Heating elements for all types of radiators and radiators with any delivery in our online store.

Radiator power calculation

What power should the heating element be?

Mistake #5

There is no need to proceed from the principle - the more, the better.

First of all, you need to ensure smooth operation of the heating element. It should not turn off and on too often.

If you choose a heating element that is too powerful, when it reaches operating temperature, it will work in the following mode: 1 minute off – click – less than a minute on – click – 1 minute off, etc.

With proper selection of power and good insulation of the room, the battery will “rest” 2/3 of the time, releasing heat to the environment, and only 1/3 of the time will work, consuming electrical energy.

Based on this, you can approximately calculate your electricity consumption per month.

In addition to clicking, a powerful battery will make a lot of noise and gurgle. Adding vinegar or citric acid to soften the liquid does not help much.

Here the effect is similar to that of an electric kettle. With a power of 2 kW we have very small vessel sizes, plus the presence of voids.

As a result of the sudden release of heat into the water, a similar noise occurs. The less water in the kettle, the louder it makes.

The same goes for the battery. When the heating element is too powerful, the heating rate is an order of magnitude higher than the rate of heat removal, plus the low circulation rate of the coolant affects it.

Mistake #6

Often, strong noise during operation occurs due to inaccurate screwing or a crooked heating element and accidental contact of the tube with the nipple partition.

To solve this problem, try turning the heating element slightly clockwise or counterclockwise, changing its position. Noisy operation at the limit and constant clicks are not only annoying, but also directly affect the service life of the relay contacts.

Therefore, when choosing the power of the heating element, proceed from the rule:

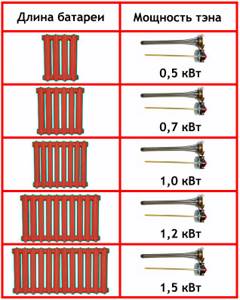

- maximum 0.5 kW – for every 4 sections

Install a heating element of lower power, and it will not turn off at all, since it will not be able to heat the water to the desired temperature.

On the one hand, this is good, the battery will never overheat, even if the thermal relay malfunctions. For example, for cast iron (4 sections 500mm high), a heating element with a power of 300W, some even manage to screw it in directly without a thermostat.

Another advantage of low power is the absence of annoying clicks. However, despite this, if there is a lack of kilowatts, you significantly lose in heat transfer.

So we have to look for the ideal formula.

When the battery is too long (12 sections), it is better to screw in two instead of one 1.5 kW heating element. At the bottom of the radiator, on one side there is 1 kW, and on the other another 0.5 kW.

Or two, 0.7 kW each. Thus, the heating of the sections will be more uniform.

Mistake #7

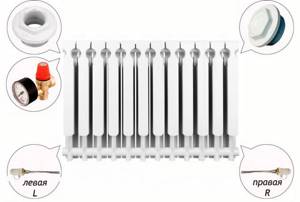

Just don't forget to check the threads on the heating elements.

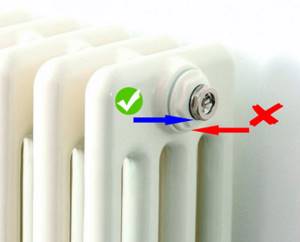

It is different on both sides of the battery. When purchasing a heating element, pay attention to the letter, which indicates a right-handed or left-handed thread (1.1/4R or 1.1/4L).

According to factory parameters, such batteries (with a height or center distance of 500 mm), when integrated into a full-fledged hydraulic heating system, are capable of dissipating slightly less than 200 W of thermal power per section (180 W aluminum, 140 W cast iron).

However, in our case, do not expect such numbers. Firstly, the heat output of 180/140W is provided only by a new battery. And for such a heater, as a rule, used options are used.

Buying a new one for such a homemade product is not economically feasible.

Secondly, such work is only possible in the 90C-supply, 70C-return mode. In this assembly we use heating elements with an optimal operating temperature of 60-65C.

When it’s cold outside down to -25C, you can turn it up to +70-75C. The maximum possible temperature is + 80C.

Therefore, you will never heat such a battery to 90C in NORMAL operation. In principle, this is not necessary, since it entails the risk of a sharp increase in pressure.

When screwing in the heating element, rarely does any of it reach the last section. Usually their length varies between 35-40cm.

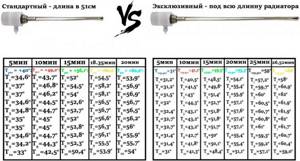

There are also exclusive models for all sections, but made to order (for example, Grepan). Here are comparative tables of uniform heating of the same battery (10 sections) with a standard short heating element and an extended one from Grepan.

However, most of us still use short ones. How then can we ensure uniform heating over the entire area?

There are certain nuances associated with filling with water.

Mistake #8

For the home, it is water that is recommended, and not some kind of chemical antifreeze (ethylene glycol, antifreeze, antifreeze).

As it works and heats up, the liquid will evaporate in any case and find its way out through the upper valves. You don't want to breathe such chemicals in your home.

But for a garage, shed or cottage with good ventilation, whether you like it or not, you will have to pour anti-freeze. Choose the most environmentally friendly one (sweet winter, warm house, etc.).

Otherwise, a battery with water that is disconnected for a long time will simply defrost.

Those who have the opportunity add oil. Not a spindle or working off, but a transformer one. With it, the battery will never freeze.

This oil is also an excellent insulator. There will be no need to be afraid of current leaks when the heating element shell is destroyed.

Just keep in mind that with such “refueling” you will have to look for a special oil heating element.

Mistake #9

An ordinary water one will overheat and quickly fail due to thick oil and poor convection.

For fire safety purposes, heating in direct contact with oil should not exceed 250 degrees. In addition, the oil will quickly corrode all the rubber gaskets between the sections.

Heating elements for heating radiators

The heating element for the radiator is used to maintain a constant temperature in the central heating system in case of temporary shutdown. Such tubular heaters are ideal for autonomous heating in separate premises (dachas, bathhouses, garages, industrial buildings).

The design and operating principle of a heating element for a radiator

A radiator heating element consists of an outer casing, a heating element made of high-resistance wire, a filler (usually water or oil), a sealing gasket, a thermostat (not in all models), protection and cable. To install a radiator heating element, you need to screw it into the battery with a little force, insert the thermostat and connect the power supply. Heating elements for radiators differ from heating elements for water heaters in that they have a narrower heating element and a thinner flange.

Radiator heating elements differ in several technical characteristics:

- Power (from 800 W to 3000 W)

- Heating element length (short 195 mm, long 450 mm)

- Material of manufacture (can be made of copper or stainless steel)

- Type of threaded fastening (right or left thread)

- Flange diameter (thread 33 mm, 42 mm)

Wide selection of heating elements for heating radiators:

In our assortment there are radiator heating elements for any need - for oil, cast iron, aluminum, bimetallic radiators and radiators, as well as sets - heating elements with a thermostat.

The main advantages of heating elements for radiators:

- Economical – all electricity is converted into heat;

- Easy to install, convenient to operate;

- Quality and reliability;

- Maintaining the required temperature during an emergency heating shutdown;

- Protection of the heating system from damage due to frost;

- Protection of the premises from freezing;

TEN and its varieties

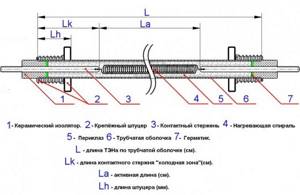

Structurally, a tubular electric heater (TEH) is a tube made of carbon or stainless steel with a heat-conducting spiral made of nichrome, a material with high resistance, placed inside. The tube is filled with a special coolant, periclase, which is a good insulator and, moreover, has a high thermal conductivity, and is hermetically sealed. Periclase, being under high pressure, fixes the spiral centered along the axis, so it does not move when the heating element is bent and, depending on the model, given the required shape. The ends of the spiral protrude from the outside, which serve to connect to the electrical network.

Heating heaters can be divided into groups according to several parameters:

- According to the type of heating surface, they are tubular, finned, rod, flat and strip: tubular electric heaters are used in all electric heating devices in which heating of the coolant occurs as a result of the conversion of electrical energy and thermal energy. They are made of carbon and stainless steel, copper, titanium, usually from 20 to 600 mm in length from a tube with a diameter of 6 to 18.5 mm of any configuration and power;

- finned tubular electric heaters are used in thermal curtains and convectors to heat gas or air that heats the room. The fins, made of metal tape, are attached to the steel heating tube with special fasteners perpendicular to its axis. The branched outer surface makes it possible to increase its heat transfer at a lower temperature, weight and overall dimensions of the heating element;

- tape heaters made of sheet aluminum or stainless steel are used to heat a flat surface, for example, a heated floor, but most often in industrial production;

- flat heaters are produced with a spiral in a ceramic heater for heating flat surfaces, also in industry;

- Rod heaters are designed to work in holes in metal parts.

In addition, heating elements, varying in power from 15 to 15,000 W per unit surface, may have additional options: thermostats and automatic shutdown sensors in case of overheating.

Heating element for a radiator: why is it needed?

Like any other heating element for heating, a radiator is designed to heat the coolant and maintain its operating temperature. The device can be installed in almost any heating device that has an internal cavity filled with liquid. Thanks to this, its scope of application is quite wide.

Radiator heating elements can act as the main or additional heating source. They are very good as heat sources for rooms with a relatively small area, which are used periodically during the cold season.

For example, various utility rooms or for heating a garage. In this case, the heating element is mounted in an autonomous radiator; it usually has impressive dimensions.

A radiator with a built-in heating element is practically no different in appearance from traditional batteries. During the off-season, when the central heating is not yet turned on, it will help residents not to freeze

The battery is not connected to the heating system and is filled with coolant, which circulates exclusively within the radiator body.

In such cases, technical oil with a low viscosity is chosen as a coolant, which allows you not to be afraid of the radiator completely freezing during non-working hours. It turns out to be an analogue of an oil-type radiator, only larger in size.

Radiator heating elements have proven themselves quite well as the main source of heat for country houses that are heated periodically. The system is set up similarly to that described above, but only the heating elements are mounted in batteries installed in each room.

It is possible to organize such heating for houses with permanent residence. In this case, the batteries can be filled with ordinary water, since there are no plans to allow the system to freeze. True, such options are used extremely rarely due to the high cost of electricity.

More widely, radiator heating elements are used as additional heat sources. They can be built into an existing heating system with a liquid coolant and come into operation when the main heating is not functioning for some reason.

This solution is especially suitable for houses with centralized heating. During the period when it is turned off, heating elements literally save apartment residents from freezing.

The so-called heating registers are very popular among DIYers. You can easily assemble them with your own hands and thus create practical heating for a garage or utility room

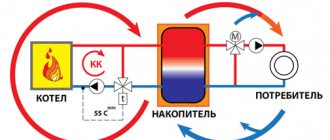

Another good option is to connect the devices to an autonomous heating system with a solid fuel boiler. This will allow maintaining a comfortable temperature in the rooms even at times when the owner is not able to supply fuel on time.

If it is possible to use a multi-tariff meter, it may be practical to switch to night heating with electricity when it is relatively cheap. During the day the boiler will start working again.

Practice shows that it is not economically profitable to use radiator heating elements as an additional heat source for autonomous systems running on gas. This type of fuel itself is relatively cheap, so replacing it with more expensive electricity does not make sense.

If boilers using liquefied gas or diesel fuel are used indoors, the benefits will be obvious. But only if you have a two-phase electricity meter.

Internal structure of electric heaters

It is convenient to consider the device using the example of a tubular model. An electric heater is a ceramic or metal tube filled with a thermal conductor with a spiral located inside. In the place where the tube is fixed to the flange there are insulating bushings that make it impossible for the conductive spiral to contact the heating element body.

Most models of heating elements use similar components, but their durability may vary depending on the build quality

The electric heater is mounted primarily with a flange connection, which allows the internal environment of the heating device to be sealed from the external space. The disadvantage of this design is the impossibility of replacing the spiral if it burns out internally.

Heating elements for heating radiators

Heating elements for heating radiators are installed in any types of batteries (ours is only for cast iron, with a G11/4 connector). They can work effectively with cast iron, bimetallic, steel and aluminum radiators. Heating elements are widely used for individual use in small rooms, cottages, warehouses or offices. A self-installed radiator heating element is well suited for providing comfortable working and living conditions if there is no central heating. In the Iskra online store you can buy and supply a heating element for a battery with the parameters you need at a competitive price.

In what cases are heating elements used?

Electric heaters for radiators can be used in different cases.

- If radiators are installed as separate heating devices. That is, a heating element connected to an outlet is mounted in each battery. No pipes, no heating boilers, no wiring diagram. Each radiator is adjusted to a specific required temperature.

- A tubular electric heater can be used as an additional heating element. The situation is this: there is an existing water heating system, the amount of fuel of which is not enough to maintain the required normal temperature in the house. This often happens in suburban villages, where in winter the gas pressure in the pipeline drops significantly due to the high consumption of blue fuel by a large number of consumers.

- This method of heating the coolant can be used in emergency situations (if for some reason the main type of fuel is not supplied). For example, the firewood or coal has run out, the gas supply has been cut off, or there is no diesel fuel. To temporarily wait out this situation, you can use heating elements for cast iron heating radiators.

Filling the radiator with water

How much liquid is needed for such a heater?

Mistake #10

When filling a radiator, you don’t want it to end up 100% full of water.

Filling occurs through the hole of the already installed passage plug. First, fill the radiator up to the neck.

Then you set it perfectly level and unscrew the plug or the Mayevsky valve (not the fitting itself), draining the excess volume.

If the battery is already hanging on the wall, you can use a small watering can with a tube or hose stretched over the spout.

Mistake #11

Try not to use regular tap water.

The water should be soft. A hard one will kill your heater very quickly.

Distilled or rainwater is best (it's free). As a last resort, water from an osmosis filter.

Just enough water is needed so that it stops flowing through the hole under the Mayevsky tap. That is, the liquid level should end exactly at the level of the small hole in the passage fitting.

When pouring water along the edge of the hole, you will automatically get the desired level of the liquid column, which will ensure uniform, proper circulation.

One section of a cast iron battery (MS 140-500) holds about 1.5 liters of water. In aluminum (height 500mm) - no more than 0.35-0.45 liters. The required volume is calculated by the number of ribs.

Radiators

For such a homemade heater, two types of radiators are usually used:

- cast iron with 32mm (1 1/4 inch) thread

- aluminum or bimetallic with 25mm (1 inch) thread

Cast iron can be used even without heating element. Pick up the battery and start moving it from corner to corner until you get warm