The Mimax gas boiler is a product of a domestic manufacturer. The company offers a wide range of floor and parapet heaters powered by gas. These devices attract buyers with their simplicity of design, efficiency and moderate cost. The manufacturer produces heaters with a power of 7–40 kW, designed to heat an area of 30–400 m².

About company. MIMAX LLC was founded in 2002. At first it was engaged in the production of automatic burners. Moreover, all ASUs are their own developments. A completely new type of burners was developed and released - AGU-T-M, equipped with a special Maxima nozzle. The burners are made of steel and are resistant to corrosion. The design feature allows the fuel combustion process to be completely silent. Next, the manufacturer released AGU-T-E-IM and AGU-T-E-IO burners, equipped with SIT safety automatics.

Today the company produces floor and parapet versions. All products of the enterprise are certified.

What types of Mimax boilers are there?

Heating heaters from the Taganrog manufacturer receive positive reviews, mainly due to their compactness and high performance. These devices can operate not only on natural gas: if you change the jets (injectors), you can switch to liquefied gas. According to their intended purpose, Mimax heaters are:

- Single-circuit - they are installed for heating purposes only. They are marked KSG. Next to the letter designation there is a number - this designates the thermal power of the device. The minimum heating capacity for KSG-7 is 7 kW, the maximum for KSG-40 is 40 kW. KSG stands for simply - Steel Gas Boiler. Based on the power, the consumer can judge the heating area. Typically 1000 W per 10 m².

- Double-circuit - they heat the home and provide the supply of domestic hot water. The two circuits have their own separate heat exchangers. Water and coolant do not mix. They are designated KSGV. Power range: 12.5–40 kW.

Any Mimax heater, single-circuit or double-circuit, has a thermometer on the facade indicating the heating temperature - a scale of 0–120 °C.

Advantages

- Low, competitive price. Depending on the power, their cost ranges from 10,000–17,000 rubles.

- Reliability. The equipment is ideally suited to our conditions.

- Availability of a certificate and compliance with all sanitation and fire safety standards.

- Wide power range, easy to find the right option.

How to choose

The gas heater model is selected for heating a specific area. Let's say a consumer decides to purchase a floor-standing boiler. To heat, for example, a private household with an area of 200 m², you will need KSG-20, and if you take it with a reserve, then KSG-25. When choosing, we use the above ratio: for every 10 square meters - 1 kW.

If, in addition to heating, you plan to heat hot water, you need to take a dual-circuit version with a power of 40 kW, no less. This is the main disadvantage of floor-standing devices with two circuits: you have to buy a model with double power.

- 7,000 W. This is the option with the lowest possible power. Suitable for a one-room apartment, a small house, a guard post. Saves fuel.

- 10,000 W. Suitable for a 2-room apartment. For a large apartment this power is not enough.

- 12,500 kW. This is the most popular option. This heating output meets most of the needs of the average home.

- 20,000 W. You can heat penthouses, multi-storey cottages, large offices.

- Versions over 20,000 W are used for heating industrial premises, warehouses, etc.

Pechkin KSG - floor-standing gas boilers

KSG "Pechkin"

Floor-standing gas boilers KSG "Pechkin" are designed for heating residential, administrative and utility premises with a total area of up to 500 square meters. m. They have a simple design and are characterized by simple, intuitive controls. Equipment characteristics and advantages:

- Wide range of models;

- Increased reliability;

- High environmental friendliness;

- Quiet operation;

- Long service life – up to 20 years;

- Power – from 10 to 50 kW.

Description of the model range

Gas heating boilers KSG "Pechkin" are represented by a large selection of models that differ in their power - it varies from 10 to 50 kW. Thanks to this, this equipment can heat large houses and buildings. Some models from this model range are built according to a dual-circuit design, so they can be used not only for heating rooms, but also for preparing hot water.

Floor-standing heating boilers KSG "Pechkin" are designed for operation in closed heating systems. They are characterized by a simple and reliable design, as well as minimal maintenance requirements. A simple design means a minimum of parts, which significantly increases the reliability of the equipment. The boilers are easy to install and do not require frequent maintenance. They can operate at fairly low gas pressures and are characterized by impeccably stable operation.

Cost-effective and environmentally friendly

The manufacturer of floor-standing heating boilers KSG Pechkin managed to achieve reduced gas consumption, and the efficiency of the equipment presented reaches 88.5%. There is also a reduced amount of pollution released into the atmosphere. The coolant temperature in boilers varies from 40 to 90 degrees, and the maximum exhaust gas temperature does not exceed +110 degrees. Network natural gas is used as fuel. The maximum coolant pressure in the heating system should not exceed 0.1 MPa. It should also be noted the low noise level created during operation of this equipment.

Owners of KSG Pechkin gas boilers note the ease of control of the equipment presented and its reliability. The boilers do not require regular user intervention and are equipped with a minimum of control elements. Their operation does not require a connection to the electrical network, so they can work in non-electrified utility buildings for various purposes. They will also become indispensable in suburban housing, where there is often a lack of electricity.

Other characteristics

The service life of KSG Pechkin boilers is up to 20 years, the warranty period is 2 years. They are easy to install and do not require special skills for installation. They are ready to work in heating systems immediately after connection. Built-in security systems from Italian manufacturers TGV or EUROSIT are responsible for the safety of others.

In order to buy a floor-standing heating boiler KSG, you should familiarize yourself with the equipment presented in the catalog and select a model that is suitable in terms of power.

Model overview

VEGA

Single- and double-circuit floor-standing models with heating output from 7 to 31 kW. Thanks to the well-thought-out design of atmospheric burners, heat exchangers and turbulators, they are characterized by high efficiency - up to 92%. Equipped with SIT automatic equipment (Italy). All Vega heaters have a built-in gas reducer, piezo ignition, a draft sensor and a sensor that prevents the device from overheating. The heat exchanger is durable, as it is made of cold-rolled steel (2.5–3 mm). The use of highly efficient thermal insulation reduces heat losses of the heat exchanger. The body is painted with powder enamel, which gives the product attractiveness and anti-corrosion resistance. Operating water pressure parameters for all modifications are 0.2 MPa. Parameters of VEGA KSGV-31:

- Heating capacity - 31,000 W.

- The maximum heated area is 300 m².

- Efficiency - 92%.

- Fuel consumption - 3.45 m³/h.

- Weight - 131 kg.

- Duration of operation - from 15 years.

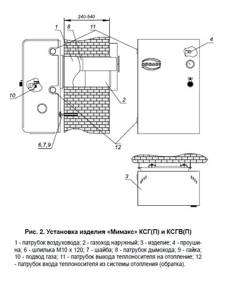

KSG(P) and KSGV(P)

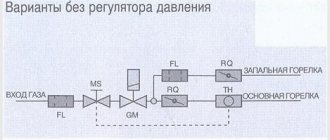

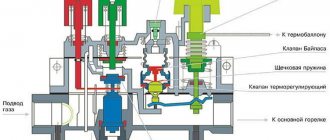

These are parapet devices with one and two circuits. Their design provides for a closed firebox. They are used to heat buildings without a chimney. Such devices can be placed both in a house and in an apartment. Oxygen for combustion and smoke removal is carried out through a coaxial chimney crossing the outer wall. Universal connection, easy installation. Non-volatile type SIT automation was used. Sectional Polidoro burners were installed. The heat exchanger is rectangular, this ensures increased heat transfer. Efficiency - 92%.

As an example, we present the characteristics of the single-circuit model KSG(P)-16:

- Heating capacity - 16,000 W.

- Designed to heat 160 m².

- Efficiency - 92%.

- Fuel consumption - 1.7 m³/h.

- Weight - 64 kg.

- Minimum service life is 15 years.

KSG(IR) and KSG(M)

The manufacturer offers single-circuit models KSG(IR) and KSG(M) and their double-circuit analogs KSGV(IR) and KSGV(M). These are steel boilers, compact, with a stylish design. The IR modifications are equipped with automatic equipment made in Italy and OPTIMA atmospheric burners. Modifications of the “M” version are equipped with AGU-T-M automatic equipment, this is our own development. The latest versions are equipped with MAXIMA stainless steel burners.

Versions with domestic hot water are equipped with a copper coil with a diameter of 14 mm. The length of the coil is 12 m. This is 2–3 m more than that of domestic competitors. The large length of the coil ensures increased circuit efficiency and uninterrupted water heating. Thanks to non-asbestos thermal insulation material, heat loss is reduced and efficiency increases. The body is powder coated.

Technical parameters of KSGV(IR)-20:

- Heating capacity - 20,000 W.

- Designed for heating 200 m².

- Efficiency - from 88%.

- Fuel consumption - 2.43 m³/h.

- Weight - 66.5 kg.

- Operation up to 15 years.

Features of operation

Installation, connection, startup, configuration and maintenance must comply with the manufacturer's requirements. Each model comes with detailed instructions for the user to follow. To avoid problems, it is recommended to follow the operating rules:

- Before lighting the wick, the room is ventilated. The firebox is ventilated for 5–10 minutes. The knob that controls the burner must be closed.

- Checking traction: Apply a thin strip of paper to the holes located at the bottom of the front panel. If there is traction, the strips will be pulled into the holes. If there is no draft, lighting the gas burner is strictly prohibited.

How to increase cravings? The slots of the front shield must be open to such an extent that the draft is sufficient. In Mimax devices, you need to regulate the draft using the grille and chimney damper.

- If the draft is sufficient, light the paper tourniquet by pressing the valve button. The flagellum is brought to the wick. When the fire becomes steady, the button is released.

- Smoothly open the control knob and make sure that the fire from the wick lights on the main burner.

- The air supply to the main burner is regulated by appropriate regulators; air must be supplied in the amount necessary to establish a stable blue-blue flame.

- While the equipment is operating, it would be a good idea for the user to periodically monitor the gas and traction. The fuel must burn without leaving soot. The color of the flame is blue-blue. Combustion should not be accompanied by hissing or popping noises.

Why does the boiler go out?

Causes of burner extinguishing and troubleshooting:

- Ice build-up on the top of the boiler. They must be removed extremely carefully; you cannot rush - you can damage the system. Ice frozen inside, on the walls of the tip, blocks the access of air, and the flame goes out. Defrosting is carried out slowly by removing the head of the device. Then it is brought indoors to allow the ice to thaw. While defrosting is in progress, the equipment can operate without the removed part.

- The pressure in the gas line has dropped. The gas distribution network or gas meter may be faulty. If the meter is broken, gas does not flow in the required volume - a problem is indicated by sounds that are not characteristic of the meter. The cause of a drop in pressure can also be a breakdown of temperature sensors or a violation of the tightness of connections. When the pressure drops, the automation signals a problem - the system turns off. You may smell gas. To solve the problem, you need to check the tightness of the connections using a damp sponge and soap foam. If there is a leak, bubbles will appear. We urgently need to call the gas workers.

How to remove soot

To clean the boiler from soot, you will need a set of tools:

- a metal brush or brush for cleaning surfaces;

- another brush needs to be purchased to clean the chimney - made of metal or plastic;

- scraper;

- steel cable;

- brush holder;

- hooks

Sequence of work:

- Shut off the fuel supply.

- Remove the door, thermocouple, nozzle, and burner tube.

- Remove the top panel.

- Remove thermal insulation.

- Remove the chimney.

- Clean the heat exchanger with a wire brush.

- To clean the heat exchanger channels you will need a vacuum cleaner.

- Clean the walls of the boiler with a brush and wipe with a rag.

- Clean the chimney with a brush. If it is too long, a steel cable may be needed.

When cleaning is completed, the device components are assembled in the reverse order.

Reviews

KSG-10: Peter G., Yurya

Mostly satisfied with the work. Having found out how much the boiler cost, we doubted its quality. Believing the reviews, we decided to purchase and did not regret it. Takes up little space and is easy to use. It is sufficient to heat our 72 square meters. The downside is low efficiency. A lot of heat is wasted and goes into the exhaust pipe. Another drawback is the inconvenient temperature setting, since there are no temperature indicators on the control knob. You need to turn the knob and wait for the readings on the thermometer.

KSG-10: Ivan E., Perm

Previously, we had a wall-mounted domestic device, which wore out and began to leak a lot of gas. We decided to take an inexpensive floor-standing model and chose Mimax. In principle, it works normally - it heats 80 square meters, and uses gas sparingly. The downside is that it is very inconvenient to light, as you have to take a long piece of paper. But the noise from it is small, and with time we figured it out with the automation.

Taganrog products are suitable for consumers interested in inexpensive floor-standing and parapet boilers. A wide power range allows each consumer to choose an option that matches the heated area. These heaters may be far from perfect, but they cope with their tasks adequately, operating reliably in harsh climates.

Advantages and disadvantages of Ochag boilers

The owner of the Ochag equipment brand has been operating since 1993. The design of the units was developed by specialists from the design bureau; it is also constantly being improved and new technologies and materials are introduced. Individual components can be purchased from the company if they need to be replaced. All equipment is manufactured taking into account the requirements of the ISO 9001-2011 standard.

The advantages include the following characteristics:

- a wide range of models, ensuring the choice of the optimal type;

- stable work;

- energy independence from external sources;

- high performance;

- ease of installation and management;

- low fuel consumption;

- low price;

- compact size and pleasant appearance.

The units have operating features:

- the pipe system should be located at a slope to ensure coolant circulation;

- To operate the boiler, it is necessary to equip it with a water pump and a turbo nozzle.

For heating systems of this type, additional equipment ensures uninterrupted operation and is not a disadvantage.