The frame construction method is a combination of low price, hygienic cleanliness, strength, and reliability. The method of constructing frame houses first appeared in Canada, then began to quickly spread throughout other countries due to its advantages. The additional arrangement of a building determines its convenience, so the technologies of insulation, sound insulation, and waterproofing should not be relegated to the background.

The microclimate in housing directly depends on high-quality insulation, so you need to carefully approach the choice of insulation material. There are different insulation methods, namely insulating a frame house with expanded polystyrene, expanded clay, polystyrene foam, and mineral wool. Like the construction of an entire frame house, its insulation can be done independently.

Insulating walls and floors with expanded clay in a frame house has its advantages and disadvantages, which will be discussed in detail in this article.

The use of expanded clay in the insulation of frame houses

Expanded clay has been used as insulation for quite a long time. Now, with the emergence of a wide variety of new high-quality insulation materials, this material remains in demand because it has a number of advantages over new insulation materials.

Expanded clay has many valuable properties that are not present in modern insulation materials

Expanded clay is a bulk material of various fractions that combines thermal efficiency, quality and ease of use. An important point is that it has passed all tests for hygienic purity, so you can count on the safety of its use. Expanded clay is an insulation material that is used both in its pure form and in combination with concrete mortar. This material is called expanded clay concrete and is most often used for insulating the floor of the first floor when laying floors on the ground.

By choosing expanded clay as insulation, you get the following positive aspects:

- The use of natural raw materials: clay and slate in combination with environmentally friendly additives, processed at high temperatures is a guarantee of the reliability of the finished product.

- Expanded clay is a raw material in the form of round granules that are easily compacted in any plane, creating the effect of insulation and drainage.

- Low thermal conductivity allows you to effectively retain heat in the room, preventing it from spreading outside. Insulating a frame house with this technology is considered a simple and smart solution.

- The sound absorption of the insulation makes the room soundproof.

- Light weight and compact dimensions play a big role in construction.

- The low price of raw materials is another positive point that should be taken into account when choosing insulation.

- The raw materials do not support combustion, therefore the spread of fire in the event of a fire is excluded.

- The durability of expanded clay - its shelf life is almost unlimited.

- Mice do not like expanded clay. They do not build nests in it, unlike mineral wool, they do not eat it, and they do not like to be in it.

Expanded clay is suitable for insulating buildings of any size, while providing thermal comfort and coziness.

Expanded clay is marked from M300 to M700, which characterizes its bulk density and depends on the fraction. The higher the density, the stronger the material, but the worse its heat-retaining properties.

Expanded clay sand with a fraction of 0.13-5 mm is used to insulate walls up to 50 mm thick.

Expanded clay gravel with a fraction of 5–50 mm is used in the production of expanded clay concrete.

Expanded clay crushed stone has a fraction of 5–40 mm and serves as a filler for lightweight concrete.

Advantages of insulation

This insulation has the following advantages:

- Low cost compared to other insulation materials.

- With its help, the service life of the floor is extended to several decades.

- It does not collapse even at high temperatures.

- Tolerates moisture and frost well.

- Has sound insulation properties.

- Lasts longer than other insulation materials.

Wall insulation

In frame houses, expanded clay is used to insulate walls, mainly due to its low price and durability. Additional advantages are its environmental friendliness, non-flammability and fairly low thermal conductivity.

The disadvantages of expanded clay used as insulation for the walls of a frame house include its high density - up to 500 kg/m, that is, it is a rather heavy material, compared, for example, with mineral wool. Another drawback, which, however, can be easily tolerated, is the extension of construction time.

If you choose expanded clay as insulation, keep in mind that although this material is considered a good thermal insulator, its thermal conductivity coefficient is significantly lower than that of mineral wool or polystyrene foam. Accordingly, the expanded clay layer should be thicker.

A thick layer of expanded clay has significant weight, which must be taken into account when choosing the wall material (they must be quite strong) and when calculating the foundation. The thickness of the expanded clay will be approximately 200-300 mm. In this case, the meaning of a frame structure is lost, the main advantage of which is the ease of wall construction. Therefore, in frame houses it is still preferable to use mineral wool or polystyrene foam as insulation. But the choice is always yours.

When insulating walls with expanded clay, it is necessary to use steam and waterproofing to protect the insulation from getting wet. Although expanded clay does not absorb moisture well, it can nevertheless become wet over time, which is not at all desirable.

When insulating the walls of a frame house with expanded clay, the insulation is poured between the outer and inner wall panels, which are attached to the frame. This is a simple process that can be done independently without special tools and equipment. Steam and waterproofing are laid between the wall panels and the insulation.

- Start building the wall by erecting the inner wall panel.

- Attach a vapor barrier to it. Tape the joints of the film with tape.

- The construction of the outer wall panel and the filling of expanded clay occur simultaneously. Having mounted a small section of the wall (about 50 cm), attach waterproofing inside the formed well from the side of the outer panel with a large margin equal to the height of the wall. Also seal the waterproofing joints with tape.

- Pour expanded clay into this well and compact it thoroughly. Fig.0

- The next step is to re-mount a small part of the outer wall panel, attach the waterproofing and fill it with expanded clay, and so on until you have mounted the entire wall.

Filling expanded clay into the wall of a frame structure

The wall pie consists of the following layers:

- inner wall panel;

- vapor barrier;

- expanded clay;

- waterproofing;

- outer wall panel.

To insulate walls, choose fractions of 5-10 or 10-20 mm.

Still, think carefully before insulating the frame walls with loose expanded clay. It's not rational. We recommend choosing mineral wool or polystyrene foam. You can also use expanded clay concrete blocks.

Manufacturers and cost

In Russia there are quite a lot of enterprises producing expanded clay, located in Moscow and the Moscow, Sverdlovsk, Belgorod, Ryazan, Samara and Leningrad regions, as well as in the Republic of Adygea. The five most popular and proven enterprises in the building materials market are:

- CJSC "Keramzit" Ryazan;

- JSC "Keramzit" Samara region;

- Belgorodsky);

- CJSC Kushvinsky expanded clay plant, Sverdlovsk region;

- CJSC "Keramzit" Serpukhov.

You can buy expanded clay from them in bulk or in bags.

Packaging in bags slightly increases the cost of products. However, packaging in bags is much more profitable when it comes to small volumes, since the integrity of the material is preserved.

One cube of expanded clay is contained in approximately 21 bags, and each bag costs about 100-130 rubles, that is, 1 m3 - 1700-2550 rubles. The average price for 1 m3 of loose expanded clay is 1000-2100. The smaller the fraction, the more expanded clay costs.

Floor insulation

Insulating the floor with expanded clay of a frame house is quite justified, unlike insulating the walls. When insulating the floor in Canadian-type housing, you need to consider the following:

- It is better to use the material as a separate thermal insulation agent, that is, there is no need to mix it with cement or other substances.

- Beacons must be permanently fixed using an alabaster compound, since the substance dries quickly, which, in the absence of markings, creates inconvenience during use.

- It is recommended to use metal mesh to reinforce the floor in order to thoroughly protect it.

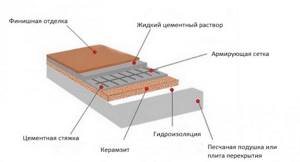

In frame houses, when installing floors on the ground, expanded clay insulation is most often used by scattering (with dry screed).

- Compact the soil under the room and make a sand cushion 10 cm thick.

- Lay waterproofing on the sand cushion, extending 10 cm onto the walls. Carefully seal all joints of the waterproofing film with tape.

- Apply edge tape along the perimeter of the floor on the walls, at a height of 10 cm.

- Spread the first layer of expanded clay over the installed beacons with a fraction of 10-40 mm.

- Apply a second layer of expanded clay mixed with cement in a ratio of 5:1. The total layer of expanded clay should be at least 15 cm.

- Apply cement screed.

- Lay the reinforcing mesh. It will add strength to the floor structure.

- Fill the mesh with cement mortar.

- Lay the finishing coat.

Scheme for insulating the floor of a frame structure with expanded clay

Similar floor insulation using expanded clay can also be performed in interfloor spaces.

floors.

Reviews

“Not long ago I made repairs and insulated the floors in the hallway, toilet and bathroom. First I made waterproofing, after which I poured expanded clay (it turned out to be 10 centimeters in height). I filled everything with “cement laitance” on top. After 20 hours, I covered everything with sand concrete and repeated this several times. Expanded clay did not float, the screed dried without cracks. When everything was completely dry, I laid the tiles. The floors are much warmer, although a little higher.”

Sergey, Nizhny Novgorod.

“I don’t sell expanded clay and don’t try to advertise it, saying that it’s a super material. In fact: I had it in a bathhouse, the first floor was a log house, and the second floor was filled. I always had enough insulation, flooded it - and after an hour and a half I could already steam. On the second floor they calmly undressed. Friends came constantly, and no one ever complained that it was cold or the bathhouse was cooling down quickly.”

Vladimir, Yaroslavl.

“We had a sloping floor in our living room, which made the furniture doors difficult to open and scratched the laminate flooring.

We hired workers to level the floor; they measured a level difference of 11 cm. They advised us to level it with expanded clay and insulate it at the same time. We had waterproofing done for the entire room; expanded clay and dry mortar were mixed right on the floor in portions. They spread it out and knead it again, so the entire area. We waited a long time for everything to dry, and then laid the laminate flooring. The floor is now both smooth and warm.” Marina, Moscow

Insulation of the attic floor

The attic can also be insulated with expanded clay. Work is carried out from the attic in the following order:

- Place vapor barrier sheets on the ceiling flooring with an overlap of 10 cm. To ensure complete insulation, tape all seams. The vapor barrier film should extend onto the roof slopes and onto all protruding surfaces.

- Pour expanded clay between the attic beams in a layer of at least 15 cm (the thickness of the layer is calculated depending on the climatic zone and the characteristics of the expanded clay). The top layer of expanded clay should be 2 cm below the top of the beams so that when walking through the attic the expanded clay does not touch. You can place a cement screed on top of the expanded clay so that the expanded clay does not crumble, or you can do without it.

- Install waterproofing. Also seal the joints with tape. The waterproofing film can be fixed to the top of the beams with a stapler.

- Lay the attic floor using boards laid across beams, plywood or particleboard. You can put linoleum or laminate on top.

Scheme of attic floor insulation with expanded clay

If the thickness of the floor beams is not enough to lay a layer of insulation - in our case expanded clay - of the required thickness, they are built up with additional bars. All joints between steam and waterproofing must be airtight.

Using the same principle, you can insulate a roof with expanded clay. In this case, instead of laying the attic floor, roofing material is laid over the counter-lattice and sheathing. For more information about insulating the roof and ceiling, see the article “How to insulate the roof and ceiling of a frame house correctly with your own hands.”

Advice from professionals

When insulating a balcony with expanded clay, you must use a protective mask or respirator to protect your respiratory tract from dust. The most dense layer of material is obtained from a mixture of all three fractions, but you need to keep in mind that a large amount of sand will increase the weight of the insulation and, consequently, the load on the balcony floor. Ordinary polyethylene film can be used as a waterproofing material.

There are standards for constructing large area screeds. You cannot fill large areas of the floor at once. If the floor on the balcony has an area of more than 25 square meters. m, you should divide it into sections and work with each contour separately. This will make the process easier and protect against possible problems with insulation.

To achieve good insulation, the layer thickness must be at least 10 cm. A screed of such thickness is difficult to level and takes a long time to dry. If the concrete thickness exceeds 6 cm, it is recommended to fill it in two stages: the first layer is 4-5 cm below the level of the future balcony floor, the second layer is the final leveling. When pouring multi-layers, it is advisable to apply the second layer immediately after the main one so that the screed is uniform. A rule (a tool for leveling the floor) can be made from a piece of flat and strong board.

According to building codes, when preparing a floor for laying linoleum or laminate, the clearance between a two-meter lath and the surface of the concrete screed should not exceed two millimeters. To check the quality of the screed, just take any flat plank, lay it on the floor with the end of the long side and evaluate the gap between the plank and the floor. For convenience, you can place a light source behind the rail, for example, put a switched-on flashlight on the floor.

Sources

- https://pechiexpert.ru/uteplenie-balkona-keramzitom-01/

- https://krovli-zabori.ru/balkony/uteplenie-pola-na-balkone-keramzitom.html

- https://dnevnik-stroika.ru/uteplenie/uteplenie-balkonov-i-lodzhiy-keramzit/

- https://keramzitka.ru/uteplenie-balkona/

- https://vdome.club/remont/balkony/styazhka-na-balkone-s-keramzitom-kak-sdelat-svoimi-rukami.html

- https://balkon.expert/uteplenie/uteplenie-pola-na-balkone-keramzitom.html

- https://instanko.ru/instrumenty-i-materialy/uteplenie-balkona-keramzitom.html

- https://uteplimvse.ru/dlya/pola/keramzit.html

Floor insulation in a frame house on stilts

A pile foundation is a reliable basis for a future frame house, but when insulating the floor, you need to take into account certain rules to avoid drafts under the floor and dampness.

The technology of arranging a foundation on piles is used mainly in swampy areas, where special attention is required to the materials used to obtain strength and resistance to movements of the soil layer. Therefore, thermal insulation is created together with the subfloor, since the layered structure protects the housing from moisture penetration from the foundation.

With a pile foundation, the floor of the first floor is especially not protected from cold and wind. There remains free space between the ground and the ceiling of the first floor. In this case, floor insulation must be done especially carefully. By correctly calculating the thickness of the insulation and accurately performing all the installation work on insulating the floor and basement described in this article, you can get a warm, cozy home even if it is located in a very low temperature zone.

Let's consider expanded clay as insulation, as the cheapest and most environmentally friendly material.

All wooden elements should be treated with an antiseptic to prevent rot.

Floor insulation

The work order is as follows:

- Place logs on the pile foundation grillage.

- Attach 50*50 mm skull blocks to the joists to support the subfloor boards.

- Lay boards or pieces of plywood on top of the skull blocks to create a subfloor.

- Lay waterproofing. The waterproofing tapes should be 10 cm apart from each other, tape the seams. Apply the waterproofing along the perimeter of the floor with edge tape.

- Fill the required layer of expanded clay with a fraction of 10–40 mm. The top layer of expanded clay should not reach the top of the log by 10 cm.

- Fill the top of the expanded clay with a cement screed or lay a vapor barrier film with an overlap of 10 cm and taping the seams.

- Apply final coat.

Floor insulation scheme for a frame house on stilts