General information

Gas holder capacity for storing gas reserves during autonomous gasification

Gas holders are special autonomous containers for storing large volumes of gases in private homes and industrial enterprises. In addition to the tank itself, the installation includes control, safety and distribution equipment.

The equipment allows you to avoid connecting to main gas pipelines. This solution is appropriate when gasification from centralized networks is impossible or economically infeasible.

For domestic purposes, gas tanks are filled with a mixture of propane and butane.

The industry produces devices with a capacity from 2500 to 20,000 liters.

Gas tanks for a country house vary in design, installation method, and functionality.

Before purchasing, determine the volume of the container, the cost of equipment and installation work. Choose an acceptable placement option on the site.

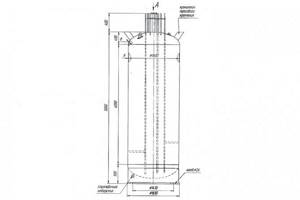

Drawing of a vertical gas tank

Rice. 1

2 The RemStroyMash production association offers vertical gas tanks with a volume of 2 to 20 cubic meters. Gas storage tanks are delivered to the customer fully equipped - shut-off equipment, cathodic protection, and a casing. The use of the latest technologies in the production process guarantees high quality products and its absolute safety. If the operating rules are observed, vertical gas tanks produced by the company can last more than 50 years.

Look at products similar to vertical gas tanks:

- Tanks for liquefied hydrocarbon gases (gas holders)

- Capacitive equipment

Download documentation on vertical gas holders

Presentation of the company

Questionnaire

Company details

Delivery Guarantees

How to order vertical gas tanks

- 1

Filing an application - 2

Coordination of equipment - 3

Cost calculation - 4

Contract and sketches - 5

Manufacturing - 6

Acceptance - 7

Delivery

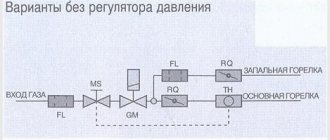

Principle of operation

The gas holder is connected by a pipe to appliances in the house

For the operation of household heating boilers, cookers and water heaters, the gaseous fraction of a mixture of propane and butane is used. To save space, the fuel is stored in a liquefied state. One liter of liquid propane-butane during evaporation occupies a volume of 0.26 m3, i.e. increases in volume approximately 260 times.

The mixture is delivered to the site and pumped into a gas tank. The container is filled no more than 85%. When liquid gas evaporates, an air-gas mixture is formed in the free part. Evaporation is possible only at temperatures above 0°C, which imposes requirements on the installation method and the composition of additional equipment. The gas mixture is supplied through a pipeline to consumer devices.

Delivery and refueling are carried out by licensed companies using special vehicles.

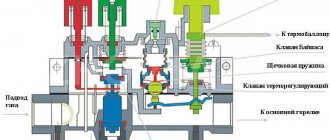

Equipment design and configuration

The classic design of gas holders for the home consists of a metal container and additional equipment.

Some factories manufacture gas tanks from polymer materials. They are more convenient to deliver and install due to their low weight, but are more expensive than metal analogues of the same volume.

The gas tank is filled through the neck in the upper part

At the top of the tank there is a neck, which is intended for refueling and collecting gas for consumers. Sometimes the necessary equipment is installed here. Russian-made gas tanks, as a rule, have a longer neck. This allows you to bury the container deeper into the ground, which is important in frosty winters.

At the bottom there are brackets for installing and securing the container to the surface.

Depending on the purpose and model, manufacturers equip gas tanks with:

- valves for filling, gas intake and safety,

- level meter for monitoring gas residues,

- pressure gauge to ensure safety and regulate modes of use,

- a reducer that regulates pressure in parameters that are safe for the operation of boilers, furnaces,

- condensate collector and waste drain valve.

Depending on the installation method, additional evaporation tanks may be installed.

Manufacturers have developed and produced various equipment models designed for different installation schemes. The designs of the equipment also differ. The range can be classified according to the intended installation location and location in space.

Selecting the gas tank volume

When choosing the size of the installation, you should know that the minimum volume of a serial gas tank is 1000 liters. It is designed for the needs of a private house with an area of 40–50 m² with brick walls. For a similar building with an area of 100 m², a capacity of 2500–3000 liters is required, for 200 m² - 5500 or 6000 liters.

If you need to calculate the volume of a gas tank for heating a brick house, multiply the area of the building in m² by 25 - this is for refilling no more than once a year. Such a tank is refilled from March to September, when the cost of liquefied gas usually decreases.

Do not forget that you will also have to lay a route - pipes for supplying gas to consumers - a boiler, geyser, stove, etc.

If the walls of the building are not brick, you can calculate the volume of the gas tank by knowing what the gas consumption for a certain period will be for the selected autonomous gas supply of a private house. If there is no such data, compare the thermal conductivity of brick walls and the walls of your house. And based on the comparison results, you increase or decrease the volume of the container.

Calculation example

An example is the calculation of a gas holder for a 200 m² house with brick walls. It is assumed that during the heating season (about six months), on average, about 25 liters of liquefied gas are burned per square meter of heated area. For a house of 200 m² during this period, 25 liters * 200 m² = 5000 liters are consumed. This will be the required volume of the gas tank for this house.

You can roughly calculate the volume of a gas tank based on the size of the house and the material of the external walls.

The calculated volume may change if there are other gas consumers in the house besides the heating system - for example, a water heater or a gas stove. They “pull” very little gas, so you can add 15-20% of the resulting figure.

Boiler power calculation

There is another method for determining the volume of a gas tank, based on the power of the heating boiler. It is usually accepted that the boiler should operate at approximately half its power or half the time. In this case, during the coldest period it will cope with heating without any problems. In addition, this approach extends the life of the boiler (it does not operate at maximum power, so it wears out more slowly). Therefore, gas consumption is considered to be 50% of the boiler power.

Calculation example. The boiler is 22 kW. To calculate, we take half the power - it is necessary that the fuel produces 11 kW of heat. When burning one liter of liquefied gas, we get 12.5 kW of heat (reference data, if you know what gas you will use, take the calorific value of your fuel). The following is the calculation:

- To obtain 11 kW you will need 11 kW: 12.5 kW/liter = 0.88 liters . This is the volume of gas required to operate the boiler for an hour.

- To find out the daily volume, multiply by 24 hours: 0.88 l * 24 hours = 21.12 liters/day .

- Monthly consumption - multiply the resulting figure by 30 days. 21.12 l/day * 30 days = 720 liters/month .

Next, calculating the volume of a gas tank for a private house is not difficult - count the number of months in the heating period and multiply. It is also worth making adjustments depending on the efficiency of the boiler. For new boilers this is not critical, but for old boilers the addition can be very significant. For example, if the boiler efficiency is 88%, you need to add 12% of the calculated volume.

Mobile and stationary models

Mobile gas holder for temporary use

There are mobile and stationary models on sale. The choice is made based on the tasks being solved.

The mobile version is produced on the chassis of car trailers. In most cases, such an installation is considered as a temporary option for unfinished construction or for use in the country.

Advantages and cases when the mobile model is beneficial:

- savings on installation work,

- the construction of the house has not been completed or the location on the site where the stationary model will be installed has not been determined,

- there is no space for installing a stationary type gas tank,

- In the near future, a main gas pipeline is expected to be supplied to a populated area or to a house.

Disadvantages of mobile models:

- due to the small capacity, you will have to frequently visit the gas station during the cold season,

- you will need a car with a tow hitch, which requires higher cost insurance,

- a trailer is a vehicle, it must be registered with the traffic police and pay taxes,

- inconvenient to use - in cold weather, heating will be required to evaporate the gas,

- the cost of gas for a mobile installation is approximately 30% higher than for a gas tank on the site,

- increased danger due to detachable connections.

The total cost of using mobile models is higher than stationary units. They should be used only when really necessary.

Above ground and underground installation

When designing a gas supply, you need to decide how to install the equipment: on the surface of the earth or in a dug pit. Each option has advantages and disadvantages.

Outdoor gas holder

External gas tank is installed on the surface

Equipment installed on the surface of the earth has significant advantages:

- for street models there is no need to dig a pit and pay for excavation work for further improvement of the site,

- corrosion processes are actively taking place underground, so protection against them will require additional material investments,

- ground installation is the only option in case of high groundwater on the site.

Disadvantages of ground gas tanks:

- increased safety requirements, leading to an increase in the cost of installation work and equipment,

- the complexity of thermal insulation - when the air temperature drops, the transition of the liquid fraction to the gaseous state slows down, the pressure in the supply pipe system drops, gas boilers stop working,

- difficulties with placing large-volume gas tanks in small areas, reducing the ability to plan the site based on landscape preferences.

Above ground tanks are a good option for small homes when there is no need for large storage capacity.

Underground option

Underground stationary gas tank

With little additional cost, tanks installed underground have many advantages:

- stable operation in any climatic conditions - the ambient temperature does not change sharply and does not drop to critical values for the evaporation process,

- increased safety - in the event of a gas leak, the likelihood of an explosion is minimal,

- there remains free space above the container.

The negative aspects are mainly associated with civil construction and earthworks:

- Digging a pit for large gas tanks will require work on a site with heavy construction equipment; excess soil will have to be transported somewhere,

- the need to arrange a reliable pillow for the container,

- increased requirements for anti-corrosion treatment,

- On clay soils, protection against movement is necessary.

Despite all the disadvantages, the additional costs are paid off due to ease of use, safety, and the absence of additional equipment on the surface.

Vertical and horizontal orientation

Depending on the individual characteristics of the site and the gas supply problems being solved, the installation of a gas holder can be carried out in different planes.

Vertical models

For ground installation, vertical models are more often used - they take up less space on the site.

For low-power consumers, the vertical type is more suitable, since the pressure in the system is maintained more stable.

At the same time, a small evaporation “mirror” does not allow obtaining the required amount of gaseous mixture for powerful equipment. The shortage is especially noticeable in winter, when more fuel is required.

To solve the problem, install additional equipment:

- heaters that consume electricity,

- additional evaporation tanks.

Additional design elements increase its cost, installation and commissioning costs. In addition, the more equipment, the higher the risk of one element breaking.

Vertical installations are better suited for southern regions.

Horizontal installations

When installing a horizontal underground gas tank, more effort and time are spent

Installation of horizontally oriented gas tanks is preferable for cold regions and is often the only possible option for large houses.

Advantages of horizontal models:

- greater productivity due to increased evaporation area,

- minimum additional equipment to ensure the required gas supply parameters,

- increased dimensions increase the duration of the period between refuelings,

- large capacity of underground gas tanks while simultaneously saving useful area of the site.

Negative points:

- large footprint for ground installation,

- large volume of earthworks,

- high cost of equipment with a high neck for deep installation.

The decision on which type of installation to choose is made based on a comprehensive analysis of the specific operating conditions.

OPERATING PRINCIPLE OF THE GAS HOLDER

The operating principle of a gas holder is based on the ability of liquefied gas to evaporate from the surface. The task of the station is to create optimal conditions for the most efficient evaporation. For this and other purposes, the gas holder device includes several important components and parts.

- The container is made of thick-walled steel that can withstand a pressure of 1.8 MPa.

- Shut-off and control valves - includes safety and filling valves and a drain outlet, a pressure gauge, and a reducer to create constant pressure in the gas supply system.

- Condensate collector - during the evaporation of LPG, condensate is formed as a by-product. A special block is installed to remove accumulated moisture.

- Evaporator for gas tank. Vertical tanks, as well as stations installed on the ground, are not always able to produce the required amount of gas. To speed up production, special evaporators are installed.

- Gas level gauge - a special indicator records the fullness of the container. Modern devices are equipped with an indicator device that transmits information over a distance using a radio signal.

The operating principle of the gas holder is as follows:

- Liquefied gas is poured into the container. The design of the gas tank is made in such a way that the LPG forms a “mirror lake” - a surface of sufficient size to ensure unhindered evaporation of gas.

- The evaporating substance is sent to the collector to create constant pressure in the gas pipeline.

- From the collector, the fuel is directed to the living space, passing through a condensate collector and a basement inlet located in the building.

The efficiency and safety of the station is influenced by correct installation and connection, taking into account the operating principle of the gas tank.

Installation procedure

The procedure for installing and putting into operation a gas tank for a home or cottage consists of the following steps:

- preparatory, including system design and equipment purchase,

- connection of gas consuming equipment.

Legal issues

The gas holder must be registered with the gas industry

Gas storage containers larger than 100 liters are subject to registration with regulatory authorities. A gas holder cannot be smaller than 450 liters. However, registration and registration requirements apply only to legal entities and individual entrepreneurs.

There are currently no penalties for installing a gas tank without registration. It is unknown what legislative decisions will be made in the near future.

Equipment design and purchase

It is better to entrust the preparation of the project to an organization that has a license for this type of activity. Only highly qualified specialists can accurately calculate equipment parameters and draw up a safe gasification scheme for a private home.

Based on the specifications, equipment is selected and purchased. It is worth giving preference to large companies - their equipment is cheaper, and warranty repairs are easier to obtain than from small fly-by-night companies.

Calculation of gas tank volume

For a house of 100 sq. m. requires a capacity of 2500 l

The consumption of the gas mixture is not constant throughout the year and depends on the street temperature, the method of installing the gas holder, individual preferences for the level of comfortable temperature in rooms and utility rooms, and the quality of insulation of building structures.

According to statistics collected by organizations operating individual gas supply systems, on average, about 25 liters of gas per year are consumed just to heat one square meter of a house.

For housing with an area of 100 m2 you will need a capacity of 2500 liters. Taking into account the operation of the gas stove and water heater in the warm season, a reserve of 10% should be made. Possible extremely low temperatures are taken into account when more fuel is needed. Therefore, it is necessary to purchase a gas tank for 3000 liters if you refill it once a year.

To save money, taking into account seasonal fluctuations in gas prices, it is profitable to refill the gas tank 2 times a year. In this case, you can purchase a 2000 liter unit.

Calculations are approximate for the entire country; it is better to find out exact figures from neighbors who use similar equipment, or from local specialized organizations.

Accommodation requirements

The location for installing the gas tank on the site is selected based on the requirements of SNiP and fire safety rules.

Basic Rules:

- it is necessary to organize a paved entrance for the tanker and fire trucks,

- the foundation is made of ready-made reinforced concrete slabs or filled with reinforced concrete with a thickness of at least 16 cm,

- the distance to open bodies of water must be at least 50 m,

- to infrastructure elements and neighboring areas at least 10 m for a gas tank volume of up to 10 m3 and 20 m for a capacity greater than 20 m3,

Outbuildings should not be located above the gas holder.

Lawns cannot be irrigated due to increased corrosion of underground parts.

HOW TO INSTALL A GAS TANK CORRECTLY

A household gas tank is installed in accordance with existing SNiP and fire safety standards (FS). Even before installation, it is necessary to take into account and calculate several important points:

- Existing requirements regarding placement.

- Installation type.

- Safety standards related to anti-corrosion treatment of storage facilities.

- Features of operation and maintenance.

There are general rules for installing a gas tank that are mandatory for use when installing household liquefied gas storage facilities.

REQUIREMENTS FOR PLACING A GAS TANK ON THE TERRITORY

SNiP and PB separately stipulate standards for the placement of gas tanks in relation to buildings under construction and residential buildings, roads and highways, etc.

- Vehicles must have sufficient and free access to the tank. It is strictly forbidden to place a gas tank structure under the roadway.

- The foundation for the container requires the manufacture of a solid concrete slab reinforced with reinforcement. Installation is carried out on special legs. The base to which the tank is attached must gain strength for at least a month after pouring the concrete. Instead of making a reinforced concrete “pillow” on site, you can buy a ready-made slab of the required size and with anchors for attaching the tank.

- Distance from the container to the building - the calculation of the distance of the storage facility depends on its volume. For large gas tanks, starting from 20 m³, you will need to maintain a distance to a residential building of at least 20 m, for 10 m³, at least 10 m. The minimum distance between a building under construction and an existing gas tank can be reduced to 5 m.

- Required permits for installation. Household storage facilities do not need to be registered with Rostechnadzor. For installation, it is sufficient that the gas supply station has mandatory certification and an operating permit.

- Security sanitary protection zone - a gas tank can be installed no closer than 50 m from an open reservoir. In the conditions of nature reserves and pre-reserve areas, coordination with local authorities regarding this construction will be required. The recommendations are in SNiP 2.07.01-89.

TYPE OF INSTALLATION – GROUND OR UNDERGROUND?

The design and calculation of the type (ground, underground) of steel tanks is carried out taking into account existing building codes. Vertical ground-type stations (usually spherical) are installed subject to a limited area of the local area.

Coordination of the installation is carried out after calculations regarding the minimum allowable storage volume. Before installation, geodetic work must be carried out to identify:

- Seismic activity.

- Groundwater.

- Presence of stray currents.

Recommendations for designing for seismic impacts require changes to be made in steel structures, with the threat of displacement of the gas tank and damage to the steel frame as a result.

The choice of above-ground or underground installation is made only after obtaining the expert opinion of surveyors.

CASE PROTECTION AGAINST CORROSION

The weak point of all gas tanks is the steel body, which is constantly subjected to pressure of several atmospheres.

Over time, under the influence of the environment and humidity, the storage unit may lose its strength and leak.

To prevent gas leakage, several types of anti-corrosion treatment must be carried out:

- Cathodic-anode protection - constant exposure to “stray” currents is not only a potentially dangerous cause of explosion, but also leads to rapid destruction of the metal. To prevent this, a special block is mounted on the tank body. The need to install cathodic protection exists in cases where geodetic studies have shown the presence of “stray” currents in the ground.

- Waterproofing - the container is treated with special mastics. The waterproofing of the neck deserves special attention, since monitoring and regulating devices are located there and it is most seriously exposed to moisture.

HOW TO REMOVE CONDENSATE FROM THE TANK

Although condensate appears in a gas tank for many reasons, the main one remains an incorrect calculation of the station’s performance relative to the boiler’s power. Liquid precipitation occurs in cases where the boiler consumes evaporated gas faster than the gas tank is able to produce it. How is condensate pumped out?

The fluid removal service is performed by a specialized team. The volume of condensate removed is simultaneously filled with liquefied gas. The procedure for removing moisture can be simplified by installing a special condensate collector.

HOW TO INSULATE A GEARBOX

If the gearbox freezes, as evidenced by the appearance of frost on the walls in the winter season, then the reason does not always lie in insufficient insulation of the unit itself. First you need to make sure that the gas pressure regulator is working properly and is sealed. The next steps are as follows:

- The gas pressure regulator needs to be heated - for this you can use hot water or an insulated heating cable.

- If the situation repeats, you can leave the heating cable for continuous operation. Safety rules for the operation of household gas tanks prohibit the use of open fire to heat the metal parts of the station.

If all calculations regarding the boiler power and gas tank performance are carried out accurately, but the gearbox is still covered with frost, the reason lies in low-quality “blue” fuel. Most likely, summer gas with an increased volume of butane was filled in.

OPERATION REQUIREMENTS FOR GAS TANKERS

The main requirement for operation is regular maintenance of gas tanks, carried out before the start of the heating season. During this period the following work is performed:

- Cleaning and drying the gas pressure regulator.

- Removing condensation.

- Refilling and replacing failed parts.

Without carrying out scheduled work, it is strictly prohibited to put the storage facility into operation.