Building a house is an important and very responsible step, since you need to not only imagine what you want, but also know exactly how to implement it in practice. The first thing any person cares about when building a house is warmth. After all, your home should be cozy both in winter and in summer. Only correctly selected material for the construction of future housing will help achieve this effect.

If you want to build a better home, but don’t know where to start, we recommend contacting. We build houses in Moscow and the Moscow region based on all requirements and standards, which means that your housing will meet all modern standards. If you want to understand construction technology on your own, then let’s move on to the topic of our article today – foam block. What kind of material is this? How warm is it? And how thick should a load-bearing wall made of foam blocks be in Moscow?

“Foam block” material – what is it?

Foam block is a fairly new building material, but despite this, builders have already recognized it as one of the best options for building houses. It looks like a regular block, but has a porous structure. The standard dimensions of the foam block are 200x300x600, but manufacturers also make others in order to meet the needs of the modern construction industry.

Foam blocks are made from a mixture of sand, cement and water

.

Some companies add clay, ash or other substances to this, depending on what characteristics they want to achieve. After mixing the solution, a foaming agent

: it can be either organic or synthetic. It is better, of course, to purchase foam blocks made from organic materials; they are environmentally friendly and will not harm your health. Synthetic materials make the foam block less durable and more harmful to health, but they are undoubtedly cheaper. If you are building a house for permanent residence, we recommend using only the best materials; you will have to overpay a little and your grandchildren and great-grandchildren will live peacefully in such housing.

There are several types of foam blocks, they differ in density (indicated by the marking “D”). The thickness of a foam block wall for a home depends on this indicator, so before you calculate it and buy the material, you need to study it.

Types of foam blocks

Thermal insulation

– used for insulating walls and constructing internal partitions. The marking of such blocks is D300-D500, which means that the density of the material is 300 kg/m3.

Structural and thermal insulation

– used for additional insulation, construction of walls of low-rise buildings. This type of foam blocks is marked D500-D900.

Structural

– used for the construction of load-bearing structures (foundation, basement, etc.). Block marking – D1000-D1200.

Separately, it is worth noting that the lower the density of the block, the better it is in terms of thermal insulation, but worse when constructing buildings. Well, blocks with better density retain heat much worse. Therefore, low-rise buildings should be erected from foam blocks with a marking of at least D600, and then additionally waterproofed, insulated and other external and internal work must be carried out.

How to insulate walls made of foam concrete

Foam concrete itself is a construction insulation material. Its thermal conductivity coefficient is about 0.2 W/mC (density 800 kg/m3, compressive strength B5), which is considered a high thermal insulation indicator for the material from which walls are built.

Therefore, it is possible to build a wall of foam concrete of the required thickness, which will meet the requirements of thermal insulation standards, and will save the owners money for heating and ensure thermal comfort in the room.

We use aerated concrete

But how thick should a foam concrete wall be? What needs to be taken into account in order to insulate such a wall correctly? It turns out that not everything is simple. And to avoid problems after insulating walls made of foam concrete, it is better to familiarize yourself with the following recommendations.

Often in everyday life, foam concrete is called factory-made autoclaved aerated concrete, which is the recommended material for building houses.

Foam concrete is cheap chemically foamed concrete, often homemade without standards, emitting harmful chemicals, and can only be used for the construction of non-residential buildings.

Further, the word Foam concrete will be understood as autoclaved aerated concrete or gas silicate, from which houses are built.

Foam concrete is a good insulator

The thermal conductivity coefficient of foam concrete directly depends on its density. For load-bearing walls, depending on the project, foam concrete with a density of 500 - 1000 kg/m3 can be used. In this case, the spread of the thermal conductivity coefficient will be 0.14 - 0.29 W/m C - 2 times.

In order for the thermal insulation qualities of a foam concrete wall to be sufficient for the southern and midwestern regions, the thickness of the material must be equivalent to foam plastic with a thickness of at least 10 centimeters. (standard - resistance to heat transfer - just below 3.0 cm/W). Then the thickness of the foam concrete wall for different densities of this material should be no less than:

- M600 – 37.5 cm,

- M-700 – 45 cm

- M-800 – 52.5 cm,

- M-1000 – 72.5 cm.

Need walls that are too thick

The higher the strength, the thicker the wall is needed for heat conservation. At the same time, in terms of structural strength, such a thickness will be completely unnecessary.

It is possible that for some conditions, a compromise solution would be to build walls 45 cm thick or more from foam concrete with a density of 700 kg/m3.

But, it should be noted that for harsh climates, the thickness of the walls must be increased, and the equivalent of insulation (foam plastic) should be 15 cm and 20 cm.

Therefore, 60 - 80 centimeter walls made of foam concrete are found in modern construction. But are they profitable?

Single-layer walls are better and more reliable, but...

Such thick walls do not need additional insulation. By building a single-layer wall from foam concrete, you can be sure of its reliability and durability, which are much higher than that of two-layer structures.

But now you can find many houses built from foam concrete so that they are not so warm. The thickness of the walls in such houses does not exceed 25 - 35 centimeters.

And for cold climates this is 2–4 times lower than the recommended standard values (economically feasible) for the wall’s resistance to heat transfer. Owners spend a lot of money on heating. Such walls need to be insulated, as it is economically profitable to do so.

External thermal insulation is used

It is not recommended to insulate foam concrete walls from the inside of the building. Fencing with insulation will cause the walls to cool and freeze. There is a high probability that the dew point will be in the wall, resulting in moisture accumulation.

But even when externally insulating walls made of foam concrete, a number of nuances must be taken into account. The main one is the vapor permeability of layers in an insulated structure.

To prevent moisture accumulation at the dew point, vapor permeability should increase towards the cold air (outside). In fact, foam concrete can be insulated on the outside with a layer of sufficient thickness only of the most vapor-transparent insulation, i.e. only with cotton wool.

Advantages and disadvantages of foam block

Any building material has its pros and cons, foam block is no exception to the rule. If you are building a house and are calculating how thick a wall made of foam blocks should be, we recommend that you study this issue, because the advantages of the material may fade next to the disadvantages, and then you will have to change the construction plan.

- environmental friendliness,

- ease,

- good sound insulation,

- excellent thermal insulation performance,

- rapid erection of houses made of foam blocks,

- low cost of building materials,

- fire safety.

- transportation: transporting foam blocks is quite simple - this is a plus, but due to their fragile structure they can be deformed - this is a minus,

- absorbency: the structure of foam blocks allows them to absorb quite a large amount of moisture, so external walls made of this material require additional waterproofing, and this is extra costs,

- shrinkage of buildings made of foam blocks: a house made of this material can shrink within 2-3 mm per linear meter, so it is better to start finishing no earlier than 3-4 months after the construction of the building. This drawback significantly increases construction time, which means you can quickly build a house, but not live in it.

- finishing of walls made of foam blocks should be carried out with special mixtures, plasters, paints, etc.,

- reinforcement is mandatory: since the material is light and subject to deformation, it needs to be reinforced, experts recommend doing this every 4 rows,

- masonry features: foam blocks should be laid on a special adhesive composition, but if you use a cement-sand mixture for this purpose, then the thermal insulation and sound insulation will be much worse.

How to insulate a house made of foam blocks - technology and important nuances of modern thermal insulation

Foam block walls, due to their ability to absorb and accumulate moisture, require insulation. But how to perform thermal insulation as efficiently as possible and without harm to the structure? I suggest you familiarize yourself with thermal insulation materials and the technology of their installation, which will allow you to independently make a house from foam blocks warm and durable.

What does it offer?

We offer you the construction of a house using frame technology or BENPAN+ technology. Both options are much cheaper than house designs made of brick, timber or foam block. In addition, they are built quickly. In just 4 months you will be able to move into a new, warm and cozy home. And note - for permanent residence. Read about our advantages and offers here: “Construction of turnkey houses in Moscow.” We have described in detail what you get from a transaction with us in addition to what was said above.

For detailed consultation, you can contact a consultant. He will answer all your questions and provide other information that interests you. If you want to discuss the issue in more detail, you can talk with our management.

We improve it by insulating it from the outside

For insulating a house from foam blocks from the outside, it is the most acceptable option. This method has a number of undeniable advantages:

- additional protection of wall material from the damaging effects of wind and moisture;

- removal of the dew point outside the enclosing structure, which prevents freezing and premature destruction of the blocks.

Insulating a house made of foam blocks from the inside significantly reduces the usable area. There is a certain feasibility of carrying out internal work in the event that the cost of money and time is significantly less than when carrying out external work or insulation is carried out on an already functioning facility with expensive finishing.

Before insulating houses made of foam blocks from the inside, carefully weigh all the pros and cons of this method of thermal insulation.

When insulating a block house located in areas with a warm climate, it is enough to plaster the walls with cement-sand mortar.

Construction of houses in Moscow

If you don’t know how to build a house, entrust this task to us! has been operating on the market for more than 15 years, we are a reliable contractor. Our specialists are ready to make a home for you, based on their own experience, modern technologies and government standards. Using all this, we get excellent housing for permanent residence. In our houses you will be warm in winter, cool in summer and comfortable at any time of the year.

Construction work involves financial expenses, effort and calculations that are not always possible to do on your own. It is not enough to build a wall of a certain thickness from foam concrete; you need to understand in detail the design, the rules for carrying out calculations, and the specifics of the work. For this reason, it is very important to understand how the thickness of future walls made of foam blocks is calculated so that it meets the requirements of generally accepted standards.

Insulation of foam block walls - outside or inside?

It is more advisable to insulate the wall of a house made of foam blocks from the outside:

- No usable area is lost.

- The dew point does not shift inside the load-bearing wall.

- Foam blocks are under reliable protection.

Materials and tools

To carry out work on thermal insulation of walls made of foam concrete blocks from the outside, you will need the following tools:

- screwdriver;

- glue container;

- a spatula for applying it (a serrated one or, as it is also called, a “comb” is suitable), as well as a wide spatula for plaster;

- stationery knife (construction knife);

- brush or roller;

- protective clothing, glasses, gloves;

- hammer drill, electric drill, hammer;

- level;

- roulette.

- mineral wool slabs;

- fiberglass mesh;

- perforated base profile;

- umbrella dowels;

- dowels for fastening the profile;

- polymer cement adhesive for mineral wool boards;

- deep penetration primer;

- plastering mixture.

Why is it important to know the thickness of the walls?

Reflecting on the question of what the thickness of walls made of foam blocks should be, you can hear a lot of reasoning, many of which are misleading.

In order for the decision you make to be correct and safe, it is recommended to know a number of features that you need to build on:

- Find out what the coldest winter temperatures are in the area where you live. It may be necessary to thicken the walls with the installation of an additional thermal insulation layer.

- The type of insulation material must be determined - you will have to install it, or everything will come down to a simple layer of plaster. If the walls of a house under construction are built from foam blocks, the thickness of which is 30 cm, it is recommended to apply thermal insulation of 5 - 10 cm.

- The insulating layer not only affects the material that retains thermal energy, but also protects the foam blocks from ultraviolet radiation.

It is necessary to select foam concrete products taking into account their density. The higher its indicator, the more expensive the material is.

Features of the definition

In order for the thickness of a foam block wall for a home to be optimal, it is necessary to understand the thermal insulation advantages of foam concrete. For example, you can take a wall whose thickness is 600 mm, and see what dimensions walls made of other materials with similar thermal conductivity should have:

| name of material | wall thickness, mm |

| timber | 520 |

| expanded clay concrete | 1010 |

| brick | 2300 |

| concrete | 4500 |

It turns out that foam concrete can only be compared with wood in its ability to retain heat; other types of building materials require an additional insulating layer. Otherwise, the walls will turn out incredibly thick, or heating costs will exceed all expectations.

The relevance of insulating foam block houses from the outside

Foam concrete was created for those buildings that are erected in one layer. It has good thermal insulation properties. However, in a continental-temperate climate, winters can be very cold and windy, so experts still recommend additional thermal insulation of foam concrete.

Scheme

Another important factor is that foam concrete can freeze during prolonged cold and even absorb moisture. To prevent this from happening, insulation is carried out exclusively on the outside of foam block houses, which has a number of advantages over the inside:

- saving space indoors;

- condensation does not accumulate inside and does not settle on the main wall;

- thermal insulation protects foam concrete from freezing and moisture penetration.

Density dependence

Remember that sound insulation and thermal conductivity depend on the density readings of the material. For example, a wall made from a D 600 block, the thickness of which is 450 mm, can be compared in its ability to retain thermal energy with an analogue built from D 800 with a thickness of 680 mm.

This feature also applies to internal partitions. The D 200 foam block, whose thickness is 100 - 150 mm, will better protect the room from extraneous sounds than the D 300 or D 400 material, which has the same thickness.

In order to understand exactly how thick a wall made of foam blocks should be, how much material is needed and what brand, you can use the calculator on one of the construction sites.

And from the corresponding SNIP II 3 79 you can take the necessary indicators, with the help of which the thermal conductivity of the wall of any composition and foam blocks of different densities can be determined.

Features of insulation technology with various materials

Once you have decided on the material for insulating the foam concrete, you can begin preparatory activities. First of all, the amount of material required is determined and the necessary tools are selected.

It is important to remember that due to the size of any sheets for wall insulation, you will need an assistant to facilitate the entire installation process.

How to insulate a house made of foam blocks from the outside with foam plastic

Before starting work on insulating foam concrete walls, they must be prepared. They must be cleaned of old paint, debris, and plaster. It is also recommended to seal all cracks and holes.

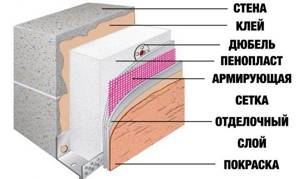

The process of foam insulation itself occurs as follows:

- A deep-penetrating primer is applied to the wall to ensure maximum adhesion of the adhesive to the foam concrete;

- a starting strip is installed at the bottom of the building to support the starting strip of foam;

- prepare the adhesive solution according to the manufacturer's instructions;

- the surface of the foam is processed to create roughness;

- Apply a layer of glue to the slab with a spatula;

- the insulation is fixed on foam concrete, the rows should go from bottom to top;

- The foam is additionally reinforced with dowels with a wide head.

After the installation of insulation is completed, decorative and finishing measures are carried out.

Insulation of foam concrete with mineral wool: stages of work

When insulating foam concrete with mineral wool, it is also necessary to pre-clean the walls. In this case, the surface should be as smooth as possible.

The whole process looks like this step by step:

- a solution of antiseptic agents is applied to the foam concrete;

- vapor and waterproofing membranes are attached;

- brackets for the sheathing are installed;

- vertical and horizontal guides are mounted;

- Insulation is inserted and secured with dowels.

When using mineral wool, plaster and further painting are most often used as cladding.

Installation of thermal panels

The most optimal option for installing thermal panels on foam concrete is a ventilated facade system. Once the structure is installed, the installation of panels begins. As a rule, they all contain special grooves for fastening, so the work is done quickly and easily. All work should begin from the corner of the building, after installing the starting elements.

In this case, it is recommended to attach a film to the main wall to protect it from moisture.

Insulation using penoplex

Work on insulating foam concrete with penoplex is completely identical to work on insulating walls with polystyrene foam. In this case, preparatory work is also carried out, an adhesive solution is prepared, the slabs are attached to the facade in a similar way, fiberglass mesh is installed, and decorative cladding work is carried out.

Thermal insulation with penoplex

When using penoplex for foam concrete, there is no need to use additional vapor barrier membranes, since the raw material already has high performance in this parameter. Also, due to the light weight of the slabs, the work can be done independently, without the help of a partner.

Calculation of wall thickness

In order for your wall made of foam blocks to be sufficiently reliable and warm, you should perform thermophysical calculations and determine the strength. The calculation actions will be based on foam concrete material, the density of which is D 600.

Remember that the thermal conductivity resistance of external walls (including all finishing layers) must exceed 3.5 degrees per m2/W.

To determine the thickness, it is proposed, taking different densities of foam concrete as a basis, to analyze this process in more detail:

- as follows from the technical indicators, blocks of the D 600 and D 800 brands have corresponding coefficients of 0.14 and 0.21 degrees * sq.m./W;

- The finishing material will be brick for facing work and a decorative plaster layer, the coefficients of which are 0.56 and 0.58 deg* sq.m/W, respectively.

Let's start performing calculations:

- First you need to decide how thick the brickwork and plaster layer will be. As a rule, an uninsulated facade is covered with a double row of brick material, which is 12 cm;

- convert the resulting size into meters and divide it by the heat conductivity index of the material for facing work. The result is a resistance index of 0.21;

- We perform the same calculations with the plaster material. The desired value should be 0.33.

The next step is to substitute the resulting numbers into a simple formula:

- (foam concrete block with a certain density - brick - plaster layer) multiplied by 0.14 (coefficient corresponding to our block). We convert the resulting result into millimeters, and the desired value will be approximately 450 mm. This is an indicator of wall thickness if you use a D 600 block;

- Having performed similar calculations for the D 800 foam block, you will obtain a thickness of the future wall of 68 cm.

Please note that the second option requires a thicker wall. It follows that the financial costs will be much more serious. And if you add a layer of expanded polystyrene, the thickness of the facade walls will decrease.

It is appropriate to add that a two-story structure with dimensions of 10 by 10 meters for every 10 cm of wall thickness creates a load reaching tens of tons. This is despite the fact that the ceiling, roofing structure and walls of the upper floor weigh 15 - 18 tons. Added to this is the mass of things on the floor, the probable load created by the snow cover, masonry defects and wear and tear of materials from use are taken into account. Based on the above factors, the design solution determines the thickness of the walls made of foam blocks to be 30 cm.

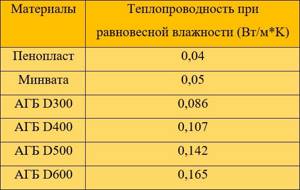

How to calculate the thickness of insulation

- The required total thermal resistance (R) is 5.28.

- R of aerated concrete wall 400 mm from D500 – 2.6.

- R of the insulation should be: 5.28-2.6 = 2.68

Now you need to use a table that shows the thermal conductivity of insulation materials, in our case mineral wool.

AGB – autoclaved aerated concrete

The thermal conductivity of mineral wool at equilibrium humidity is 0.05.

The thickness of the insulation is determined quite simply: the required thermal resistance of the insulation is multiplied by its thermal conductivity, that is

2.68 x 0.05 = 0.134 meters.

Conclusion: we need mineral wool with a thickness of 134 mm. But mineral wool slabs are sold in multiples of 50 mm, which means the insulation layer will be 150 mm.

Important! The economically justified thickness of mineral wool for wet facades is from 100 mm.

Since when installing insulation (wet facade) it is necessary to use several layers of plaster, mesh, facade umbrellas, and other fasteners, there will not be much savings between insulation thicknesses of 50 and 100 mm. And the cost of work and consumables when installing insulation of different thicknesses is almost the same.

We also note that 100 mm of insulation, in 90% of cases, shifts the dew point from the wall to the insulation. That is, moisture will never freeze in the wall, therefore, the service life of such a wall will be almost endless.

How to insulate aerated concrete, mineral wool or polystyrene foam

Mineral (stone) wool and polystyrene foam are the main insulation materials for aerated concrete houses. Low-density aerated concrete (D200) and sprayed polyurethane foam are used much less frequently.

Insulation should be carried out only from the outside of the building so that the dew point is closer to the outer layer of the wall.

Dew point is a place in the wall with zero temperature. In this zone, a zone of increased condensation (moisture) is formed; the wall in this place constantly freezes and thaws.

If we compare polystyrene foam and mineral wool, then wool is a more expensive and correct solution for aerated concrete walls; it’s all about vapor permeability. Cotton wool has excellent vapor permeability, which ensures that moisture is removed from the wall to the outside of the house. Thus, the interior will be drier and more comfortable. The thickness of mineral wool insulation can be made to any thickness, but it is more economically feasible - from 100 mm.

Polystyrene foam does not allow steam to pass through well, trapping it in the wall and creating increased humidity in the house. Moreover, aerated concrete walls need to be insulated with foam plastic with a thickness of 100 mm or more in order to guarantee that the dew point will shift from the wall to the insulation. Otherwise, at the boundary between the foam plastic and the wall, moisture will constantly freeze and thaw, reducing the service life of the wall.

In general, we recommend using mineral wool or foam plastic with a thickness of 100 mm or more, but it is better to give preference to mineral wool.

How to insulate

Since the foam block does not have very high strength, it is necessary to use lightweight materials for its finishing.

Outside

The most commonly used insulation materials for external walls of a house:

- Mineral wool. This is an inexpensive material with high thermal insulation characteristics. It is vapor permeable, so moisture does not linger inside the blocks, has a long service life, and is not flammable. The material must be well protected from moisture, otherwise its characteristics are reduced, and you must work in a respirator.

- Expanded polystyrene (foam plastic). This material is not afraid of high humidity, it is frost-resistant, and has an affordable price. Please note that polystyrene foam deteriorates when exposed to sunlight, so it requires additional coating.

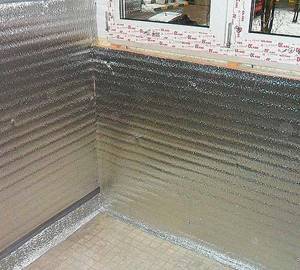

Inside

If you decide to carry out the above work inside the house, then first decide whether it needs to be done.

Foam concrete has high heat and sound insulation characteristics, and if you additionally insulate it from the outside, then there is no need to do this inside.

Materials

Indoors, it is best to use fiberglass or basalt wool as insulation, and so that you can lay it yourself, it is recommended to take it not in rolls, but in slabs.

Cork

This material not only acts as insulation, but can also be used as a finishing coating.

Before using it, the walls must be properly leveled using plaster; they must be clean and dry. The only drawback of cork is its high cost.

Penofol

If you insulate walls made of foam concrete with it, then about 95% of the heat will remain indoors. Thanks to the presence of foil, heat returns to the room.

The slabs are laid tightly, and all joints are taped, after which you can begin installing the finishing material.

Polyurethane foam

This is a foam material, with the help of which all cracks and voids are sealed, so cold bridges do not form.

This material hardens within 20-30 seconds after application and will serve for at least 50 years.

The disadvantage of polyurethane foam is its low vapor permeability and the fact that additional equipment is required for its application.

When to start insulating an aerated concrete house

Autoclaved aerated concrete leaves the factory very wet; in order to dry sufficiently, it takes time, which depends on the thickness of the blocks, precipitation, temperature and winds. If fresh aerated concrete is covered with insulation, this will significantly increase its drying time, and wet aerated concrete retains heat less well. Moreover, a lot of moisture from aerated concrete will penetrate into the insulation, worsening the properties of the insulation itself.

If you insulate a house with mineral wool, then you should wait 3-6 months; in the case of polystyrene foam, it is better to wait 6 to 12 months.

Features of aerated concrete insulation

The technology for insulating aerated concrete blocks is not much different from the thermal insulation of other stone buildings. The sequence of work is described in detail in SP 12-101-98 and other regulatory documents. Mineral wool slabs are attached to aerated block walls using glue and are additionally secured with dowel nails for aerated concrete. When is it necessary to insulate a 300 mm aerated concrete house? Thermal insulation work can be carried out immediately after completion of construction at any time of the year at temperatures down to -15 °C. When insulating in winter, you should choose an adhesive labeled “frost-resistant,” and before applying it, clean the aerated concrete from ice and moisture.

Before attaching thermal insulation, you need to inspect all seams. It is recommended to reseal the seams. For sealing, you can use an aerated concrete adhesive solution or special polyurethane foam.

It is quite possible to insulate a foam concrete house yourself. It is important to properly treat the walls before covering them with insulation. Depending on what kind of house you have and what material it is built from, the insulation procedure may differ slightly.

Whatever material you choose for wall insulation, you need to do everything strictly according to the rules, and then your home will be warm. If you don’t know which material is better to choose, mineral wool or polystyrene foam, consult with the experts. But as practice shows, mineral wool/glass wool is most often used, as it has many advantages.