For a modern person, one of the most important components of comfort in the premises where he lives or works is a stable air temperature. To maintain it, various automation tools are being introduced into modern climate systems, which in heating systems are simultaneously capable of providing significant savings in energy costs. This article introduces readers to the advantages of automated heating systems and ways to increase their energy efficiency, with the necessary technical requirements for individual components of heating equipment, and also contains recommendations for their selection.

Purpose and advantages of automation tools

Automated heating systems are designed to maintain a microclimate in buildings and premises that is most comfortable for work and rest. In addition, due to the ability to use energy resources more efficiently, such systems are much more efficient than traditional ones.

Setting a comfortable temperature in the rooms is ensured by thermostats or temperature sensors, which constantly monitor its changes and allow the heating system to take into account all current factors affecting the temperature in the room: human heat, solar heat, heating from lighting fixtures, radiation from other electrical appliances, etc.

If automatic control of coolant supply is used directly at the heating point of the building, which monitors the outside air temperature, this results in savings in energy consumption of approximately 15–20%. The use of thermostatic valves on heating radiators further reduces energy consumption by another 5–7%.

Automation also allows you to flexibly change the temperature in the premises at different times of the day. During transitional calendar periods (autumn/spring), characterized by temperature instability, the automated system will reduce heat output during those hours/days when the air temperature rises significantly.

If the heating system is equipped with GSM modules, then this makes it possible to monitor the thermal conditions of the building/room remotely, for example, using mobile devices.

Options for controlling the boiler via smartphone

Three solutions are available for remote control of a domestic gas boiler:

- GSM module connection;

- use of a “smart thermostat” via WI-FI communication;

- installation of thermostats.

Each remote control method is good in its own way, and its choice depends on several factors: availability of the Internet, gas boiler model, financial capabilities.

Let's consider all three options - one of them may suit you, and as a result of a partial upgrade, managing the heating system will become much easier.

We recommend: Carbon filter for hood: types, principle of operation, how to replace it yourself

Option #1 – connecting the GSM module

This is the most common solution, applicable even in areas not covered by the Internet.

The gas boiler is controlled using a GSM unit - a compact controller module. A SIM card is inserted into it, which personalizes the owner and makes it possible to keep in touch with remote equipment

In order to save money, the homeowner can choose the most suitable cellular operator and favorable tariff.

The GSM module is programmable and its operating principle resembles a computer with limited functions. This block is connected to sensors installed both in equipment and in the environment - in rooms, on the street. Depending on the parameters produced by the sensors, the gas unit automatically changes the program or is controlled from a smartphone.

To communicate with the control unit installed in the house, you will need any electronic device - a laptop, tablet, but it is most convenient to use a smartphone, which is more compact and versatile

For ease of control, selection of modes and programs, developers have created applications for various operating systems: iOS, Android, Windows Phone.

There are several modes by which a gas boiler is controlled:

- Fully automatic control. The unit operates according to the specified parameters entered into the program in advance. If changes are required, the program should be adjusted.

- Transmission of alarm notifications in the event of emergency or repair situations. If there is a gas leak or the boiler suddenly stops working, a signal is sent to the smartphone.

- “Communication” using SMS messages. There is a list of commands that the automatic gas boiler recognizes and then makes changes to the operation of the equipment.

- Advanced management options. Using a special program, you can control all systems connected to the GSM unit.

The advantage of remote control via mobile communication is considered to be almost constant control and unlimited possibilities, depending only on the selected application and installed equipment.

A few more advantages of using a GSM module:

Image gallery Photo from Depending on the modification of the unit, you can connect several mobile phones to the module, and then from 2 to 10 people will be able to monitor the operation of the unit. In addition to the gas boiler, sensors installed in various rooms heated by the boiler can be connected to the module: in the kitchen, in the hall, bedrooms and even in the basement or attic In addition to the controller, key reader, antenna, sensors and power supply, you can connect a microphone, gate control unit and other “smart” devices By installing temperature sensors outside, you can set automatic mode changes depending on weather conditions Monitoring the operation of the boiler by all family membersConnecting additional sensors to the program Possibility of connecting basic or extended configurationsAutomatic operation of “weather” sensors

Problems can happen if the cellular connection is poor. The homeowner needs to carefully monitor the expenditure of funds - if the balance is negative, the ability to control the heating equipment will be interrupted.

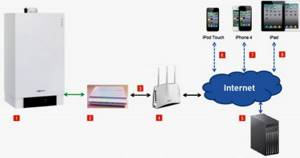

Option #2 - using the Internet

If the Internet network extends to the area with your country home, then you can control the gas boiler using it.

A WI-FI router is installed in the house, and an Internet thermostat is connected to the boiler equipment. He is the link between the owner of the building and the heating equipment

As soon as the temperature in the room drops below normal, the sensor transmits a signal to the receiver, which interacts with the boiler and turns on the desired heating mode.

The user can control the entire process from a smartphone, monitor changes, and make adjustments. The provider acts as an intermediary between the home owner and the equipment. For continuous communication, it is important to provide access to the Internet both in the home and at the user’s location.

The advantage of the system is the unlimited number of gas boiler sensors - the heating level can be adjusted in all areas served by the building’s heating system.

As with remote control of a gas boiler via a GSM module, the homeowner can control the heating process remotely and make relevant changes. It is possible to install a program that changes the boiler operating mode depending on the time of day, days of the week, and season.

Thermostats, the operation of which depends only on the stability of the Internet connection, are different, but their operating principles are similar.

Portable temperature sensors with preset settings are installed in living rooms and other heated rooms. They are connected to an electronic thermometer, the program of which includes operating parameters

If desired, you can set an economical temperature regime for water used for domestic use or for heating “warm floors”.

The operation of the boiler and other equipment can be monitored using application diagrams or graphs. If an unusual situation occurs, the user receives alerts.

The boiler is controlled from an electronic device - a personal computer, tablet, smartphone, but there is also the possibility of manual control from a panel on the unit.

Option #3 – installing thermostats

If a router is installed in the house and the Internet is connected, it is possible to control even an old boiler model without electronic components and automation.

To do this, you need to buy universal type thermostats and create a network connecting all heating equipment. The system can be controlled via an Internet connection

The main element of the system is an electronic controller and a WI-FI transmitter “all in one”. It is programmed, after which it becomes possible to control heating functions in different zones. The number of such zones depends only on the capabilities of the homeowner - electronic thermostats can be installed on each radiator.

The controller is connected via a special channel to the boiler shutdown unit. If the need arises, the unit is turned off from a distance of hundreds of kilometers or from the next room. The controller is controlled not only wirelessly, but also manually, directly on the unit.

The thermostat system easily covers several zones, and up to 6 thermostats can be installed in each area.

Tips for saving energy resources

An effective way to save energy is to use automation devices that allow you to maintain different day and night temperatures in rooms. So, in non-residential premises you can lower the temperature at night, and during the day you can set it exactly at a comfortable level, but not higher. This is important because an increase in temperature of just one extra degree leads to an increase in energy consumption by 5-7%.

You can also save heat in residential areas. Automation with a timer-programmer, in accordance with the individual needs of the user, will regulate the heating temperature and operating time of the heating system in one or another specified mode. While the residents are at home, the system will maintain a comfortable temperature, and when they are at work, school, away, etc. — will switch to economy mode and provide the minimum required temperature (for example, for plants or pets).

A serious means of saving money when operating heating systems is also the use of energy-efficient technologies such as heat pumps and condensing steam boilers.

Expert advice: how to protect yourself from controller breakdowns

Repair of control units for gas boilers is not a common occurrence. However, before purchasing equipment from a certain manufacturer, ask if there are service centers in your region.

To protect yourself from troubles at the wrong time, you should, with the help of specialists, inspect the boiler before and after the heating season. A network voltage stabilizer will help protect the electrical controller from pressure surges, thereby protecting the device from damage.

You can prevent possible damage to the control unit the first time it is put into operation. The unit system is complex and fragile in its own way; settings may be lost during transportation or assembly of the equipment. Therefore, during installation, they first carefully check all the subtleties associated with the wiring, water and gas supply, and then check the operation of the CU sensors.

The latest models of controllers have been brought to almost complete independence. The gas boiler control unit reports faults using indicators, as can be seen in the diagram below.

If you notice any failure, even a minor one, it is better to immediately call a boiler service specialist, this will prevent a serious breakdown and save yourself from more serious problems.

Heating appliances are often the subject of experiments, which result in towel dryers for example. At a technology competition in 2007 in the United States, among the various designs one could see a radiator in the form of a rack of hangers, designed in the shape of a chair with a heated seat.

Modern home heating equipment is as convenient as possible for users. Having set the necessary parameters for the device, you do not need to constantly monitor its operation, relying on the automatic mode. And timely diagnostics of heating devices will allow you to avoid troubles due to incorrect operation or breakdowns.

An example of installing the controller can be found in the video:

Types of automation devices

To change the temperature in heating systems, two-position control devices (thermostats) and smooth control devices (temperature sensors) are used.

Thermostats are used to maintain a constant set temperature in the room. They work on the principle of turning off the heating of the heating system boiler when the desired temperature is reached and, accordingly, turning it on when the temperature drops below a given level. These are the simplest and most reliable devices for controlling indoor climate. Thermostats provide a fairly high level of comfort and fuel savings of up to 20%. They are ideal for use in separate heating of apartments and other small areas.

Smooth control devices - temperature sensors - allow you to maintain the temperature in the room at a given level, regardless of changes in temperature outside, and also reduce energy consumption. They are connected to the steam boiler system and transmit temperature values to it, from which the automation independently selects the required coolant temperature. Thermal sensors have higher accuracy than thermostats, and thanks to the timer function with a remote control and programming module, they can also provide an increased level of indoor comfort and energy savings.

About automatic control of the heating system

When considering the automation of heating systems, it should be borne in mind that heating can be controlled by temperature:

GSM module for heating boilers: purpose and operation of the remote controller

- coolant;

- air in the house;

- outside air, weather dependent.

Control systems based on coolant temperature control operate regardless of current conditions. The consequence of this will be high inertia of the entire process, low efficiency and wastefulness. The best results are shown by an automatic heating system that works to maintain the set temperature in the house.

Elements of a weather-compensated heating control system

Weather-dependent regulation is considered the most progressive and effective, since it allows you to quickly respond to changing environmental conditions. However, conventional means that monitor and control the heating system can ensure its fairly efficient operation.

Requirements for radiators for automated heating systems

Effective operation of automated heating systems is impossible without the use of heating radiators that have a number of necessary properties. Firstly, such radiators must have low thermal inertia, i.e. quickly heat up and cool down, which will allow automation to flexibly control the temperature in the room. Secondly, radiators must have high heat transfer, which makes it possible to use relatively small volumes of coolant fluid in the heating system. The result is an additional reduction in the inertia of the system, as well as an increase in its energy efficiency.

Selection of radiator material

Among the radiators on the market, only those that are entirely made of aluminum alloys meet the above requirements. Of all the materials used in the production of radiators, aluminum has the lowest thermal inertia and the highest heat transfer with a low specific gravity. In addition, its high manufacturability (ease of manufacturing structures with a large fin area) makes it possible to additionally and significantly increase the heat transfer of finished radiators.

Bimetallic and steel screen radiators, while slightly inferior to aluminum ones in heat transfer, are inferior due to greater thermal inertia and greater specific gravity (which makes installation difficult). Cast iron radiators lag even further behind in these two indicators. In addition, it is much more difficult to make a durable and compact structure with a large number of fins from this material, and in terms of the required coolant flow, traditional cast iron radiators are absolute “anti-record holders.”

To the already listed advantages of aluminum radiators, one should add ease of installation (light weight of structures) and affordable prices (aluminum is a widespread and easy-to-process metal).

Aluminum radiators Global

Recommendations for the selection of aluminum radiators

So, aluminum radiators are the only right choice for automated heating systems. But are they all equally suitable for this purpose? Our answer is no. The fact is that the Russian market is flooded with cheap products from the Asian region, which have a number of disadvantages that do not allow them to be recommended for building reliable heating systems.

First of all, it is worth saying that in many Chinese factories, when producing radiators, the stability of such an important characteristic as heat transfer is not ensured. In addition, in the technical data sheet this figure is often overestimated, which leads to errors in the calculations of heating systems. The second serious problem is the insufficient strength and reliability of the design of radiators manufactured in small factories without a well-functioning quality control system. An important role in ensuring the durability of radiators is played by their corrosion protection inside and high-quality painting on the outside. But Asian manufacturers often neglect these means in order to reduce the cost of production.

To avoid unpleasant surprises during operation, for heating systems you should choose products from large companies that have proven themselves in the domestic market and have an extensive network of official trading partners. One of these companies is the Italian Global, which has been producing heating radiators since the 70s of the twentieth century and has been present on the market in Russia and the CIS countries for more than 20 years. High-tech production and the company’s own research base are a guarantee of the reliability and durability of the products. In addition, the use of only high-quality certified aluminum alloy in production provides such an additional advantage of Global radiators over competitors, such as higher heat transfer at a lower coolant temperature. This becomes especially relevant when using heat pumps and condensing steam boilers in the heating system.

conclusions

The heating system is one of the most important components of maintaining the necessary conditions for home life or work, especially in the harsh Russian climatic conditions. A properly designed and constructed system will provide not only the required level of comfort, but also serious savings in the long term. Therefore, there is no point in saving on any components, be it heat generation equipment, control automation equipment or final devices - heating radiators. The greatest effect can be achieved and can be maintained for a long time only if balance is maintained.

Operating principle of the control unit (controller) for boilers

Controllers are electronic devices that are designed to optimize the control of a gas heating device under changing environmental conditions. The capabilities and functions of different devices differ, but they are united by the presence of pressure and temperature sensors.

Example of controller connection diagram

The electronic gas boiler control unit (ECU) is responsible for the operation of the gas burner, heating of the coolant and the safety of the system as a whole. Its operating principle is based on the use of an electromagnetic valve.

The controllers of the latest heating devices are equipped with an automatic mode function, which allows you to regulate the operation of the device during the week without human intervention.

Connecting the computer to external temperature sensors and boiler control terminals allows you to configure independent changes in the operation of the burner.

For such a controller, it is necessary to install a voltage stabilizer and an uninterruptible power supply to ensure the operation of the boiler during voltage surges in the network or in its absence.

We recommend: Setting up a gas boiler: adjusting the power, how to adjust the pressure, adjusting the gas supply valve