space formed between the foundation and the formwork is filled with expanded clay. This method allows not only to reduce the depth of the foundation, but also to insulate the building.

Due to the fact that this material absorbs moisture, it should be covered on both sides with a special waterproofing layer. Most often, workers use rolled waterproofing materials, laying them using the overlapping method. To process joints, mastic, tape, and bitumen are used. Sand is poured onto the waterproofing layer and carefully compacted.

If you are thinking about why expanded clay is used in construction, then it is worth noting that it is widely used in arranging the floors of wooden houses. This is an economical option. It can be combined with other materials: mineral wool, expanded polystyrene.

It is enough to lay out a layer 10-15 centimeters thick and heat loss in the room will decrease by 60-70 percent. Quite often used in screeds or when laying self-leveling floors. A polyethylene film is laid on the base. Expanded clay is carefully scattered onto it. In order to get the most even surface possible, you should install beacons and navigate by them when laying the floor. When laying self-leveling floors, fine-grained material is excellent.

Expanded clay gravel is indispensable when making sand-cement screed. With this technology, the entire floor area is carefully divided into sections using slats. The slats are set according to the level. After this, expanded clay is poured into the resulting space. A sand-cement screed is laid on top of the flooring. This coating has excellent thermal and sound insulation. Another advantage of such a screed is the absence of a dew point. This means that the moisture content in its composition does not depend on the material underlying the floor.

In conclusion, it is worth noting that expanded clay is one of the few universal building materials today. But, before buying it, you should make sure that you are offered truly natural material. The fact is that some manufacturers, in an effort to reduce costs, resort to various chemicals. This approach negatively affects quality. In order to determine the level of quality, just look at its appearance and check for a quality certificate.

Main advantages

Characteristics that contribute to the spread of expanded clay in modern construction:

- Long operational period. It differs from similar products in durability. Even after a large amount of time it will retain its original operational, quality parameters;

- Excellent thermal insulation and sound insulation properties. Does not let cold air into the room, reliably protects from extraneous noise;

- Fire resistance. Practically does not burn;

- Frost resistance. Withstands extremely low air temperatures;

- Possesses chemical inertness. It is not destroyed by acids.

Expanded clay – granules you can’t do without

The lower this indicator is, the more porous the expanded clay is, and, therefore, it will have higher thermal insulation properties; it is much lighter, but due to this, its degree of fragility will sharply increase, as a result of which denser expanded clay from 410 kg per cubic meter is used for construction.

Moreover, the material will differ in size, fraction 0, for example, from 0.8 to 2 cm or t 0.4 to 1 cm. Based on this size, products should be divided into sand, crushed stone and even expanded clay gravel. Expanded clay gravel will be familiar to us, and at the same time, expanded clay crushed stone has gained enormous popularity in Europe - it is angular in shape and has dimensions from 0.5 to 4 cm.

This product is obtained by crushing the expanded mass of expanded clay. Expanded clay sand will be a filler, the particles of which have a size of 0.01 to 0.4 cm. Sand is obtained by burning clay fines in shaft or even rotary kilns, by crushing large pieces or the main expanded clay mass. This is practically industrial waste, which is still used in business.

Properties of expanded clay

Also, the products are absolutely safe for humans and the environment. Expanded clay is a quickly fired product for low-melting clays. From Greek, a word such as “expanded clay” is translated as “burnt clay,” and this will fully correspond to reality. Despite the heat treatment, it will not lose the properties that are inherent directly in the clay, but will also acquire additional ones and become porous. Based on them, it is possible to make expanded clay concrete blocks, the mechanical and thermal insulation properties of which make it possible to use them for the thermal insulation construction of walls, floors, ceilings, foundations and basements. Thanks to expanded clay filler, such blocks also acquire its properties. They are durable, lightweight, fireproof, acid resistant and more.

Technical properties

| Indicators | 0.8/2 cm | 0.4/1 cm | 0/0.4 cm |

| Bulk type density, kg per cubic meter | From 280 to 370 | From 300 to 400 | From 500 to 700 |

| Crushing strength, N/mm2 (Mpa) | From 1 to 1.8 | From 1.2 to 2 | From 3 to 4 |

| Frost resistance 20 cycles, loss of gravel mass, % | From 0.4 to 2 | From 0.2 to 1.2 | Not regulated |

| Percentage of crushed particles, % | From 3 to 10 | From 3 to 10 | No |

| Thermal conductivity, W/mK | 0.0912 | 0.0912 | 0.01099 |

| Water absorption, mm | 250 | 250 | 250 |

Scope of expanded clay use

So, you know about all the properties of expanded clay, and one of the main uses of the material is as a filler for lightweight concrete. Monolithic walls are erected from this material, and rough screeds are also poured. This will be especially true when you need to lay a screed of an impressive size, however, you cannot overload the ceiling. Expanded clay makes it possible to reduce structural weight and its cost. The construction of expanded clay concrete walls will provide high sanitary and hygienic characteristics, and they are also durable and at the same time have an affordable cost.

Moreover, expanded clay is also used as insulation, but it must be a highly porous material, and before using it as a backfill insulation, you will need to perform not very complex calculations, but only accessible to specialists. Regarding its capabilities in terms of thermal savings, we will only say that as a backfill option it will be inferior to other insulation materials. The estimated thickness of a backfill made of expanded clay with a density of 600 kg per cubic meter is approximately 0.4 meters. This is not effective at all.

At the same time, when used in the manufacture of expanded clay concrete blocks, it will significantly increase their heat-saving characteristics. Expanded clay will also be actively used when constructing dry screeds. Nowadays this method is extremely popular because it allows you to obtain a solid base for linoleum, laminate, and cork in a short time, literally in 1 day. Due to its unique characteristics, including immunity to frost and moisture, it is actively used for pouring foundations during the construction of various structures and buildings. This will make it possible to reduce the depth of the foundation by almost a couple of times - from 1.5 meters to 0.8 meters, and this will lead not only to savings in building materials, but also to the prevention of freezing of the ground near the foundation of the building. By the way, the latter will be fraught with distortion of doors, as well as window frames in the building.

About strength, stability and additional features

This material has deservedly gained wide popularity not only among builders, but also farmers and landscape designers. What are the main advantages of expanded clay?

- High strength. Expanded clay is durable, so it can be used repeatedly.

- Good sound and heat insulation.

- A light weight.

- High frost resistance (25 cycles or more) and fire resistance.

- Chemical inertness and acid resistance. Expanded clay is resistant to chemically aggressive environments.

- Low water absorption (no more than 20%). Expanded clay prevents moisture from evaporating and thereby controls the water balance of the plant.

- Environmental friendliness of the material. Expanded clay does not contain harmful additives, so it is safe for health.

- Presentable appearance. Small pebbles of expanded clay fit perfectly into the design of any flower garden. They look natural, are barely noticeable and do not overshadow the decorative plants.

- The optimum ratio of price and quality. The material is already inexpensive, but if you don’t throw it away after the first use and reuse it, then it will cost mere pennies.

Thanks to these properties, expanded clay is used as insulation in the construction of garden buildings (for floors, walls, roofs, basements) and as a mortar filler for foundations. And also during the construction of garden paths. This is especially true in areas located in wetlands.

A special pillow is made from expanded clay, which forms a dense layer and withstands strong pressure

But most often expanded clay is used in the garden, vegetable garden and landscape design. It serves as insulation and drainage for the roots.

Expanded clay gravel provides plants with comfortable growing conditions: it improves the structure of the soil, making it air- and water-permeable, protects plant roots from drying out in hot weather and mold from forming in rainy weather, reduces the risk of plant diseases, as well as the appearance of various pests.

Mulching with expanded clay increases the productivity of fruit, berry and vegetable crops

Expanded clay can also be used when growing various crops in hydroponics.

- When planting trees and shrubs, dig a hole, pour expanded clay gravel into the bottom, and on top of it - a small layer of soil on which to place the seedling. You need to sprinkle the seedling with a little earth on top, and fill the remaining space of the hole with expanded clay. This method is called layer-by-layer.

- Simply mix small (about 5 mm) expanded clay with soil and plant the plant in the resulting mixture.

Fine-grained expanded clay can also be used in the garden for mulching. This will help protect the soil surface from mold, as well as reduce the number of waterings and retain moisture in the soil for a long time.

In gardening, expanded clay is widely used for drainage under apple trees, pears, currants, grapes, etc.

Expanded clay not only brings great benefits to plants, but also performs a decorative function in the flower garden. Using this material, you can fill the resulting space in rock gardens and rockeries, and also, by filling in the holes, level the surface.

If traditional brown material seems boring, use decorative expanded clay painted in various colors

Now you know how to inexpensively increase soil fertility, relieve plants from stagnant water and poor air circulation, and create an attractive flower bed. Have a rich harvest and beautiful ornamental plants!

The high strength of the material allows it to be used as a filler when pouring concrete and making expanded clay blocks. Expanded clay concrete is used for the construction of structures for various purposes, be they residential or industrial. This speaks of versatility.

Expanded clay acts not only as a construction material, but also as an insulation material. It has a low moisture absorption coefficient and is characterized by durability and ability to withstand low temperatures. Frost resistance allows its use in northern regions where thermal insulation properties are in demand. It is also recommended for use as drainage, because the material has a low absorption coefficient and moisture resistance.

Disadvantages of expanded clay in construction

- High water absorption of some types of expanded clay.

Expanded clay made by dry crushing, the pores of which are open, absorbs moisture and liquid well. This material can be distinguished by its rough surface with visible and open pores. Quickly absorbs and releases moisture for a long time. In this case, the properties of the material as insulation are lost. Such expanded clay, nevertheless, can be used as insulation, but for this it is necessary to provide a moisture-proof and vapor-proof layer. - Eats up space. For effective thermal insulation and sound insulation, it is necessary to lay a layer of expanded clay of at least 10 to 15 cm. For some structures, a layer of expanded clay embankment is recommended up to 30 cm. It eats up a lot of area

- Not suitable as insulation for regions with high humidity, long and cold winters. This material is more likely for the southern territories, where there is a drier climate and short, fairly warm winters. In order to insulate a room in harsh conditions of negative temperatures, a layer of expanded clay up to one meter is required. In such conditions, alternative materials such as mineral wool or expanded polystyrene will be most effective.

- Dusty material. expanded clay dusty material

Varieties of expanded clay

Expanded clay is produced in the form of such fractions as:

- gravel;

- crushed stone;

- sand.

The scope of each type is quite wide. The material is also divided by density. This parameter represents the ratio of the weight and volume of the granules. Thus, the M300 brand of expanded clay has a density of 300 kg/m³, and M400 – 350-400 kg/m³

It is important to consider that the lower the grade of the material, the higher its quality

The properties of expanded clay also include strength, which is divided into grades P15-P400. In this case, a high grade of material means high-quality products and the raw materials from which they are made. Strength and density are directly proportional indicators, therefore expanded clay M400 should be no lower than P50 in terms of strength parameters.

According to the table of qualities of materials for insulation, the thermal conductivity of expanded clay is low even in comparison with foam plastic and mineral wool. The calculation of the indicator is influenced by such characteristics as:

- fraction;

- humidity;

- porosity of granules.

Thermal conductivity ranges from 0.7-0.16 W/m. Comparison of the indicator with brick shows that the material conducts cold 2-3 times worse. After all, the lower the thermal conductivity coefficient of expanded clay, the higher its thermal insulation characteristics.

Clay absorbs moisture well, which leads to loss of thermal insulation properties. And an increase in weight puts additional stress on the floors

Therefore, it is important to do high-quality waterproofing to prevent water from penetrating into the insulation. However, it has a low moisture absorption coefficient, which distinguishes it from other natural thermal insulation materials

If expanded clay is used for insulation, its characteristics must be high to provide high-quality protection from the cold.

Expanded clay gravel

Gravel is the largest fraction. Its granules have a size of 20-40 mm. Such large material is used as an insulating layer on roofs, basements, garage floors or in the construction of heating mains. This fraction of expanded clay has the lowest thermal conductivity and the highest strength.

Crushed stone or gravel is used to insulate floors, walls, and ceilings, since they are fairly large fractions. To fill the voids that form between the granules, material from both fractions is mixed. This allows not only to increase the density index, but also the thermal conductivity of the insulation layer.

Expanded clay crushed stone

Crushed expanded clay has properties slightly different from gravel. The difference primarily lies in the size of the granules. Their diameter is 10-20 mm, which increases the thermal conductivity of the material. Crushed stone is formed by crushing gravel, so the granules have an angular shape. Grains of this type allow you to pour a dense layer of material without using a finer fraction to fill voids. The technical characteristics of expanded clay of a given size will be lower than those of gravel.

Expanded clay sand

Sand is obtained by grinding large fractions or by burning the remains of clay that was used to produce gravel. The particle size does not exceed 5 mm. The material is used as expanded clay backfill for interior partitions, for the production of ultra-light concrete, to fill voids between large fractions.

Expanded clay sand is highly resistant to frost, rotting and burning. This allows the material to be used for making a foundation. Since expanded clay has thermal insulation properties, the thickness of the concrete layer may be less than without this component.

Expanded clay concrete screed

A screed using expanded clay is made so that the floor is warm and does not allow sound to pass through. Cement-sand mixtures are inferior in these parameters. Expanded clay concrete has thermal insulation properties up to 10 times better than a simple concrete mixture. The insulation is also lighter, which allows for less load on the floors. In order for the screed to have the best performance, it should be made using the correct technology.

Technical properties

Let's take a closer look at the characteristics of expanded clay.

- Strength. This characteristic directly depends on the composition of the feedstock and the size of the fractions. The less porosity of the material, the stronger it is.

- Compaction coefficient - taken into account when storing and selling building materials. This parameter for expanded clay should not exceed 1.15.

- The thermal conductivity of expanded clay is in the range of 0.1-0.18 W/meter (at 0°C). Expanded clay with a thickness of 25 cm retains as much heat as an 18-centimeter thick polystyrene foam crust. The more holes in the granules, the higher the thermal insulation qualities of this insulation.

- Moisture absorption. The proportion of water in its composition can reach 20% if stored improperly. Insulation with a burnt crust allows less moisture to pass through. The more water in expanded clay, the faster it loses its thermal insulation properties.

Dry expanded clay Source userapi.com

- Noise insulation. Expanded clay has excellent soundproofing properties, so it is often used in the construction of interfloor and interior floors.

- Fire safety. Expanded clay is a good insulator. It is non-flammable and chemically inert.

- Heat resistance Expanded clay granules tolerate temperature changes well and can be stored for a long time in frosty open air. The main condition is to keep the material away from water. At high humidity, expanded clay can be destroyed due to freezing of water in its holes.

Among other properties of expanded clay, buyers highlight the low cost of this material and the safety of its use - both for humans and for the environment.

Expanded clay is an environmentally friendly material Source ogorod.ua

See also: Catalog of companies that specialize in home insulation

Varieties of expanded clay

Floor screed with expanded clay is performed in different ways, which can be divided into dry, wet (traditional) and combined. For each of them, the material is selected individually. More on the methods below, but for now let’s figure out what expanded clay is and what properties and characteristics it has.

Expanded clay granules: dense on the outside and porous on the inside. Source ec-nn.ru

The basis of the material is clay with special additives. The raw material is subjected to high-temperature firing, as a result of which it swells with the formation of many small closed voids inside and a dense crust on the surface. This porous structure allows the use of expanded clay as insulation with unique properties. With a sufficiently high density and strength, it is lightweight and resistant to moisture.

Depending on the production method, shape and size of individual particles, the material is divided into 3 types:

- expanded clay crushed stone, the main difference of which is the irregular shape of particles 0-40 mm in size, obtained by grinding large stones;

- expanded clay sand, consisting of round granules less than 5 mm in diameter;

- Expanded clay gravel is also a mixture of oval or round granules with a diameter of up to 40 mm. It can be homogeneous, from granules of 5-10, 10-20 or 20-40 mm, or it can consist of elements of different sizes.

Some types of expanded claySource 1nerudnyi.ru

This bulk material also differs in density, which depends on the size of the granules and voidness. The lower these indicators, the greater the weight.

For thermal insulation, expanded clay flooring in the form of crushed stone or gravel is used. Sand is not suitable for this, as it has a high density. It is used when it is necessary to level bases with large differences in level or damaged surfaces as a material that gives less shrinkage.

Manufacturers and prices

Expanded clay production facilities are available in all CIS countries. The quality of the products varies, but it depends primarily on the raw materials (the quality of the clay). The human factor is also present, but minimally.

In Russia there are similar enterprises in almost every region. The TOP 10 includes:

- "Expanded clay" (Ryazan);

- Expanded clay concrete plant ZhBI-3 (Belgorod);

- "Klinstroydetal" - a brick factory in the city of Klin;

- "Expanded clay plant" (Serpukhov);

- "PSK Shchurovsky Plant" (Kolomna);

- "KSK Rzhevsky" (Rzhev, Tver region);

- "Meliz" (Kursk region);

- “Experiment” (Kostroma);

- "Expanded clay plant Aleksinsky" (Aleksin, Tula region);

- "Belkeramzit" (Stroitel, Belgorod region).

The price depends on the type of ceramic pellets (gravel, sand, crushed stone), the size of the fraction, which is reflected in the brands of expanded clay and packaging. Thus, a big bag with a volume of 2.8 m3, a fraction size of 10-20 mm, can be purchased for 2040 rubles. (728 rub./m3).

Small packaging costs much more, from 1800 to 3640 rubles. for 1 m3 (the price of a bag with a volume of 0.05 m3 of the M200-250 brand starts from 99 rubles).

Insulation of walls using expanded clay

The optimal option for wall insulation using this material is considered to be a three-layer type construction.

The supporting structure, made of expanded clay concrete, serves as the first layer with a thickness of about 40 cm. The blocks are durable, safe, and have high thermal insulation characteristics.

When performing the second layer, use a mixture of expanded clay and cement laitance in a ratio of 1:10 - capsimet. Gluing of cement granules to each other occurs after filling the mixture under the influence of natural humidity. A layer thickness of 10 cm is sufficient to provide a high level of thermal insulation. The mass of a fairly rigid structure is distributed over the surface of the house building foundation.

The third layer, made of wood or brick, protects the insulating material from the influence of external environmental conditions.

Another simple way to insulate walls is to pour expanded clay into the space between the wall and the sheathing, for example, clapboard. The dry material is poured with a specially prepared cement solution of liquid consistency.

Quite often the material is used in the construction of additional walls. The essence of the method is that fine gravel is poured into the space between the wall and a metal frame fenced with plasterboard.

Mortar for cement screed with expanded clay and its proportions

Before you start leveling the floor, you need to mix expanded clay and DSP. In its composition, this mixture is close to expanded clay concrete or plain concrete. We recommend the following ratios when preparing expanded clay concrete:

- 20-25 bags of expanded clay of various fractions;

- 12-15 bags of sand concrete (M150, M300);

Deviations of proportions in different directions will bring different results. Thus, increasing the concrete in the solution will increase strength and reliability, as well as thermal conductivity.

Insulation technology

Despite all the similarities in the laying of bulk material, there are some distinctive features.

On the ground

Ground flooring is appropriate in garages and basements. In winter, such rooms will not be too cold if the appropriate work is done.

To insulate the floor on the ground, the fertile layer must be removed, the soil leveled and thoroughly compacted. A layer of crushed stone and sand is poured onto the compacted area. Thus, additional leveling of the surface occurs.

Waterproofing will protect the insulation from high groundwater. It should be placed on a prepared pillow. Then expanded clay is poured in and leveled so that the height over the entire area is the same. The top layer is fixed by impregnation with cement mortar. Next comes a layer of vapor barrier.

The insulation on the ground is completed with a reinforced cement screed. If desired, you can lay a plank floor on it after complete drying.

By lags

When insulated with expanded clay, logs serve double duty. On the one hand, they are convenient for leveling the backfill, on the other hand, they serve as the basis for the subfloor.

The granular fraction is laid along the joists on concrete foundations. First, the working area is cleared down to clean concrete. Any flaws are eliminated. Cracks are covered with mortar, joints and corners are foamed if necessary. The logs are pre-treated with an antiseptic and then secured to the base with corners. In this case, the upper edges of the wooden guides are displayed in one horizontal plane.

As waterproofing you can use:

- Ruberoid;

- Polyethylene;

- Polymer mixtures;

- Bitumen mastics;

- Rubber hydraulic barriers.

The concrete surface, joists, and walls around the perimeter of the room are subject to treatment to a height slightly higher than the height of the wooden parts. In the case of liquid mastics, concrete is primed for better adhesion. If film is used, it is attached to the bars with a stapler. Insulation is poured into the sinuses so that there are no empty spaces left and the height is the same everywhere. Expanded clay is covered with a vapor barrier layer. Then the subfloor is installed, and the finishing floor is installed on it.

On the balcony

In essence, a balcony is an enclosed protruding reinforced concrete slab. Standing on a concrete floor is uncomfortable even in summer. Often, apartment owners decide to insulate their balconies. Light granules are better suited for this purpose than other heat insulators.

It is not necessary to level the base. The main thing is that the new floor does not have slopes. To do this, beacon slats are installed on concrete covered with insulation. Beacons can be attached to the slab with mortar or plaster. The distance between parallel slats should not exceed the length of the rule. The smaller the step between the beacons, the easier it is to complete the job.

The height of the warm layer is equalized by the beacons. The finished pillow is poured with a cement composition. After hardening, a full screed is made on top. If desired, a wooden floor can be laid on top of the screed on the loggia and on the closed balcony.

In a wooden house

Expanded clay is widely used in the private sector. And this is not surprising, since the material is so unpretentious that homeowners work with it themselves.

Expanded clay is used to insulate the floors of the first floor and attic floors. Granular material is used for floor insulation in steam rooms, utility rooms and living spaces

In the latter case, it is important to ensure that dust generated by rubbing gravel does not penetrate into the room

A stone or concrete house is built on a foundation and has a basement or basement. In such buildings, the floors are not always insulated. It is impossible to live in a frame house built on screw piles without thermal insulation. To ensure comfort in such a structure you will have to work hard.

The funds saved on building the foundation should be spent on thorough insulation of the floor. The waterproofing here should not be the simplest roofing felt or polyethylene, but modern, reliable building materials. Vapor-permeable, moisture- and wind-proofing membranes will provide excellent protection against negative impacts. The rest of the work is carried out similarly to other types of floors. Exactly the same work on floor insulation will be required for a light wooden log house.

Expanded clay production and composition

Composition of expanded clay

The main material from which construction expanded clay is made is sedimentary clay rocks. The composition of clayey rocks is quite diverse and includes not only ordinary clay, but various impurities: quartz up to 30%, organic compounds, feldspar, carbonates and a small amount of compounds of various kinds of metals. The composition of expanded clay depends on the characteristics of a particular area where the extraction of raw materials for production was carried out.

In addition to the components originally contained in the raw material, to achieve the swelling effect, artificial impurities and organic compounds (solar and oil) can be added to the composition at the production stage.

Production of expanded clay

It depends on the composition of natural raw materials and is carried out in three main ways:

Dry production method

It is used for the production of expanded clay from the most homogeneous clay rock, with a minimum amount of impurities present. The extracted homogeneous rock is crushed and sent for roasting. It is considered the simplest and cheapest method of producing expanded clay.

Wet production method

With this method, clay rock is mixed with water and additional impurities that are necessary to obtain certain properties of expanded clay. This mixture is fed into a rotary kiln, where it clumps naturally and is dried under the influence of furnace gases.

This method is effective when using wet clay rock and the need for additional inclusions in the material.

furnace for the production of expanded clay

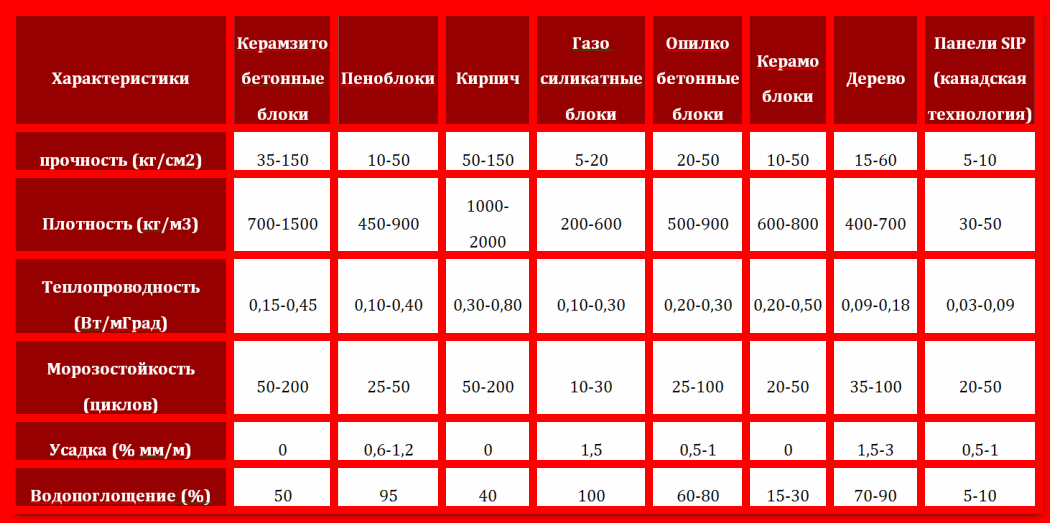

Plastic production method

The most expensive method by which a material with improved technical characteristics is created. In this case, we also use moistening of the raw materials and the addition of additional impurities to achieve a homogeneous mass. But unlike dry production, granules of approximately the same shape are formed from the resulting mixture on a belt press, which are fed into an oven for firing and drying. Thus, a solid expanded clay of uniform shape is obtained, with all the properties of a brick. However, unlike brick, it has greater thermal efficiency due to porosity and is significantly lighter in weight. Read more about the properties of brick.

How to determine the required volume of expanded clay

If there is a need to carry out thermal insulation inside or outside the room, then the question will arise about how much building material to purchase. In this case we are talking about expanded clay. If you are also among those who are wondering how many cubes of expanded clay you will need, it is important to calculate how much material is in one cube.

The weight of expanded clay will depend on the brand and density of the internal structure, as well as humidity and fraction size. As practice shows, 1 cube of expanded clay weighs from 200 to 400 kg. For a visual representation, it can be noted that one cube of expanded clay is 20 bags of 50 kg, 25 bags of 40 kg or 40 bags of 25 kg.

Expanded clay

It is a lightweight material whose structure includes many pores, which determines its high thermal insulation properties. It is produced by firing clay shales or clay itself at high temperatures (1000-1300 degrees) for quite a long time (20-40 minutes). Depending on the type of feedstock and processing technology, the density of the resulting expanded clay can range from 0.35 to 0.6 g/cm3.

There are the following types (depending on the shape of the fragments):

Expanded clay gravel. It consists of cellular elements of a streamlined oval shape, their size varies from 5 to 40 mm in diameter. Typically, this type is used when there is a need to create a layer of insulation over 5 centimeters.

Expanded clay crushed stone. The size of the pieces is approximately similar to expanded clay gravel, but their shape is more like a cube, the edges and corners of which protrude sharply. The technology for its production comes down to crushing larger fragments of expanded clay.

Expanded clay sand. The particle size ranges from approximately 14 to 50 millimeters. The peculiarity of this type of building material makes it possible to create a layer of thermal insulation less than 5 centimeters thick without losing its insulating qualities. In addition, it is used in the range of 14-50 millimeters. Small dimensions allow the use of expanded clay sand with a heat-insulating layer thickness not exceeding 5 centimeters. It is also used as a filler for concrete or other mortar.

Advantages of expanded clay

This thermal insulation material is very economical. When using expanded clay, you can sound and heat insulate your home with the least investment of money. The material has a high fire safety rating and a high degree of environmental friendliness, since various types of clay are used for its production. It also has a significant service life. This is due to the fact that the material does not condense moisture.

Any material used for construction must meet environmental safety requirements. Expanded clay is made exclusively from pure clay, which does not contain various chemical additives. Therefore, it is completely safe for human health. In the production of oval varieties of expanded clay, clay is fired.

Expanded clay gravel allows you to fill various types of voids. In this way, thermal insulation of the roof is carried out. Often, when installing insulation, expanded clay gravel is mixed with foam chips, which increases the thermal insulation properties of the layer.

Disadvantages of the material when insulating the roof

One of the important disadvantages of expanded clay is its increased fragility. This point must be taken into account when carrying out work, and the building material must be handled with care. When material is poured into a cavity, some of its elements may be damaged, which leads to their partial loss of their properties.

Expanded clay should only be used as a material for dry backfill. It is not advisable to mix it into cement or mortar.

However, even without being a professional builder, you can still use expanded clay. Everyone will be able to produce high-quality insulation of a building, while spending a minimum of time on the process.

Features of granular material

It has good performance characteristics, which makes it possible to use it in various areas of construction. Experts know exactly why expanded clay is needed on the floor, under the roof and in other parts of the structure. Its main advantages:

- Low thermal conductivity. Due to the fact that their internal pores are filled with air, the granules conduct heat very poorly. But they preserve it well. This makes the material an effective insulator.

- Durability. Ceramics last for decades without losing their performance characteristics.

- Inert to most chemical compounds. Acids and alkalis do not destroy ceramic balls.

- Fire safety. Ceramics can withstand high temperatures without damage, do not emit toxic substances and are not flammable.

- Good noise absorption. The air-filled pores effectively block the passage of sound waves.

- Frost resistance. Low temperatures are safe for granules whose shell is not damaged. If this is not the case, and water gets into the pores, it can destroy the ceramic when it freezes.

- Environmentally friendly. Only natural raw materials are used for production, which makes the products completely safe for living organisms.

Among the disadvantages, it is worth noting the slight hygroscopicity of expanded clay. Once wet, it takes a very long time to dry, which must be taken into account when carrying out construction work. For this reason, it is advisable to perform vapor and waterproofing when laying ceramic insulation.