A thermocouple is a control and measuring module installed in gas boilers that acts as a protective element for emergency shutting off of the gas supply valve when the fire goes out. Its operation does not depend on the supply of electricity, that is, this module is completely autonomous. It is also actively used in industry for accurate temperature measurement in aggressive environments. And thermocouples are now installed everywhere in smartphones and computers. It is with their help that the device monitors the heating of components located on motherboards.

Why is a thermocouple needed in a gas boiler?

A thermocouple is installed on a gas boiler to provide additional protection against possible gas leaks when the fire dies out. Sometimes it is also called a “fire control sensor”. As soon as the temperature inside the combustion chamber decreases, the gas supply valve is automatically closed and blocked. As a rule, you cannot even open the valve manually until the sensor cools down.

Read more: Why is the gas boiler humming?

conclusions

If you decide to heat your home using a gas boiler, remember that a thermocouple is a key element in the safe operation of the unit. The thermocouple device is quite simple and understandable. The price is more than reasonable, and the connection connectors are standard. Therefore, if you need to replace the temperature sensor in case of breakdown, there will be no problems. The only thing to consider is the type and technical characteristics of the device.

Despite the fact that the design of the thermoelectric element is very simple, it is one of the most important parts of modern gas equipment. Acting as a temperature sensor, providing gas control and the presence of a flame, a thermocouple is an ideal element to protect your safety in a house heated with a gas boiler. In any emergency situation, the temperature sensor and shut-off valve will operate in such a way that the gas supply will stop.

Video on the topic:

How does a thermocouple work in a gas boiler?

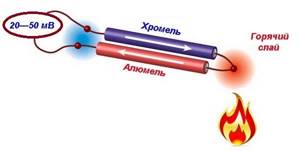

The operating principle is based on such a physical phenomenon as electromotive force (EMF, discovered by Thomas Seebeck back in 1821). Basic provisions of the phenomenon:

- in a closed circuit, an electric current arises between two contacting conductors made of different materials;

- The higher the temperature difference at the point of contact (adhesions), the higher the voltage of the generated current.

That is, the operating principle of the installed gas boiler thermocouple is as follows:

- when there is no fire inside the combustion chamber, the sensor generates a certain voltage;

- When a fire is ignited inside the combustion chamber, the temperature rises, a large temperature difference occurs at the point of contact of the conductors, due to which an electric current is generated.

Did you know how a thermocouple works before?

Of course I knew

100%

No. Live and learn

0%

Voted: 1

The current generated when the sensor heats up is sufficient to hold the gas supply solenoid valve in the open position. But as soon as the fire goes out, the voltage drops, the valve automatically closes.

The general design of thermocouples installed in gas boilers is as follows:

- thermoelectrode with a junction of two conductors;

- extension contact (located inside the capillary tube, it also acts as a negative contact);

- positive contact (the locking dielectric washer is screwed onto it);

- fixing washer (dielectric that does not allow current to pass through).

The main advantage of this module is that in order for it to work together with the solenoid valve, it is not necessary to install a control unit or microprocessor. That is, the entire system works autonomously; there is no need to connect it to electricity. The average voltage generated by the module installed in gas boilers: from 15 to 60 mV.

We recommend reading on our website: Why a gas boiler does not reach the set temperature.

Device and principle of operation

The main principle of operation of a gas boiler draft sensor is the closing and opening of contacts.

It works according to the laws of physics, thereby controlling the temperature of the burned fuel. When the temperature indicator shifts into an unacceptable zone, the draft sensor transmits a corresponding signal to the electronic control unit of the boiler.

The type of sensor directly depends on the type and design of the gas boiler in which it is installed.

Boiler with natural draft and open combustion chamber

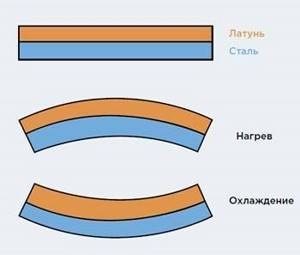

The main element is a plate consisting of two metals that have different deformation characteristics due to heating, as well as two contacts that are brought together and separated by these plates. As a rule, one of these plates is fixedly fixed to the sensor body, and the second is deformed due to thermal effects.

The sensor must match the fuel type. If the boiler operates on compressed natural gas, the sensor must operate in the temperature range from 95 to 950 °C, if on liquefied gas - from 75 to 1500 °C.

If the traction force becomes less, burnt gases accumulate. Due to this malfunction, the temperature of the measuring device increases. The bimetallic plate opens the contacts and the gas supply to the burner stops, that is, the boiler control unit performs an emergency shutdown.

Work will resume when the sensor cools down and its temperature drops within the appropriate range. This means that it also acts as a thermostat.

With forced draft and closed combustion chamber

In this case, the draft sensor has a pneumatic relay design with a very sensitive membrane. The blowing device creates strong draft and movement of burnt gases. Under their influence, the membrane is deformed and closes the sensor contacts. At this time, the control unit detects normal operation of the boiler with sufficient draft.

But, with insufficient traction, there is not enough force to displace the membrane and it returns to its original position. The contacts open and the heating device stops operating.

With condensing heating type

The sensors, as on boilers with natural draft, operate on the principle of deforming a bimetallic plate, but are set by the manufacturer to a lower temperature regime.

Diagnostics, repair and replacement

An initial check of the thermocouple is performed even without disassembling the gas boiler. The most common “symptom” is the extinguishing of the fire after releasing the ignition button, even when the boiler has already warmed up quite hot from the inside. If the fire goes out, it means the valve is not being held open. That is, the thermocouple does not generate enough voltage to open it.

Also read with this article: The main reasons why a gas boiler does not turn on.

The thermocouple is also checked by visual inspection. The presence of burns, holes or hollows is a clear sign of a malfunction.

How to test a thermocouple for functionality

To confirm the “diagnosis” you should check the thermocouple with a multimeter. How to remove the module is precisely indicated in the technical documentation for the boiler.

As a rule, this requires:

- unscrew the fixing nut near the solenoid valve;

- remove the sensor from the groove, disconnect the terminals (if provided);

- heat the sensor in any convenient way (it is recommended to use a candle, but heat it so that the module body is completely enveloped by the flame);

- measure the voltage (apply one probe to the sensor body, the second to the output contact).

Expert's word!

Martyanov Pavel

Specialist in the field of gas equipment maintenance, 20 years of experience

Ask a Question

When checking the serviceability of a thermocouple with a multimeter, install one probe on the thermocouple body, the other on the lead end. The voltage should gradually increase and be at least 15 mV (in this case, the gas valve is in the open position and the wick does not go out).

As a rule, the operating voltage of the thermocouple after thorough warming up is 0.015 - 0.06 V. If the current is less than 15 mV, then this clearly indicates a malfunction of the sensor and requires its repair or replacement.

But to check the tester’s performance through a “dialer”, as is recommended on numerous forums, is not the best option. It is quite possible that due to overheating or oxide, the junction has “broken” and the conductor has shorted to the body. That is, there is actually an open circuit, but the multimeter will not show it.

Thermoelectric flame sensor device

The thermocouple is a safety element of a gas boiler that generates voltage when heated and keeps the fuel supply valve open while the pilot light is on. The sensor shown in the photo operates autonomously, without connecting an external power source. The scope of application of thermocouples is gas-using non-volatile installations: ovens, kitchen stoves and water heaters.

Let us explain the principle of operation of a thermocouple for a boiler, based on the Seebeck effect. If you solder or weld the ends of 2 conductors from different metals, then when this point in the circuit is heated, an electromotive force (EMF) is generated. The potential difference depends on the temperature of the junction and the material of the conductors, usually in the range of 20...50 millivolts (on household appliances).

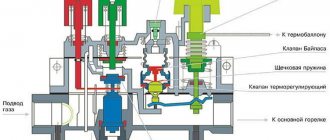

The sensor consists of the following parts (the device is shown in the diagram below):

- a thermoelectrode with a “hot” junction made of two dissimilar alloys, screwed with a nut to the mounting plate next to the boiler pilot burner;

- extension cord - a conductor enclosed inside a copper tube, which simultaneously plays the role of a negative contact;

- positive terminal with a dielectric washer, inserted into the socket of the automatic gas valve and secured with a nut;

- There are types of thermocouples that are connected to automation using conventional screw terminals.

In this model, the heated electrode is attached to the boiler plate without a nut - it is inserted into a special groove

Note. A copper tube is needed to protect the positive conductor from external noise created by a 220 V household network and other electrical appliances. Remember: the minimum thermocouple voltage is only 20 mV.

For the manufacture of electrodes that generate EMF, special metal alloys are used. The most common thermal couples:

- chromel - alumel (type K according to the European classification, designation - THA);

- chromel - copel (type L, abbreviation - THK);

- chromel - constantan (type E, designated THCn).

The principle of operation of a thermal couple made of two different alloys

Reference. Alumel is an alloy of nickel with aluminum, manganese and silicon. The composition of chromel is 90% nickel, 10% chromium. Copel also includes nickel combined with copper and silicon.

The use of alloys in the design of thermocouples is due to better current generation. If you make a thermal couple from pure metals, the output voltage will be too low. Most heat generators used in private homes have TCA (chromel - alumel) sensors installed. For more information about the design of thermocouples, watch the video:

Advantages and disadvantages of using thermocouples

There are 2 key advantages of such modules:

- low cost of production;

- autonomous work.

Additional advantages of thermocouples installed in the boiler:

- can also act as a temperature sensor;

- wide range of operating temperatures (with a tungsten conductor they can work at temperatures above 2000 degrees);

- accurate measurement indicators;

- easy installation and replacement.

The only drawback: if the soldering is done poorly, the thermocouple fails quite quickly. And this happens even when soldering conductors in the factory. A visually unnoticeable microcrack will lead to the formation of oxide, and subsequently burnout. This is an additional reason why repairing a burnt-out module at home is impractical.

Read more on the website: Rating of the cheapest and most economical gas boilers for a private home (apartment)

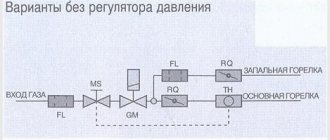

Gas valve selection

In order to choose a solenoid gas valve, you should pay attention to a number of nuances:

Firstly, you need to decide on the place where it will be used and based on this you need to look at the properties that it should be characterized by. Electrical maintenance. It is best to choose a valve with low power and intrinsic safety or with additional manual adjustment. Pressure. When choosing a valve, be sure to check what pressure is in the pipeline. It should not exceed the rated pressure of the accessory, as too high a pressure may damage the mechanism. Network voltage This indicator should be given special attention, since increased/lowered voltage can lead to a negative outcome - the valve may simply break

Environment It is also important to consider the conditions in which the valve will operate. It is important that the technical characteristics of the valve are similar to the characteristics of the working environment: humidity, vibrations, temperature changes, etc.

DIY thermocouple repair

In 95% of cases, thermocouple repair is not practical or possible. Exceptions are the following situations:

- The cause of the malfunction is the presence of carbon or soot in the working area (where the solder is located). You can remove it with alcohol or other solvents. But grinding or treating with sandpaper is not worth it.

- Oxidized contacts at the junction with the terminals. They can be removed by careful sanding using “zero” sandpaper. Sometimes treating with alcohol helps.

If there is a visible burn or dent on the thermocouple, then the only repair option is to replace the sensor with a known good one.

We recommend reading on our website: The procedure for replacing an old boiler with a new one

But what you definitely shouldn’t do is fix the ignition button to force the gas supply valve to open. This is sometimes done when the temperature sensor module is faulty, and it is not possible to replace it right now. You need to understand that this carries a potential risk for everyone who is in the room where the boiler is installed. Indeed, if it fades (for example, due to blowing in from the chimney), the gas supply will not be automatically shut off.

Principle of operation

Many foreign-made gas stoves have a thermocouple component such as a gas control sensor. This device often acts up and cuts off the gas supply when it is completely inappropriate. For example, if a little water gets on the gas stove or there is a draft in the kitchen, the sensor will work and shut off the gas supply. The thermocouple in a gas stove is installed near the gas burners and in the oven.

First you need to determine what is the reason for the poor performance of the sensor. It may either not work at all, or work intermittently, or turn off the gas supply for no reason.

Often the cause can be outgoing contacts.

Sometimes the thermocouple just needs to be corrected or dirt removed. To clean the thermocouple, take a piece of sandpaper and rub it under the flame breaker structure several times.

There are two simple ways to check whether your sensor needs cleaning.

- Press the button and activate the electric ignition. If the burner is on, but as soon as you release the button it goes out, it means the contacts are not working. They need to be cleaned or corrected.

- After you lit the burner and released your hand, after a few seconds the flame went out - you need to check the contacts.

Differences from temperature sensor

In automatic gas boilers, in addition to a thermocouple, a temperature sensor can also be installed - it allows you to reduce the intensity of the flame when the user-specified temperature is reached.

Visually they are similar, so they can be confused. Main differences:

- the base of the temperature sensor is a massive cylindrical siphon in the shape of a sealed copper flask;

- the temperature sensor has a thinner capillary tube;

- the temperature sensor is installed near the water radiator (since it measures the temperature of the coolant, not the flame in the combustion chamber);

- The temperature sensor is connected to the automation valve.

Thermocouple Temperature sensor

The operating principle of a temperature sensor is also different. Inside the flask is a special liquid, which expands when heated, transmitting pressure to the automation, which, in turn, regulates the position of the valve.

We recommend the article: How to choose the right uninterruptible power supply

How and in what cases can it be restored?

The thermocouple is designed in such a way that any damage or contamination can reduce the voltage it produces below a critical level. A very common cause of malfunction is carbon deposits or a layer of soot on its working (heated) part. To restore the thermocouple, just clean it with a soft brush or cotton wool and alcohol, while avoiding scratches and other damage. After cleaning, it is worth checking the voltage again following the instructions above.

Oxidized contacts are also a common cause; they can be carefully treated with sandpaper. If the thermocouple has a deep black dent or hole due to burning, it is guaranteed to need to be replaced.

Types of thermocouples

Thermocouples for domestic gas boilers are predominantly chromel-alumel. They are among the cheapest to produce and can withstand heating up to temperatures of about 1500 degrees (in the combustion chamber it is on average 1000 - 1200 degrees). But they are also made from other materials. The most common:

- platinum-rhodium-platinum-rhodium (TPR);

- platinum-rhodium-platinum (TPP10);

- tungsten rhenium.

Mostly such variations are used in industrial boilers. The principle of their structure and operation is similar. The only difference is the maximum permissible operating temperature (as well as the current generated).

Connection nuances and verification

Connect the thermoelectric converter to the measuring device using a compensation cable. In order to minimize the measurement error as much as possible, the cores of this wire are made of the same material as the sensor itself.

Check the functionality of the thermocouple as follows:

- one end of the device is connected to a multimeter;

- the other end is manually heated using a lighter or gas torch.

If the device is in good condition, this is indicated by the presence of a voltage in the region of 50 mV.

How to connect a burnt-out thermocouple of a gas boiler automation system

In theory, it is possible to solder a burnt-out module. Possible welding options:

- in a salt electric welding machine;

- using an acetylene torch;

- welding in coal or graphite powder (in a ceramic container).

But the welding current is approximately 80V 5A. This is the reading for a chromel-alumel thermocouple. That is, you can’t do without a laboratory autotransformer (aka LATR). And in addition to this, the likelihood that the seam will turn out uneven and when heating the module will not generate electricity at all is high.

The cost of a new thermocouple for a boiler is from 200 to 1500 rubles (depending on the model). The cheapest ones can actually be repaired at home if you have the right equipment for this. But expensive ones (with platinum or tungsten conductors), as a rule, cannot be repaired; they are simply replaced.

In summary, a thermocouple is a technically simple device that will protect against gas leakage in the event of a boiler extinguishing. The average service life of such a module is 5 years. Boiler manufacturers recommend that they be diagnosed at least once every 3 years.