Expanded clay as floor insulation or mineral wool - the choice of specialists

Nowadays, the cost of heating housing and premises in general is constantly increasing.

At the same time, for some reason, salaries remain almost the same - not a good trend, but it has to be taken into account. In such conditions, almost every owner of a house or apartment begins to worry about the issue of saving energy. Today, walls, floors, ceilings, and slopes are being insulated en masse - such measures make it possible to distribute heat throughout the room as efficiently as possible due to the fact that the level of heat transfer of the building is reduced. This article will touch upon such a difficult issue as floor insulation - we will figure out what is better suited for this: mineral wool or expanded clay. In principle, foam plastic is also often used, but this is not the best option, because the possibility of ventilation and ventilation of the ceiling practically disappears. Although, undoubtedly, the thermal insulation characteristics of polystyrene foam are excellent.

So, mineral wool and expanded clay, which is better - you can start with a review of the first material and compare everything based on specific properties.

Mineral wool and its properties, features

This insulation consists of soft coarse fiber boards or rolls. This material is made from waste metal and carbon alloys of various minerals such as basalt. In its structure, it resembles glass wool, only the latter is much worse in terms of thermal insulation characteristics. In principle, mineral wool is used quite widely in construction and is especially popular for insulating facades. However, the facade is not floor insulation - there are still different specifics.

The main advantages of this insulation are considered to be several points.

This is a rather controversial property, since in order for the insulation to last for a really long time, it is necessary to ensure that there is no moisture in the space where it is laid. Weak resistance to moisture is the main drawback of the material, because if the mineral wool gets wet, then all the thermal insulation qualities in this place are instantly eliminated. Of course, manufacturers have now learned to treat rolls with various moisture-proofing compounds, but this does not always work effectively.

In addition, mats and rolls are afraid of mechanical damage, that is, simply put, they can tear even due to the activity of mice. Therefore, the question of durability is still largely questionable. It is difficult to 100% protect such insulation.

- Quick installation.

This is true, but it is also debatable - what is easier - to roll out the rolls on a flat surface or to fill the space with expanded clay? There is not much difference in difficulty. Therefore, compared to working with expanded clay, this quality is definitely not an advantage.

- Fire resistance.

Likewise, expanded clay is also not afraid of fire.

- Breathability.

What is, that is - basalt roll has good vapor permeability, due to which steam, in theory, will not accumulate in the floor space. However, if this same quality is applied to expanded clay, then the same situation is visible here - steam passes perfectly between the scattered granules of the material and, accordingly, the vapor permeability here is also high.

It turns out that while the rolled insulator is “losing” to expanded clay due to the fact that it is afraid of moisture and is not very tensile strength.

Now it’s time to consider the structure of expanded clay.

Expanded clay as insulation

Essentially, it is a bulk material with pores. The granules are light in weight, which, in general, is not particularly different from the weight of cotton wool. Expanded clay is made on the basis of clay, which contains about 30% quartz, and, as you know, clay is a natural, natural insulation that does not emit any harmful fumes.

If we compare the latter quality with mineral wool, then the latter is not so good in this regard, because it contains small dust particles that are harmful to human breathing. In principle, since the roll will eventually be covered with various layers of insulators (not counting the finishing floor itself), it is practically impossible for these impurities to get into the air of the room, but this possibility still remains.

That is, here the third drawback of mineral insulation automatically arises (the first is the fear of moisture, and the second is low tensile strength) - it is not 100% environmentally friendly.

As practice shows, maximum protection from the harmful “side” of the issue is possible only with very competent and correct installation. And this is not always possible due to the different qualification levels of installers.

Of course, expanded clay may also have disadvantages in terms of environmental friendliness, but only in the case when the raw materials were mined in a quarry that has increased levels of radioactivity. This happens very rarely, but it’s still worth checking with sellers for safety certificates for the material.

Also, when buying expanded clay, you should pay attention to the following:

- Per granule fraction. For floor insulation, it is better to take smaller sizes - a gradation of 5-10 is optimal.

- For porosity. The more pores in the stone, the better the thermal insulation characteristics.

- The strength of the material - this affects the service life.

Here a difficult point automatically emerges in terms of using expanded clay - you need to try to find a good, high-quality material in order to achieve a low level of thermal conductivity. Basalt material “wins” here, since it is relatively standardized, and it is quite difficult to find a fake or defective product on the market.

Expanded clay is not afraid of moisture, since all the steam or all the water simply “passes” through the pores or directly into the granules of the material. There is certainly a percentage of moisture absorption here, but it is very small compared to soft insulation.

It is also worth noting such a point as the almost complete absence of the possibility of incorrect laying of expanded clay for floor insulation. Yes, choosing a material is quite difficult, but it is very easy to insulate with it, and the risk of any mistakes is minimal.

These are the main characteristics of expanded clay. Now we need to touch on the most important thing.

Specific thermal insulation parameters of expanded clay and rolled insulators

So, it turns out that the advantages and disadvantages of materials are known, but what happens if we compare their thermal conductivity? Everything here is actually quite simple.

For a clear example, you just need to take good quality insulators.

Approximately 0.04 W/m*K

As can be seen from the table, cotton wool insulation has a better level of thermal conductivity than expanded clay, which means that to achieve the same thermal conductivity effect, the expanded clay layer for the floor must be made twice as thick as it would be when using basalt rolls.

If we talk about exact figures, then in average climate conditions the required thickness of wool on the ceiling should be about 7 cm according to SNIPs. Accordingly, to fill the expanded clay you will need a space of about 13-17 centimeters (it all depends on the quality of the granules). Of course, the numbers may vary in one direction or another, since the specifics of the situation are of great importance, but in general the ratio is approximately the same.

Based on all the above information, we can draw some conclusions.

Conclusion

It turns out that both materials are good in their own way, and at the same time, each has its own specific disadvantages.

Basalt wool is not as environmentally friendly and durable, but its installation requires less space (but more professionalism).

It is important to use expanded clay as insulation when you want to achieve maximum environmental safety in a room and when it is possible to lay the required floor thickness.

So the choice is not so difficult - you just need to weigh all the features of the situation and the decision will become obvious.

Certain insulating parameters of expanded clay sand and rolled insulators

So, it turns out that the pros and cons of materials are known, but what happens if we compare their heat conductivity? Everything here is actually very easy.

For a clear example, you just need to take insulators of excellent quality.

Mineral wool

Approximately 0.04 W/m*K

Approximately 0.09 W/m*K

As can be seen from the table, cotton wool insulation has a better degree of thermal conductivity than expanded clay sand

, which means that to achieve the same thermal conductivity effect, the expanded clay layer for the floor must be made twice as thick as it would be when using basalt rolls.

If we talk about exact figures, then in average climate conditions the required thickness of wool on the ceiling should be about 7 cm according to SNIPs. Naturally, a space of about 13-17 centimeters will be required to fill expanded clay sand (everything may depend on the quality properties of the granules). Of course, the numbers may change in one direction or the other, since the specifics of the situation are of great importance, but in general the ratio is approximately the same.

Based on all the above information, we can draw some conclusions.

Expanded clay or mineral wool, which insulation is better?

Even if the heating system is of high quality, efficient and reliable, without good insulation these indicators are reduced to a minimum due to large heat loss. You need to insulate the floor, roof, walls, ceilings of residential buildings. Expanded clay or mineral wool are most often used as insulation.

Expanded clay is a lightweight building material due to its porous structure, which is made from heaving clay. This is a bulk breathable material that is durable. Mineral wool is a soft rolled artificial insulation material. It is made from carbon alloys and metal waste. It has good technical performance and is durable.

Both thermal insulators have advantages and disadvantages. Before making a choice, you should consider the performance characteristics of each insulation. The main ones are thermal conductivity and weight. The thermal conductivity coefficient of expanded clay is 0.1, for mineral wool - 0.04. Therefore, mineral wool releases less heat than expanded clay with the same thickness. The weight of expanded clay is 250 kilograms per cubic meter, and the mass of mineral wool is only 30 kilograms. Expanded clay is characterized by a high degree of soundproofing, which is important in the construction of residential premises. Mineral wool is not inferior in this indicator. The affordable price of both materials also plays a big role. The choice of a particular material depends on the specific construction conditions, financial and technical capabilities. In addition, these insulation materials complement each other perfectly. Often they are combined. If you use building materials separately, then it is worth considering that expanded clay is a completely natural material and does not contain toxins. Mineral wool is a fragile and non-moisture-resistant material that is unsafe for the human body and has a harmful effect if it enters the lungs.

Analogs of expanded clay

If expanded clay turns out to be a heavy material for the planned construction work, then other porous backfills can be selected. An analogue of expanded clay is agloporite - pumice, similar in structure to glass. But the material is not so environmentally friendly; it contains various harmful additives. As an option, expanded perlite is used. Its thermal conductivity is similar to that of mineral wool, and moisture absorption is not much lower than that of expanded clay. The best option in terms of its characteristics would be expanded vermiculite. The material is non-toxic, expanded clay weighs less. Therefore, it places less load on the floor.

Can expanded clay emit harmful substances?

There is an opinion that after some time expanded clay can release substances harmful to the body. And it is better to use polystyrene foam. But expanded clay is ordinary red clay, which can swell when exposed to high temperatures. Therefore, the assumption that the material is harmful is not justified. In addition, if you choose polystyrene foam as insulation, then when moisture gets in, it will begin to rot, and within a year it will turn black and mold will appear. And expanded clay in this case, due to the ventilated gap, will not retain moisture, it will evaporate. In addition, expanded clay is fire-resistant, like brick, and will not be damaged in case of fire. The foam will release substances harmful to health.

Insulation with spray insulation

By the way, quite recently an innovative sprayed heat insulator based on polyurethane foam (PPU) appeared on sale. While it has not yet become popular among domestic homeowners, this material has good positive characteristics:

True, the spraying device itself must have a power of at least 380 W, and the compressor capacity must be at least 700 liters per hour. It is usually customary to rent such equipment rather than buy it for one-time use. However, sprayed thermal insulation also has its significant disadvantages, according to the statements of many builders.

Among them are the following: quite high cost, polyurethane foam has a low fire resistance class (in the event of a serious fire, the house will blaze like a match - this is the most significant drawback).

After drying, the sprayed heat insulator acquires a fibrous structure

You can add a special impregnation to the heat insulator to reduce flammability, but the foam of the polyurethane foam will not be as strong. In general, you need to decide all this yourself; here the pros and cons are approximately equal.

How to insulate the floor? Types and characteristics of floor insulation in a private house

Warm floors in a private house are the key to the health and well-being of residents. First of all, this concerns the first floor of the building. And it doesn’t matter whether the floor is in contact with the ground or whether there is a basement under the first floor. In any case, the floor must be insulated.

- URSA;

- KNAUF;

- Rockwool;

- Expanded polystyrene;

- Mineral wool;

- Expanded clay;

- TechnoNIKOL.

Today, purchasing floor insulation is not a problem. It is important that the material has low thermal conductivity, is resistant to moisture, has sufficient strength, is durable and does not have a harmful effect on the organisms of residents. In a private house, the choice of heat insulator is determined by the type of floor. A wooden structure requires one type of insulation, while a concrete screed requires another type of insulation. What types of insulation are there today?

URSA Products

Rolled thermal insulation material URSA.

A special professional high-quality thermal insulation material is URSA insulation. It is used for installing floors over basements, for insulating walls and roofs.

- URSA roll material is characterized by a low thermal conductivity, which is maintained even when in contact with water.

- The heat insulator is also a sound-absorbing material.

- URSA products do not burn or emit harmful or toxic substances when exposed to open flame.

- URSA mineral wool is characterized by high chemical resistance and is an environmentally friendly material.

- Thermal insulation is available both in the form of mats and in the form of slabs.

- The insulation is installed between the ceiling and the floor.

KNAUF insulation

KNAUF thermal insulation is successfully used to insulate a private home. All products are made in accordance with GOST and are environmentally safe for people and animals.

KNAUF thermal insulators have the following properties:

Floor insulation using polystyrene foam.

- ease of installation;

- low thermal conductivity;

- breathability;

- durability;

- excellent sound insulation.

Knauf insulation comes in several types.

- The KNAUF Dacha roll insulation has a thickness of 5 cm. One roll of mineral wool is enough to insulate 9 square meters. m of horizontal surface.

- Plates with a 3D effect are excellent floor insulation. The thickness of the “Heat KNAUF House” slab is 5 cm, and the “Heat KNAUF House+” version has a thickness of 10 cm. When using tile material, there is less waste in the form of scraps.

- To carry out thermal insulation of the floor in a private house with minimal weight to the structure, KNAUF Thermo Rolls are best suited. They are mats rolled into rolls. The material is laid on joists or ceilings, and is also used to insulate the attic and pitched roof.

Thermal insulation Rockwool

Rockwool basalt floor insulation has its advantages. It is considered an ideal material for floor insulation.

Laying Rockwool thermal insulation boards

- The insulation is absolutely safe for residents and pets.

- The material is convenient to install yourself.

- There is a wide range of thermal insulators, where you can choose roll or slab materials.

- ROCKWOOL is not flammable and is not afraid of temperature changes.

- The basis of the material is stone wool, which repels moisture and at the same time has vapor permeability.

- The structure of the insulation allows you to absorb noise, reducing the acoustic load in the room.

Expanded polystyrene

You can insulate the floor using polystyrene foam. It is characterized by accessibility and good performance parameters.

KNAUF insulation is available in the form of plates and rolls.

- Expanded polystyrene boards are light in weight, so they do not create unnecessary loads on load-bearing elements.

- The insulation is non-hygroscopic, does not cake, has a smooth surface, and is also characterized by stable geometric dimensions.

- With fire retardant additives, polystyrene foam will have reduced flammability and smoke-generating ability.

- The material is environmentally friendly and safe.

- Expanded polystyrene insulation is not afraid of dampness, does not rot and is resistant to mold.

The material is easy and convenient to install. The best effect is achieved by constructing a “pie”. A polyethylene film is laid on the floor slab. Then polystyrene foam is installed, on top of which a cement-sand screed is formed.

Mineral wool

You can also insulate the floor in a private house using mineral wool. It is available in the form of a solid slab, flexible mat or rolls. The material is characterized by:

Mineral wool in rolls is a popular floor insulation

- low thermal conductivity coefficient;

- fire resistance;

- excellent sound insulation;

- excellent water-repellent properties.

Today, mineral wool is produced by different manufacturers. The most popular thermal insulation materials are:

- ISOVER products (Profi and Classic);

- mineral wool GEO M-11 from URSA;

- basalt mineral wool PAROC UNS 37;

- roll insulation KNAUF Insulation with a density of 11 kg/cubic. m.

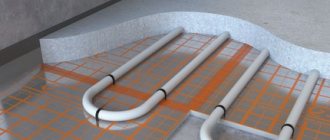

When laying mineral wool, make sure that the perforated side is at the bottom. The layered “pie” of the floor looks like this.

- A layer of waterproofing is laid on the compacted soil.

- Then a gravel backfill is made, on which mineral wool is placed.

- The insulation is covered with a layer of vapor barrier on top, a cement-sand screed is made and the floor covering is laid.

Expanded clay

Floor installation with expanded clay layer.

Expanded clay is an excellent material for flooring in a private home. This lightweight, porous and granular insulation is made from fired crushed clay. Thanks to expanded clay, it is possible to immediately perform the following operations when installing a floor:

- alignment;

- thermal insulation;

- waterproofing (with a thick layer).

Most often, expanded clay is used to insulate floors that are in contact with the ground. Laying is done in layers, compacting the material. The thickness of the expanded clay layer is 15 cm. Each layer is filled with liquid concrete mixture.

TechnoNIKOL

The Technonikol company offers consumers a wide range of insulation materials for private homes.

- For thermal insulation of the floor, you should pay attention to extruded polystyrene foam C-XPS CARBON. It is produced in the form of slabs and can be used to insulate floors made using dry screed.

- Rocklight basalt wool is also sold in the form of slabs. Low phenol content improves the environmental friendliness of the material.

- Long Teploroll mats made of stone wool are wound into rolls. In addition to high heat-insulating characteristics, they have sound-absorbing properties.

Average prices for floor insulation in Russian cities

| Material | Novosibirsk | Tyumen | Chelyabinsk | Ekaterinburg |

| Ursa | 1.057-1.410 | 1.110-1.460 | 1.080-1.450 | 1.108-1.450 |

| Knauf | 1.120-4.127 | 1.150-4.125 | 1.210-4.120 | 1.180-4.130 |

| Rockwool | 5.300-6.100 | 4.900-6.025 | 4.900-6.025 | 4.850-5.900 |

| Expanded polystyrene | 1.350 (regular) 5.000 (extruded) | 1.300 4.630 | 1.240 4.140 | 1.250 4.200 |

| Mineral wool | 1.210-5.500 | 1.800-4.660 | 1.080-5.300 | 1.100-3.900 |

| Expanded clay | 1.300-2.500 | 1.300-2.900 | 1.300-2.900 | 1.278-3.300 |

| TechnoNIKOL | 1.350-4.700 | 1.350-4.580 | 1.350-4.720 | 1.350-4.690 |

Pitfalls when insulating floors

When designing a new home, you can correctly fit any floor insulation. But when it comes to renovating an old country house, completely unexpected problems often arise.

For example, insulating a wooden floor in a mother-in-law’s village resulted in serious repair work. I had to level the joists, repair the foundation, and then deal with thermal insulation. The material used was 10 cm thick polystyrene. It was laid tightly between the joists, and the cracks were filled with polyurethane foam. We hope that in winter, even with stove heating, it will become much warmer.

I would like to know how you solved such problems with floor insulation?

About thermal conductivity

First of all, let's define what thermal conductivity is. This is essentially the ability to transfer heat from a warmer surface to a colder one. If we apply the definition to construction, we can put it this way: this is the process of transferring heat from indoors to outdoors.

Accordingly, the higher the thermal conductivity, the simpler and easier the material transfers heat from the apartment (house) to the outside. This means that we need to use materials with the lowest indicator of this parameter.

For calculations when designing a structure, the thermal conductivity coefficient is used, which is a number indicating how much energy passes through a body with an area of 1 m2 and a thickness of 1 m per unit of time - W/(m*K).

Data for most building materials are summarized in tables of thermal conductivity, also indicating the density of these materials, but since this parameter can vary depending on the composition of the material and additives made by the manufacturer, there may be variations even within the same type.

The thermal conductivity of thermal insulation or other insulating materials, as a property, also allows you to choose the most suitable material, but at the same time more convenient to install, or an insulator with a smaller thickness, when this is critical.

First, we present the indicators specifically for building materials:

- sand-lime hollow brick - 0.66;

- ceramic hollow brick - 0.57;

- clinker brick - 0.8;

- solid brick - 0.6;

- laminated veneer lumber (150 x 150 mm) - 0.1;

- concrete (on sand) - 0.7;

- concrete (on crushed stone) - 1.3.

Now - a table of thermal conductivity of insulation:

Density comparison table (average values):

Now let's look briefly at each of these materials.

Expanded clay or mineral wool - choosing the best insulation

While the summer heat is still in the yard, during the construction of a new house someone will not care about precisely calculated thermal insulation, but they should immediately decide what will serve as insulation, expanded clay or mineral wool , and how thick the layer will be. After all, sooner or later winter will come, and even if there are no cracks in the walls with accompanying drafts, something with low thermal conductivity should separate you from the street.

- Article

- Video

- Photo

What is preferable - expanded clay or mineral wool?

First, let's figure out why. You can insulate walls, ceilings and roofs. Now let's look at the characteristics of the materials between which we have to choose. We are primarily interested in thermal conductivity; for expanded clay its coefficient is 0.1, but for mineral wool it is only 0.04 . Consequently, the latter will release much less heat outside than the former, with the same thickness of thermal insulation. And now the second important factor is weight. What is better, expanded clay weighing up to 250 kilograms per cubic meter or mineral wool, the mass of which is no more than 30 kilograms for the same cubic meter?

The friability of expanded clay depends on the size of the granules, which can have a diameter of less than 5 millimeters (sand) and up to 20-40 millimeters, and coarse-grained material is cheaper.

But it is too early to draw conclusions. Let’s say that a 5-centimeter layer of mineral wool is enough to insulate the ceiling. Accordingly, expanded clay will need to be poured 12 centimeters. Even if it weighs 8 times more than fibrous insulation, it is unlikely that expanded granules from baked clay will require an increase in the load-bearing capacity of the walls and foundation. We make a low box over the entire floor area, fill it with expanded clay, cover it with a vapor barrier, and everything is in order. One should also take into account the fact that the smallest particles of mineral wool, if they get into the lungs, can lead to serious diseases, and clay is an environmentally friendly product.

Which is cheaper: comparison of the cost of two materials

1 cubic meter of expanded clay gravel can be bought for 1,500 rubles, 1 roll of mineral wool measuring 8200x1220x50 mm costs from 1,400 rubles.

The cost estimate for insulation should include costs for:

- for the services of loaders - for the delivery of heavy bags of expanded clay;

- additional consumables - timber, vapor barrier membrane, fasteners;

- personal protective equipment - important when using mineral wool insulation.

To simultaneously solve the problems of thermal insulation and sound insulation, it is clear that mineral wool is better. Expanded clay is not an insulation material, and the low cost of the material can be completely offset by the need to use it in large quantities.

Insulation of the foundation from the inside. Why and how do they do this? on the Nedvio website

- Select House Cottages

- Houses in villages and villages

- Houses in SNT, DNP, DNT

- Houses in villages and villages

- Dachas

- Mansions and estates

- Duplexes

- Townhouses

- Cottage villages

- Ready-made, built villages

- New buildings, settlements under construction

- Without a contract

- Questions and answers

Question from a reader of our portal: Insulating the foundation from the inside. Why and how do they do this?

Answer: Internal insulation of the foundation is an important stage in the process of building or operating a house, and here’s why. The foundation is the most important building structure, on the “shoulders” of which lies the performance of many main functions. Depreciation of a living space is the main task of the foundation; however, an equally important function is to protect the lower log houses and basement from excess moisture. This protection is necessary throughout the year, since in winter, autumn, and spring, the basement and other lower parts of the house are exposed to floods and other unfavorable environmental conditions.

Why insulate the foundation from the inside?

Proper insulation of the foundation inside the house is the key to warmth and comfort in your home and other wooden buildings. The strength of the lower rims will depend on the correct performance of the thermal insulation work.

First you need to explain the importance of insulating the foundation from the inside. To understand this, you need to know about the existence of such a thing as temperature heaving of soil. Low temperatures freeze the moisture in the soil. After which the soil expands in the places where the foundation is laid, the blocks are pushed to the surface of the earth, and the wall structures are warped.

There is a foundation based on screw piles, in relation to which the level of soil compression does not matter. This is the main advantage of this type of foundation, which affects its popularity. But even the strongest pile-screw foundation is recommended to be insulated for greater durability.

What materials are best to use?

Typically, when choosing thermal insulation materials, builders look at two indicators - the thermal conductivity coefficient and the behavior of the material under real operating conditions.

Expanded polystyrene is considered the best option to maintain a balance between these properties. Insulating the foundation from the inside with polystyrene foam is especially common in mid-latitudes, where the coefficient of soil heaving and freezing is low. However, it is worth remembering that over time this material gradually depolymerizes, producing styrene.

The foundation is also insulated from the inside using cotton wool insulation and spray-on compounds, but they also have their drawbacks - the need to create a vapor-tight barrier and the inability to produce insulation yourself.

How to insulate the foundation from the inside of a house?

Modern technologies for thermal insulation of foundations on piles include several step-by-step procedures:

- Waterproofing the buried and above-ground layer of the grillage with waterproofing film or roofing felt;

- Laying polystyrene foam and polystyrene foam - insulation materials;

- Finishing the surface with sheets of plasterboard or using plastering.

This technology will allow you to create optimal conditions for the favorable operation of the building. If there are deposits of groundwater on your site, then you need to build a drainage hole to drain it and lay a layer of special material under the pile cap.