The term “smart home”, which recently surprised society, is quite commonplace today. Actually, if we consider the level of household appliances used in almost every home, we can draw an unambiguous conclusion - the degree of automation is very high.

It is not surprising that automatic control also affected heating in a smart home, which, thanks to innovation, has become significantly smarter. Let's take a closer look at this option in order to get to know the device and all the advantages of smart heating.

Smart heating system strategy

There is no need to talk once again about how controversial the issue of heating residential premises is. It is directly related to the costs of energy consumption and these costs significantly burden the family budget.

Therefore, the smart heating strategy is a really important and worthwhile topic to not only consider, but also try to implement.

It is enough to set the temperature parameter on a separate thermostat and the “smart” heating will do all the necessary work to provide the owner of the apartment (private house) with comfortable conditions

If you apply the smart home strategy to the heating system in its entirety, there is every chance of significantly reducing costs. Precise control of consumption and rational distribution of heat resources will contribute to savings.

The smart home strategy in relation to the heating system has been calculated and tested in practice. The result promises widespread adoption of this approach.

What is being automated?

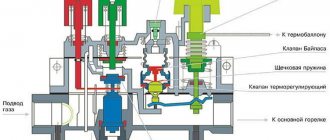

The main purpose of installing the device is to facilitate temperature control in the building. The main component that is included in the mechanism is the boiler. After checking the readings of street sensors, the device changes the fuel supply. This allows you to reduce costs to the minimum possible.

Automation is programmable. It is configured to change the temperature not only according to the meters, but also according to the days of the week .

Reference! The wizard is able to set the program to turn itself off when the owner presses a pair of keys , which will allow you to save money when you are away.

- High price. Simple devices are quite cheap, but programmable ones are more expensive.

- Writing a work algorithm requires a lot of time or calling a specialist.

- Using a gas boiler results in high costs.

Options for implementing smart heat supply

Actually, the principle is obvious - constructing a heating circuit diagram taking into account the introduction of control sensors, as well as actuators at energy distribution points.

Energy distribution point – temperature control on an individual heating device. There may be several such points in total within the heating circuit

The control sensors and mechanics, in turn, are connected to the lines of a controller equipped with control software.

In principle, everything is simple, given the development of monitoring and control technologies through controllers.

A controller option from a series of digital equipment designed to equip a “smart” home. Such devices are developed in different designs and architectural forms, different in technical capabilities.

When considering possible scheme options, of course, one should take into account their application depending on the type of housing and its location.

Traditionally there are two options:

- Urban sector.

- Suburban sector.

The heat supply systems for these two options are somewhat different, because in urban environments, centralized heat supply is increasingly taking priority.

The suburban sector is characterized by an autonomous type heating system. Therefore, the “smart” heating solution for these two options may differ.

Solution #1 – for a city apartment

Let's consider a possible “smart” heat supply scheme in relation to the residential urban sector. Nowadays, the majority of urban infrastructure is already partially automated.

As a rule, there are coolant control systems in each individual apartment building. What remains for the owner of an individual apartment to do?

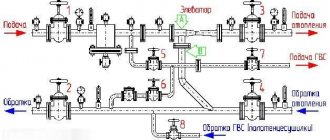

Thermal unit of one of the city apartment buildings, where the principle of automatic adjustment of the coolant supply to the house circuit has been established, depending on the temperature conditions (weather) outside

Inside one specific apartment of an apartment building, you can use an automated control system taking into account heat consumption. However, the general (house) distribution scheme of the coolant is important.

If this scheme has a sequential nature of switching on devices, individual metering of energy consumption will not be possible, as well as separate adjustment.

With this option of switching on a heating device in the circuit of an apartment building, it is almost impossible to install a “smart” circuit. True, there is an option if you turn on the jumper pipe and install the automation after the jumper

The parallel connection of heating devices allows you to control consumption and keep records. This is done by installing temperature sensors, regulators and a controller.

An example of simple automation in a city apartment by turning on the thermostat on the coolant supply line. A parallel system for connecting the house circuit is used here, so the circuit is easier to implement

Temperature sensors are installed directly on the supply and return water lines, plus an indoor temperature sensor will be required.

Control valves are installed on the return pipeline of heating devices. All these devices are combined with a management controller.

Solution #2 – for a country house

The solution for a country or city private autonomous house is characterized by unlimited possibilities.

Autonomous private households, as a rule, operate on their own heat supply system, for example, from a boiler. In this option, automation is easier in terms of independence, but from a technical point of view it is somewhat more difficult.

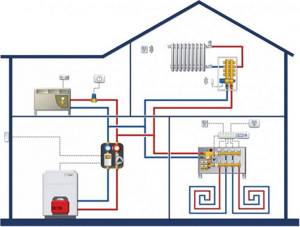

Block diagram of heating automation (one of the options), where, along with external heating devices (batteries), a “warm” floor is also used. Two battery automation options, one wireless

The complexity is due to the use of automation and control not only to home heating devices, but also directly to the heat source - the boiler.

The proposed designs of modern boiler equipment support full automation, including:

- fuel loading;

- combustion intensity;

- media circulation;

- temperature limits;

- active action timer.

If a device of this particular configuration is used, it is enough to coordinate the indoor heating control system of a smart home with the boiler equipment controller. In another case, if there are design features of the boiler, you will have to initially automate the boiler installation.

Then, for example, the set temperature value on a sensor located indoors will serve as an additional reference point for the boiler controller.

Based on this guideline, fuel consumption, combustion intensity and other operations of boiler equipment will be carried out.

Separate automation of the thermal background for each room of a residential building (scheme example): 1, 2 – individual control panel (controller) with individual valves and temperature sensors; 3 – controller for controlling “warm” floors

However, it is permissible to create different temperature conditions in each individual room, provided that acceptable sealing of one room from another is ensured.

In this option, heat flow is additionally regulated with the help of individual thermostats and regulators that control the flow of coolant through devices (batteries, underfloor heating system).

How to install a heating boiler in a private house with your own hands

Most models have built-in circulation pumps and expansion tanks. The simplest and most common piping scheme involves the location of a supercharger with a bypass line and a sump on the return line. An expansion tank is also installed there, which is necessary to compensate for the temperature increase in the volume of the coolant. A pressure gauge is used to monitor pressure, and air is removed from the boiler circuit through an automatic air vent.

A solid fuel heater must be equipped with an external circulation pump, an expansion tank and a safety group. Additionally, a cooling circuit is installed, designed to lower the temperature of the coolant in case of overheating. To protect the internal surfaces of the boiler from condensation, the system is equipped with a three-way valve that regulates water heating.

Heating of private housing construction can be implemented independently. The owner must carefully comply with the requirements of regulatory documents, follow the recommendations of manufacturers and the advice of specialists. The successful completion of installation is facilitated by watching videos that show the step-by-step execution of the work.

Benefits of full heating automation

Before discussing the benefits of smart heating, there is something of an initial disadvantage for the end user.

When setting up a system of this kind, you will have to spend money on purchasing the required components, as well as on installation and configuration.

Not the most expensive and advanced set of “smart” heating, however, it allows you to organize a completely effective home automatic control system

Of course, the possibility of doing everything yourself cannot be ruled out. However, to implement this option, you must have the status of a highly qualified specialist or a jack of all trades. But the costs of setting up the system are ultimately compensated in full.

Average statistical calculations showed up to 30% savings in heating costs during the cold season. Thus, the “smart” heating device pays for itself in the short term.

Among the obvious advantages of the technology is the ability to control all parameters directly from your phone or tablet.

Modern smartphones allow the installation of special applications through which monitoring and adjusting the parameters of the heating system is carried out.

A smartphone and the ability to remotely create a comfortable environment in the home are a reality of modern life. At the same time, it is possible to control heating from other popular digital devices

An obvious advantage of such systems is the factor of accurate and stable temperature background.

Moreover, using the application, you can set the desired mode at a certain time of the day: cooler at night for a restful sleep, and a gradual increase in temperature an hour before returning from work.

When the inside of the room is “not cold - not hot,” that is, the temperature background that is optimal for the body is noted, the risk of colds is sharply reduced. In such conditions, the body is in an active phase, the person feels a state of comfort.

The convenience factor is also an advantage. There is no need to turn the taps or measure the temperature with a thermometer. All these actions will be performed automatically with high accuracy. In addition, it becomes possible to take into account the energy consumed. And this, again, is savings.

Why is it worth equipping your heating boiler with a remote control system?

The need to equip a home with a system that can remotely control a heating boiler becomes obvious not only if permanent presence is not possible, but in terms of direct economic benefits and general convenience from such an event:

- Opportunity to save up to 45-50% of money spent on heating your home every month;

- Increasing the service life of heating equipment due to fewer switches on and off of electronics;

- For any prolonged absence, you can reduce the room temperature and increase it in advance of your arrival;

- During thaws, the GSM control system for the gas boiler will turn it off automatically;

- You can set heating modes for night and day;

- Ability to maintain different temperature levels in different zones (rooms);

- All information about non-standard situations will be immediately transmitted by the gas boiler control unit for prompt decision-making;

- The heating system can be turned on automatically before the onset of cold weather.

How to solve the issue from the technical side

Regardless of which heat supply system is responsible for heating the room (except, of course, manually loaded wood stoves and fireplaces), it can be equipped with electronics for remote control of the heating boiler.

This is due to the fact that most modern boiler systems have electronic matching boards in their structure, through which remote units can be connected. If the equipment for heating old models does not provide for such modernization (or it is homemade), we will still resolve the issue.

The consumer has three main options to choose from on how to implement remote control of the boiler in their home:

- Using special GSM modules for controlling heating devices;

- By connecting the so-called “smart thermostat” via WI-FI;

- Equipping radiators with multifunctional thermostats.

Remote GSM control of heating boiler

The GSM heating boiler control unit, which is best suited if there is no Internet in the house, is a controller module for communication with the homeowner, which has a slot for a SIM card. You can choose the services of any cellular operator, determining for yourself the best tariff in terms of savings.

The operation of the GSM boiler control module is very similar to the operation of a computer, only with more limited functions. It is schematically connected to sensors that monitor the parameters of the heating equipment and the room environment.

Communication with such an electronic assistant can be carried out either through a regular mobile phone or any other device.

Programmers have developed special mobile applications for the Android, Windows Phone and iOS operating systems.

Available modes when the heating boiler is controlled by GSM:

- Automatic control according to specified parameters - a program is entered into the electronics, which it independently executes until the next change;

- Communication by sending SMS. The owner of the house can carry out any settings of the GSM unit using short text commands;

- The mode for transmitting alarm notifications when non-standard situations occur: equipment is turned off, pipes become airy, gas leaks;

- The ability to remotely control any automatic systems that are consistent with the GSM heating control unit.

All the operator needs is not to forget to control the account status of the communication package used.

Heating control via the Internet

In the case when the house has the Internet and a WI-FI router, you can very easily supplement the boiler equipment with a remote unit, the so-called Internet thermostat.

They come in different types, but work on the same principle:

- A special temperature sensor with customizable parameters is portable and can be installed in any room;

- He compares the readings of the electronic thermometer with those installed in it by software;

- When the room temperature drops below the set temperature, the sensor transmits a signal via radio to the receiver, which turns on the heating;

- Communication with the operator here is carried out wirelessly via WI-FI.

Features of the arrangement of “smart” heating

The most important thing that can be classified as recommendations for installing thermal systems in a smart home is the use of high-quality control equipment, as well as reliable filters.

Effective filtration of the coolant flow and the use of reliable adjustment mechanisms contribute to the accurate and flawless operation of the system.

Even the most automated system will not be able to function normally without the presence of a familiar and simple element - a filter. This point should be taken into account when solving an automation problem.

Automated modules based on controllers provide a high degree of sensitivity and allow you to regulate processes with an accuracy of up to one percent.

However, in the absence of filter modules, the operation of the flow regulators may be disrupted after only a short period of operation.

It is recommended to technically correctly calculate and select the installation points of thermostats (sensors), since the correctly chosen installation location allows you to achieve the maximum effect of regulation as a whole. Information on effective placement points can always be found in the device data sheet.

Automation for pump

Regulates the operation of the system, controlling many functions, such as, for example, pressure, water distribution.

For normal operation, the following components are required: a manifold that provides water supply, a relay that controls the pump, a pressure gauge that measures pressure, a dry-running sensor that prevents the device from overheating if the water runs out.

All automation responsible for the pump is divided into several models, based on the time of creation:

First generation automation;

The first simplest water supply design. Used to solve simple problems when it is necessary to provide a room with a source of water. It consists of three components: a dry running sensor, a hydraulic accumulator that performs the task of accumulating water and contains a membrane, and a relay that controls water pressure. It usually does not cause any difficulties during installation, since the system completely eliminates complex electrical circuits. The mechanism is also extremely easy: the order is cyclical—when the water is completely filled, the pump turns off, then the cycle repeats.

Second generation automation

The sample differs from the previous one in that sensors have been added to the control to monitor the operation. As a result, a hydraulic accumulator is not necessary, since its function is performed by sensors. The second generation automation is not in great demand, as it is similar to the first, but is much more expensive.

Third generation automation

It is a more worthy version of its predecessors, and costs more accordingly. The unit stands out for its greatest reliability, efficiency, improved safety program, and most importantly, maximum accuracy of the device.

To maintain the device in automatic mode, a relay is installed. The mechanism is simple: when the water pressure decreases, the relay starts the system, and similarly, when the pressure increases, it stops.

Thermostat to turn the pump on or off

The most common type of automation for a pump in home heating. Mechanism: first, information is collected from the sensor, then the indicators are compared, the operation of the pump depends on this. For example, if the owner sets the mode to +60 and the hysteresis to +5, then the water must be +65 for the system to start, and for it to stop, the temperature must be +55.

Conclusions and useful video on the topic

The following video offers a rather interesting option for introducing automation of the heating system:

Technology moves society forward. The level of comfort and convenience increases. A striking example of this is the heating system of a private house or apartment, endowed with the functions of full process control without human intervention. The user only needs to determine the level of comfort in order to get the desired microclimate throughout the house and, in addition, substantial savings.

If you have valuable information on arranging heating in a smart home system, please share it with our readers. Leave your comments and ask questions in the block below the article.

Gas boiler room for your home

Gas is an explosive substance, so the requirements for gas boiler houses are very strict. If a boiler with a power of up to 30 kW is sufficient to heat the house, then there is no need for a separate room for the boiler room.

The boiler can be placed in a well-ventilated kitchen on a wall made of non-combustible materials, provided that the volume of the room is at least 15 m ᶾ, the height from floor to ceiling is from 2.5 m, and the floor area is from 6 m².

If there are no walls made of non-combustible materials in the kitchen, then the boiler is installed on a surface plastered and insulated with a special screen

All requirements for gas boiler houses are related to preventing the consequences of possible gas leaks. For this purpose, the window area in the room where gas equipment is installed starts from 0.5 m², and the door width from 0.8 m.

The chimney of such a boiler room must rise above the roof ridge by at least 500 cm and have an additional channel for cleaning. Condensate collectors must be installed on the chimney and ventilation.

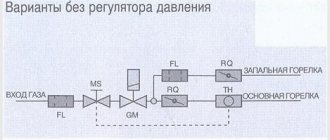

When gas enters the boiler, electronic or piezo ignition is turned on. A spark occurs and it ignites the igniter, and from it the main burner, heating the coolant to the set temperature. Next, the automation turns off the burner

If the power of a gas boiler exceeds 30 kW, then a separate building is required for it.

The requirements for a separate boiler room are set out in the building codes:

- the foundation of the boiler room building must be separate from the foundation of the house;

- a certain percentage of sand must be present in the concrete solution used in the construction of the building;

- a separate foundation is placed under the boiler, raising it above the finished floor by 0.2 m;

- under the boiler you need a backing made of flat slate or tiles protruding beyond its limits by 0.1 m along the entire perimeter;

- to drain the coolant in case of an emergency, the boiler room must be equipped with a sewerage system;

- within a radius of 0.7 m around the boiler, the space must be free;

- interior decoration must have a fire resistance rating of 0.75 hours.

There are special regulatory requirements for the boiler itself, since it does not belong to the category of household appliances, but to the category of complex engineering equipment. Gas boilers, like all others used in the domestic sector, must have a certificate certifying that they have passed a safety examination.

Control services will never give permission to put into operation a boiler room with a gas boiler if there is no gas detector in the room.

Electric boiler for a private boiler room

Of all the models used in a private home, the safest is the electric boiler. It is not necessary to equip a separate boiler room for it. When heating the coolant, no combustion products are released, so ventilation is not needed for it.

Installation of such boilers is simple, they do not create noise during operation, and they are easy to care for. Electric boilers have high efficiency, reaching 99% in some cases. The disadvantage is the high requirements for network power, as well as the dependence on its stable operation.

You can place an electric boiler in any corner of the house, as long as it is convenient. It consumes a lot of electricity and is most often used as an additional heat source

The connection of an electric boiler is carried out according to different schemes: it is connected to heating radiators, and the possibility of installing a cascade is provided in cases where it is necessary to heat a large area.

The piping is carried out according to two schemes - direct and mixing. In the first case, the temperature is controlled using a burner, and in the second, using a servo-driven mixer.

Boiler room with solid fuel boiler

In accordance with the requirements of building codes, solid fuel boilers are installed only in non-residential premises. If the power of the unit is large, the construction of a separate boiler room will be required.

What should the room be like?

There are a number of requirements for placement under a solid fuel boiler:

- the distance between the firebox door and the wall is from 1.2 to 1.5 m;

- the distance from the side walls of the boiler to a wall made of fireproof material or protected by a special screen is at least 1 m;

- the gap between the rear wall of the boiler and the surface of combustible material with a protective screen is at least 0.5 m for boilers with a rear connection;

- ban on superstructures above the boiler room;

- effective supply ventilation , located in the lower part in the form of a gap between the door and the floor or a hole in the wall.

If the wall is made of material that meets fire safety requirements, then it is permissible to attach the pipe located behind the boiler to it using brackets.

In order to operate a CT with parameters of 1x0.8 m at the base with at least a minimum of comfort, you need to install it in a room of 2.8x2.5 m. As the dimensions of the unit increase, the area of the boiler room also increases.

It is necessary to plan the installation of a solid fuel boiler at the stage of building a house in order to allocate space for the chimney in advance

If the boiler room is in the form of an extension, then the correct location for it is a blank wall. The distance to windows and doors in both vertical and horizontal directions must be at least 1 m. If the boiler room is located in the basement, ground floor or first floor, it is necessary to install a door that opens outward.

Equipment for solid fuel boiler house

A functional and well-designed diagram of a boiler room with a solid fuel boiler should include a number of elements:

- Heat generator equipped with appropriate bunkers, fuel chambers, etc.

- TT boiler piping , consisting of a circulation pump, 3-way valve, safety group.

- Chimney.

- water heater for supplying the house with hot water.

- Automation - weather-dependent or in-house.

- Fire extinguishing system.

Coal, peat, and firewood are used as fuel for TT. The diameter of the chimney in a boiler room with a TT unit must be equal to the cross-section of the boiler pipe. The room requires exhaust ventilation, designed so that for every 8 cm² of its area there is 1 kW of boiler power. If the boiler is installed in the basement, this parameter is multiplied by 3.

A steel sheet must be laid around the base of the boiler. It needs to protrude 1 m on each side. The layer of plaster on the walls should be no less than 3 cm thick.

In the chimney itself, which has the same cross-section along its entire length, holes are provided for collecting and removing soot. A mandatory attribute is fire extinguishing equipment.

A high-quality solid fuel boiler is capable of converting any type of solid fuel into thermal energy. This allows you to save money

For 1 kW of TT boiler power there should be about 0.08 m² of glazing area. The maximum permissible area of the boiler room is 8 m². If you plan to load the firebox with coal, then the electrical wiring must be protected from coal dust, because it can explode at a certain concentration.