Automation for a gas boiler of the Arbat-1 model is a fairly simple device that provides basic functions of regulation and safety of heating systems. It is its technical specifications, possible examples of application and configuration procedures that will be discussed in detail in the future. Price offers for this component will also be indicated and recommendations regarding where to purchase it will be given. In addition to this, reviews from owners of heating and heating units based on such an automation system will be given.

Oleg Nikolaenko from Samara asks:

We live in the private sector and recently switched to autonomous heating. Many questions arise, but the main one is how to check the draft sensor on a gas boiler without calling a technician?

Our expert's answer:

Owners of private houses often prefer not to depend on a central heating system and install gas boilers that heat the room autonomously. Since gas is a potentially dangerous substance, for safety reasons, a so-called thermal relay is installed on such devices - a device that gives a signal in the event of a threat to the health and life of people living in the house due to a change in the direction of carbon monoxide circulation. In such situations, you need to know how to check the draft sensor on a gas boiler.

Operating principle of the sensor

The device guarantees trouble-free operation of the equipment and prevents the leakage of carbon monoxide into the heated room. The principle of its operation is quite simple: it monitors the direction of movement of working waste and gives a special signal if a problem is detected - the temperature in the chimney will begin to rise rapidly. At the same moment, the automation activates the valve, which shuts off the gas supply to the burner, and the equipment stops functioning.

If the device does not operate correctly, the situation may get out of control due to the formation of backdraft: all carbon monoxide will be pushed not into the street, but directly into the house. To avoid unpleasant consequences, you need to carefully monitor the equipment and seek help from specialists at the first sign of a structural malfunction.

Three ways to check the functionality of a thermal relay

Sometimes the heat supply is turned off too often for no external reason, and then it is worth making sure that the device is working properly. This can be done in several ways:

- A mirror is attached at the level of the thermal relay, and the system starts. During operation of the equipment, it should not fog up.

- You may not completely shut off the chimney: if everything works as it should, the system should automatically turn off immediately.

- If the controller turns off when the hot water supply mode is turned on without heating and the tap is open, the problem lies in the thermostat.

In certain cases, the sensor may periodically turn off on its own, and such a malfunction must be corrected as soon as possible: in an emergency, the security system will not work correctly, and waste may enter the house. To avoid emergency situations, it is necessary to regularly check the proper operation of the equipment, and its installation should only be carried out by professionals: a sensor installed at the wrong level or without taking into account the specific design will not be able to warn of danger in a timely manner.

Video: Draft sensors for mounted gas boilers

Arbat 1 automation does not work

The Solly Standard boiler, whenever you try to turn it on or hot water, displays a GS error. Wolf boiler in operation. Lately it has begun to behave strangely: during the pause between starts, it turns on the burner for one second five times, and 70 degrees appears on the display.

Where to look for a problem? ACV Wester Line works very unstable: it often crashes, makes a characteristic knock and stalls when starting, but at times everything is fine. The unit is almost new, what's wrong with it? In the gas boiler Demrad, the gas supply to the burner stopped. The piezo element clicks, but there is no ignition.

There is nothing wrong with the gas stove, there is gas. What is the reason? The Kiturami world boiler is malfunctioning and stops periodically. I clean the flame sensor and the unit works fine for a while, but soon the same thing happens again.

He also began to smoke heavily. Maybe the problem is that the chimney is short, and it needs to be lengthened? Malfunctions of boilers with the possibility of automatic unlocking. My boiler systematically raises the temperature to 80 degrees in winter mode. I called the repairman three times.

He said that many models have this problem and suggested installing a programmer, but it’s not certain that it will help. Tell me how to solve this problem and will this programmer help? Models Technical characteristics. Control elements of the automation unit. Installation and maintenance. Malfunctions and their elimination. The AOGV gas boiler was installed and put into operation. Problem with hot water supply. The heat exchanger was washed. Less than a month has passed and the water is not flowing again.

We put a filter on the water, but time passed, and again there was no hot water. What kind of breakdown could this be? Malfunction of the Neva Lux boiler It gives error E7 twice a month. But after reboot it still works. Now it gives error E6. It will work for 15 minutes and turn off. What could it be? Tell me, is it possible that due to low gas pressure the Atem Zhytomyr boiler goes out, a click occurs and goes out. What is the problem? Is it possible to temporarily disable automation and how? After turning off the main burner, a clicking sound occurs after a couple of minutes, what is the reason? Tell me?

I installed the Mayak gas boiler and connected it. It works fine.

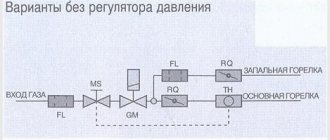

Keber boiler installed. What to do if the main burner takes in gas when turned on, but there is not enough for the igniter? How can I regulate this? Eurosit automation Check the gas pressure before automation.

But the reason is this. When it works on the unit it squeaks a lot, if you turn the knob the squeak disappears. We installed and connected a Danko gas boiler with automatic Kare, it works great on the igniter, but as soon as you add power to the burner, it goes out completely, yesterday it went out within 5 minutes, today it works for about 20 minutes and goes out completely.

Has anyone encountered this problem? In operation, the gaseko boiler When you turn on the hot water, the pressure in the system drops after replenishment, the pressure reaches 3 bar.

Have to reset. What's wrong, how to fix it? Water often boils in the boiler, causing it to fail due to overheating. The heat exchanger was recently washed, the system is not clogged. What's the matter?

Rinnai RMF boiler malfunction. Recently it started showing an error How can I fix the problem? The Celtic DS boiler heats up to 45 degrees and sits all day, does not turn off and does not heat the batteries, sometimes it shows error A3.

How can I fix this problem? The Seoul gas wall-mounted boiler stopped turning on due to a no-ignition error. How can it be eliminated?

Its contacts must be firmly attached to the body. There should be no oxidation on them. We check the traction sensor with a tester, measuring its resistance. We are trying to ignite.

Be sure to check the draft after igniting the main burner. No heat should come out of this hole. If ignition fails, we move further along the chain. If this condition is met, we perform the following actions. Checking the thermocouple. We ignite the igniter.

The solenoid valve rarely fails. Let's examine the thermocouple.

Related Posts

It happens that the thermocouple contact disappears. This is not a reason to replace it, just solder it. Especially if it had to be soldered. The parts should not be pressed too hard. The force must be sufficient to ensure reliable contact.

We crimp the terminals with pliers and, after wiping them with alcohol, try to ignite. This occurs due to a clogged nozzle. Tip: you can lightly tap the igniter to make it easier to remove the jet. Accordingly, the gas pressure at the igniter may also decrease.

This may require adjusting the gas pressure at the igniter. The adjustment is made by turning the screw on the valve.

When turning it counterclockwise, the gas pressure on the igniter increases.

Possible uses

Such automation for gas boilers is quite common. It is aimed at working in conjunction with an injection burner. Its advantages also include reliability and ease of operation. In addition to this, it has a very, very affordable price. A similar system is used both as part of heating systems and double-circuit units, which can not only heat the coolant, but also provide hot water.

Also, the automatic device for a gas boiler of this model allows its use in gas boilers. Another possible option for using Arbat-1 is gas hot water heaters.

ARBAT automation repair

ARBAT automation repair

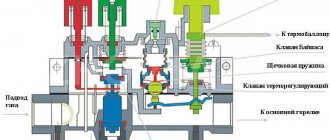

Puller for removing the control rod of a thermostatic valve.

automation bypass Arbat 1

This is an addition to the repair of gas automatics Arbat 1, and someone may need it.

Replacing the thermostat thermostat bellows on automatic Arbat 2, Arbat 1, Orion.

How to change the thermocylinder bellows on a gas boiler with automatic control Arbat 1, Arbat 2, Orion. In this case, diss.

Automation of gas boiler Orion, Arbat repair. Thermostatic valve.

Let's look at one of the breakdowns of the thermostatic valve, in which the main burner turns off but not completely.

How to check the bellows of a thermal bulb. Gas boiler thermostat.

How to check the bellows of a thermal bulb. Gas boiler thermostat. If you purchased or removed this part from.

Thermocouple failure, the first of 5 reasons for failure, or why the boiler does not ignite.

I will show you how to clean the solder on the thermocouple and make it between the thermocouple and the solenoid valve.

Lesson 4 - How to clean soot from a boiler.

Disassembling a thermocouple

I am disassembling a thermocouple from a gas boiler.

How to check the thermocouple of a boiler, stove, column.

Installation and adjustment of a gas burner device with SABC-TB

Features of a gas burner device with SABC-TB Due to the overall firebox of furnaces designed for combustion.

Do-it-yourself boiler automation repair

Repair of heating element automation.

Review of major breakdowns (malfunctions) and repair of gas automatics of the Eurosit 630 boiler (Eurosit 630)

How to properly use a gas boiler thermostat

In order for the boiler automation thermostat to serve for a long time, you need to know the rules of use. How correct.

How to check a thermocouple using a multimeter (the wick goes out)

█ The wick goes out and does not light. Boiler automation repair (AOGV). Replacing the thermocouple.

How to check the solenoid valve of a gas boiler.

How to check the solenoid valve of a gas boiler? Checking the valve is very easy with just a few.

The gas boiler goes out and turns off when the main burner is turned on.

The gas boiler goes out, goes out, turns off when the main burner is turned on. What can be done in the situation.

The automation of the AOGV-11.6-1 boiler is faulty.

How is the boiler constructed? How does boiler automation work? How to do without a gas man? How to look for a fault.

Malfunction of the automation of an old gas boiler

0:05 My story is connected with the operation of AOGV automation 2:50 A common problem with AOGV automation More.

REPLACING THE EUROSIT THERMAL BELLOWS WITH YOUR OWN HANDS

Why does the gas boiler go out, go out, or not ignite? Boiler thermocouple repair.

One of the common reasons why a gas boiler goes out or goes out is that it does not ignite. Why does it go out, goes out?

Technological features

It should also be noted that all previously discussed units must be household and not industrial. They should also be based on an injection burner. The operating principle of the latter is based on the fact that during the combustion of fuel, the required volume of air mass is “sucked in” naturally due to a special design. Again, the lack of a forced ventilation component means that the gas-air ratio is not always strictly met. Therefore, in one case there is an excess of fuel, and it does not burn completely. In the second case, more air is already produced, and the natural gas is not completely burned.

Basic contours. Characteristics

The automation of the Arbat-1 gas boiler includes the following main circuits.

Monitoring the presence of pilot and main burner flames. If it is absent, the gas supply is suspended.

Changing the gas supply depending on the degree of heating of the coolant. In this case, the desired temperature value is set manually. The regulation process itself is “two-position”. That is, when the maximum set temperature is reached, the gas supply stops. When the water cools to the lowest permissible value, the heating system automatically starts.

That is, this automation for a gas boiler essentially provides control of two main parameters: coolant temperature and the presence of flame. The technical characteristics of this system are as follows:

- The gas pressure should be between 1300 and 2000 Pa.

- Connecting size G1/2.

- The limits of water temperature regulation are 40... 90 0 C.

- Accuracy – ±5 0 С.

The principle of operation of automation on old-style gas boilers

Frequent problems when heating a room with gas boilers are flame attenuation in the burner and gas pollution in the room. This happens for several reasons:

- insufficient draft in the chimney;

- too high or too low pressure in the pipeline through which gas is supplied;

- the flame on the igniter goes out;

- leakage of the pulse system.

When these situations arise, the automation is triggered to stop the gas supply and prevent the room from becoming gas-filled. Therefore, installing high-quality automation on an old gas boiler is basic safety rules when using it to heat a room and heat water.

All automation of any brand and any manufacturer has one operating principle and basic elements. Only their designs will differ. Old automatic machines “Plamya”, “Arbat”, SABC, AGUK and others work according to the following principle. When the coolant cools below the temperature set by the user, the gas supply sensor is activated. The burner starts heating the water. After the sensor reaches the user-specified temperature, the gas sensor automatically turns off.

On a note! When using modern automation, it is possible to save heat up to 30%. Old-style automation is non-volatile and does not require electricity. Its adjustment, connection and disconnection are carried out by a person. Commands are transmitted using electromagnetic pulses.

The video explains how the automation of gas boilers AOGV and KSTG works.

Setting procedure

Gas heating boilers in conjunction with this automation system are started as follows:

- The presence of traction is checked.

- Then set the thermostat knob to position “0”.

- We open the shut-off valves and supply natural gas.

- By pressing the start button for 30 seconds, we light the igniter.

- After this, the main burner will automatically light up.

- We set the required temperature value on the thermostat, and after that the system is in operation.

Price

Currently, this model of automation system for gas heating boilers, designed by Arbat-1, costs about 2500-2700 rubles. Possible places to purchase it are online stores, market kiosks, construction supermarkets and specialized retail outlets. Experience shows that it is most optimal to purchase such equipment in the last place. Still, this equipment is specialized in nature, and it is best to buy it from professionals. In other cases, problems may occur when starting up this equipment and its further operation.

Reviews

Automation for gas heating boilers "Arbat-1" has a number of significant advantages, which owners in their reviews include ease of operation and setup, low cost and reliability. But the main disadvantages of this unit include the fact that it is designed to work in conjunction with injection burner devices. The latter today can no longer provide the required quality of combustion of natural gaseous fuels and have a low efficiency factor. Therefore, use such devices only when repairing old boiler units.

Types of gas boiler draft sensor and its operating principle

The design of the draft sensor varies depending on what type of combustion chamber is installed on the boiler being used. There are two types of such cameras:

- Open combustion.

- Closed combustion.

According to government regulations on the safety of gas equipment, manufacturers of gas boilers are required to install draft sensors in devices with open combustion chambers. A typical location for mounting the sensor is a smoke extractor. The principle of its operation is as follows: the gas supply to the boiler is interrupted when the material from which the sensor is made exceeds the expansion rate set in it due to the excessively high temperature inside the unit. In fact, in this case, the gas boiler draft sensor functions as an overheating sensor.

The basis of the alarm is a plate made of bimetal, which deforms and bends, breaking the contact if the temperature of the sensor rises above seventy-five degrees Celsius. Accordingly, the valve that regulates the gas supply to the igniter and burner shuts off the fuel supply. Simply put, as soon as the alarm has checked and made sure that the draft is decreasing, and less and less air with substances released during combustion escapes through the chimney into the environment, the more overheating inside the gas boiler increases, resulting in the activation of the automatic system and shutdown gas supply.

A particular danger for owners of geysers in which gas burns in an open chamber is reverse draft . What it is? Sometimes, for some reason, for example, a strong wind outside, a clogged chimney, smoke and carbon monoxide begin to be drawn from the chimney back into the room, and as a result, a threat to the health and life of people arises. The draft sensor is usually not designed for such cases, therefore, in order to eliminate the risk and protect yourself, you should think about purchasing and installing a special device called a gas sensor in the gas boiler.

If your house has a gas boiler with a closed type of combustion chamber, then it has a draft indicator that differs in operating principle, called a pneumatic relay. The task of this device is to monitor the performance of the fan, which creates draft in the direction from the boiler to the chimney.

The principle of operation of the pneumatic relay is that it contains a membrane that is highly sensitive to the presence of pressure created by hot gases inside the boiler. This membrane is supported by a spring, which manufacturers adjust to a value determined by safety requirements. Therefore, as soon as the pressure inside the gas boiler exceeds the set limit for which the spring is designed, the contacts of the microswitch responsible for the operation of the gas supply valves will open and the gas boiler will stop working.

Simultaneous pressing of the start and stop buttons is not allowed.

The pilot flame touches the housing of the thermocouple temperature sensor. After some time, the latter, in turn, fixes the rod in the lower one as in Fig. The start button can now be released.

To submit a response, you must log in or register. Hi all!

The traction sensor consists of a bimetallic plate and a contact (Fig. If a pipe is clogged, its temperature rises sharply. The bimetallic plate heats up and breaks the voltage supply circuit to the electromagnet - the rod is no longer held by the electromagnet, the valve closes and the gas supply stops.

The location of the automation device elements is shown in Fig. It shows that the electromagnet is covered with a protective cap. The wires from the sensors are located inside thin-walled tubes. The tubes are attached to the electromagnet using union nuts.

The body terminals of the sensors are connected to the electromagnet through the housing of the tubes themselves. The sensor is not protected by a casing, so see through the bimetallic plate. The coat of dust is removed with a soft brush. Then the plate is pulled away from the contact and cleaned with fine sandpaper.

We should not forget that it is necessary to clean the contact itself. It contains substances that actively destroy the oxide film. Registration: Look at the magnitude of the low burn, it is likely that the slippage occurs during the transition from high to low burn, and not from low to igniter.

If so, then it is possible that the valve is clogged with lubricant, and that the gas lubricant has carried onto the screw of the bypass jet. Try loosening the bypass screw, what will change? Sergey O, I turned the bypass screw, during high combustion it slightly decreases when tightened and increases when unscrewed!!! And the flame breakthrough to the injectors begins to occur when the igniter lights up. I read the entire forum here, yesterday a friend from Gorgaz came and tormented the automation for two hours, and nothing happened!!! All night there was a boiler on the troika and the burners were burning, but in the morning they went out and after a few minutes the igniter started to puff and the nozzle ignited.

The bypass screw has almost no effect on the large combustion! This means there is no low combustion - the jet is clogged. Low combustion - the size of the flame is reduced by half from the large one. There can be only two reasons: a malfunction of the click spring, the gas supply stops slowly, and a leak occurs.

Well, what has already been described - no small combustion, the path through the bypass is clogged. How can I check this clearly??? By the way, it burned on a low flame!!!! See if there is a transition to low combustion by reducing the flame by half, and then listen for the shutdown click.

Preparing for work

When the light was low, there was a click and the burners went out!!!! Then after a few minutes it slips onto the nozzles and that’s it!!!! Conversation between a deaf man and a blind man. Click, the burners have gone out, one pilot light is on. How can there be a leak on the injectors of a burner that has gone out? If we allow the presence of gas to leak through the valve, then by the time it reaches the igniter, it mixes with air, then ignition will occur with a not so weak pop! And I say - this is impossible - where are the nozzles, and where is the igniter? Bang is inevitable..

Slavik64 likes this.

During the use of heating equipment, owners have to deal with various problems and failures, and gas devices are no exception. There are many reasons why boilers malfunction, but there are a number of those that occur most often. The reason for their occurrence is mainly illiterate installation of equipment, neglect of safety rules, or lack of systematic maintenance.

And it’s the same with all the neighbors. There are three reasons for the malfunction. We cover the first two, for the third reason we prepare materials.

Overheating sensor and ionization sensor

The function of an overheating alarm as one of the most important elements in the automatic safety system of a geyser is to protect it from heating above the value set by the manufacturer. As a rule, it is one hundred degrees Celsius. When the temperature threshold is exceeded, it turns off the gas supply to the column. Usually it is either a bimetal plate or a thermistor.

An ionization sensor or, in other words, a flame presence sensor is a device with which a gas water heater can track whether there is a flame in the burner or not. Experts include a certain period of time in the alarm program, which varies among different manufacturers of geysers and is called the safe ignition time of the flame. If the unit, with its help, is unable to detect a flame in the igniter after this time, then the gas supply is blocked.

The operating principle of the flame detector is very simple and is based on the postulate that flame is an excellent conductor of current. It has two electrodes between which the fire should burn. If the flame burns, current passes between the electrodes. In this simple way, the alarm device checks whether the gas is burning in the burner.

Self-adjustment of plastic PVC windows

Plastic windows provide reliable protection of the home from the external, sometimes unfavorable, environment. With a metal-plastic structure, strong winds, rain, and foreign odors from the street are not afraid. The reliability and durability of Euro windows depends not only on the material from which the window is made, but also on proper installation. However, even with high-quality assembly, it is periodically necessary to adjust the plastic windows yourself.

How to adjust plastic windows

Servicing the locking mechanism is not as difficult as it seems. Despite the apparent complexity, you only need a small set of tools:

- 4 mm hex key,

- crosshead screwdriver.

At the end, when opening the sash, you can see 3 eccentrics , also known as DAPFs. These elements are regulators and allow you to create a comfortable atmosphere and the required temperature in the apartment. Each eccentric is turned with a hex key in both directions. Turning to the left will provide tighter pressure; turning to the right will provide less pressure. It is necessary to achieve such a position that it does not blow from the street. The main condition is uniform adjustment of the plastic windows so that the pressure density on all eccentrics is the same.

If you press one of the CAPFs harder than the others, the rubber seal on the window unit will wear unevenly. Correct adjustment of the fittings will free the consumer from frequent adjustments of double-glazed windows, which will keep the seals on the sashes in good condition longer.

Adjustment of the position of the glass unit is carried out using a hex key.

- In the horizontal plane, adjustment is carried out from the side of the upper hinge. You need to open the window; there is a key hole on the hinge. It must be rotated clockwise to press the corner against the hinge, and counterclockwise to move it away.

- You can adjust the euro window vertically by adjusting the bottom hinge. Under the cap that covers the hinge there is a hex socket. When you rotate the key counterclockwise, the sash rises, and when you rotate it clockwise, it lowers.

Diagnosis of problems and ways to solve them

If your gas water heater , equipped with an automatic security system, does not work, you need to make sure that the problem lies in the operation of one of the sensors:

- If your draft sensor goes off, you will most likely smell burning or gas in the room at that moment. To make sure that the problem is indeed incorrect draft, place your palm or a piece of paper near the chimney. If the draft is disrupted and air flows from the chimney into the room, then the solution to the problem often lies in calling a stove technician who will clean the chimney of soot and combustion products deposited in it.

- The overheating sensor will work in your geyser if the cause of an excessive increase in temperature is contamination of the heat exchanger. You need to proceed as follows: open the windows and doors, wait until the room is cleaned with fresh air and the boiler has cooled down, then contact a qualified specialist.

- If you have an ionization sensor installed, it may make it impossible to ignite the igniter due to the fact that the igniter nozzles are clogged with soot, and the safe ignition time programmed in the flame detector will expire. The solution in this situation is to clean the nozzles at the igniter and try to ignite again. If it is unsuccessful, you should contact a qualified technician.

“>

Automation Arbat device and repair

Leave your details and we will call you back.

You can leave a request and we will send a response to your email. mail.

carries out repairs and service maintenance:

- All types of gate systems,

- fencing systems,

- Rollstaven,

- Warehouse equipment,

- Barriers and parking automation systems,

- Entrance groups and doors.

Maintenance and repair of each of the above categories of goods has its own specifics. For example, for the normal functioning of gate systems and the full performance of the resource built into such a design, it is necessary to regularly change the rollers, adjust the springs, tighten the cable and lubricate the moving elements. If these simple steps are not performed regularly, the structure may experience excessive stress, distortions appear, this leads to improper functioning of the gate system and can even lead to its destruction.

If you need to replace the door leaf, our specialists will also be able to help you select and install the door leaf of the required dimensions, suitable for the design features of your door system and aesthetically acceptable to you.

"Spetstechniks" also provides services for setting up and reconfiguring automation, including programmable ones. Our specialists eliminate malfunctions of controls, photocells, etc.

The next category of products that requires regular maintenance is warehouse equipment. This:

- Leveling platforms

- Reloading vestibules

- Sealers for openings

- Dock docks

- Dock shelters

- Dock levelers

- Mechanical swing axles

- Portable bridges

- Mobile ramps

- Lift tables

- Remote trusses

- Cargo docks

These systems require lubrication of moving parts and regular oil changes. Timely replacement of damaged elements of warehouse equipment will help you maintain its functionality for many years!

Equipment designed to operate in open spaces is especially susceptible to aggressive external factors. In particular – climatic ones.

For such equipment, regular maintenance is seasonal service, preparing the systems for operation at a certain temperature, humidity, etc.

On our website you can leave a request for seasonal or periodic maintenance of gates, barriers, roller shutters, fences and warehouse equipment.

Our specialists are ready to service your systems and equipment, regardless of whether they are products from or were sold by another company!

Did you like the service from Spetstechniks? We offer you certificates for annual service!