Review of manufacturers and prices

Among the most well-known manufacturers of such devices are the following companies:

- Hutterer & Lechner, DN110. The average price is about 3,000 rubles;

- McAlpine. The cost ranges from 400 to 1400 rubles, depending on the specific model. The most famous models are MRAA1S-CLEAR, MRAA1N, etc.;

- Ostendorf. A polypropylene device, the price of which will be 500 rubles.

There are also cheaper domestically produced models, the cost of which does not exceed 100-200 rubles. The choice is determined by necessity, the specifics of the system and the capabilities of the owner.

Everything useful about sewerage - gidkanal.ru

Correct and incorrect placement

Each device, open or closed, has the direction of movement of the drains drawn on the body. Indicated by an arrow or triangle. It is in the direction of the water that the water seal is installed.

The shutter only works in one direction and in different positions: whether the device is vertical or horizontal. If all installation conditions are met, in the first minutes it will be clear that the device is functioning and water is passing through the membrane.

The correct position of the device is also determined by the installation method. From the socket to the empty end (that is, into the socket), only the empty end of the pipeline can be inserted. On the other side there is only a connecting extension of the pipe with a rubber seal.

Incorrect placement can lead to permanent problems with the device. A device installed incorrectly or in the wrong place will immediately show its failure. Any work begins with reading the instructions, installation of the codpiece is no exception.

Difficulties that may arise if installed incorrectly:

- Hard to reach place. The device requires constant monitoring after installation, therefore, if the shut-off valves are located in a corner or under a layer of concrete in another inaccessible place, it is not possible to maintain it.

- The device was installed in violation of the technological process. Leaky joints, constantly leaking lids - seals are an unpleasant sight. If the rubber bands in the socket are not lubricated with oil during installation, they will ride up or fall inward. Even when all the joints are attached to each other tightly and tightly, they can leak due to the rotation of the O-rings.

- The throttle cannot be installed immediately after the rotating part of the system. During movement, the drains gain decent speed, which means they create pressure. The pipe became clogged or could not cope with the backflow, and the valve closed. The problem was not immediately detected and water continued to flow from the plumbing fixture. The flow of water approaching the membrane will receive resistance and can knock the outlet out of the connecting joint. Therefore, the device is installed strictly on a straight section.

- The valve installation direction is incorrect. Any device has a water movement indicator; installation must be carried out according to this figure. If the device is turned over or placed with the lid down for inspection, the unit will stop working.

What is it and what is it for?

A check valve is one of the elements of protective pipeline fittings.

The main purpose is to prevent changes in the direction of water flow. It automatically closes the pipeline if the flow direction changes in the opposite direction.

Water check valve

Also performs the following functions

- When the water supply is turned off, it prevents its outflow through the riser

- Blocks hot water from entering the cold water supply system and vice versa

- Significantly reduces the likelihood of water hammer

- Increases the operating time of equipment (pumps, meters, etc.)

- Reduces the risk of broken connections in the plumbing system

Selecting the right product

Before purchasing a shut-off element for personal use, you must carefully study the features of your sewer system. Based on its specifics, it is worth choosing a device to protect against sewage backflow.

When choosing the best option, you should pay attention to the following characteristics:

- diameter of sockets;

- material;

- size;

- complexity of installation;

- quality and guarantee;

- price.

Moreover, the cost does not affect the reliability and functionality of the product. For example, there is no reason to purchase a sophisticated model of shut-off valves with an electric motor that costs 100,000 rubles for cheap sewer pipes made of plastic.

The most important parameter is the diameter of the sockets. It must match the diameter of the sewer pipe into which the shut-off element is installed. Buying a smaller or larger device cross-section and then using special adapters will be a dubious decision. This will disrupt the pipeline's capacity.

As for the size, it should be chosen based on the availability of space for its installation. If there is little space, then it is better to use wafer models, for installation of which you only need seals.

The cost of installation work depends on the ease of installation if you plan to invite a plumber. If this is a simple plastic model, then a home craftsman with a minimum set of tools can install it.

Also, before purchasing, it would be a good idea to look at the model you like and check it so that nothing dangles or creaks under your fingers.

It is necessary to pay attention that there is an arrow on top, marked by the manufacturer

Each high-quality product must indicate the direction of movement of sewage, which eliminates errors during installation.

You need to ask the seller for a manufacturer's warranty for this product. A high-quality product produced at the factory always has warranty documents and installation recommendations.

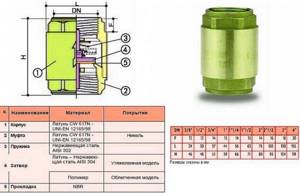

Materials, markings, sizes

The check valve for water is made of stainless steel, brass, larger sizes are made of cast iron. For household networks, brass is usually used - it is not too expensive and durable. Stainless steel is, of course, better, but it is usually not the body that fails, but the locking element. This is where you should approach your choice carefully.

For plastic plumbing systems, check valves are made from the same material. They come in polypropylene and plastic (for HDPE and LDPE). The latter can be welded/glued or threaded. You can, of course, solder adapters to brass, install a brass valve, then again an adapter from brass to PPR or plastic. But such a unit is more expensive. And the more connection points, the lower the reliability of the system.

For plastic and polypropylene systems there are check valves made of the same material

The material of the locking element is brass, stainless steel or plastic. Here, by the way, it’s hard to say which is better. Steel and brass are more durable, but if a grain of sand gets between the edge of the disk and the body, the valve jams and it is not always possible to return it to functionality. Plastic wears out faster, but it doesn’t jam. In this regard, it is more reliable. It’s not for nothing that some manufacturers of pumping stations install check valves with plastic discs. And as a rule, everything works for 5-8 years without failures. Then the check valve begins to “poison” and is replaced.

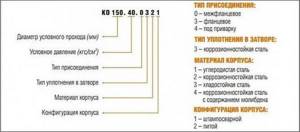

What is indicated in the labeling

A few words about the marking of the check valve. It states:

- Type

- Conditional pass

- Conditional pressure

- GOST according to which it is manufactured. For Russia, this is GOST 27477-87, but there are not only domestic products on the market.

Return valve for water: marking according to GOST

The conditional diameter is designated as DU or DN. When choosing this parameter, you need to focus on other fittings or pipeline diameter. They must match. For example, you will install a check water valve after a submersible pump, and a filter next to it. All three components must have the same nominal diameter. For example, all should have DN 32 or DN 32 written on them.

A few words about conditional pressure. This is the pressure in the system at which the shut-off valves remain operational. You should definitely take it no less than your working pressure. In the case of apartments - no less testing. According to the standard, it exceeds the working one by 50%, and in real conditions it can be much higher. You can find out the pressure for your home from the management company or plumbers.

What else to pay attention to

Each product must come with a passport or description. It indicates the temperature of the working environment. Not all valves can work with hot water or in a heating system. In addition, it is indicated in what position they can work. Some should only stand horizontally, others only vertically. There are also universal ones, for example, disk ones. That's why they are popular.

Opening pressure characterizes the “sensitivity” of the valve. For private networks it rarely matters. Only on supply lines close to the critical length.

Also pay attention to the connecting thread - it can be internal or external. Choose based on ease of installation. Don't forget about the arrow that indicates the direction of water movement.

Dimensions of check valves for water

The size of a check valve for water is calculated according to the nominal diameter and they are produced for all - even the smallest or largest pipeline diameters. The smallest is DN 10 (10 mm nominal bore), the largest is DN 400. They are the same sizes as all other shut-off valves: taps, valves, drains, etc. Conditional pressure can also be referred to as “dimensions”. The lowest is 0.25 MPa, the highest is 250 MPa.

Each company produces check valves for water in several sizes.

This does not mean that any of the valves will be in any variant. The most popular sizes are up to DN 40. Next come the main ones, and they are usually purchased by enterprises. You won't find them in retail stores.

And also, please note that for different companies, with the same nominal diameter, the external dimensions of the device may differ. The length is understandable. Here the chamber in which the locking plate is located may be larger or smaller. The diameters of the chambers also differ. But the difference in the area of the connecting thread can only be due to the thickness of the walls. For private houses this is not so scary. Here the maximum working pressure is 4-6 Atm. But for high-rise buildings it can be critical.

How to check

The easiest way to test a check valve is to blow into it in the direction that is blocking it. No air should pass through. At all. No way. Also try pressing on the plate. The rod should move smoothly. No clicks, friction, distortions.

How to test a check valve: blow into it and check for smoothness

Also inspect the seat and disc. Especially in the place where they are adjacent to each other. Everything should be even/smooth. The tightness of this type of fitting depends on how accurately everything fits. In more expensive models, a rubber/polymer/plastic sealing ring is installed on the plate. Needless to say, it should lie flat, without waves, and there should be no scratches or burrs.

Installing a check valve on a sewer system with your own hands. Step-by-step instruction

Installing the vent valve yourself is quite simple. The operation is performed in five simple steps:

- Select the insertion location. Usually this is the junction of the toilet with the sewer pipe or the junction of two sections of pipe.

- Using a level, align the device strictly horizontally, without distortions. For a vertically mounted device, the angle does not matter (within reasonable limits), so checking the plumbness is not necessary.

- Assemble the system so that the pipe sockets are directed in the opposite direction to the water flow.

- Assembling sewer system connections does not require the use of any lubricant or sealant other than standard rubber seals. If desired, you can coat the connections with silicone sealant for greater reliability.

- Secure the valve or the pipe sections closest to it with two clamps to the floor or wall. The fasteners must be rigid, since vibration from the operation of the valve over time can cause the loose connection to diverge and lose its tightness.

As you can see, the procedure is really not anything complicated and does not require special skills.

Possible malfunctions and methods for eliminating them

Despite the high reliability of such devices, they, like any technical element, have operating features and can also break down and fail. Most often the check valve stops working:

- If debris and stones get into the housing;

- If the spring is damaged;

- When the surface of rubber or plastic seals wears out;

- Gradual aging and loss of elasticity of plastic and rubber;

- Exposure to water and chemicals dissolved in it.

Traditionally, if the valve operates unsatisfactorily, it is simply replaced, since the cost of replacing individual parts and assemblies far exceeds the price of a new one. But it is quite possible to extend the service life of such a device; to do this, it is enough to install a regular, simplest mesh filter at the inlet. Such a simple device is quite enough to almost double the service life of the valve.

How to install a check valve on a sewer pipe

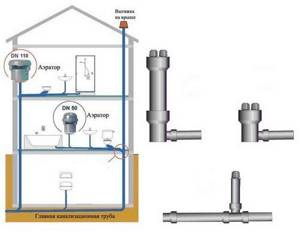

There are two ways to install a check valve in a sewer system. The first involves installing a shut-off element on a common sewer in an apartment building. In the second case, the device is installed for each drain source. This option is used for private households.

The sewer check valve can be installed in two ways

When installing the locking mechanism, it should be remembered that the valve is not mounted on the sewer pipe into the drain gap under the inspection cover. The dampers can operate effectively in a horizontal system. Otherwise, problems will arise with the drainage of wastewater, since the membrane in this position will not create their unimpeded movement.

When choosing a place to install a check valve, it is necessary to take into account that the device must be easily accessible so that in the event of an accident you do not have to dismantle the decoration or move furniture. A 110 mm sewer check valve is installed in the basement after the rotary elbow - before the pipeline enters the wall. In an apartment, the device is placed on a cross or tee near the central drain into the riser. If there is no technical possibility, then you can attach one shut-off element with a diameter of 50 mm to the outlet towards the bathtub or kitchen, and install a second valve with a size of 110 mm on the toilet.

Installing a 110 mm check valve for one riser is insufficient protection against flooding

The shut-off valves are mounted in such a position that it is possible to ensure free movement of flow in one direction. A hint is the indicator on the valve body, which indicates the direction of flow. It is necessary that the valve is at least 100 mm from the highest siphon.

The size and material of the valve must match the characteristics of the pipeline. Otherwise, you will have to use adapters, which will weaken the reliability of the system.

Expert advice

If the purpose of check valves is to protect water supply elements, it is necessary to install mechanisms made of brass and other alloys that are resistant to corrosion. When it comes to heating that runs on a special coolant that prevents rust, you can use iron models.

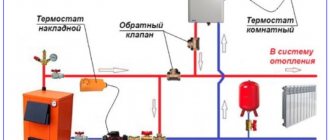

Experts recommend embedding the shutter elements at a distance of 350 mm from the floor or more. This rule applies to any type of valve. When the system does not require a drain, the installation point should be the highest in relation to the drainage level. And when it is planned to modernize the heating system, the valve fits into the return circuit in front of the boiler with heat exchangers.

Before installing equipment in an apartment building, you need to take into account the location of the water meter. The valve is installed after it. This is the case when separate water supply to apartments is provided. In any case, all connected appliances, including the washing machine and dishwasher, will be safe. And it makes sense to even equip the sewer with a return shut-off mechanism to avoid flooding with sewage.

HelpfulUseless

What is a check valve for sewerage 110 mm and other sizes

A check valve is a type of shut-off valve. It is installed in the lumen of the pipeline to block the reverse flow of liquid in case of clogging of the system. The device is installed in the basement on a horizontal section of the general sewer at the junction of the pipes. It can also be installed at a 90º turn in the pipeline.

To achieve maximum safety, a 50 mm sewer check valve can also be mounted on branches to plumbing fixtures on the first and second floors of an apartment building. This enhanced measure is justified by the fact that fecal water, when flowing back, can only rise above the first floor. Further, the accumulated mass is able to independently push through the plug formed in the pipe.

The check valve can be installed where the pipeline turns 90º

For the private sector, a check valve is installed before discharge into the sewer well (for each house separately - on the inside of the foundation). Such a device is also intended for an autonomous system, where wastewater accumulates in a drainage pit or in a septic tank. In this case, you should worry about how to fill the sewer cover with your own hands.

The check valve is characterized by simplicity of design, reliability, efficiency, durability, easy installation and convenient maintenance.

Operating principle

A water check valve is an essential element of a plumbing system. Experts identify a number of points at which the use of the device becomes necessary:

- In an apartment in a multi-storey building, hot and cold water are supplied separately from each other. Each water stream has its own riser. As a rule, the water pressure in them does not match. When a person opens the tap, hot and cold water starts flowing. Due to the difference in pressure levels in the pipes, an uneven distribution of water supply to the tap occurs. Those flows that come with high pressure go first. It is they that lead to an increase in pressure in the line. Water flows with lower pressure can flow back into the pipe and riser. Many people are familiar with the situation when hot water comes out of a tap with cold water. To correct this situation, use a check valve for water.

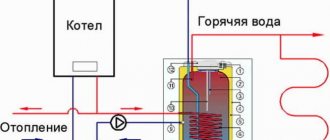

- When installing a storage heater (boiler), installing a check valve at the cold water inlet is mandatory. The peculiarity of the operation of boilers is that they are filled only with cold water pressure. During the heating process, the pressure inside the container increases, and hot water tends to exit into the cold water supply line. Installing a check valve eliminates this situation.

- In private modern houses, the heating system consists of several circuits. Each of them has a different coolant temperature. For example, a building has one circuit for operating a boiler, the second is for the heating system, and the third circuit is for heated floors. Each circuit has its own resistance, so they are equipped with pumps with different characteristics. In order to prevent a situation where the pump provokes a reverse movement of the coolant with a smaller pump in the circuit, a check valve is used.

- Pumps for water wells must be equipped with a check valve. Taking into account that the pump can be located at a depth of tens of meters, if the unit is turned off, water will certainly rush back from the water supply. This situation cannot be allowed to happen; the pump hose will not help in this case.

- When connecting a heating device to the main lines supplying the house, experts recommend installing a check valve on the heating line before entering the system. This ensures the correct direction of the coolant.

If the leaking check valve is a treadle valve in the well, you will be faced with the more difficult task of opening the well and pulling up the well line and treadle valve. But this allows you to check the well line - you may find that the problem was not even a foot valve, but a hole in the well line.

Since hot water or steam heating boilers use a potable water supply line to supply water, we need to prevent water from being diverted from the heating system due to contamination of the water supply line to the building.

Lack of draft in the riser, failure of the water seal

This problem is typical for apartments on the upper floors: one day, a persistent sewer smell appears in the bathroom and kitchen.

What's happening? First, you need to explain to the reader how ventilation of a sewer riser works in normal mode.

You've probably noticed that on flat roofs there are pipes with a diameter of 100 (less often - 50) millimeters protruding above the roof level, which are the source of the characteristic sewage smell. These are the conclusions of the sewer risers.

Sewer vents on a flat roof

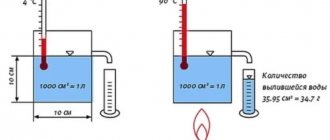

Inside the riser, due to the relatively high temperature of the wastewater, a draft arises that transports moist vapors and odors outside the house. In winter, evaporation gradually freezes onto the inner wall of a cold pipe, reducing its clearance to zero in a few weeks.

Snow cap on the walls of the sewer riser

What will happen?

The traction in the riser will not go away. However, instead of the atmosphere, it will transport fumes and odors to the apartments of the upper floor through leaky connections of the comb (internal sewage system) with the siphons of plumbing fixtures.

Now let’s imagine a volley discharge of wastewater (in other words, the simultaneous discharge of two toilet tanks or a pair of bathtubs) provided that all connections of the devices to the sewerage system are sealed and the riser is not ventilated.

- The flow of water filling it rushes down the riser;

- An area of high pressure is formed at the flow front. At the time of draining, many residents notice the appearance of air bubbles in the sink or bathtub;

- After the flow passes, a vacuum arises in the riser, sucking water out of the hydraulic valves of washbasins and sinks. After the water seals stop functioning, fumes and odors begin to flow uncontrollably into the apartment - until the moment when the siphon is refilled with water drained into the sink.

Hydraulic seals prevent air from entering the apartment from the sewer system

Mechanism for breaking water seals

By the way: dismantling the sewer riser above the tee or cross on the top floor leads to the same result as snow caps. Residents of upper apartments sacrifice the ventilation outlet for the sake of a cabinet above the toilet, poorly imagining the consequences of their actions.

Elimination

How to get rid of aromas that are unusual for your apartment:

- Ensure that all sewer connections are tight. To connect plumbing priors, rubber cuffs and adapters are used. As a last resort, the connection can be sealed with microporous rubber or any foam insulation;

All sewer connections must be sealed

- If odors appear during the cold season, go up to the roof and pour a bucket of hot water into the frozen riser. Re-freezing of the snow cap can be prevented by insulating the riser from the outside;

- The missing ventilation outlet of a riser on the roof can be replaced by a so-called vacuum valve - a simple device that sucks in air when the pressure inside the sewer riser drops.

A vacuum valve is installed instead of the ventilation outlet of the riser on the roof

Vacuum valve device

Very useful tips

Threaded connections must be tightened with a wrench and not by hand to ensure the required tightness.

To connect fittings, protective devices and the pumping station itself, it is better to use pipes whose diameter is slightly larger than the calculated one in order to compensate for the load increased due to bends in the line. To protect the pump from idling, you can install a recirculation line. To do this, tees are placed on the supply and suction pipes and the free pipes are connected with a return line.

A valve should be placed on it to control the intensity of the reverse flow. This addition will improve the pressure, but will slightly reduce the performance of the device.

A bracket can be used as a base for the pumping station, but it must stand level on shock-absorbing pads to minimize vibration.

About once every three months you need to check:

- condition of joints for leaks.

- condition of filters for timely cleaning.

- relay settings for their correction;

- the condition of the hydraulic tank to determine the location of leaks.

Types of valves and principle of operation

There are several types of sewer check valves of 110 and 50 millimeters, which differ in their scope of application. Accordingly, all types of mechanisms have a different design and operating principle of one element.

When the waste liquid approaches, the damper automatically rises, after which it returns to its original position. It is by the mechanism of operation of the damper that models of sewer check valves are classified.

Rotary

This type of sewer valve has a spring-loaded membrane (it is called a plate because of its round shape). When the wastewater moves in the right direction, the plate rotates and moves upward without impeding the movement of liquids.

However, when the drains are directed in the opposite direction, the spring-loaded membrane is pressed tightly against the outer rim, as a result of which the working area of the pipeline is blocked.

Some models additionally have a built-in additional damper, which is controlled manually. This locking mechanism can be adjusted using a special button located on the body of the device.

Thus, the pipeline first has an expanding and then a narrowing section, which is a possible place for the formation of a blockage in the sewer system. The solution to this problem is to place the lid mechanism at the top of the housing. By removing it, you can easily and quickly remove the clog that appears.

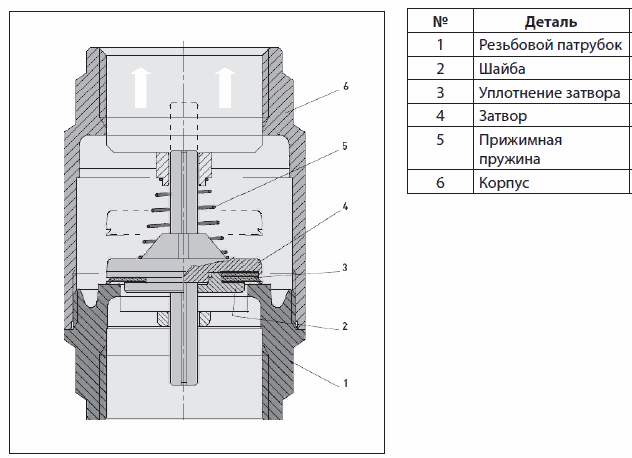

Lift valve for sewerage

The name of this type of device is based on the mechanism of the damper. When wastewater moves in the correct direction, the flapper is positioned at the top.

Operating principle: the liquid exerts pressure on the membrane, which blocks the movement of waste, the internal spring is compressed, as a result of which the damper rises. If the wastewater does not move, then the spring is in its normal state, and the path of the wastewater is blocked.

Due to the nonlinear body shape, when the fluid moves in the opposite direction, opening the valve is impossible, which ensures complete safety from flooding.

This type of check valve for sewage 110 or 50 mm has greater operational reliability than the rotary (petal) model, but there is also a drawback.

The shape features make it necessary to regularly clean the system, because... it gets clogged periodically. To perform this procedure, you will need to unscrew the bolts (4 pcs.), then thoroughly clean or, if such a need arises, replace the working mechanism. If the owner has the opportunity to carry out regular cleaning, then it is better to purchase a similar version of the check valve.

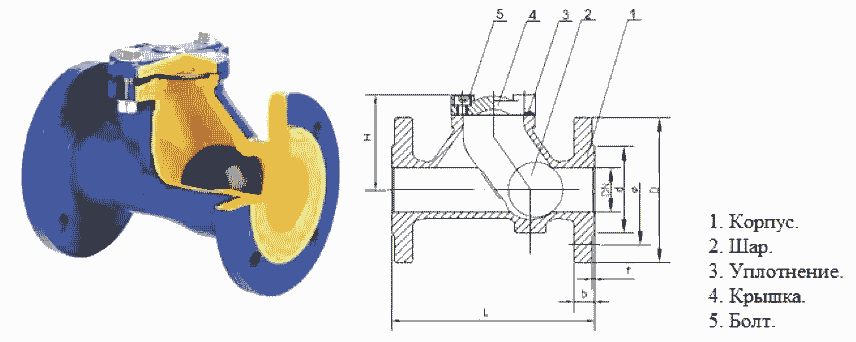

Ball valve

In this type of device, the locking element is a small ball. The upper part of the body is designed in such a way that when wastewater flows, the ball falls into a separate hole and allows the flow to move.

When there is no fluid present, the working area of the pipe is blocked, preventing flow from flowing in the wrong direction. However, such models have a drawback - unlike the rotating and lifting mechanism, in this design the ball valve does not completely adhere to the rim of the device.

As a result of a leak, a small amount of waste water may leak. Of course, the likelihood of severe flooding, as if the sewer check valve were missing entirely, is minimal.

Wafer

The main advantage of this type of locking mechanism is its small dimensions, which makes installation possible even if there is no free space behind the plumbing fixtures. Externally, the device looks like a miniature cylinder with a special rotary valve.

This element can consist of 2 components that are fixed to the central rod, or in appearance it can resemble a small plate that is fixed to the body using a spring mechanism.

It is advisable to install this option only if other varieties cannot be installed. Even taking into account the small size, it is still advisable to give preference to other types of devices. A 50 mm wafer check valve for sewerage is installed quite rarely, because... belongs to the category of water supply equipment. For sewer systems, its efficiency is quite low.

Another disadvantage of this design is the inability to quickly clean the device. Due to its shape, the connection will need to be completely disassembled to clean the valve.

Types of check valve

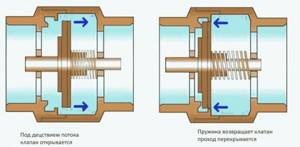

Spring (lifting)

Its design is similar to a shut-off valve. With sufficient pressure, the valve rises up, opens the hole, allowing the flow to circulate. At low pressure it falls down onto the seat and the water path is blocked. All this happens automatically.

It is used only on horizontal pipes, with mandatory vertical axial installation.

Advantages of a spring valve. Repair is possible without dismantling, as it has a removable cover. Plus it can be used at high temperatures.

High tightness. Versatility, can be used in both private and industrial water supply systems.

One of the disadvantages of spring valves is sensitivity to dirt and mineral impurities contained in water, which can damage them. But this can be solved by installing a filter.

Ball valve

The locking element in this device is a metal ball. Sometimes the ball is covered with rubber for reliability.

If there is no pressure in the water supply, the ball, under its own weight, tightly blocks the passage hole and prevents the liquid from moving in the opposite direction. When water is supplied, the resulting pressure lifts the ball, opening the way for the water flow.

Ball check valve

Pros. Ball check valves can be installed in vertical and horizontal pipes

Simple design and absence of mechanical components increases service life.

However, it should be remembered that with an equal internal cross-section, the outer dimensions of a ball valve are larger than that of other types of valves.

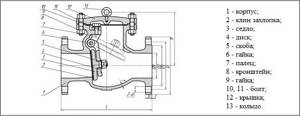

Rotary or paddle

The valve received this name because of its design.

It is based on a metal disk (“plate”) and an axis with a spring. The axis of rotation is located above the through hole. When open, the disc is parallel to the movement of water; when closed, it is perpendicular. Under fluid pressure, the disc opens. When the pressure drops, the spring is activated, the disk turns and blocks the flow. rotates under fluid pressure. If the pressure drops, the spring is activated and the disk blocks the path of water

The disadvantage is that in valves of large diameter there is a strong impact when slamming, which can lead to rapid failure of the structure.

Rotary check valves are divided into two groups:

Simple - with a small diameter of up to 400 mm. Used in systems where shocks cannot greatly affect the operation of the hydraulic system and the valve itself

Impactless - valves with a special mechanism that ensures smooth closing of the disc. The downside is that they are more expensive.

Double check valve

This device has two locking segments, which are located on a rotating axis. The plates are located in the center of the passage hole.

Water moving in the right direction opens the doors. If the direction of flow changes, the plates, under the action of springs, close the passage of the liquid.

Butterfly valves come in a wide range of sizes so they can be installed on pipes of various diameters.

They are also recommended for installation in systems where high pressure is present.

Product materials and sizes

When choosing a sewer check valve model, it is recommended to know what materials the device is made of, as well as the dimensions of the products. The most common materials:

- stainless steel;

- cast iron alloy;

- bronze;

- plastic.

The dimensions of the device depend on the amount of free space. There is also such a characteristic as the connection method - horizontal or vertical. In most cases, devices for horizontal connections are used, but if there is not enough free space behind the toilet, bathtub and other plumbing fixtures, then vertical check valves are installed. If there is critically little space, then it is recommended to purchase a wafer type of mechanism. For its installation, only seals are required.

What material should the valve be made of?

When choosing valves, it is important to know what material it was made from and what advantages each option has:

- Cast iron. They are extremely rarely used in household systems. Mainly used in industrial enterprises. Such a seemingly durable alloy, like cast iron, is very susceptible to the formation of lime deposits in water, which can cause it to break and limit the access of water.

- Brass. Ideal for home water supply systems. Brass is not subject to corrosion, does not accumulate lime deposits, and does not oxidize. The service life of parts made from this alloy is quite long.

- Made from stainless steel. Such parts have the highest cost among the rest. And this is not surprising - after all, stainless steel has incredible strength and resistance to corrosion. If possible, it is best to buy just such valves, because their service life is measured in years.

Carefully read on the packaging what other materials were used in the manufacture of the part. For example, a plastic spring may be hidden under a brass body. If you are on a budget, a brass pump station valve may be your best option. A fairly long service life and a reasonable price are the main advantages of such a part.

Installing an air valve in a sewer system

For any sewer system with a height of 2 floors or more, according to the rules, a ventilation outlet is installed on the roof. In the documents, this output is called a fan pipe.

Plastic ventilation valve.

The point of installing such a pipe is this: in a closed system, the pressure constantly fluctuates, and if it is made completely sealed, then during a massive drainage of water, the water seals in the plumbing on the upper floors will simply be torn off and sucked out like a pump.

And if the water seal fails, sewer gases will begin to flow freely into living quarters and an unbearable stench is the least that such a failure can cause.

But the installation of this ventilation is still associated with a number of difficulties. In a private house, the pipe must be installed in a strictly defined place, ensure a tight connection with the roofing pie, and be secured somehow.

The operating principle of the factory design.

In city high-rise buildings, many owners of apartments on the upper floors simply want to remove the vent pipe so as not to spoil the interior. So, the non-return air valve serves precisely to normalize the pressure in the system in the absence of a drain pipe.

There are several designs; you can even make such a valve yourself, but the principle of operation is almost always the same:

- When the pressure in the room and in the system is the same, the membrane is in a closed state;

- But if the pressure drops, the membrane opens slightly, air enters the system and normalizes the pressure again.

Making an aeration valve from a pipe plug.

An air valve for sewerage is even easier to install than a liquid valve. It is mounted at the top point and must be at least 300 mm higher than the extreme horizontal outlet.

In practice, it looks something like this: a tee is installed on the riser or at the outlet from the riser, and either the check air valve itself or a pipe with a valve is inserted into this tee on top. The structures are joined as usual through rubber gaskets and sealed with silicone.

Scheme of combined sewer ventilation.

Operating principle of a check valve

- The flow of water flowing through the pipes under pressure acts on the shut-off element and presses out the spring, which keeps the valve closed.

- After the spring has compressed, the valve opens and water flows freely through it in the desired direction.

- When the pressure in the water supply drops or when water moves in the opposite direction, the spring mechanism of the device moves the valve to the closed state.

- All the actions of the shut-off valve prevent the formation of backflow in the water supply system.

Operating principle of a check valve

Determining the installation location

For installation in an apartment, the device is mounted on a pipeline in a vertical position. This method will not provide ventilation to the riser, but will eliminate odors in a specific area.

It is recommended to install a sewer air valve in a private house. In this case, it is possible not to carry the fan structure through the roof. But some experts argue that it should be mounted only as an auxiliary part to the riser.

In private houses and apartments, plastic sewers are installed. Air elements are also made from polypropylene or PVC.

The valve must be installed:

- In high-rise buildings that are connected to wastewater treatment plants.

- In waste disposal areas.

- When connecting sewerage to sanitary facilities.

- In systems that can be connected horizontally.

Valve classifications

There are three main characteristics by which valves differ. This is the actuation system of the closing mechanism, the material of manufacture and the type of flap design. The first classification has already been partly touched upon. It concerns the initial state in which the valve is. In a permanent operating position, it can be open (the most common configuration) or closed. This classification can also include valves that are installed on the horizontal contour of the pipeline and universal fittings with valves that allow devices to be integrated also on vertical channels. There are different types of check valves depending on the material of manufacture. The body base can be made of bronze, steel alloys, brass, titanium and other metals

It is important that they are impact-resistant, heat-resistant and resistant to corrosion processes. And to ensure the tightness of the valve, seals are used, which, in turn, can be made of plastic, rubber or based on hard surfacing. Types of products that differ in the type of flap itself should be considered separately

Types of products that differ in the type of flap itself should be considered separately.

Top Installation Tips

Installation of the ventilation valve can be carried out:

- vertical; horizontally; in the attic or indoors.

It all depends on the design and installation method. Available tips for a valve in an unheated attic include Insulating the riser. However, there is no need to insulate the valve itself, since the air gap between the lid and the body serves as a good heat insulator.

To protect the movable membrane from the ingress of water and dirt that violate the density of the structure, the valve is installed 30 or more cm above the upper gravity pipe with attached sanitary devices at a distance of more than 20 cm from the nearest siphon. When installing a valve in a bathroom or toilet, experts recommend especially carefully monitoring the possibility of free air access. It is necessary to remember that water has an increased ejector capacity, attracting air 25 times its own volume.

Installation of water back pressure valves

The material for stamping elements of the prefabricated body is brass. The alloy is resistant to aggressive substances (oxygen, mineral salts, sulfur, manganese, iron compounds, organics, etc.) that are dissolved or suspended in water. The outer surface of the product is galvanized (nickel-plated).

The spool parts are made of copper-zinc alloy or high-strength polymer. The material of the sealing gasket between the locking discs is rubber or silicone. The spring is made of a special grade of stainless steel.

Choosing an aerator

Before you buy an aerator for your sewer system, you need to know how to choose it correctly. Experts recommend that before purchasing, you familiarize yourself with the internal sewage system in a private house, find out its weaknesses and decide on the appropriate type of device.

Before purchasing an aerator, you need to consider the following nuances:

- type of sewerage pipeline in a private house;

- nominal pressure level in the riser;

- dimensions of the valve pipe mechanism;

- installation method;

- material of the aeration valve and its strength level;

- type of aerator (membrane, anti-vacuum, etc.);

- the ability to smoothly adjust the device in the event of a breakdown;

- valve operating mechanism;

- the presence in the design of a specialized unit that prevents the penetration of microorganisms and bacteria from the sewer into the premises.

The most important selection criterion is the diameter of the pipe. At the same time, you need to focus on certain tasks that the installation of a sewer air valve must perform. The sewer valve is very important for the proper operation of the drainage system in the house.

Types of aerators

Experts group aerators into groups based on various characteristics.

At the installation location:

- to the main riser;

- for draining plumbing fixtures (sinks, washbasins).

According to the principle of operation:

- automatic. These are the most common gravitational mechanisms. They are used in apartments and country houses because they do not have a large throughput;

- anti-vacuum. They work not only for air intake, but also for air exhaust. They can ensure reliable operation of several systems at once;

- combined. The mechanism combines the properties of both previous types.

By type of execution:

- membrane The role of the vacuum valve of the aerator is a rubber gasket, which bends under high pressure and allows the required amount of air to pass through;

- cylindrical. These are the highest quality devices, made of durable metal and equipped with a threaded cap that serves as a check valve. Such designs are intended for sewerage in a private house or small apartment;

- lever Such devices are made of high quality metal. The check valve is located on a special lever, which rises under high air pressure from the sewerage system and lowers under the influence of its own weight.

The most common devices are models that are designed for installation on a pipeline with a diameter of 110 mm. They are often installed near the main riser so that they instantly respond to any change in pressure and maintain the water seals of plumbing mechanisms.

Valve diameter

The diameter of the aerator valve comes in two types: 50 and 110 millimeters. These numbers correspond to the diameter of the pipeline where the device is supposed to be installed.

The first type is used on locally running branches of the system. In many cases, such aerators are installed in country houses or small apartments with an inclined or horizontal pipe arrangement.

This method prevents the pipeline from clogging and protects against the negative effects of too low temperatures in winter.

This device is also used for auxiliary risers, since thanks to the valve, only one riser can be brought to the roof.

Sewer aerator 50

Such a device can only cope with a small amount of waste, so it is mounted directly on the drain from sinks or toilets. There are certain rules to install a vacuum valve for sewer ventilation.

The mechanism can only be connected to a pipeline with the smallest diameter. A 50 mm aerator is connected after the very last drain hole and installed at the highest point of the riser.

Sewer aerator 110

These aeration units can easily handle huge quantities of liquid and are connected to a main riser with a diameter of 110 mm, or a valve is placed at the end of the aeration pipe. They are available with both internal and convenient external mounting mounts.

Their main advantage is that there is no need to route the pipeline through the roof and floor slabs. They also have automatic pressure regulation, are distinguished by a simple installation method for sewer pipes with a cross-section of 110 mm and a fairly low price.

Do you have an aerator installed? Yes 9.09%

No 90.91% Voted: 11

I like1I don't like

Valve Maintenance

Timely inspection and periodic maintenance of the check valve increases the service life of the device and ensures its reliable operation.

Important! At the stage of designing the drain system and installing the valve, it is necessary to provide for ease of access to the product for the necessary maintenance. The sewer valve is serviced quarterly

To do this, remove or unscrew the top inspection cover. Then a visual inspection of the condition of the product is carried out, the debris accumulated in it is removed, and, if necessary, the edging and/or damper is replaced. The reason for unscheduled maintenance of the check valve may be deterioration of the drain system, the presence of additional unnatural noise and vibrations in the valve when draining waste.

The sewer valve is serviced quarterly. To do this, remove or unscrew the top inspection cover. Then a visual inspection of the condition of the product is carried out, the debris accumulated in it is removed, and, if necessary, the edging and/or damper is replaced. The reason for unscheduled maintenance of the check valve may be the deterioration of the drain system, the presence of additional unnatural noise and vibrations in the valve when draining waste.

When servicing the valve in use, you should also follow the manufacturer's recommendations specified in the product instructions.

Possible malfunctions and methods for eliminating them

Despite the high reliability of such devices, they, like any technical element, have operating features and can also break down and fail. Most often the check valve stops working:

- If debris and stones get into the housing;

- If the spring is damaged;

- When the surface of rubber or plastic seals wears out;

- Gradual aging and loss of elasticity of plastic and rubber;

- Exposure to water and chemicals dissolved in it.

Traditionally, if the valve operates unsatisfactorily, it is simply replaced, since the cost of replacing individual parts and assemblies far exceeds the price of a new one. But it is quite possible to extend the service life of such a device; to do this, it is enough to install a regular, simplest mesh filter at the inlet. Such a simple device is quite enough to almost double the service life of the valve.