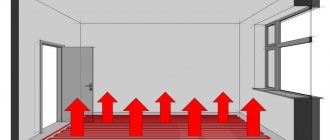

Frame houses on stilts mean quick construction and low cost. But they do not have a solid foundation, which leads to the cooling of the floors. Therefore, it is recommended to install underfloor heating in these houses.

If you are planning to build a frame house on stilts, then this article will be of interest to you. You will learn about the positive and negative aspects of underfloor heating systems. We will figure out which model is better to choose, and tell you how to install the heating yourself.

Pros and cons of heated floors in a frame house on stilts

Warm floors are artificially created heating that can provide comfort in the home. There are two ways to insulate a house with underfloor heating, using water or electrical systems. We will understand the advantages and disadvantages of such systems specifically in relation to installation in a frame house, which does not have a permanent foundation, but is placed on screw piles.

The main advantages of heated floors in a frame house on screw piles:

- uniform heating;

- saving usable space;

- there is no movement of air, thereby no movement of dust and microbes;

- they improve the appearance, since there are no heating radiators;

- have a convenient way to maintain temperature due to automation and regulators;

- long service life - especially for water ones.

In addition, since frame houses on stilts do not have a permanent foundation, the advantages of heated floors include the fact that they cut off the cold air that moves under the floor.

And an additional advantage of electrical types, especially infrared systems or cable mats, is ease of installation.

Let's consider the disadvantages - high cost and inability to install in a thick concrete screed. In addition, complex calculations are required.

Electrical systems are a fire hazard when considered in tandem with wooden houses. But if the installation technology is followed, the risk of fire is minimized. The disadvantages of water heating include the possibility of leakage and the large mass of the screed into which the “pie” is placed.

Screw piles

A pile foundation is installed when the soil is weak or we observe a high groundwater level. It is used when there is a significant difference in height. But often people choose a pile foundation simply for the sake of economy and ease of installation.

Screw piles for the foundation.

Screw piles are metal pipes with a screw at the end. Such piles are inexpensive and quickly installed mechanically by a professional team or manually by a team of migrant workers.

An adjustable cap is placed on top of each pile if the house is supposed to be made of timber or a log house. If part of the house subsides, by adjusting the headrest, you can correct the situation.

Adjustable head for screw piles.

If the house is supposed to be built using frame panels, a frame is welded on top of the piles, on which all load-bearing structures will rest.

The frame on which the entire frame house structure will rest.

The foundation on screw piles has both its pros and cons.

The advantages include:

- low cost of construction;

- fast construction;

- reliability of the foundation at high groundwater levels;

- construction of a cheap foundation with a significant difference in height;

- low delivery costs.

It is better to choose galvanized piles. Although such piles are more expensive, they are more resistant to corrosion and will last longer. Ungalvanized piles can rot in as little as 15 years, requiring you to repair the foundation.

Disadvantages of a pile foundation:

- cold underground;

- possible heaving of the soil, pushing out piles that fall into the freezing zone;

- possible settlement of the house;

- pile corrosion.

The main problem with pile foundations is the cold underground. The underground turns out to be cold due to the fact that the ceiling is raised above the ground and there is free space under it.

Often builders leave the basement open until “better times”, because there is not enough money and time to insulate it. It is more important to first complete the house, install heating there, and complete the interior decoration.

There are several techniques for insulating the floor of the first floor:

- insulate the floor underneath the house;

- insulate the base;

- make a warm floor.

Each of these methods can be used for insulation.

What type of underfloor heating should I choose?

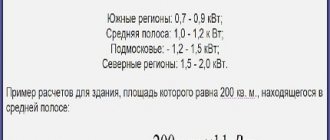

Before choosing a heating floor model, you should decide whether it will be the main heating or additional heating. If the main one, then you need to take a more powerful system.

Electric floors (cable or infrared) can be installed everywhere, but the water type can only be installed on the ground floor - there will always be a risk of leakage. In addition, if a screed is poured, the result is a heavy structure, and it is not recommended for frame frames, since this is an additional load on the piles.

When choosing a model, the following are taken into account:

- climatic conditions;

- geological features of the region;

- house design;

- level of heat loss.

From the point of view of energy saving, water heating is more profitable; heat is released due to the movement of hot coolant through pipes. The coolant is heated in boilers, which often operate on gas or solid fuel.

However, the installation process is more labor-intensive and expensive, but these investments quickly pay off during operation. In addition, you should pay attention to the fact that today lightweight systems have been developed specifically for frame buildings.

Electric types (heating cable, mats or film) are easier to install, and the structure is lighter in weight, especially infrared film. Electric floors can be laid without screed, in a “dry” way, or in a layer of tile adhesive. But they run on electricity, so their use will cost more.

Auxiliary protective coatings

When choosing a material for arranging the waterproofing and windproof layers of the insulating “pie,” we advise you to pay attention to modern film or membrane coatings that combine both protective functions at once.

For these purposes, a special wind- and moisture-proof film can also be used.

On the finished floor side, a vapor barrier is laid on the insulation, using ordinary polyethylene film.

Auxiliary protective coatings: vapor barrier and wind protection

External wooden structural elements from which the subfloor frame is made, as well as plank and plywood blanks, are necessarily treated with antiseptics that protect them from fungus, mold and insects.

Important ! Conventional antiseptic compositions in conditions of high humidity do not always provide the required degree of protection for wood, since they can “wear out” over time. To protect the wood elements of the insulating “pie”, it is recommended to use special deep penetration compounds.

Installation of heated floors on stilts

We will look at the simplest and most convenient technologies for constructing water and cable heating.

Warm floor in a frame house according to SNiP. Build Yourself a House.

Water

Water floors can be installed using two technologies: a floating screed or a flooring method (wooden or polystyrene). The heater is a 16 mm metal-plastic pipe.

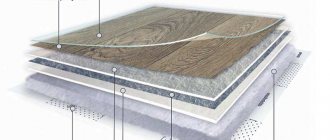

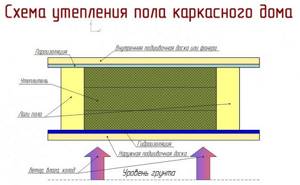

For frame houses on stilts, a “dry” screed made of polystyrene foam mats is better suited, since it is lightweight compared to concrete. The “pie” of such a hydrofloor consists of:

- flat base;

- waterproofing;

- damper tape;

- polystyrene plates with grooves;

- special aluminum reflectors;

- pipeline;

- second layer of waterproofing;

- GVL sheets;

- floor covering.

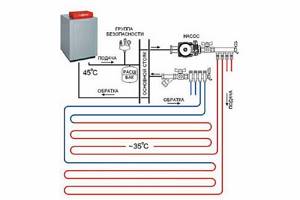

The coolant is heated in a boiler; it can be gas or solid fuel.

Cable mats

Although the infrared system is easier to install, we will consider installing a cable floor, since the film is only suitable for installation on the second floor. To heat the first floor of a house on stilts, which does not have a capital foundation, its power will not be enough.

Cable mats are wires fixed to a mesh with a standard pitch. The peculiarity of installation is that they can be mounted in a layer of tile adhesive. It is enough to prepare the base and cover it with waterproofing material and insulation on which the mats are placed.

In addition, to regulate the temperature level you will need a thermostat and a sensor.

Let's sum it up

From everything said above, it becomes clear that the main task when forming a floor that needs to be solved is protection from the penetration of air and moisture, both from the outside and from the inside. Therefore, it is impossible to lay vapor-permeable membranes, as is the case with the facade of a frame house.

Thermal insulation material must be hermetically protected on all sides - including on top, because something can always spill or leak in the house.

To reduce the penetration of water into the floor frame to a minimum, we recommend making another one on top of the hard protective layer - from tongue-and-groove gypsum fiber board and pouring a thin self-leveling screed. It is already possible to install any covering on it, but it is better if it is also sealed. Ceramics for such a design may be heavy, but quartz vinyl tiles or welded linoleum are just the thing.

Tongue-and-groove chipboard sheets

Alternatively, you can provide a layer of dense tongue-and-groove EPS, on top of which lay Quick-Deck or cork slabs.

EPPS is an excellent base for any type of coating

Floor design with Quick Deck Plus slabs - tongue-and-groove chipboard with decorative face covering

They also have a tongue-and-groove connection, and the joints are also sealed with sealant. In addition to beauty and a reliable barrier to water, this will also provide two additional insulating layers.

Subfloor installation

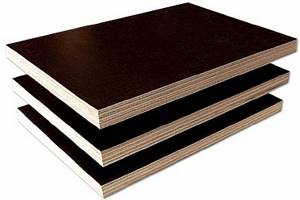

The subfloor is a flat covering located between the blocks; the finishing is installed on it. Since overloads are not desirable for piles, a durable but not heavy material is required.

There are several suitable options for arranging the foundation of a frame house:

- OSB - the material is durable, but vulnerable to water. It needs to be treated with a special protective compound. The weak points of this coating are the joints.

- Chipboard is easy to install, but is also susceptible to moisture. In addition, it is less environmentally friendly than OSB.

- Multilayer plywood - only moisture-resistant types (FK or FSF) are suitable. They contain formaldehyde resins, which make the material more resistant to aggressive environments.

Often boards up to 10 cm thick are used to construct the flooring. The result is a durable and reliable floor.

Insulation materials and their properties

The floor, like the external walls, is an enclosing structure, as it separates the warm rooms of the house from the ground. Accordingly, it is also subject to the rules on the need to lay effective thermal insulation protected by anti-diffusion layers.

Basic insulation scheme

Unlike vertical structures, not only rolled mats or slabs, but also bulk or loose materials can be used to insulate the floor (methods for insulating a frame house are described in detail in our article). You just need to remember that they must be light, since the structure does not have the ability to rest on the ground. Therefore, such a fairly weighty material as expanded clay cannot be used in this case.

But what is possible? We hope that the next chapter will help in choosing the right insulation.

Slabs and cut mats

The use of rolled soft insulation or more rigid rectangular blocks is a traditional option for floor insulation.

Variety of materials

These materials include:

- Mineral wool (GOST 4640-2011), produced either from the melt of gabbro-basalt rocks, or from volcanic or metallurgical slag. The advantage of these wools is not only the thermal conductivity coefficient required for this design, but also its almost absolute non-flammability. According to the standard, the temperature limit for them ranges from -180 to + 700 degrees (read the article about insulating a frame house with mineral wool).

Basalt slab

Cutting mat made of slag wool

Glass wool in roll

- Foam plastics (GOST 15588-2014). This term may hide slabs made of foamed plastics, two types of which are actively used in construction. One is polystyrene and the other is polyurethane. The latter is also molded into slabs, but due to the higher price in this form it is less popular among the people. If it is used, it is often in the form of foam, but expanded polystyrene is in great demand. PPS slabs come in three types: the cheapest type “P”, which is cut from one large block and has a pronounced grain structure, and “T”, formed by pneumatic, vacuum or combined methods. Both options may contain graphite, which is added to improve thermal insulation characteristics.

Eps with graphite

Extruded polystyrene, type "T"

Polystyrene type "P"

Note: Polystyrene boards may have a quarter molded edge. But here this is not required, since the slabs are not joined to each other, but are laid between the logs. Therefore, to insulate the floor inside the frame, you need to take the option with a regular rectangular edge. The sizes of these slabs are different, as are the variations in thickness.

- Ecowool (GOST 16381-77). This term is usually used to refer to cellulose insulation containing fire retardant and biocidal additives, but according to the standard, the type of ecowool raw material used may differ. That is, they can be made not only from inorganic substances, but also from organics or a combination of both. So you shouldn’t rely on the absolute environmental friendliness of this material, which is so promoted by its sellers. However, it is quite suitable for floor insulation, especially if it is not loose wool, which can lose volume, but slabs or mats.

We produce flooring

When choosing the type of material for the floor, it must be not only durable, but also lightweight. After all, it is desirable to minimize the load on the supports. It is better to choose wood - aspen, oak or coniferous trees. The tree must be dry and without damage. It must be treated with antiseptic agents before installation.

The floor in a frame house on a pile foundation is two-layer - the base and the wooden material. It should be equipped immediately after installing the base of piles and grillage.

The work consists of several stages. First, the strapping is done, for this you need beams 10 by 10 cm. They are installed on piles and connected with screws. If there is more than 3 m between them, then additional racks in the middle are required.

Logs with a cross-section of 10 by 25 cm are mounted on the beams, in increments of 50 cm. To install them, grooves are made in the harness into which the logs are inserted and secured to the base with screws. The bottom of the logs is covered with boards 3 by 3 cm.

To make the structure more durable, slats are placed on top of the logs in increments of 150 cm. Flooring made of OSB boards or plywood is mounted on them. Hydro- and heat-insulating material is first laid in the logs.

Floor insulation

It is recommended to choose thermal insulation from the following types of materials:

- Mineral wool - slabs of basalt fiber. The material is environmentally friendly, non-flammable, has low thermal conductivity, and a water absorption level of 2%. When using cotton wool, do not treat boards with water-based emulsion.

- Extruded polystyrene foam is a leader today. PPS is resistant to deformation, elastic, easy to install and does not absorb water. The main disadvantage is the high price and flammability of the product.

- Expanded clay is a budget option, an alternative to sheet insulation. It is fireproof, but is slightly inferior to the above listed types in terms of thermal insulation.

- Polystyrene foam is inexpensive and has good heat-shielding properties. But under the influence of cold and moisture, its structure is disrupted.

Mineral wool is most suitable for a frame house on stilts. It is lightweight and does not create a serious load on the floors. A layer thickness of only 10 cm is enough to ensure good thermal insulation of the building.

For thermal insulation of the first floor, the best option is expanded polystyrene foam .

It creates a hard coating that protects against moisture and other influences. Expanded clay is recommended for insulating the base - cheap and high quality.

Installation of the pick-up

The installation of the fence depends on the method of cladding the building:

- Leafy.

- Brick.

- Frame.

Collection when using sheet materials

Frame houses are decorated with siding, lining, panels and other materials. In such cases, the ground floor is constructed using masonry. To do this we do the following:

- We install the frame - we attach horizontal belts to the pipes of the piles.

- We attach the base - it is better to use flat slate or DSP.

- We attach the waterproofing - it is better to use it in the form of rolls. It should pass under the blind area, while bending it onto the DSP to the top.

- We fasten the cladding - stone, clinker, porcelain stoneware.

- We install a blind area - it can be paving slabs, paving stones, etc.

Picking up when using brick materials

This masonry method is the most expensive. To save materials, we use half a brick for the plinth. We place the first row on a sand cushion. For waterproofing we use roofing felt tape, which we lay under the masonry and under the blind area.

Gathering when using frame materials

This is the most economical and simplest way to simulate a basement floor. This is an analogue of a ventilated facade, in which we attach the lathing not to the walls, but to the piles. The creation process is as follows:

- We create a frame on piles - for this we install two horizontal beams along the perimeter.

- We lay a layer of waterproofing - this is a roofing material installed vertically on the sheathing, which bends at the ground along the entire perimeter of the blind area.

- We install basement siding - these are PVC sheets with stone or brickwork shown. We fasten the material with clamps, self-tapping screws to a metal profile or nails to wood.

- We install a blind area - this is any material with which the sidewalk is decorated.

Using this type of drainage, we can install storm drains and trays that drain water into the sewer system.

Technology for insulating the floor under the house and the first floor

To keep a frame or log house warm, it is important to properly insulate the floor of the first floor. For thermal insulation of the floors of the lower floor of a house on stilts, polystyrene foam boards are suitable. They are taken standard 1 meter by 120 cm.

The technological process is simple:

- the slabs are laid along the joists;

- the slabs are screwed onto long self-tapping screws to the joists, while boards are placed across the joists;

- all joints are sealed with foam from the house;

- 200 mm insulation is laid between the joists on the side of the house. Mineral wool is suitable;

- vapor barrier is installed;

- a subfloor is installed - inch boards or chipboard.

With this insulation option, the dew point will be in the house, so it will be warm inside.

What is most often used to hem the floor from below? We count the money

Probably the most common option for lining the bottom floor that I have seen on other people’s construction sites is inch or OSB + VVZ film. The use of such materials is argued in different ways, from the fact that “we have always done it this way”, ending with the fact that it is cheaper than “newfangled windproof boards or insulation”.

It is important to understand that there must be material underneath your home

- with good vapor permeability;

- with sufficient wind protection;

- capable of leaking liquid in case of leakage.

Neither OSB nor films/membranes fall under these criteria in any way, so I would refrain from using them.

As for the cost, using windproof insulation turns out to be cheaper than film + boards. Although the windproof insulation itself is three times more expensive than usual! Because of this price difference, there is a common misconception that the whole pie is also three times more expensive, but this is not true. Firstly, you need to use only 50mm of such insulation (the first layer), and secondly, let’s do the math.

There was already an argument about this once, but here are some brief calculations that were relevant at the time of the argument:

The difference in the cost of two insulation materials is 145 rubles per 1 m2. Now let's consider the filing as board and film:

Those. we see that in my version you will have to pay an additional 150 rubles for 1m2 of insulation, but you will not have to pay an additional 225+ rubles per m2 of board and film lining, so the myth “it is unreasonably more expensive” was not confirmed, it turned out the other way around.

There remains only one controversial point: these calculations do not take into account the metal mesh, which is often not installed when hemming with an inch. But the mesh protects the house from rodents and, in an amicable way, is needed in any implementation option.

Installation of a water heated floor in a polystyrene screed

Warm floors on a pile foundation. Sewerage. Water pipes. Frame house. "Build and Live"

We propose to make a warm water floor with a polystyrene screed in a frame house on stilts. The arrangement diagram looks like this:

- The rough base is being cleaned.

- If heating is installed during the construction of the house, this assumes that the floor is level. If the room has already been used, then it is necessary to level the surface.

- A thick polyethylene film is laid on the base, it serves as waterproofing. It is overlapped and secured with a stapler.

- Damper tape is glued along the walls - it will compensate for expansion when heated.

- Polystyrene mats with bosses are laid. They are connected using locking connections.

- Metal plates are placed between the grooves; they are designed for proper heat distribution.

- The pipeline is laid out in the grooves of the plates, according to the “snake” or “snail” pattern.

- A second layer of polyethylene is placed.

- The device is covered with GVL sheets in two layers. The joints are sealed with glue. The second layer is laid in a checkerboard pattern.

Before covering the “pie” with gypsum fiber sheets, the pipeline should be connected to a power source. In private buildings, this is boiler equipment that is responsible for heating the coolant.

The pipes must be connected to the boilers through a mixing and distribution group; with its help, the temperature level is adjusted and the coolant is distributed along the circuits. After this, the system is pressed, and only then can the structure be covered with plywood and the finishing laid.

How to calculate the load on wooden floors from a screed

If a warm floor is installed in a screed, then you need to correctly calculate the load on the logs - whether they can withstand the weight of concrete.

To calculate the load, the average mass of 1 cubic meter is taken. meters of concrete with a reserve of 2300 or 2500 kg. The size of the total cubic capacity of the screed is calculated: the area of the house is multiplied by the height of the screed. For example: area 87 m2 and screed 6 cm.

87 x 6 = 5.22 m3

the mass of the screed is 5.22 x 2500 = 13000 kg.

13000 x 87 = 150 kg per m2.

It is better to do the load with a margin so that the m2 can withstand a weight of not 150 kg, but more.

Installation of electric heated floor

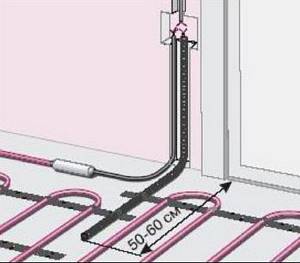

You need to start installing any electric floor by choosing a location for the thermostat. In this area, a sub-station with the wiring removed is being prepared. A vertical groove is made to the floor for the wires.

After that, you can move on to laying the “pie” itself. We will make a heated floor in a frame house based on cable mats. The special feature of installing mats in a frame is that they are placed directly on the finished surface.

- The surface is cleared of debris and treated with a primer.

- A reflective substrate is laid.

- Mats are spreading.

- A temperature sensor is placed strictly between the heating conductors. It is placed in a corrugated pipe and placed in a pre-made groove.

- A thermostat is installed in the prepared area, to which the wires from the sensor and the floor are connected.

- The system is being tested.

- The mats are filled with a layer of tile adhesive.

Typically, such heating is installed under ceramic tiles. In a frame house on stilts, even in severe frosts, it can be comfortable with a properly designed heating system.

Installing heated floors, especially on the ground floor, will prevent cold air from entering through the floor, and the house will be warm and cozy.

Heating of a Frame House / Warm Floor. Energy consumption.

Screed

Some people make a heated floor under a laminate, but I decided to make tiles (more precisely, porcelain stoneware) throughout the house; it conducts heat much more efficiently, and even when installing it, the unevenness of the screed is not so critical.

And this is the screed after drying:

PS The screed turned out to be almost perfect after checking it with a level! Hooray!